2014 Volume 20 Issue 5 Pages 1021-1026

2014 Volume 20 Issue 5 Pages 1021-1026

The present study aimed to develop sericin-added bread in an effort to promote the effective consumption of the silk protein sericin and to evaluate bread-baking performance with sericin addition, with respect to effects on bread structure and palatability. Sericin supplementation resulted in decreased specific volume and darker crust color of the bread. No significant difference was observed in other physical properties. Sensory evaluation revealed that bread with up to 2 g of added sericin tended to be preferred. In a comprehensive evaluation of specific volume, crust color and preference rating by sensory evaluation, the optimal amount of added sericin was determined to be 2 g. Further, approximately 330 mg of sericin can be consumed in 1 slice of bread. We thus propose sericin-added bread as a desirable processed food that enables the effective ingestion of sericin.

Sericin is a type of silk protein and accounts for 20 – 30% of the total weight of silkworm cocoons. When cocoons and raw silk are processed into fiber, sericin is mostly removed and the remaining fibroin is used as silk fiber. Before sericin, fibroin was widely studied as a potential food ingredient (Hirabayashi et al., 1990; Hirabayashi et al., 1991; Hirao et al., 1998; Hirayama et al., 2006; Ito et al., 2006; Osaki and Ichikawa, 2012). In recent years, however, sericin has been reported to have a wide variety of functions, leading to increased efforts for its utilization as a functional food ingredient. Researchers have already proposed a number of possible applications in cosmetics or processed fiber products, as well as in the medical field, (Zhaorigetu et al., 2003a; Ogino et al., 2006; Sasaki et al., 2005; Nishida et al., 2010) in an effort to promote its commercial viability.

Sericin has a unique amino acid composition. It contains a very high amount of serine (33 – 39%), while 40% or more of sericin is composed of hydroxyamino acid, including serine and threonine. Sericin therefore exhibits high hydrophilicity and water retention, with a strong affinity for other proteins (Rainer, 1998). In addition, sericin is a resistant protein not easily digested by proteases (Kato, 2012). In 1998, the Japanese Association for Dietary Fiber Research stated that “food ingredients that are hardly digestible or absorbable within the human small intestine and exhibit a physiological effect that is useful for the maintenance of good health via the digestive tract” should be collectively termed “luminacoids”, i.e., substances with various physiological properties. Of these substances, resistant protein (RP) is the only protein component. RP, in addition to its well-established value as a nutrient (used as essential amino acids or a nitrogen source), exerts a physiological function useful for the maintenance of good health via the digestive tract due to its moderately low digestibility. Among its wide range of physiological functions, sericin has been reported to ameliorate constipation (Sasaki et al., 2000a), suppress colorectal cancer (Sasaki et al., 2000b; Zhaorigetu et al., 2001; Zhaorigetu et al., 2007), suppress skin cancer (Zhaorigetu et al., 2003b), and apply cell activating/cytoprotective properties (Terada et al., 2002; Terada et al., 2005; Ohnishi et al., 2012) and adiponectin-increasing/promoting effects (Okazaki et al., 2010). In addition, supplements exerting physiological effects have been put to practical use.

Although sericin has been suggested as a useful food ingredient due to its wide functionalities (Jin-hong et al., 2007), few studies to date have reported on the efficient use of sericin as an ingredient in daily foods. We have attempted to effectively use sericin as a food ingredient, and previously reported its possible application as a salad dressing ingredient (Takechi et al., 2011). In our previous report, we focused on the emulsifying and antioxidative properties of sericin, and utilized this natural material that exhibits low allergenic potency as an emulsifying and antioxidant agent. Because sericin, as described earlier, is a RP with high physiological effects, its consumption in ordinary food items is considered desirable. No food application, however, has been reported so far. We thus investigated the addition of sericin to white bread, a product that many consume daily, in an effort to promote its intake. The objective of the present study is to produce bread containing the maximum quantity of sericin, from the standpoint of health effects, to evaluate bread-baking performance with sericin addition and to develop a food item that promotes the effective consumption of silk protein.

