2015 Volume 21 Issue 3 Pages 317-325

2015 Volume 21 Issue 3 Pages 317-325

This study was designed to evaluate different combinations of broken rice grains, passion fruit peel flour and whey powder considering the physical, chemical and functional properties of extruded breakfast cereals. A completely randomized delineation was used, with four treatments (T1: 100% BRG; T2: 97% BRG + 3% PFPF; T3: 87% BRG + 3% PFPF + 10% WP; T4: 90% BRG + 10% WP) and five repetitions. The co-products were characterized according to their grain size and proximate composition. The physical, chemical and functional properties of the experimental breakfast cereals were evaluated using official methods. The obtained data underwent an analysis of variance (ANOVA), and the means were compared using Tukey's test considering 5% probability.

Rice (Oryza sativa) is one of the three most produced and most consumed cereals in the world, only behind wheat and corn. In the harvest of 2012, an estimated 730 million tons of unhulled rice were produced. Moreover, Brazil participates strongly in the global production of this grain and is considered the tenth-largest global consumer (FAO, 2013). During rice processing, the breakage of grains is a common occurrence and generates an economic problem for the rice industry (Carvalho et al, 2012). Although the broken grain contains the same average proximate composition as whole grains, the value of this co-product is only one-fifth of the value of whole grains (Silva, 2009).

Brazil is the world's largest passion fruit producer, with approximately 400 thousand tons of the fruit produced annually. Information from the Brazilian Enterprise for Agricultural Research (Empresa Brasileira de Pesquisa Agropecuária — Embrapa) indicates that the Brazilian production of passion fruit in 2010 was 920 thousand tons, approximately 70% of the global production (Well, 2013). Passion fruit peel represents 52 – 67 g 100 g−1 of the fruit mass, varying according to the fruit size (Coelho, 2011). Passion fruit peel flour (PFPF) is obtained from the fruit after selection, washing, sanitization, pulp cutting and separation, trituration, dehydration and grinding of the peels, which are considered an important source of dietary fiber (Vernaza, 2009). Because of its functional properties, passion fruit peel has been used in the formulation of many food types, such as breads (Lopes, 2006), cookies (Ishimoto, 2007), cereal bars (Silva, 2009), pasta (Spanholi, 2009), and breakfast cereals (Leoro, 2007).

Whey powder (WP) derives from cheese production, a process with the separation of two main proteins: one solid (casein) and another (lactalbumin) that remains liquid, constituting the whey (Lima, 2010). This co-product has been drawing attention from researchers around the world because of its nutritional, functional and economic potential. The high environmental pollution factor of WP can be decreased by using it as a co-product because whey is often discarded on soil and in river springs with no previous treatment.

Broken rice grains (BRG), passion fruit peel and WP are gluten-free co-products, which makes them interesting for the production of alternative foods, such as products for celiac or gluten-intolerant consumers. Extrusion technology may allow the use of such co-products as raw materials for the production of processed foods ready for consumption with long shelf lives and high acceptance by consumers. In this process, the raw materials are cooked and texturized by the combined action of moisture, pressure, temperature and mechanical shear, leading to the formation of a new molecular structure, thus generating a series of products ready for consumption or of ingredients widely used by the food industry (Singh, 2007). Because of the flexibility associated with the extrusion process, the raw materials, the shapes and the aromas, many products can be created starting from the same production line, such as breakfast cereals.

Breakfast cereals are very important meals for athletes and children because of the many desirable characteristics of cereals, such as practicality, convenience, flavors and diverse shapes in addition to nutritional value. The purpose of this study was to evaluate the influence of different combinations of BRG, PFPF and WP on the physical, chemical and functional characteristics of extruded breakfast cereals to evaluate the technological viability of the use of these co-products by the breakfast cereals industry.

Raw materials The raw materials used to formulate the experimental extruded breakfast cereals used in this study were broken rice grains (BRG) provided by the Crystal Sugar Enterprise (Empresa Arroz Cristal), located in Aparecida de Goiânia, Goiás State, Brazil; passion fruit peel flour (PFPF) of the brand Natural Life, located in São José do Rio Preto, São Paulo State, Brazil, obtained in the local market of Rio Verde, Goiás State, Brazil; and whey powder (WP), provided by the Italac Dairy Industry (Indústria de Laticínios Italac), located in Santa Helena de Goiás, Goiás State, Brazil.

