2015 Volume 21 Issue 5 Pages 733-738

2015 Volume 21 Issue 5 Pages 733-738

The rutin content of dough made with ‘Manten-Kirari’, a new Tartary buckwheat variety with trace-rutinosidase activity and minimal bitterness, was assessed in a time course study of rutin hydrolysis in doughs with various water contents and blending ratios of Tartary buckwheat flour. In the normal rutinosidase variety, ‘Hokkai T8’, the majority of rutin was hydrolyzed within 30 min of water addition, whereas about 90% of rutin remained in ‘Manten-Kirari’. We also investigated the residual rutin ratio in white bread, butter enriched roll, pound cake and galette. With ‘Hokkai T8’, rutin was hydrolyzed almost completely in all foods tested, whereas 88.5%, 49.8%, 31.0% and 26.2% of rutin remained in ‘Manten-Kirari’-containing pound cake, white bread, butter enriched roll and galette, respectively. Also, ‘Hokkai T8’ bread exhibited strong bitterness, whereas ‘Manten-Kirari’ foods showed minimal bitterness. These results indicate that ‘Manten-Kirari’ is a promising material for the production of rutin-rich food products without bitterness.

The flavonoid rutin is widely distributed throughout the plant kingdom (Sando et al., 1924; Couch et al., 1946; Haley et al., 1954; Fabjan et al., 2003). Notably, buckwheat is the only cereal known to contain rutin in its seeds. Rutin has a number of bioactive properties, such as strengthening of blood capillaries (Griffith et al., 1944; Shanno, 1946), and antioxidative (Jiang et al., 2007; Awatsuhara et al., 2010), antihypertensive (Matsubara et al., 1985) and alpha-glucosidase inhibitory effects (Li et al., 2009). For these reasons, buckwheat has been identified as a potential rutin-rich material for use in food products (Kreft et al., 2006; Ikeda et al., 2012).

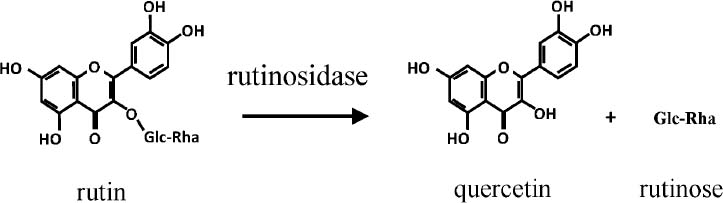

Among buckwheat species, Tartary buckwheat (Fagopyrum tataricum Gaertn.) contains approximately 100-fold higher levels of rutin in seeds than that found in common buckwheat. However, Tartary buckwheat seeds also display rutinosidase activity (Fig. 1), which is sufficiently high to hydrolyze the rutin present in buckwheat flour (approximately 1% − 2% [w/w]) within a few minutes after the addition of water (Yasuda et al., 1992; Yasuda et al., 1994; Suzuki et al., 2002). Tartary buckwheat rutinosidase activity is attributable to at least two isozymes that possess similar characteristics (Yasuda et al., 1992, Yasuda et al., 1994, Suzuki et al., 2002, Suzuki et al., 2004). The investigation of rutin hydrolysis in foods such as bread and confectionaries has revealed that the majority of rutin contained in these foods is hydrolyzed as a result of rutinosidase activity (Brunori et al., 2010; Vogrincic et al., 2010; Brunori et al., 2013). In addition to possessing rutinosidase activity, the flour of Tartary buckwheat, also known as ‘bitter buckwheat’, is highly bitter, thereby limiting its potential use in food products. At least three bitter compounds have been reported in Tartary buckwheat dough (Kawakami, et al., 1995), and the mechanisms responsible for generating these bitter compounds remain unresolved. In this context, the development of a Tartary buckwheat variety with low rutinosidase activity has been highly anticipated for the production of rutin-rich foods with low bitterness.

