2015 Volume 21 Issue 1 Pages 125-128

2015 Volume 21 Issue 1 Pages 125-128

Here, we investigated the potential preservation of soymilk by freezing. The physicochemical properties of raw and heated soymilk and the texture of tofu curds prepared using raw and heated soymilk were analysed after freeze-thawing and heating. Centrifugation results revealed increased precipitates in heated soymilk, suggesting that it was not possible to maintain the quality of soymilk before freezing. On the other hand, the physicochemical properties of soymilk and the texture of tofu curds were found to be equivalent when raw soymilk was used, even after freeze-thawing and heating. Furthermore, the viable cell count in raw soymilk did not change after freezing. These results suggested that raw, unheated soymilk may be preserved for long periods by freezing.

Tofu is the major processed soybean product in East Asian countries such as China, Japan, and Korea. Tofu curd has traditionally been prepared by adding a coagulant to heated soymilk. Two methods are mainly used for preparing soymilk: ‘nama-shibori’ and ‘kanetsu-shibori’. In the nama-shibori method, which is used mainly in Okinawa and Asian countries other than Japan, raw soymilk is processed by squeezing the slurry and then heating. In contrast, in the kanetsu-shibori method, which is used by most tofu manufacturers in Japan, soymilk is obtained by squeezing the slurry after heating (Toda et al., 2007). The soymilk from both methods is heated prior to adding the coagulant. Thus, the coagulation of soymilk is thought to require thermal denaturation of protein in the soymilk (Guo et al., 1997; Ono, 2008). On the other hand, heated soymilk is coagulated by the freeze-thaw process (Hashizume, 1979; Shimoyamada et al., 1999). Nakagawa and Kashima (2008) reported that soymilk homogenized after freeze-thawing did not form tofu curd after the addition of coagulant. Therefore, they concluded that soymilk preserved by freezing is not suitable for the preparation of tofu, and that tofu curd processing should be carried out immediately after soymilk formulation. However, preservation of soymilk by freezing may lead to decreased losses during production and reduced labour requirements for the preparation of tofu.

Recently, Morita and Yokoi (2011) reported a simple method for fractionation of 7S and 11S globulins in raw soymilk using the freeze-thaw method, and both of the fractions obtained could be formulated into tofu curd after heating. The tofu curd made from the 7S globulin-rich fraction was soft and smooth, whereas that made from the 11S globulin-rich fraction was firm. Thus, these results suggested that raw, unheated soymilk may be preserved by freezing.

In this study, we investigated the physicochemical properties of soymilk after freeze-thawing and assessed the texture of tofu curds derived from the freeze-thawed soymilk. Finally, we evaluated the possibility of preserving soymilk by freezing.

Preparation of soymilk Soymilk was manually prepared from commercially available soybeans (Glycine max L Merrill, Enrei). Soymilk samples were prepared by the nama-shibori method with modifications (Toda et al., 2007). Soybeans were washed and soaked in distilled water at 20°C for 16 h. The swollen soybeans were then drained and ground into a homogenate with a volume of distilled water equivalent to six times the dry weight of soybeans. The homogenate was filtered through an absorbent cotton sheet to remove okara. This filtrate was termed raw soymilk. The raw soymilk was heated in an oil bath at 95°C for 2 min and then cooled in ice-cold water. This heated soymilk was termed raw-H soymilk.

Freeze-thaw treatment of soymilk The raw soymilk and the raw-H soymilk were frozen at −20°C for 7 days and then thawed at 10°C for 24 h. These freeze-thawed soymilk samples were termed raw-FT soymilk and heated-FT soymilk, respectively. Next, the raw-FT and heated-FT soymilks were gently agitated and heated in an oil bath at 95°C for 2 min and then cooled in ice-cold water. These heated soymilk samples were termed raw-FT-H soymilk and heated-FT-H soymilk, respectively.