Physical and chemical characterization of the co-products The grain size of the raw materials (BRG, PFPF and WP) was determined by the Association of Official and Agricultural Chemistry method (AOAC, 2000), modifying the series of sieves. Regarding the chemical characterization, the levels of moisture, ashes, proteins and lipids were determined using the methods recommended by the AOAC (1990). The soluble, insoluble and total fiber contents were determined by the AOAC enzymatic-gravimetric method (AOAC, 2000). The analyses of moisture, ashes, lipids and protein in the WP were performed according to Brasil (2006). The digestible carbohydrate content was calculated by the difference between 100 and the sum of the percentages of moisture, ash, protein and lipid contents.

Breakfast cereal formulation and processing The tested breakfast cereal formulations are presented in Table 1. The BRG, PFPF and WP contents used and the extrusion variables were determined in preliminary tests.

| Treatment | C1 | C2 | C3 | C4 |

|---|---|---|---|---|

| BRG (g.100g−1) | 100 | 97 | 87 | 90 |

| PFPF (g.100g−1) | 0 | 3 | 3 | 0 |

| WP (g.100g−1) | 0 | 0 | 10 | 10 |

The formulations with the different combinations of raw materials were conditioned to 13 g of moisture per 100 g of sample by manual spraying with distilled water and homogenization of the mixtures in a type Y mixer (Tecnal, TE 201/05, Piracicaba, Brazil) for 5 min. The calculation of the water content to add to the samples considered the amount of mixture to be extruded and its initial moisture (Equation 1). The conditioned material was packaged in low-density polyethylene (LDPE) bags and kept at 4°C for 24 h to homogenize the mixture's moisture before being processed.

|

Where: Qw= quantity of water to be added (mL); Hf= desired final moisture (g 100 g−1); Hi= sample initial moisture (g 100 g−1); Ms= sample mass (g).

The experimental breakfast cereals were processed in equipment with a simple screw (Inbramaq, PQ-30, Ribeirão PretoSP, Brazil) using the following fixed process parameters: motor rotation of 177 r.p.m.; circular matrix opening of 3.85 mm in diameter; pre-matrix with 22 orifices; screw with three 30-cm-long entrances and screw compression rate of 3:1; helical jacket with (335 g min−1) feed rate; and temperatures in the first, second and third heating zones of 40, 60 and 80°C, respectively. After extrusion, the breakfast cereals were dried in an oven with circulating air at 80°C for 1 h. The dry product was kept at 25°C in flexible LDPE packaging until the moment of analysis. The physical, chemical and functional properties of four experimental breakfast cereals were evaluated.

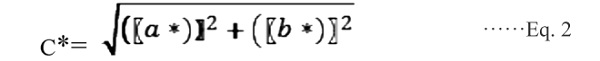

Physical, chemical and functional properties of the breakfast cereals The instrumental color parameters of the products were evaluated using a Color Quest II (HunterLab, Reston, VA, USA) colorimeter and based on the CIEL*C*h systems (a polar representation of the L*a*b* system). In the CIEL*a*b system, L* indicates luminosity, which ranges from zero (black) to 100 (white); a* and b* represent the chromatic coordinates, where +a* indicates the tendency toward red, and −a* toward green, +b* toward yellow, and −b* toward blue. In the L*C*h system, the chroma (C*) and hue angle (h) were determined using Equations 2 and 3, respectively.

|

|

The levels of moisture, ashes, proteins and lipids in the experimental breakfast cereals were determined according to the recommended methods of the AOAC (1990). The total, soluble and insoluble dietary fiber contents were determined according to the methods 985.29 and 991.43 of AOAC (2000), with each test conducted in triplicate. The carbohydrate content was found by the calculation of the difference. The expansion index (EI) of the experimental breakfast cereals was calculated based on the ratio between the sample diameter and the matrix diameter. The considered value was obtained as the arithmetic mean of 20 replicate measurements for each repetition. The water absorption index (WAI) and the water solubility index (WSI) were determined according to the methodology of Anderson et al. (1969) in triplicate. An instrumental texture analysis was performed in the dry extruded samples. The ultimate rupture strength (or hardness) was determined using the TA-XT2 (Stable Micro Systems, Surrey, England) texturometer with a 5 kg load cell, equipped with Texture Expert® software for data analysis. The 2 cm long samples were uniaxially cut using a probe with a guillotine-type straight blade using the methodology described by Chang et al. (2001). The following conditions were employed: pre-test velocity: 2.0 mm s−1, test velocity: 2 mm s−1, after-test velocity: 5 mm s−1, probe calibration distance: 5 mm, force threshold: 5 g, and measurement under shear stress. The analyses were performed in 20 replicates.