Sericin sample We purchased sericin powder from Kashiro Sangyo Co., Ltd. (Nagahama, Japan). The amino acid composition included serine (36%), aspartic acid (16%), glycine (14%), threonine (8%), alanine (5%) and leucine (1%).

Composition and adjustment of bread dough According to the bread maker (Panasonic) instruction manual, we determined the basic ingredients and the composition of the bread dough (Table 1). All ingredients were placed in the machine (Matsushita SDBM101), and the bread was made using the preset standard course (4 h).

| Ingredient | Amount (g) |

|---|---|

| Wheat flour (Camellia; Nissin Flour Milling, Tokyo, Japan) | 250 |

| Sugar (White Sugar; Mitsui Sugar Co., Ltd, Tokyo, Japan) | 17 |

| Salt (The Salt Industry Center of Japan, Tokyo, Japan) | 5 |

| Dry Yeast (Super Camellia; Nissin Foods Group, Tokyo, Japan) | 2.8 |

| Butter (Yotsuba Milk Products Co., Ltd, Hokkaido, Japan) | 10 |

| Water (Tap Water)1 | 180 |

Investigation of the upper limit of sericin addition Since our preliminary experiment demonstrated that dough tended to rise less and made less desirable bread with an increasing amount of sericin, we investigated the upper limit of sericin addition. In addition to the control bread (with no added sericin) described in Table 1, we made bread with the addition of 8, 9, 10, 11, 12, 13, 14, 18, or 22 g of sericin. After allowing the baked bread to cool for 2 h to ambient temperature (25°C), we sliced it into 20 mm sections and observed the cut surface at the same point in each loaf.

Measurement of RP in sericin The weight of RP contained in sericin powder was measured using an enzymatic-gravimetric method based on the Prosky method (Prosky et al., 1985).

Determination of the optimal amount of added sericin In comparison with the control bread (Table 1), we made bread with four different levels of sericin addition, to a maximum of 8 g. The composition of sericin bread is shown in Table 2. All ingredients were placed together in the bread maker machine (SD-BM101) and the bread was baked using the preset standard course (4 h).

| Ingredient | Control bread (no added sericin) | Sericin-added bread | |||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | ||

| Wheat flour | 250 | 250 | 250 | 250 | 250 |

| Sericin | 0 | 2 | 4 | 6 | 8 |

| Sugar | 17 | 17 | 17 | 17 | 17 |

| Salt | 5 | 5 | 5 | 5 | 5 |

| Dry Yeast | 2.8 | 2.8 | 2.8 | 2.8 | 2.8 |

| Butter | 10 | 10 | 10 | 10 | 10 |

| Water | 180 | 180 | 180 | 180 | 180 |

Measurement of bread specific volume After allowing the baked bread to cool for 2 h to ambient temperature (25°C), we measured the weight [g] and volume [mL] of each loaf using the rapeseed displacement method (Approved Methods 10 – 05; AACC International, 2000). We obtained the specific volume [mL/g] by dividing the measured volume by the weight.

Measurement of bread hue After allowing the baked bread to cool for 2 h to ambient temperature (25°C), we measured the L* values (lightness), a* values (a*: red axis, -a*: green) and b* values (b*: yellow, -b*: blue) of the crumb and the surface of each loaf using a spectrophotometric colorimeter (KONICA MINOLTA, CM-600d). Measurement was conducted at four points in the center of the crumb and five points on the surface, including four points in the center of both sides of each loaf and a point on the top. Average scores were then calculated.

