2014 年 20 巻 3 号 p. 599-605

2014 年 20 巻 3 号 p. 599-605

In order to improve the utilization ratio of mulberry tea 1-deoxynojirimycin (DNJ), mulberry tea was prepared based on the common production process of green tea, and corresponding experimental design and statistical analysis were set using Design-Expert software. The results suggested microwave power 602.28 W and processing time 11.41 min were found to be optimal for microwave-assisted extraction DNJ. The confirmatory experiment showed the coincidence rate of detection was 99.58%. It provided a reference for efficient use of mulberry tea DNJ for people who would drink mulberry tea to control blood glucose levels or to prevent diet-induced obesity.

Mulberry leaf, a medicinal and edible food, has been widely used in food, medicine and cosmetics industry, and shown a thriving trend with the return of healthy eating values. Mulberry leaf contains minerals, vitamins, dietary fiber, amino acids, phytosterols, flavonoids and other functional components, and has various kinds of biological activities including hypoglycemic activity (Nojima et al., 1998; Kimumar et al., 1995; Kimura et al., 2007), antiobesity action (Tsuduki et al., 2013), antioxidant activity (Doi et al., 2000), antiviral activity (Tierney et al., 1995; Thipamon et al., 2010), hypolipidemic activity (Doi et al., 2000; Kojima et al., 2010), antineoplastic activity (Kim et al., 2000), antimutagenicity activity (Thipamon et al., 2010), etc. Most impressively, mulberry leaf is rich in N-containing sugars including DNJ, which is known as one of the most potent α-glycosidase inhibitors (Asano et al., 1994; Yatsunami et al., 2008). It makes mulberry tea not only has hypoglycemic activity but also has a significant role in targeted prevention and treatment of its complications. As a natural food, mulberry tea retains the nutrients and active functions of mulberry leaf, also is well accepted by the majority of user due to its unique flavor, low prices. However, at present mulberry tea was supplied as functional foods in many countries, but the utilization rate was relatively low owing to the methods of making tea were not suitable for extracting DNJ in a greater degree that resulting in waste of resources to some extent. Thus it is necessary to obtain an more efficient and convenient DNJ extraction method.

Compared with conventional extraction methods, microwave- assisted extraction has the advantages of high extract rates, high energy efficiency, and environmental-friendly (Maimaitijang et al., 2010; Wang et al., 2008). Meanwhile, as a very important experimental design and analysis methodology applied to biologically active substances extraction more and more, response surface methodology be able to perform a comprehensive study for test in a cost-effective way and less test time and quantity (Montgomery, 2004). Nowadays a number of published works indicated the microwave-assisted extraction bioactive substances methods (Wang et al., 2010; Li and Jiang, 2010a; Wang et al., 2011; Teng and Lee, 2013; Zou et al., 2012; Li et al., 2010b). However there were not recorded on microwave-assisted technology for extracting DNJ from mulberry tea at that time. Therefore, in experiment we used response surface methodology to optimize microwave-assisted extraction mulberry tea making conditions for maximal DNJ yield. Our results may provide a basis for efficient use of active substances in mulberry tea for industrial preparation mulberry tea drinks with high DNJ content and for people who would be of particular interest in drinking mulberry tea to control blood glucose levels or to prevent diet-induced obesity. And the extraction condition is more convenient and effective than common hot-water immersion extraction method.