Scheme of rutinosidase activity in Tartary buckwheat seeds

Recently, our research group identified a trace-rutinosidase individual of Tartary buckwheat lacking bitterness (Suzuki et al., 2014a) and developed a variety named ‘Manten-Kirari’ (Suzuki et al., 2014b). The rutinosidase activity of ‘Manten-Kirari’ flour is about two to three orders of magnitude lower than that of common buckwheat varieties, such as ‘Hokkai T8’. Moreover, ‘Manten-Kirari’ flour is not bitter. To obtain basic information enabling the usage of ‘Manten-Kirari’, we conducted a time course analysis of rutin hydrolysis in doughs with different blending ratios of Tartary buckwheat and water. In addition, we evaluated rutin-rich breads produced using this novel variety of buckwheat.

Materials Tartary buckwheat varieties ‘Manten-Kirari’ (trace-rutinosidase variety) and ‘Hokkai T8’ (normal rutinosidase variety) were grown in the experimental field of the National Agricultural and Food Research Organization in Memuro, Hokkaido, Japan (longitude, 143°03E; latitude, 42°53N). Seeds were sown on June 6th, 2012 and harvested in late August of the same year. Harvested seeds were dried at 40°C for one week and then threshed and stored at 4°C until used for milling. Tartary buckwheat seeds were milled using a test mill (Quadrumat Junior; Brabender GmbH & Co., Duisburg, Germany) at a flour milling percentage of 63%. Tartary buckwheat flour was stored at −20°C until used for experiments. Commercially available wheat flour was also used for blending with Tartary buckwheat flour in the preparation of dough.

Time course analysis of rutin hydrolysis in doughs with various blending ratios of Tartary buckwheat and water Tartary buckwheat flour was mixed with wheat flour at final ratios [w/w] of 10%, 30% and 60% for both ‘Manten-Kirari’ and ‘Hokkai T8’. Portions of the flour mixture (150 mg) were placed in test tubes and then incubated at 25°C for 3 h. Water incubated at the same temperature and duration was added to each tube at volumes of 165, 300, 500 and 1,500 µL to make dough with a final water content of 33%, 60%, 100% and 300%, respectively. After water addition, the flour and water were immediately mixed using a spatula for 1 min to obtain a uniform dough, which was then placed in a 25°C incubator for 30, 60, 120, 240 and 480 min. Next, 9 mL of methanol containing a 20% volume of 0.1% (v/v) phosphoric acid was added to the dough samples for the extraction of flavonoids during a 3-h incubation at 80°C. After the extraction, the centrifuged supernatant was analyzed using HPLC (Suzuki et al., 2002) to determine the rutin and quercetin contents in the dough samples.

Preparation and evaluation of bread and food products containing Manten-Kirari To investigate the amount of rutin in ‘Manten-Kirari’-containing foods compared to foods prepared using ‘Hokkai T8’, a representative normal rutinosidase variety, we prepared white bread, butter-enriched rolls, pound cake and galette using these two varieties. All food products were prepared at the National Agricultural and Food Research Organization in Memuro, Hokkaido, Japan. Prior to the start of experiments, the blending ratio of Tartary buckwheat flour in that was considered to produce palatable food was evaluated. In the present study, blending ratios of Tartary buckwheat to total flour of 10%, 25% and 50% were used for white bread, butter-enriched rolls, pound cake and galette (corresponding to 8.7%, 7.3%, 6.5% and 9.9% [w/w] of the final dough, respectively).

Breads The bread making tests were performed using the no-time method (Yamauchi, et al., 2004). For the preparation of white bread, the dough contained 90 g wheat flour, 10 g Tartary buckwheat flour (control bread contained 100 g wheat flour), 5.0 g sugar, 5.0 g shortening, 5.0 g salt, 2.0 g yeast, 100 ppm ascorbic acid and a suitable quantity of water. For butter-enriched rolls, 12 g sugar, 15 g butter, 3.0 g powdered nonfat milk, 1.8 g salt, 3.0 g yeast, 10 g whole raw egg, 100 ppm ascorbic acid and a suitable quantity of water were used. The optimal water absorption for the white bread and butter-enriched rolls was estimated using a Farinograph at 500 BU. The dough was mixed for an optimal time to just beyond peak development, which represents the peak of the current curve of the mixing motor. The dough was rounded and allowed to rest for 20 min in a fermentation cabinet at 30°C. The dough was panned and proofed at 38°C with 85% humidity for 70 min, and was then baked at 200°C for 25 min for white bread and 13 min for butter-enriched rolls. For both types of bread, baking was completed within 120 min after water addition. Breads were stored in polyethylene bags at 20°C for one day. The specific volume of bread was measured by the rapeseed displacement method (Yamauchi et al., 1999).