Measurement of degree of bread gelatinization After allowing the baked bread to cool for 2 h to ambient temperature (25°C), it was sliced into 20 mm sections (6 pieces per loaf) and the gelatinization degree was measured on the day of baking (day 1), day 4 and day 7 using the β-amylase-pullulanase (BAP) method (Matsunaga and Kainuma, 1981; Nakamura and Kainuma, 1998). For preservation, bread was placed in polyethylene bags and left at room temperature after the air inside the bag was removed. The bag was then sealed. For sample collection, a 10 × 10 cm section was excised from the center of a slice, then a 10 g sample was dehydrated three times with 45 mL of ethanol and twice with acetone, and air-dried to make a powder sample. We employed the enzymes β-amylase (Nagase ChemteX Corporation, derived from soybeans, 5 IU/mg) and pullulanase (Hayashibara Biochemical Laboratories Inc., derived from Aerobacter aerogenes, crude 2 IU/mg).

Preparation of wheat flour gel (model dough) One hundred grams of wheat flour (with the addition of 3 g of sericin) was mixed with 70 mL of water and kneaded into dough in a mixer (Toshiba CQ-26; Tokyo, Japan) for 1 min. Subsequently, the mixture was put into a Teflon vessel (20 mmø × 10 mm), and incubated at 90°C for 2 h to make a heat-denatured gel. Six replicate gels were prepared at the same time.