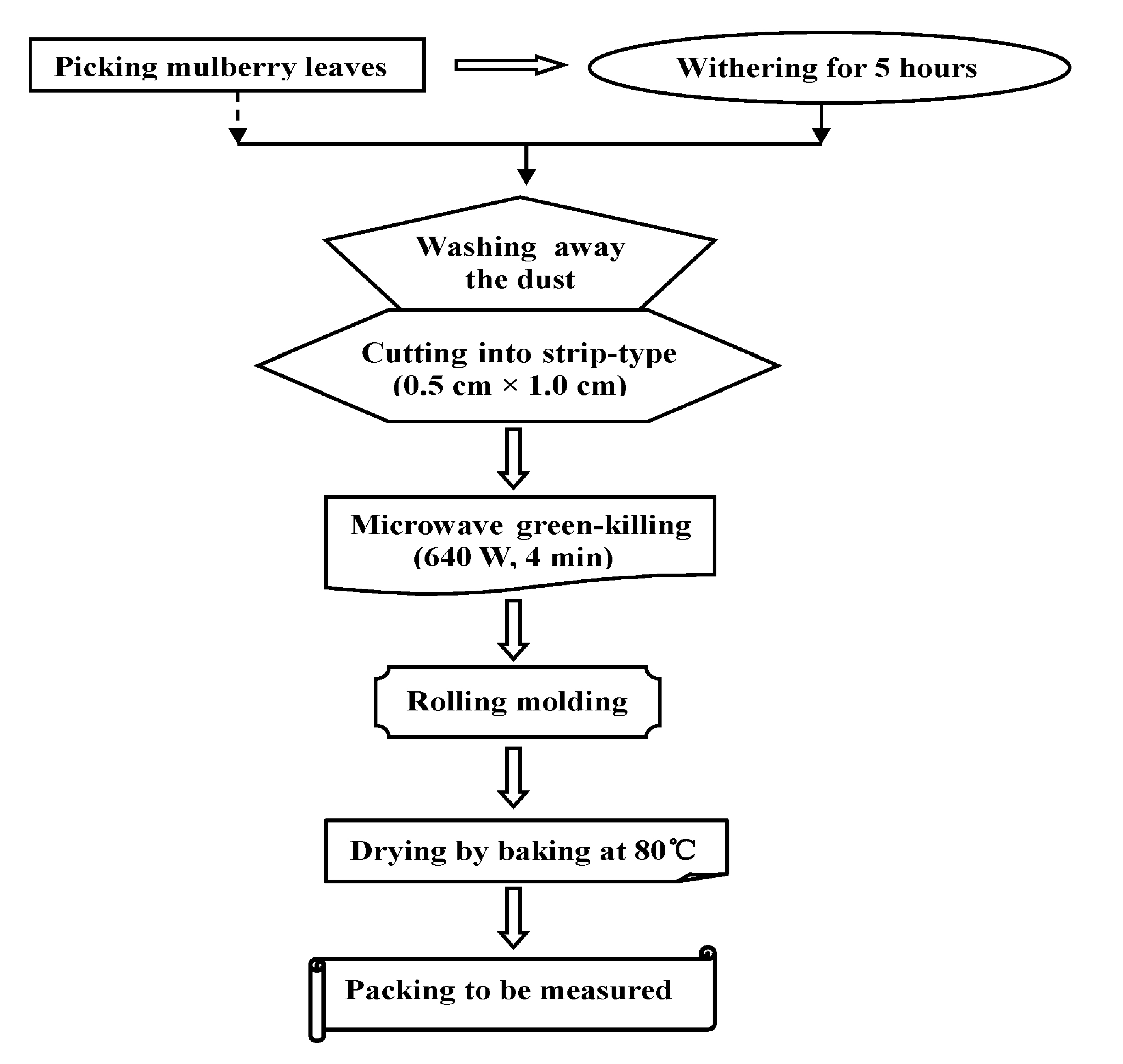

Mulberry tea processing flow chart

Materials The mulberry leaves (Jialing 20, an artifical triploid mulberry variety) were obtained from the mulberry germplasm resources garden of southwestern university. DNJ was purchased from Chengdu mansite bio-technology co., ltd (Chengdu, China). Glycine was purchased from Dachuan speciality chemical co., ltd (Ningbo, China). 9-fluorenylmethyl chloroformate (FMOC-CL) and acetonitrile (HPLC grade) was purchased from Sigma-Aldrich (St. Louis, MO). Potassium chloride and boric acid were purchased from Beibei chemical factory (Chongqing, China). Acetic acid (analytical grade) was purchased from Chuandong chemical co., ltd (Chongqing, China).