Evaluation of physicochemical properties of soymilk The particle size distribution of soymilk was analysed with a laser diffraction particle size analyser (SALD-2100; Shimazu Co. Ltd., Kyoto, Japan). After centrifugation of the soymilk at 3000 × g for 10 min, the precipitate was collected, and precipitate wet weight was determined. The precipitate content was obtained as the weight ratio of the precipitate to the total weight. The protein content of the supernatant was also determined after centrifugation by the Kjeldahl method, using a nitrogen-to-protein conversion factor of 6.25.

Preparation of tofu curds and texture analysis After cooling the soymilk in ice-cold water, 0.30% glucono-delta-lactone (GDL) was added. After mixing, the soymilk and coagulant mixture was poured into a stainless steel cylinder (23 mm diameter and 25 mm height) and heated at 80°C for 1 h, followed by cooling at 20°C. The tofu curd was carefully removed from the cylinders and cut into a columned sample 20 mm in height. The breaking stress of the tofu curd was measured with a rheometer (Rheoner RE-33005; Yamaden Co. Ltd., Tokyo, Japan) using a disk adapter 30 mm in diameter. The moving speed of the adapter was 1 mm/s.

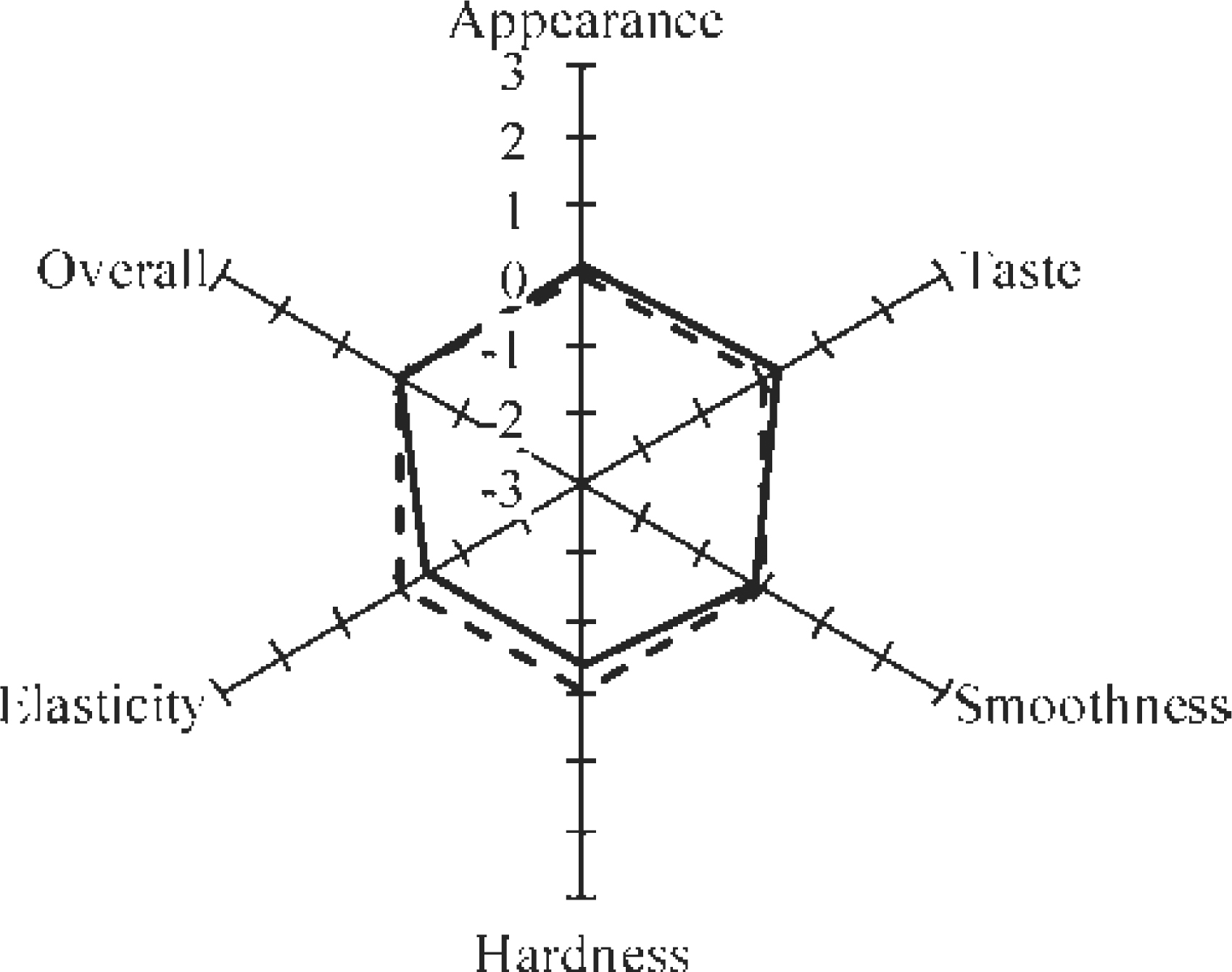

Sensory evaluation The appearance, taste, smoothness, hardness, elasticity, and overall impression of tofu curds were judged by 15 volunteers (9 men and 6 women; age range, 26 – 58 years) using a seven-point score (−3 = very bad, 3 = very good).

Microbiological analysis The number of viable cells in soymilk was determined by culturing on Standard Methods Agar (Nissui Co. Ltd., Tokyo, Japan). Soymilk samples were plated onto appropriate media, and the plates were incubated at 37°C for 48 h. The number of bacterial colonies on each plate was manually counted and converted to log CFU per mL.

Statistical analysis All collected data were subjected to statistical analysis using one-way analysis of variance (ANOVA) and multiple range comparison by Tukey's test. A p value of < 0.05 was considered statistically significant.