The lack of bitterness in ‘Manten-Kirari’ flour is a desirable trait. We predicted that ‘Manten-Kirari’-containing foods would be palatable and lack the bitterness found in foods prepared with common-rutinosidase varieties, such as ‘Hokkai T8’. Therefore, sensory analysis of the prepared white bread and butter-enriched rolls was performed by 11 expert panelists (five males and six females), who evaluated the texture, flavor and bitterness of the samples. Bread texture and flavor were evaluated according to the following four grades: 0, ‘Poor’; 1, ‘Somewhat poor’; 2, ‘Somewhat good’; 3, ‘Good’. In addition, bitterness was evaluated according to the following four grades: 0, ‘Extremely bitter’; 1, ‘Bitter’; 2, ‘Somewhat bitter’, and 3, ‘Not bitter’.

Pound cake and galette Pound cake batter contained 75 g wheat flour, 25 g Tartary buckwheat flour (control batter contained 100 g wheat flour), 80 g sugar, 5.0 g baking powder, 100 g butter, and 100 g whole raw egg. The batter was panned and baked at 170°C for 40 min. Galette dough contained 50 g wheat flour, 50 g Tartary buckwheat flour (control bread contained 100 g wheat flour), 1.0 g salt and 400 mL water. The dough was baked at 180°C for 7 min. For both pound cake and galette, baking was performed within 30 min of the addition of water.

Analysis of rutin and quercetin contents in ‘Manten-Kirari’-containing food products Each food product was lyophilized and milled to a fine powder using mortar and pestle. Rutin and quercetin were extracted with 10 mL of methanol containing a 20% volume of 0.1% (v/v) phosphoric acid per 0.1 g sample at 80°C for 3 h. After the extraction, the centrifuged supernatant was analyzed using HPLC (Suzuki et al., 2002), and rutin and quercetin contents were determined.

Time-course analysis of rutin hydrolysis in doughs prepared with various blending ratios of Tartary buckwheat flour and water contents The residual rutin ratio of ‘Hokkai T8’ (normal rutinosidase variety) flour decreased rapidly immediately after the addition of water (Figure 2 A, C, E). At 30 min after water addition, the residual rutin ratio was only approximately 10% – 15% in samples with a 33% water to flour ratio and 10% or 30% blending ratio of Tartary buckwheat flour (Figure 2 A, C). In other samples, the residual rutin ratio approached zero. This result is consistent with a previous report (Brunori et al., 2013). In contrast, the residual rutin ratio of ‘Manten-Kirari’ flour decreased slowly with increasing water to flour ratio compared to ‘Hokkai T8’ flour. It is notable that more than 50% of rutin remained in samples with a water to flour ratio of < 60% at all blending ratios of Tartary buckwheat flour (Figure 2B, D, F). The residual rutin ratio was related to the water to flour ratio; samples with a 33% water to flour ratio showed a higher residual rutin ratio compared to those prepared with 60%, 100% and 400% water to flour ratios. This finding indicates that a lower water content can markedly reduce rutin hydrolysis during food processing. The residual rutin ratio did not differ at the water to flour ratios of 100% and 400%. This result indicates that a water to flour ratio of 100% is sufficient for rutinosidase to hydrolyze rutin. The blending ratio of Tartary buckwheat flour, with the exception of the water to flour ratio of 33%, was not associated with the residual rutin ratio. Taken together, these results indicate that selecting the appropriate conditions, particularly the water to flour ratio and blending ratio of Tartary buckwheat flour, are important for the successful production of rutin-rich foods using ‘Manten-Kirari’ flour.