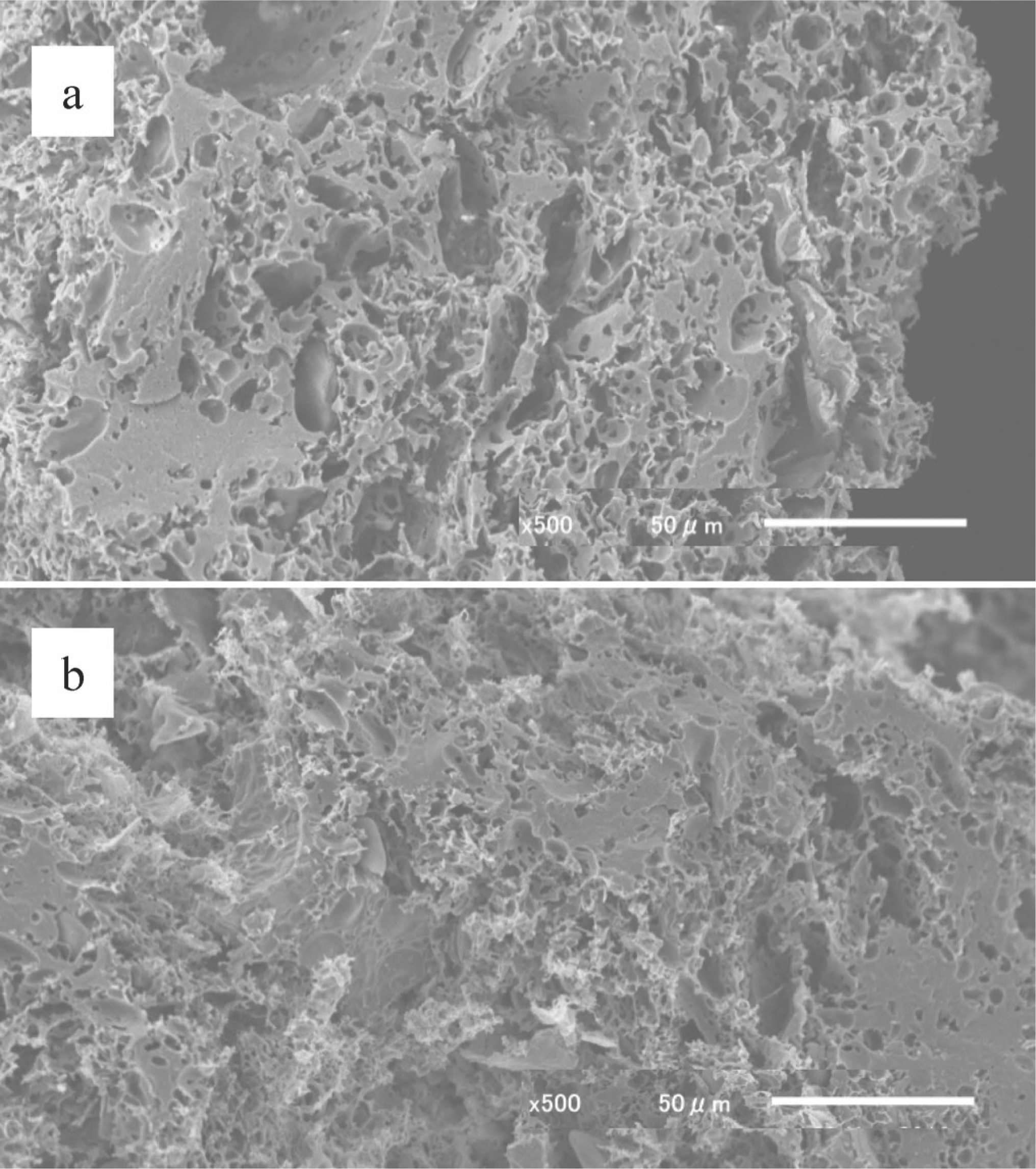

Electron microscopy For scanning electron microscopy, small pieces of gel samples (10 × 2 × 2 mm) were fixed with 2% glutaraldehyde solution for 5 h at room temperature. After washing 3 times with distilled water, samples were serially dehydrated with ethanol (35 to 100%). Samples in gelatin capsules filled with 100% ethanol were cut in a freeze fracturing apparatus (Eiko Engineering, Ibaraki, Japan). Cut samples were thawed in 100% ethanol, and ethanol was replaced with water by a decreasing series of 100 to 0% ethanol. Subsequently, starch granules in the samples were digested in 100 mM acetate buffer (pH 5) containing 0.1% glucoamylase (Optidex L-400, Genencor, USA) for 20 h at room temperature. After washing 3 times with distilled water, samples were post-fixed with 2% osmium tetraoxide solution for 30 min at room temperature. After washing 3 times with distilled water, samples were serially dehydrated with ethanol, and dried further using a critical point dryer (JCPD-5; JEOL, Tokyo, Japan). After coating with platinum in an ion sputtering apparatus, specimens were observed with a scanning electron microscope (JSM 6640 A; JEOL).

Sensory evaluation of sericin-added bread After allowing the baked bread to cool for 2 h to ambient temperature (25°C), the bread was placed in plastic bags, sealed and left at room temperature for a day. The bread was then sliced into 20 mm-thick sections, which were subsequently cut in half widthwise and used as test samples (62 × 170 × 20 mm). The sensory panel was composed of 35 females, including 34 students and a staff member from the Kobe Shoin Women's University. Sericin bread (with addition of 2, 4, 6 or 8 g) was evaluated in comparison with control bread without added sericin (0 point).

For sensory evaluation, discrimination and preference tests were performed on a 5-point rating scale. In the discrimination test, six factors: “Color of the crust: light - dark,” “Texture: rough - fine,” “Hardness: hard - soft,” “Flavor: weak - strong,” ”Chewiness: weak - strong” and “Ease of swallowing: difficult - easy” were evaluated on a 5-point scale from −2 to +2. In the preference test, an overall evaluation was made in addition to the six factors assessed in the discrimination test, and each factor was assessed as “not preferable (−2) to preferable (+2).” For each factor, Bonferroni's test was performed for between-group comparisons (control and sericin-added bread).

Investigation of the upper limit of added sericin Figure 1 shows images of breads and cross-sections of loaves at 2 h after baking. With an increasing amount of added sericin, bread height tended to be lower and its volume smaller. The interior texture however remained fine, with uniform bubbles seen up to 10 g sericin addition. The basic characteristics of high quality bread include: 1) starch is gelatinized fully into the central part of the bread and 2) bread has the specific volume preferred by consumers. To represent such conditions, we measured the volume of baked bread. After investigating the volume and internal state of each loaf, we determined that the upper limit of sericin addition is 8 g.

Images of breads and cross-sections of loaves prepared with various sericin additions

Determination of RP content in sericin The amount of RP contained in the sericin powder employed was 19.4 g per 100 g of sericin.