Preparation and extraction of mulberry tea The preparation of mulberry tea was based on the common production process of green tea, and a methods using an oven was gave (keelrein, Shanghai, China) to improve, the method has the advantages of simple and efficient. The general procedure was shown in Fig. 1.

Mulberry tea sample (0.50 g) was weighed in a plastic beaker (electronic balance from Shanghai Jingtian Electronic Instrument Co.,Ltd, China) and 40 mL of tap water was added. And then processed them with different design conditions (microwave oven from Galanz, Foshan, China) of single factor and response-surface experiment. The extract was treated to remove the mulberry leaves and the volume was diluted to 40 mL. Finally, took part of them to the 10 mL centrifuge tubes, and kept in a freezer at 4°C (fridge from Frestech, Xinxiang, China) until analysis. Each sample was repeated three servings.

DNJ derivatization and HPLC analysis Mulberry tea extract (30 μL) or the same volume of pure DNJ were mixed with 30 μL 0.4 mol L-1 potassium borate buffer (pH 8.5) in a 0.5 mL centrifuge tube. 60 μL 5 mmol L-1 FMOC-Cl in acetonitrile was added and reacted in a 25°C water bath for 20 min. 30 μL 1 mol L-1 glycine was added to terminate the reaction by quenching the remaining FMOC-Cl. 30 μL 0.1% (v/v) aqueous acetic acid was used to stabilize the DNJ-FMOC and the mixture was diluted with 120 μL distilled water. And then filtered through a 0.22 μm nylon syringe filter. Between each step, it is necessary to vortexed for 15 s to ensure the solution was evenly blended (Kim et al., 2003).

An HPLC system consisting of a reverse phase 5 μm C18 (4.6 × 150 mm) column (Waters, Atlantis, Ireland) connected with an Waters 2487 HPLC, and equipped with an dual λ absorbance detector (Waters technologies, USA). The chromatography conditions were as follows: column temperature 30°C; flow rate 1.0 mL min-1; injection volume 10 μL; a mobile phase of acetonitrile-0.1% aqueous acetic acid 55:45 (v/v); detection wavelength 254 nm (Kim et al., 2003).

| Run order | X1 | X2 | Mean observed yield (%) | Predicted yield (%) |

|---|---|---|---|---|

| Microwave power (W) | Microwave processing time (min) | |||

| 1 | 480 (−1) | 13 (1) | 0.18 | 0.18 |

| 2 | 480 (−1) | 7 (−1) | 0.14 | 0.14 |

| 3 | 640 (0) | 10 (0) | 0.19 | 0.19 |

| 4 | 640 (0) | 10 (0) | 0.18 | 0.18 |

| 5 | 640 (0) | 7 (−1) | 0.14 | 0.14 |

| 6 | 640 (0) | 13 (1) | 0.18 | 0.18 |

| 7 | 800 (1) | 13 (1) | 0.17 | 0.17 |

| 8 | 480 (−1) | 10 (0) | 0.18 | 0.18 |

| 9 | 640 (0) | 10 (0) | 0.18 | 0.19 |

| 10 | 800 (1) | 7 (−1) | 0.12 | 0.13 |

| 11 | 800 (1) | 10 (0) | 0.18 | 0.17 |

| 12 | 640 (0) | 10 (0) | 0.19 | 0.19 |

| 13 | 640 (0) | 10 (0) | 0.19 | 0.19 |

Standard curve of DNJ

Single factor and response-surface experimental design Under the condition of 1:80 solid liquid ratio (the common parameters for brewing green tea), two factors including microwave power and microwave processing time, which could have an influence on the microwave-assisted extraction efficiency of mulberry tea, were applied to the single factor experimental design. To different design groups, absorption peak areas were detected and yields were calculated.

According to the results of single factor and Miscellaneous experimental design, the effect of independent variables X1 (microwave power, W), X2 (microwave processing time, min) at three variation levels was shown in Table 1.