Physicochemical properties of freeze-thawed soymilk After freeze-thawing, the raw soymilk prepared without heating was separated into two layers, and the heated soymilk was loosely coagulated. The freeze-thawed soymilk samples (raw-FT soymilk and heated-FT soymilk) and unfrozen raw soymilk were heated, and the particle size distribution was measured. The freeze-thawed soymilks were gently agitated before heating. Differences in the particle size distribution among these soymilks were estimated using a laser diffraction particle size analyser (Fig. 1). In comparison with the particles in raw-H and raw-FT-H soymilks, which exhibited sizes ranging from 0.3 to 1 µm with a 0.45-µm mode diameter, the particles in heated-FT-H soymilk showed much larger sizes ranging from 10 to 100 µm, with a 20-µm mode diameter. This shows that the freeze-thaw process increased the size of particles in heated soymilk. On the other hand, the particle size of the raw-FT-H soymilk was almost equal to that of the raw-H soymilk, showing that the raw soymilk was unaffected by the freeze-thaw process.

Particle size distributions of raw-H soymilk, raw-FT-H soymilk, and heated-FT-H soymilk

Differences in the precipitate content and supernatant protein content among raw-H, raw-FT-H, and heated-FT-H soymilks were determined after centrifugation at 3000 × g for 10 min (Table 1). The precipitate content was higher in the heated-FT-H soymilk than in the raw-H and raw-FT-H soymilks. The supernatant protein content of raw-FT-H soymilk was much higher than that of heated-FT-H soymilk and was equivalent to that of raw-H soymilk. These soymilks contained 66 g kg−1 of protein before centrifugation; thus, most of the protein remained in the supernatants of raw-H and raw-FT-H soymilks, even after centrifugation.

| Raw-H | Raw-FT-H | Heated-FT-H | |

|---|---|---|---|

| Precipitate content (%) | 5.0a | 4.8a | 58.1b |

| Supernatant protein content (%) | 6.6a | 6.6a | 3.7b |

The precipitate content indicates the weight ratio of the precipitate to the total weight. Values are means of triplicate experiments. Means with different letters in the same row are significantly different by Tukey's test (p < 0.05).