Effects of added sericin on bread characteristics The physical properties of bread with different amounts of added sericin are shown in Table 3.

| Sericin addition (g) | Specific volume1 (mL / g) | Bread hue2 | gelatinization degree3 (%) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| crumb | crust | |||||||||

| L* | a* | b* | L* | a* | b* | Day 1 | Day 4 | Day 7 | ||

| 0 (control) | 4.70 ± 0.24 | 74.8 ± 3.0 | −0.5 ± 0.1 | 11.1 ± 1.0 | 58.7 ± 2.0 | 11.9 ± 0.3 | 23.9 ± 1.3 | 66.8 ± 3.7 | 47.6 ± 0.8 | 46.6 ± 1.6 |

| 2 | 4.52 ± 0.15 | 74.8 ± 3.0 | −0.4 ± 0.1 | 11.3 ± 0.7 | 58.0 ± 0.8 | 12.0 ± 0.4 | 23.1 ± 0.7 | 61.4 ± 1.2 | 43.8 ± 4.1 | 43.3 ± 3.0 |

| 4 | 4.32 ± 0.14a | 74.1 ± 2.9 | −0.4 ± 0.1 | 11.2 ± 1.0 | 58.2 ± 0.4 | 12.4 ± 0.4 | 23.6 ± 0.8 | 64.6 ± 3.6 | 47.1 ± 0.4 | 45.8 ± 2.5 |

| 6 | 4.30 ± 0.12a | 73.8 ± 3.8 | −0.4 ± 0.1 | 11.6 ± 1.1 | 56.0 ± 1.7 | 12.2 ± 0.4 | 21.9 ± 1.0a | 67.6 ± 6.0 | 45.9 ± 0.4 | 43.5 ± 0.7 |

| 8 | 4.16 ± 0.16a | 73.2 ± 3.7 | −0.3 ± 0.1a | 11.7 ± 1.4 | 54.6 ± 2.0a | 12.9 ± 0.7a | 22.0 ± 1.2 | 70.1 ± 5.1 | 45.0 ± 2.3 | 44.1 ± 2.7 |

mean ± SEM;

Increased sericin addition resulted in decreased bread specific volume. With an 8 g addition, the volume was significantly lower than the control (p < 0.001). The addition of sericin appeared to inhibit dough rising. Because it was assumed that some changes would occur in the behavior of gluten, we observed model dough samples using an electron microscope. Scanning electron micrographs of the model dough is shown in Figure 2. The gluten structure was slightly more indistinct in the sericin-added dough compared to control, and it is thought that there is an irregular distribution of starch granules within the gluten matrix. Taken together, it suggests that sericin addition affected gluten formation.

SEM image of model dough with (b) or without (a) sericin

A significant difference was observed in the surface hue of bread. While L* values (lightness) were significantly decreased with the addition of 6 g or more of sericin, a* values (red) were significantly increased with an 8 g addition. This finding indicated that the brown color on the bread surface darkened with sericin addition. The addition of sericin, a protein, might have promoted an aminocarbonyl reaction.

In a comparison of all bread types, no significant difference was found in the degree of gelatinization. The characteristics of high quality bread include full gelatinization in the core. This result suggested that sericin addition had no effect on starch gelatinization.

Effects of added sericin on bread palatability To investigate possible changes in bread palatability upon sericin addition, we conducted a sensory evaluation of bread supplemented with 2, 4, 6, or 8 g sericin using a grading scale. The results are summarized in Table 4.

| Sericin addition (g) | crust color | texture | hardness | flavor | chewiness | ease of swallowing | overall evaluation | |

|---|---|---|---|---|---|---|---|---|

| Discrimination | 0 (control) | 0 | 0 | 0 | 0 | 0 | 0 | |

| 2 | 0.03 ± 1.20 | −0.46 ± 1.24 | −0.17 ± 1.33 | −0.37 ± 1.00 | 0.14 ± 1.12 | −0.20 ± 0.90 | ||

| 4 | 0.40 ± 1.03 | 0.06 ± 1.11 | 0.34 ± 1.19 | −0.20 ± 1.05 | 0.17 ± 1.12 | 0.20 ± 1.08 | ||