Statistical analysis The obtained data underwent an analysis of variance (ANOVA), and the means were compared using Tukey's test considering 5% probability using the Assistat (2013) version 7.6 program.

Grain size and proximate composition of the raw materials All of the WP particles were smaller than 0.297 mm, with almost four fifths of the sample composed of fine grains (<0.147 mm). The largest grain sizes were found in the BRG, with almost all of its particles being larger than 0.841 mm, considering that this raw material was not ground before the extrusion step to facilitate the gravity-fed equipment (Coutinho, 2013). The PFPF was composed of intermediate-size particles between 0.297 and 0.595 mm. Particle-size irregularity negatively influences the physical properties of the product, such as hardness and expansion of extruded products (Mohamed, 1990). In turn, homogeneity promotes adequate and uniform cooking of the raw material during the extrusion process, avoiding hardness and partial cooking. Such problems cause undesirable particles to appear with different cooking degrees, compromising the quality of the extruded product's appearance and palatability (Borges, 2003). The grain-size irregularity of the raw materials in this study may have influenced the expansion, texture and appearance of the obtained breakfast cereals.

The proximate composition of WP (Table 2) was similar to the values reported in the technical specification sheet from the dairy industry that provided the product, which established the following factors as standard: maximum of 3 g 100 g−1 for moisture, 8.5 g 100 g−1 for ashes, minimum of 11.0 g 100 g−1 for proteins and maximum of 1.5 g 100 g−1 for lipids.

| Component | WP | VC | BRG | VC | PFPF | VC |

|---|---|---|---|---|---|---|

| Moisture | 3.96 ± 0.02 | 0.66 | 10.52 ± 0.06 | 0.57 | 5.73 | 0.10 |

| Ashes | 7.27 ± 0.02 | 0.36 | 0.58 ± 0.006 | 1.07 | 6.62 ± 0.02 | 0.41 |

| Protein | 13.50 ± 0.008 | 0.06 | 8.96 ± 0.02 | 0.27 | 8.93 ± 0.006 | 0.07 |

| Lipids | 1.38 ± 0.02 | 1.44 | 0.76 ± 0.01 | 1.31 | 1.45 ± 0.01 | 1.05 |

| TDF | - | - | 3.85 ± 0.01 | 0.29 | 53.94 ± 0.03 | 0.05 |

| SDF | - | - | 2.95 ± 0.02 | 0.67 | 14.87 ± 0.01 | 0.10 |

| IDF | - | - | 0.9 ± 0.05 | 6.66 | 39.06 ± 0.03 | 0.07 |

| Carbohydrates* | 73.89 | - | 79.18 | - | 77.27 | - |

The BRGs presented moisture levels lower than the recommended value of Ordinance ndegrees 269 (Brasil, 1988), which determines a maximum moisture of 14 g 100 g−1 for grain fragments. Mendonça (2005), Silva et al. (2007), Limberger et al. (2009) and Carvalho et al. (2012) reported moisture values ranging from 10.87 to 12.44 g 100 g−1 for broken rice flour. The rice moisture is particularly influenced by the drying, conditioning and storing process of the grains, and this moisture is an important factor for preserving food quality (Silva, 2007).

The ash and insoluble dietary fiber contents (IDF) of the BRG were 94 and 14.3% higher, respectively, than those reported by Walter, Marchezan and Ávila (2008) for rice flour. In turn, the protein content was similar, and the total dietary fiber (TDF) and soluble dietary fiber (SDF) contents were 2.5 and 38.3% lower, respectively. The ash content of the BRG was 142% higher than the value found by Carvalho et al. (2012) for rice flour, whereas the lipid content was similar, and the protein content was 13.3% lower. In this study, the value found for lipids was similar to those found by Walter, Marchezan and Ávila (2008) and Carvalho et al. (2012), who also reported values lower than 1 g 100 g−1. The protein content in rice is considered low, with an average of 7 g 100 g−1. However, great variation in protein concentration was observed, with contents between 4.3 and 18.2 g 100 g−1 (Lumen, 1995).