Effects of blending ratio of Tartary buckwheat flour and ratio of water to flour on rutin hydrolysis.

Blending ratio of Tartary buckwheat flour to total flour: A, 10%; B, 30%; and C, 60%. Data are means of two independent experiments.

Residual rutin ratio in ‘Manten-Kirari’ food products In ‘Hokkai T8’-containing foods, rutin was completely hydrolyzed. It was reported that the rutin content in bread containing Tartary buckwheat flour rapidly decreased during the dough making process, and the final residual rutin ratio was only several percent (Vogrincic et al., 2010). This finding is consistent with the results for ‘Hokkai T8’ in the present study. In contrast, ‘Manten-Kirari’-containing foods retained a large proportion of the original rutin content (Table 1). Therefore, ‘Manten-Kirari’ is a promising material for the production of rutin-rich food products.

| Variety | Blending ratio of Tartary buckwheat flour | Ratio of water to flour | Rutin | Quercetin | Residual rutin ratio | |

|---|---|---|---|---|---|---|

| % | % | mg/100g | mg/100g | % | ||

| White bread | Manten-Kirari | 8.7 | 70.0 | 63.4 | 31.6 | 49.8 |

| Hokkai T8 | 8.7 | 70.0 | 0.00 | 55.3 | 0.00 | |

| (Control) | - | 70.0 | 0.00 | 0.00 | - | |

| Butter-enriched roll | Manten-Kirari | 7.3 | 60.8 | 60.8 | 66.7 | 31.0 |

| Hokkai T8 | 7.3 | 60.8 | 0.00 | 112 | 0.00 | |

| (Control) | - | 60.8 | 0.00 | 0.00 | - | |

| Pound cake | Manten-Kirari | 6.5 | 27.9 | 22.3 | 1.43 | 88.5 |

| Hokkai T8 | 6.5 | 27.9 | 5.03 | 19.5 | 11.3 | |

| (Control) | - | 27.9 | 0.00 | 0.00 | - | |

| Galette | Manten-Kirari | 9.9 | 400 | 33.1 | 45.1 | 26.6 |

| Hokkai T8 | 9.9 | 400 | 0.31 | 69.9 | 0.22 | |

| (Control) | - | 400 | 0.00 | 0.00 | - |

Data are means of two independent experiments

The residual rutin ratios in white bread, butter-enriched rolls, pound cake and galette were 49.8%, 31.0%, 88.5% and 26.6%, respectively. Among these foods, pound cake contained the highest residual rutin ratio, whereas galette had the lowest. In the time-course analysis of rutin hydrolysis, doughs with a high water content tended to hydrolyze rutin to a greater extent than those with low water content. Of the foods investigated, pound cake had the lowest water to flour ratio, whereas galette had the highest. Therefore, differences in the water to flour ratio may be associated with the observed differences in the residual rutin ratios between pound cake and galette.

It was also found that the duration from the time of water addition to baking influences rutin hydrolysis. Among the four food products assessed in this study, galette and pound cake were ready for baking in the shortest duration of time (about 30 min), whereas the white bread and butter-enriched rolls required a relatively long duration of time (about 120 min). In the time-course analysis of rutin hydrolysis in dough, approximately 60% of rutin remained in samples prepared with a 60% water to flour ratio and baked 120 min after the addition of water. In contrast, the residual rutin ratios of the white bread and butter-enriched rolls were 49.8% and 31.0%, respectively. The differences between these products with respect to residual rutin content may relate to the dough temperature. The time-course analyses were performed at 25°C, whereas the breads were proofed at 38°C. The optimum temperature of Tartary buckwheat rutinosidase is approximately 40°C (Suzuki et al., 2002). Therefore, rutinosidase enzyme in proofed dough would have higher activity than that in the dough of pound cake and galette. From these results, the optimal blending ratio of Tartary buckwheat for the preparation of rutin-rich bread was 7% – 8% at a 60% – 70% ratio of water to flour.