Coagulation of heated soymilk by the freeze-thaw process has been reported to occur due to the increase in disulphide and/or hydrophobic interactions among proteins concentrated by freezing (Shimoyamada et al., 2000; Shimoyamada, 2003). However, in the case of raw soymilk, coagulation of proteins did not occur, despite the freeze-mediated concentration, resulting in separation of the sample into two layers (Morita and Shimoyamada, 2013). In this study, the heated-FT and raw-FT soymilks also showed different solubilising behaviours after further heating. Raw soymilk was reported to show lower surface thiol content and surface hydrophobicity than heated soymilk (Shimoyamada et al., 2000). Therefore, interactions among proteins are not expected to be accelerated by freeze-mediated concentration. Low-affinity interactions among proteins may lead to increased solubility of the raw-FT soymilk after heating. Therefore, the physicochemical properties of raw-FT-H soymilk were considered to be similar to those of raw-H soymilk.

Breaking stress of tofu curds and sensory evaluation To verify the physical properties of tofu curds made from raw-H, raw-FT-H, and heated-FT-H soymilks, we determined the breaking stress of tofu curds (Fig. 2). The breaking stress of tofu curds prepared from the raw-FT-H soymilk was similar to that of tofu curds prepared from raw-H soymilk. The breaking stress values of tofu curds prepared from the heated-FT-H soymilk were obviously lower than that of tofu curds prepared from the raw-H and raw-FT-H soymilks.

Breaking stress of tofu curd made with 0.3% GDL from raw-H soymilk, raw-FT-H soymilk, and heated-FT-H soymilk Values are means ± standard error of triplicate experiments. Means with different letters are significantly different by Tukey's test (p < 0.05).

Furthermore, tofu curds made from raw-H and raw-FT-H soymilks were evaluated by sensory tests (Fig. 3). Category scores did not differ significantly between the raw-H and raw-FT-H soymilks. Moreover, fewer coagulated tofu curds were prepared from the heated-FT-H soymilk. Therefore, it was not possible to compare the results with those of tofu curds prepared from raw-H and raw-FT-H soymilks by sensory evaluation.

Sensory evaluation of tofu curds made with 0.3% GDL from raw-H soymilk (dotted line) and raw-FT-H soymilk (solid line)

The physical properties of tofu curds depend on the physicochemical properties of soymilk (Toda et al., 2007). Therefore, the raw-FT-H soymilk appeared to have properties similar to those of the raw-H soymilk.

Effects of freezing duration on the number of viable cells in soymilk samples Microbiological kinetics is important for the preservation of unheated raw soymilk. To verify the microbiological kinetics in raw soymilk under freezing conditions, the numbers of viable cells in the raw soymilk were measured after 1, 7, and 28 days of frozen storage at −20°C (Fig. 4). The number of viable cells in raw soymilk immediately after preparation (control) was 5.3 log CFU/mL, while that after 28 days of freezing was 5.3 log CFU/mL, indicating that the number of viable cells was not changed by freezing at −20°C for 28 days and subsequent thawing at 10°C for 24 h. Furthermore, heating of these soymilk samples at 95°C for 2 min dramatically decreased the number of viable cells (< 100 CFU/mL).

Effects of freezing duration on viable cell count in raw soymilk

Control cells were counted immediately after preparation. Values are means ± standard error of triplicate experiments.

The particle size and precipitate content in heated soymilk increased after freeze-thawing and subsequent reheating. Therefore, it was not possible to maintain the quality of soymilk before freezing. On the other hand, the physicochemical properties of raw soymilk and the texture of produced tofu curds were equivalent, despite the freeze-thaw and heat treatment of soymilk. Furthermore, the viable cell count in raw soymilk did not change after freezing. Taken together, these results suggest that raw, unheated soymilk may be preserved for long periods by freezing.