Determination of DNJ standard curve and HPLC analysis 0 μg mL-1, 20 μg mL-1, 40 μg mL-1, 80 μg mL-1, 160 μg mL-1 and 320 μg mL-1 pure DNJ were used for the determination of standard curve, the result was shown in Fig. 2. As shown in Fig. 3, the retention time of DNJ was about 2.10 - 2.20 min and the absorption wave was very obvious in chromatogram.

Analyzes of single factor experimental results As shown in Fig. 4a, the DNJ yield was increased with the increase in power from 160 W to 640 W. But there was a slow downward trend between 640 W and 800 W. So we selected 480 W, 640 W and 800 W as the three variables of microwave power for response surface methodology.

As shown in Fig. 4b, the DNJ yield was increased with the increase in time from 3 min to 9 min. But there was a slow downward trend between 9 min and 13 min. So we selected 7 min, 10 min and 13 min as the three variables of microwave processing time for response surface methodology.

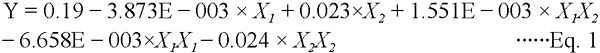

Analysis of variance The results of microwave-assisted extraction experiment for studying the effects of two independent variables on DNJ yield of mulberry tea were presented in Table 1 along with the mean observed yield and predicted yield. The coefficients of the regression equation were calculated using Design Expert and the following regression equation was obtained, which was an empirical relationship between DNJ yield and the two test variables in coded units.

|

Standard chromatogram of DNJ (a) and chromatogram of mulberry tea extract (b)

In conditions of microwave processing time 3 min and solid liquid ratio 1:80, the relationship between microwave power and yield (a) and in conditions of microwave power 640 W and solid liquid ratio 1:80, the relationship between microwave processing time and yield (b)

| Source | Sum of squares | df | Mean square | F-value | p-value | ||

|---|---|---|---|---|---|---|---|

| Model | 5.678E-003 | 5 | 1.137E-003 | 46.99 | < 0.0001 | Significant | |

| X1 | 8.998E-005 | 1 | 8.998E-005 | 3.72 | 0.0952 | ||

| X2 | 3.175E-003 | 1 | 3.175E-003 | 131.15 | < 0.0001 | ||

| X1X2 | 9.624E-006 | 1 | 9.624E-006 | 0.40 | 0.5484 | ||

| X1X1 | 1.224E-004 | 1 | 1.224E-004 | 5.06 | 0.0593 | ||

| X2X2 | 1.603E-003 | 1 | 1.603E-003 | 66.21 | < 0.0001 | ||

| R2 | 0.9711 | ||||||

| Adeq precision | 17.703 | ||||||

| Residual | 1.694E-004 | 7 | 2.421E-005 | ||||

| Lack of fit | 7.051E-005 | 3 | 2.350E-005 | 0.95 | 0.4965 | Not significant | |

| Pure error | 9.893E-005 | 4 | 2.473E-005 | ||||

| Cor total | 5.858E-003 | 12 |

with Y, the response for DNJ yield (%); X1, microwave power (W); X1, microwave processing time (min).

The main results of analysis of variance (ANOVA) obtained from the experiment were summarized in Table 2. The significance of each coefficient was determined using the t test and p value. It could be seen that the variable with the largest effect was the linear term and quadratic term of microwave processing time (X2). Model

P-values lower than 0.0001 indicated that the model was considered to be statistically significant at the 99% confidence level. An adequate precision of 17.703 indicated an adequate signal as it measures the signal-tonoise ratio. The coefficient of determination (R2) of the predicted model was 0.9711, suggesting a good fit, which ensured a satisfactory adjustment of the quadratic model to the experimental data and indicated that 97.11% of the variability in the response could be explained by the model. Thus, the response was sufficiently explained by the model.