The moisture, ash, protein and lipid contents in the PFPF were 6, 19, 24% and 8.5% lower, respectively, than those verified by Souza, Ferreira and Vieira (2008), while the ash, proteins and lipids contents were 7.3, 14 and 58.6% higher, respectively, than the values found by Vernaza, Chang and Steel.6 Regarding the PFPF dietary fiber, the observed values were 15.9 and 22.1% lower than those obtained by Vernaza, Chang and Steel (2009), for total and insoluble dietary fiber, respectively, while the soluble dietary fiber content was 6.5% higher. This pattern confirms that PFPF is a food rich in fiber, which suggests its use as flour to increase fiber ingestion.

The high fiber content indicated that PFPF could be included in the diet as a food rich in fiber according to the rules established by the Brazilian legislation (Brasil, 1998). Dietary fiber is composed of an insoluble and a soluble part. The insoluble fraction is related to the increase in fecal matter, therefore ensuring intestinal peristalsis, avoiding constipation and eliminating the risks of hemorrhoids and diverticulitis. The soluble fraction, in turn, has proven beneficial effects on insulin metabolism and cholesterol levels. The SDF can also be consumed by diabetics. Because the fiber is not water soluble, it exerts a hyperglycemic effect by delaying gastric emptying, therefore reducing intestinal transit and glucose absorption (Corrêa, 2002).

Instrumental color parameters The extruded breakfast cereals presented variations of 28.8% for the luminosity values (L*), 506.9% for chroma a*, 446.5% for chroma b*, 454% for C* and 5.7% for the hue angle (hab) (Table 3). All the instrumental parameters were different from each other except for C1 and C2 in regard to L*. C4 obtained the highest L* value (lightest) and the lowest a*, b* and C* values (the least red and yellow, the most neutral), followed by C1. C3 presented the lowest L* (darkest) and the highest a*, b* and C* values (most red and yellow), followed by C2.

| Component | Experimental breakfast cereals (treatment) | ||||

|---|---|---|---|---|---|

| C1 | C2 | C3 | C4 | VC | |

| L* | 77.74 ± 1.10b | 77.70 ± 1.13b | 74.59 ± 0.20c | 95.95 ± 0.19a | 0.99 |

| a* | 2.86 ± 0.10c | 4.37 ± 0.11b | 7.04 ± 0.25a | 1.16 ± 0.02d | 3.89 |

| b* | 12.59 ± 0.40c | 14.72 ± 0.39b | 18.84 ± 0.86a | 3.44 ± 0.03d | 4.18 |

| C* | 12.91 ± 0.41c | 15.35 ± 0.39b | 20.11 ± 0.90a | 3.62 ± 0.04d | 4.11 |

| hab | 77.16 ± 0.17a | 73.43 ± 0.50b | 69.48 ± 0.19d | 71.36 ± 0.22c | 0.42 |

The color parameters of C3 were close to those reported by Matsuura (2005), for cereal bars containing meal from untreated passion fruit albedo. C4 was the breakfast cereal with the lightest color, most likely because it did not contain PFPF (darkest) and did contain WP. The white color of milk is caused by the dispersion of light reflected by fat globules and by casein and calcium phosphate colloidal particles (Fennema, 1993). WP does not contain the same amounts of such components as milk does; nevertheless, WP still provides this characteristic to its derivatives, such as C4. The hue angle hab, expressed in degrees, defines the coloration of products. In this study, 0 degrees is equal to +a*, i.e., red, and 90 degrees is equal to +b*, i.e., yellow. Overall, all the breakfast materials presented a mostly yellow tonality because the hab range values reported were from 69 to 77°.