Qualitative evaluation of ‘Manten-Kirari’ food products The specific volumes of white bread and butter-enriched roll samples containing Tartary buckwheat were smaller than those of the control samples (Table 2); however, it was determined that these differences had a negligible impact on product quality. The texture of ‘Hokkai T8’ was not statistically different from that of ‘Manten-Kirari’. Therefore, rutin hydrolysis is likely not related to changes in dough texture. The flavor of ‘Hokkai T8’ was rated significantly worse than that of ‘Manten-Kirari’ and the control for white bread and butter-enriched rolls. It was speculated that the flavor evaluation scores were influenced by the perceived bitterness. Consistent with this speculation, the bitterness of white bread and butter-enriched roll prepared with ‘Hokkai T8’ flour was rated much stronger than that of foods prepared with ‘Manten-Kirari’ flour. Therefore, most panelists evaluated ‘Manten-Kirari’-containing breads as being more palatable than those containing ‘Hokkai T8’ flour. In addition, it was determined that 5,000 mg flour/kg was the no-effect dose in acute and subacute tests in experimental animals (Suzuki et al., 2015). Taken together, these results demonstrate that ‘Manten-Kirari’ is a suitable ingredient for the production of palatable breads with minimal bitterness.

| Variety | Specific volume | Texturea | Flavorb | Bitternessc | |

|---|---|---|---|---|---|

| ml/g | |||||

| White bread | Manten-Kirari | 5.5 | 2.1 ab | 1.5 a | 1.8 a |

| Hokkai T8 | 5.6 | 1.7 a | 0.2 b | 0.4 b | |

| (Control) | 5.9 | 2.5 b | 2.5 c | 2.7 a | |

| Butter-enriched roll | Manten-Kirari | 5.1 | 2.0 ab | 1.5 a | 1.9 a |

| Hokkai T8 | 5.0 | 1.7 a | 0.1 b | 0.2 b | |

| (Control) | 5.7 | 2.5 b | 2.5 c | 2.6 a |

a,b,c Data are means scores from 11 expert panelists (5 males and 6 females)

a,b 0; Poor, 1;Somewhat poor, 2; Somewhat good, 3; Good

c 0; Extremely bitter, 1;Bitter, 2; Somewhat bitter, 3; Not bitter

d Different letters indicate a significance level of 1% in the Mann-Whitney U-test

In this report, ‘Manten-Kirari’-containing foods retained higher rutin concentrations compared to those prepared with ‘Hokkai T8’ flour. However, foods requiring proofing or containing large volumes of water were characterized by relatively low residual rutin ratios. To increase the residual rutin ratio, the processing of ‘Manten-Kirari’ flour by short-duration heating or ammonium gas treatment (Asami et al., 2010) may be effective. To prevent rutin hydrolysis in previously characterized varieties of Tartary buckwheat, strong and long-duration heat treatment of the seeds or flour is required; however, such processing leads to the deterioration of texture (Yoo et al., 2012), color and flavor of the prepared foods, and is associated with higher production costs. However, for the variety ‘Manten-Kirari’, we anticipate that only short-duration heat treatment would completely inactivate rutinosidase without causing a deterioration of quality.

Recently, the clinical effects of rutin in a double-blind crossover study were investigated, and reductions in serum myeloperoxidase and cholesterol levels (Wieslander et al., 2011), mucosal symptoms, headache, and tiredness (Wieslander et al., 2012) were observed. The clinical effects of ‘Manten-Kirari’-containing foods will be investigated in a future study.

Acknowledgements We thank Dr. Mukasa and Dr. Yamauchi for providing useful advice on the planning of experiments. We also express our gratitude to Kobayashi-Shokuhin Co., Ltd. for help with the preparation of foods. We thank Mr. A. Morizumi, Mr. T. Hirao, Mr. S. Nakamura, Mr. K. Suzuki, Ms. K. Shimizu, Ms. K. Fujii, Ms. M. Hayashida, and Ms. T. Ando for providing technical assistance, and thank Mr. K. Abe, Mr. T. Fukaya for their assistance in the field and with the preparation of foods. This work was partly supported by a grant from the Research Project on Development of Agricultural Products and Foods with Health-promoting Benefits (NARO), Japan.