Three-dimensional response surface (a) and for contour plot (b) DNJ yield of mulberry tea versus microwave processing time and microwave power

Comparison results chart of different processing conditions

Model interpretation Fig. 5a and b contains the response surface and contour plot, showed the effect of microwave processing time, microwave power and their mutual interaction on the DNJ yield. The curve pattern represented that DNJ yield increased at first followed by slightly declined with the increasing of microwave processing time, the change was highly significant. However the curve pattern of microwave power was different, namely DNJ yield slightly increased at first followed by declined with the increasing of processing time, the change was not significant. That was consistent with the results of table 2. The result indicated that by increasing the microwave power, an increase in size of pressure generated by water absorbs heat of vaporization, that resulted in the generation of cracks and holes on cell surface, hence more DNJ molecules were released into extract. Likewise, the effects of the processing time could also be interpreted as that. However, a higher amount of microwave power and processing time might cause change in the structure of DNJ molecules due to microwave radiation energy produced a high heat. So there were the optimum values of microwave power and processing time correspond to the highest extraction efficiency. The analysis result of Design-Expert software showed that microwave power 602.28 W and processing time 11.41 min were found to be optimal for microwave-assisted extraction DNJ. Under these conditions, the yield was 0.19%. However the optimal extraction conditions are different among DNJ from mulberry leaves, anthocyanins and polyphenols from mulberry fruits (Zou et al., 2012; Teng et al., 2013). The author thinks that microwave- assisted extraction condition may also associated with the physical and chemical properties (such as molecular structure, stability and solubility) of the extracts.

Verification of results The suitability of the model equation for predicting the optimum response values was tested using the recommended optimum conditions (microwave power 600 W, processing time 11.41 min). The experimental values were found to be in agreement with the predicted ones, the coincidence rate was 99.58%.

However, not all of the microwave ovens could be adjusted to the power of 600 W in daily life. So we changed the optimum microwave power 600 W to 560 W and 640 W respectively to detect the difference degree of DNJ yield among them. At the same time, the optimized conditions (soak mulberry tea in 98°C water for 400 s) of Vichasilp et al (2012) also were compared. From the result (see Fig. 6) we could find it was significantly different between microwave heating and immersion heating and the efficiency of microwave heating was significantly better than that of immersion heating. This may be because microwave assisted extraction technology is a combination of thermal effects and non- thermal effects (i.e., electrical effect, magnetic effect, and chemical effect). But the DNJ yield was not significantly different among the three microwave heating processing conditions, that was consistent with the results in Table 2. So when does not have the optimum conditions, power with somewhere around 600 W (like between 560 W and 640 W) also can greatly improve the DNJ yield of mulberry tea. Furthermore the tea drinkers can made them into strong tea or weak tea by mastering the ratio of tea and water based on the respective requirements.

Because of the increasing interest in mulberry tea as a possible nutraceutical product for diabetic patients, this is a requirement for effective measures to improve DNJ yield. Here, we proposed a fast and convenient method for the extraction of DNJ using response surface methodology to optimize microwave-assisted technology.

For the present study, the mulberry tea was prepared based on the common production process of green tea. DNJ was measured by optimizing the methods of others. And then Design-Expert 8.05 software was used to set experimental design and statistical analysis. The regression model of DNJ yield based on microwave power and microwave processing time was obtained. The results indicated the optimal conditions were microwave power 602.28 W, processing time 11.41 min. Under these conditions, the yield was 0.19%. The ANOVA results suggested the response was sufficiently explained by the model. We also tested the suitability of the model equation for predicting the optimum response values using the recommended optimum conditions (microwave power 600 W, processing time 11.41 min), and found the coincidence rate was 99.58%.

Our optimum conditions not only could be applied commercially to prepare mulberry tea drinks with high DNJ content but also provided a basis for efficient use of DNJ for people who drink mulberry tea to control blood glucose levels or to prevent diet-induced obesity, and could be used both at home and in the office. So the experiment results has a good practical significance.

Acknowledgments This work was supported by the Fundamental Research Funds for the Central Universities (Grant no. XD-JK2013C053) and the Fundamental Research Funds for the Central Universities (Grant no. XDJK2011D012).