Proximate composition of the breakfast cereals In the present study, significant variations were observed for the moisture, ashes, lipids, TDF, SDF and IDF contents in the breakfast cereals, reaching variations of 157.4, 163.8, 3 900%, 200, 40.8 and 1 604%, respectively (Table 4). All the breakfast cereals differed in their proximate compositions, with the exception of the protein content, which did not differ among the treatments. The ash content of C3 and C4 also did not differ C3 presented the highest moisture, followed by C4, C1 and C2. All of the breakfast cereals remained within the legal specifications regarding the moisture (Taco, 2011). When present in the formulation, WP increased the moisture of the product after extrusion, most likely because lactose is able to retain water in the product as a result of its hygroscopicity. The ash content was highest in C3 and C4, lowest in C1 and intermediate in C2. The ash content was higher in the experimental breakfast cereals with more WP and PFPF because these raw materials contain high ash contents (Table 2).

| Component | Experimental breakfast cereals (treatment) | ||||

|---|---|---|---|---|---|

| C1 | C2 | C3 | C4 | VC (%) | |

| Moisture | 2.55 ± 0.35c | 2.02 ± 0.44d | 5.20 ± 0.57a | 4.35 ± 0.05b | 11.43 |

| Ashes | 0.47 ± 0.06c | 0.60 ± 0.11b | 1.24 ± 0.07a | 1.23 ± 0.07a | 9.61 |

| Protein | 9.33 ± 0.40a | 9.06 ± 0.43a | 9.27 ± 0.46a | 9.45 ± 0.41a | 4.64 |

| Lipids | 0.01 ± 0.00d | 0.20 ± 0.00b | 0.21 ± 0.00a | 0.19 ± 0.00c | 1.98 |

| Total Fiber | 2.85 ± 0.01c | 6.75 ± 0.01a | 6.15 ± 0.01b | 2.25 ± 0.01d | 0.32 |

| Soluble Fiber | 2.04 ± 0.01c | 2.83 ± 0.01a | 2.25 ± 0.01b | 2.01 ± 0.01d | 0.67 |

| Insoluble Fiber | 0.80 ± 0.01c | 3.92 ± 0.01a | 3.9 ± 0.01b | 0.23 ± 0.01d | 0.60 |

| Carbohydrates | 87.64 | 88.12 | 84.08 | 84.78 | |

The protein content obtained in the experimental breakfast cereals ranged between 9.06 and 9.45 g 100 g−1. Fortification of extruded food formulations with proteins from selected sources can improve consumer's health and promote the quality of snacks and breakfast cereals (Day, 2013). Silva et al. (2011) studied extruded manioc breakfast cereals enriched with whey protein concentrate and found average protein values of 8.38 g 100 g−1, which is lower than the values determined for the breakfast cereals in the present study. The lipid contents of the breakfast cereals were low, demonstrating the low energetic macronutrient content, which is an important selection factor for a consumer worried about his/her health and who prefers products with low lipids content to prevent obesity and chronic diseases, such as diabetes and cardiovascular diseases. Compared to the values found by Silva et al. (2011) in breakfast cereals made of manioc starch and whey powder (0.7574 g 100 g−1), the lipid contents of the breakfast cereals from the present study were lower. Souza, Ferreira and Vieira (2008) reported values from 12.37 to 12.74 g 100 g−1 in a sweet extruded breakfast cereal from Brazil nut with manioc, which is well above the values verified in the present study.

Fibers belong to the group of biologically active compounds, and fiber consumption is of fundamental importance for human health. The total dietary fiber contents of some breakfast cereals were reported by Menezes et al. (2001): “All Bran” breakfast cereal: 21.53%; oatmeal, almonds and honey breakfast cereal: 4.90%; “Corn Flakes” corn breakfast cereal: 3.57%; corn, wheat and oatmeal breakfast cereal: 2.15%. The total dietary fiber content of the breakfast cereals in this study ranged from 2.25 to 6.75 g 100 g−1, close to that of commercial breakfast cereals in the market, with the exception of “All Bran”, which is already labeled and commercialized as a product essentially made of fiber.

Therefore, the fiber contents observed in C1 and C4 are close to those of foods considered sources of fiber (>3 g 100 g−1), and C2 and C4 can be considered rich in fiber (>6 g 100 g−1) according to the Ministry of Health (Brasil, 1998). However, the incorporation of fiber in breakfast cereals may lead to texture issues, thus decreasing their acceptance by consumers. This change is partially caused by microstructural deterioration, one of the primary quality attributes of extruded breakfast cereals (Chassagne-Berces et al., 2011).