| 6 | 0.26 ± 1.29 | 0.23 ± 1.21 | 0.60 ± 1.42 | −0.06 ± 1.35 | 0.00 ± 1.24 | −0.63 ± 0.97* | ||

| 8 | 0.77 ± 1.11* | 0.34 ± 1.26 | 0.71 ± 1.27* | −0.03 ± 1.42 | −0.26 ± 1.33 | −0.40 ± 1.22 | ||

| Preference | 0 (control) | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 2 | 0.26 ± 0.98 | −0.03 ± 1.27 | −0.11 ± 1.37 | 0.29 ± 0.99 | 0.29 ± 1.20 | 0.26 ± 0.95 | 0.46 ± 1.01* | |

| 4 | 0.46 ± 1.07 | 0.34 ± 1.08 | −0.20 ± 1.16 | −0.06 ± 1.11 | 0.11 ± 1.23 | 0.06 ± 1.03 | 0.20 ± 0.93 | |

| 6 | 0.40 ± 1.06 | 0.09 ± 0.98 | 0.40 ± 1.35 | −0.11 ± 1.08 | 0.20 ± 1.02 | −0.09 ± 0.92 | 0.06 ± 1.21 | |

| 8 | 0.06 ± 1.21 | −0.09 ± 1.31 | 0.43 ± 1.44 | −0.34 ± 1.21 | 0.29 ± 1.30 | −0.34 ± 1.28 | −0.23 ± 1.17 | |

n = 35, mean ± SEM;

The discrimination test revealed a significant difference in both groups in crust color, hardness and ease of swallowing. Crust color was found to be significantly darker with the addition of 8 g of sericin. A similar tendency was observed with respect to hue measurement. The bread was judged to be significantly harder with 8 g of sericin addition. As for ease of swallowing, bread with 6 g of sericin was found to be difficult to swallow, and the panel often pointed out difficulties swallowing the bread with other levels of sericin addition. Taken together, sericin addition caused the crust to darken and the bread to be harder, leading to difficulty in swallowing the bread.

The preference test revealed no large differences were found between the two groups in all factors, except the overall evaluation. With respect to crust color and chewiness, the panel give positive ratings in general to the sericin-added bread compared to the control bread. The result of the discrimination test showed that the crust color darkened with sericin addition. It appeared that darker crust colors were preferred by the panel. In contrast, the hardness, flavor and ease of swallowing were evaluated as lower in the sericin-added bread. In the overall evaluation, however, the panel showed the greatest preference for the bread with 2 g of added sericin (p < 0.0125), and bread with up to 6 g of added sericin received positive ratings on average and tended to be rated preferably (tasty).

Our present study aimed to develop sericin-added bread in an effort to promote the effective consumption of the silk protein sericin and to evaluate bread-baking performance upon sericin addition, with respect to effects on structure and palatability.

Sericin addition resulted in decreased specific loaf volume and a darker crust color. Since no significant differences were observed in other physical parameters, we concluded that sericin addition exerted no major impact. In contrast, sensory evaluation revealed that in overall preference, the panel significantly preferred bread with 2 g of added sericin and bread with up to 6 g of added sericin tended to be preferred.

Based on the above findings, although sericin addition may inhibit dough rising, it does not appear to have a profound effect on other physical properties or palatability. In a comprehensive assessment of specific loaf volume, crust color and preference rating by sensory evaluation, the optimal amount of added sericin was determined to be 2 g. Assuming that people usually eat onesixth of a loaf of bread in a meal, 330 mg of sericin can be obtained from a slice of bread. Since 330 mg of sericin powder contains approximately 20% RP, a slice of bread can provide about 67 mg of RP. We thus propose that sericin-added bread is a desirable processed food that enables the effective ingestion of sericin.

Acknowledgements We would like to thank Dr. Y. Hatanaka, Osaka Municipal Technical Research Institute, Osaka, for the valuable comments regarding this study.