The carbohydrate content of the experimental breakfast cereals ranged between 84.08 and 88.12 g 100 g−1. Vernaza et al. (2009) found carbohydrate values of 85.37 g 100 g−1 when evaluating the effects of the inclusion of passion fruit meal on technological properties in the development of organic and functional corn-flour-based breakfast cereal. Silva et al. (2011) found carbohydrate values of 84.21 g 100 g−1 in whey protein-enriched manioc breakfast cereals. The values obtained by these authors are close to the estimations in the present study for the treatments of C3 and C4, respectively.

The quality of an extruded product depends on the raw materials used in its formulation, such as particle size, moisture, temperature, pressure, shear and specific mechanical energy employed during the processing, as well as the equipment variables (mechanical profile, rotation speed and screw configuration, type and dimensions of the exit orifice). Whey and wheat protein fortification resulted in acceptable extrusion of snacks and breakfast cereals (Day, 2013). The same acceptance was verified in the present study with the whey powder, rice and passion fruit peel.

Functional properties of the breakfast cereals All of the breakfast cereals were significantly different in relation to the EI but similar in regard to the WAI and the WSI, with the exception of C4 for the WAI and C3 for the WSI, which presented values lower than the others (Table 5). For hardness, the lowest values were verified in C2 and C4, which did not differ from each other; the highest value was obtained with C3, and C2 had an intermediary value.

| Component | Experimental breakfast cereals (treatment) | ||||

|---|---|---|---|---|---|

| C1 | C2 | C3 | C4 | VC | |

| EI | 4.46 ± 0.48a | 3.97 ± 0.36b | 2.53 ± 0.19d | 2.80 ± 0.19c | 9.62 |

| WAI1 | 9.53 ± 0.74a | 9.20 ± 0.96a | 9.30 ± 1.10a | 7.83 ± 0.42b | 9.42 |

| WSI2 | 5.11 ± 1.00a | 4.87 ± 1.19a | 3.62 ± 0.45b | 5.94 ± 0.74a | 18.24 |

| Hardness3 | 566.28 ± 135b | 342.37 ± 113bc | 841.77 ± 348a | 318.43 ± 68c | 38.35 |

The EI of the experimental breakfast cereals varied by 78.4% because of their formulations, as the extrusion conditions were kept constant. C3 presented the lowest EI. The addition of fibers in the formulation of extruded products considerably decreases expansion (Huber, 2001). The largest particles, such as fibers, tend to break the cell walls of the extruded product, causing an EI reduction (Riaz, 2002), as was the case of the PFPF fibers in the present study (Table 3).

Non-amylaceous polysaccharides (such as fiber) are bonded more strongly to water during extrusion than proteins and starch. This bond inhibits the water loss in the matrix, i.e., in the extruder outlet, thus reducing expansion. Furthermore, the present starch cannot be completely gelatinized in the presence of fibers and therefore is no longer capable of supporting expansion (Camire, 1991). Trombini, Leonel and Mischan (2013), studying the physical, rheological and sensorial characteristics of extruded products with passion fruit flour (10 g 100 g−1) and manioc starch (90 g 100 g−1) mixtures, found EI values of 2.53 and 3.51, which are similar to the values observed for the experimental breakfast cereals in the present study, which were formulated with 3 g 100 g−1 of PFPF (C2 and C3). Nevertheless, Leoro (2007) found values ranging from 1.02 to 4.11 for an organic and extruded breakfast cereal made of corn flour and passion fruit meal.

The EI lowered with higher contents of fine particles in the sample, as verified in the experimental breakfast cereals produced with the WP (Table 4). This tendency was also observed by Onwulata et al. (2001), who observed that corn-based expanded and extruded products (using both high and low shear stresses during extrusion) showed smaller expansions with increased WP content. Silva et al. (2011) obtained the value of 11.49 for the expansion index of whey protein-enriched extruded manioc starch, which differed from the present study, where the values of C3 and C4 were approximately four times smaller.

The structure of expanded products depends on the starch content, the gelatinization degree of starch and its fusion inside the extruder (Ferreira, 2006). In this study, C1 presented the highest EI due to its higher starch content because BRG contained the greatest amount of carbohydrates (Table 2), which are basically composed of starch. The EI is a primary quality indicator of extruded products, associated with crunchiness, hardness and chewing. Generally, the product expansion is directly related to texture, and products with greater expansion are crunchier (Mercier, 1998). Hence, the breakfast cereals that presented the lowest EI (C3 and C4) should be processed under extrusion conditions other than those used in the present study (such as altered extrusion temperature, moisture and screw speed, among others) and best adjusted to the cereal's chemical composition because these experimental breakfast cereals contained less starch and more minerals and carbohydrates (basically composed of lactose) (Table 5). Sugars, in addition to providing sweetness, are involved in many chemical reactions during extrusion (Singh, 2007) and are able to affect properties such as specific volume, texture and color by changing the expansion of the extruded product or through interactions with protein and/or with starch (Nabeshima, 1995). The substitution of part of the starch with sugar in the formulation reduces the vitreous transition temperature, decreasing the formulation's molten mass viscosity. The radial reduction of expansion and the density increase with the addition of sugar may be interpreted as a combination of a reduction in the growth of air bubbles (responsible for the extruded mass expansion) and an increase in shrinkage at the matrix exit (Fan, 1996).

The mean WAI values varied by 21.7%. C4 presented the smallest result, most likely because of reactions between starch, proteins and sugar (lactose from the WP), forming less-soluble complexes. The PFPF fibers made this reaction more difficult, and such tendency of the WAI was not observed in C3. The WAI is related to the availability of hydrophilic groups (-OH) to bond with water molecules, promoting gel formation. The WSI, in turn, is a parameter that evaluates the degradation of starch grains (Carvalho, 2002). The WAI values found in the present study were within the range reported by Schmiele (2009), of 6.49 – 9.44 g gel g−1 dry matter in expanded extruded products using corn flour with different grain sizes. Silva et al. (2011) found an average WAI of 5.8 g gel g−1 dry matter in cinnamon-flavored manioc-based extruded breakfast cereals, a value lower than those obtained in the present study. Breakfast cereals are generally consumed with milk, and during their immersion in this liquid, cereals suffer hydration and undesirable changes in their textures because of water absorption. Therefore, lower WAI values are more convenient for this type of product to maintain crunchiness after its preparation and before consumption.

The result obtained for the WSI was lowest in C3 because of the addition of PFPF, which is rich in fiber. Fibers are water-insoluble substances, and WSI is related to the amount of soluble molecules as a result of dextrinization, i.e., this factor measures the degree of damage to the starch. The WSI values were higher than those determined by Ferreira (2006) of 2.7% and by Alvim et al. (2002) of 2.2%.

Texture is an important factor for the product acceptance, given that it is one of the most important parameters of quality for extruded products. The mean texture values varied by 165% between the lowest and the highest determined value. The variation coefficient was high (38.35%), most likely because of the extruded material heterogeneity. A material with an irregular surface and porous structure, when analyzed with the guillotine-type probe, may have cut areas of the product containing bubbles or of the continuous matrix, promoting different readings. C3 presented the greatest hardness, most likely because of the formation of complexes between the starch, proteins, sugars and fibers. Molecular interactions between proteins, starch, lipids, sugars, fibers and water during the fusion of components inside the extruder cannon are the basis for the appearance of the extruded product as well as for its physical, textural and sensorial properties. The covalent bonds of disulfide and sulfhydryl, in addition to electrostatic and hydrogen bonds and the hydrophobic affinity developed between the molecules during extrusion, will determine the sensorial quality, digestibility and availability of nutrients in the extruded product (Day, 2013).

The combinations between the agro-industrial co-products WP, PFPF and BRG affected the physical, chemical and technological characteristics of the breakfast cereals studied. The breakfast cereals containing PFPF were richer in TDF, SDF and IDF, but the cereal expansion was smaller, and the color was darker. The breakfast cereals with WP were sweeter (because of the high sugar content of this co-product), lighter and softer (with the absence of PFPF), although they had little expansion. WP use is therefore recommended in sweet breakfast cereals because the use of WP can be accompanied by decreased use of sweeteners. New studies, with alterations of the extrusion conditions for each formulation, may help to improve some undesirable technological characteristics, such as low expansion and excessive hardness, caused by the addition of fiber and/or sugars to the formulations of breakfast cereals with rice starch as a major component.

Acknowledgements The authors thank the Goiás Research Foundation (Fundação de Amparo à Pesquisa do Estado de Goiás — FAPEG) and the Coordination for the Improvement of Higher Education Personnel (Coordenação de Aperfeiçoamento de Pessoal do Nível Superior — Capes)for the Post-Doctorate program fellowship and the Italac and Arroz Cristal enterprises for the donation of raw materials.