2016 Volume 22 Issue 2 Pages 159-172

2016 Volume 22 Issue 2 Pages 159-172

Roasting with superheated steam as the medium are used to obtain gelatinized rice for “green” Chinese wine brewing. The microstructure, pasting properties and starch crystal of rice are determined. That can learn the change in rice during the roasting process is considered the basis to optimize the operating parameters and enlarge the fluidized bed. It is found that the whole process can be divided into two stages, i.e., heating and puffing, with their demarcation point occurs at 20 seconds to 25 seconds after the rice is heated. Heating is a key stage of the processing that is characterized by rapid heat transfer and significant changes in the molecular structure of rice. The temperature of the rice starch needs to be controlled to prevent thermal decomposition and abiotic browning at puffing stage. Through numerical simulation analysis of rice temperature changes in the roasting process, it was found that the two stage strategy is the best mode of roasting process, and standard temperature control curve was put forward as rice temperature control reference during roasting. The comparison between air and superheated steam as two different media shows that the gelatinization effect of rice is practically the same given the same fluidized state, although superheated steam exhibits a slight advantage.

Obtaining a high gelatinization ratio of rice was a new application of roasting technology, which has been applied in Japanese sake and shochu production (Beizhao, 1997). Rice was heated by hot air in the fluidized bed, and then used in wine-brewing after complete gelatinization. In China, researchers have carried out some attempts to apply roasting to Chinese rice wine brewing (Zhu et al., 2004; Zhang et al., 2005; Peng et al., 2002; Mao et al., 2007). It was supposed that brewing using roasted rice could not only eliminate the problem of soak wastewater, but also add a new flavor to rice wine (Zhang et al., 2005; Peng et al., 2002).

During roasting, air was the most common heating medium, but would cause many problems, primarily the energy waste and environmental pollution caused by exhaust emission as well as the oxidation of materials. Superheated steam can be used as an alternative to air. Using superheated steam can condense and recover the residual heat, without polluting the environment. Since there was no oxygen in superheated steam, it would not oxide the materials. Thus, superheated steam was an ideal heating medium (Taechapairoj et al., 2003; Soponronnarit et al., 2006; Pronyk et al., 2004; Ono, 2008; Mujumdar, 2006). For this reason, we have made a series of studies on the use of superheated steam for roasting rice, and had been published (Chen et al., 2012).

It can be discovered from the analysis, the obtained results and the comparison with other research results, that there were two problems blocking the industrialization of roasting technology. Firstly, browning and carbonization was the major side effects influencing the flavor of rice wine produced from roasted rice. Secondly, it was shown in Table 1 that the gelatinization ratios of rice in different researches were basically the same, while there were significant differences between the operating conditions thereof. The result showed that, there were limitations to expressing the optimized technological conditions as operating conditions, and it was of minor guiding significance to the scale-up of fluidized bed. Reattempts including pilot scale test were necessary to achieve success in the scale-up of fluidized bed.

| Initial moisture of rice (%) | Gas temperature (°C) | Roasting time (s) | Degree of gelatinization (%) | Medium | |

|---|---|---|---|---|---|

| scheme 1a | 28∼29 | 290 | 45 | 85∼90 | Air |

| scheme 2b | 24 | 300 | 50 | 93 | Air |

| scheme 3c | 14 | 200 | 40 | 90 | Superheated steam |

Previous researches (Whistler et al., 1984; Biliaderis et al., 1986) showed that, the temperature of starch exceeding its melting point would result in the gelatinization of starch, the starch would be in molten condition and the tight structure was destroyed. Therefore, the temperature of starch during processing was a key factor to the gelatinization of starch. Meanwhile, the temperature also determined the occurrence of side effects and the speed of the side effects. Generally, heating temperature and heating time can determine the extent of side effects. The extent of side effects decreased with lower temperature and shorter time, and the effect of temperature became greater as well. During the roasting, the water content in rice decreased with the increase of heating time and the melting point of starch continuously increased with the decrease of water. Thus the roasting process was a dynamic process. On one hand, the temperature of rice continuously increased; on the other hand, the melting point of starch also continuously increased due to water loss. The ideal gelatinization can be achieved only when the rise of rice temperature is faster than that of the melting point of rice, so the increasing speed of the temperature of rice must be faster. In addition, how to limit the side effects was another problem needed to be solved during the process. Despite the understanding of rice gelatinization principles in process, it's also important to learn about the detailed information about the change in rice during the whole process so as to establish the optimal control conditions for the desired change in rice besides the external conditions.

Based on the above analysis, it can be realized that there were great limitations to determining the optimized conditions of experimental fluidized bed by experiment, which cannot meet the requirements of process optimization and equipment scale-up. Moreover, the temperature variation of rice itself was the critical point for success or failure of roasting. Therefore, understanding the variation in the temperature and related properties of rice can deepen the understanding of the essence of roasting process, providing necessary basis for the optimization of roasting process and the scale-up of roasting equipment.

During roasting process, the temperature variation of rice was a complex process. Firstly, the temperature inside the rice was uneven, with a temperature gradient. Secondly, the temperature of rice continuously varied with heating time. So that was an unsteady heat conduction process, which should be determined by indirect method rather than direct determination through analyzing heat transfer mechanism.

This paper aimed at summarizing the optimized conditions and requirements of the variation of rice itself during roasting process, based on the understanding of the gelatinization and variation in the related structures and properties of rice during heating process, in combination with the analysis on the temperature variation of rice during roasting process by the established model. Furthermore, comparing different of two heating mediums is the focus of the research

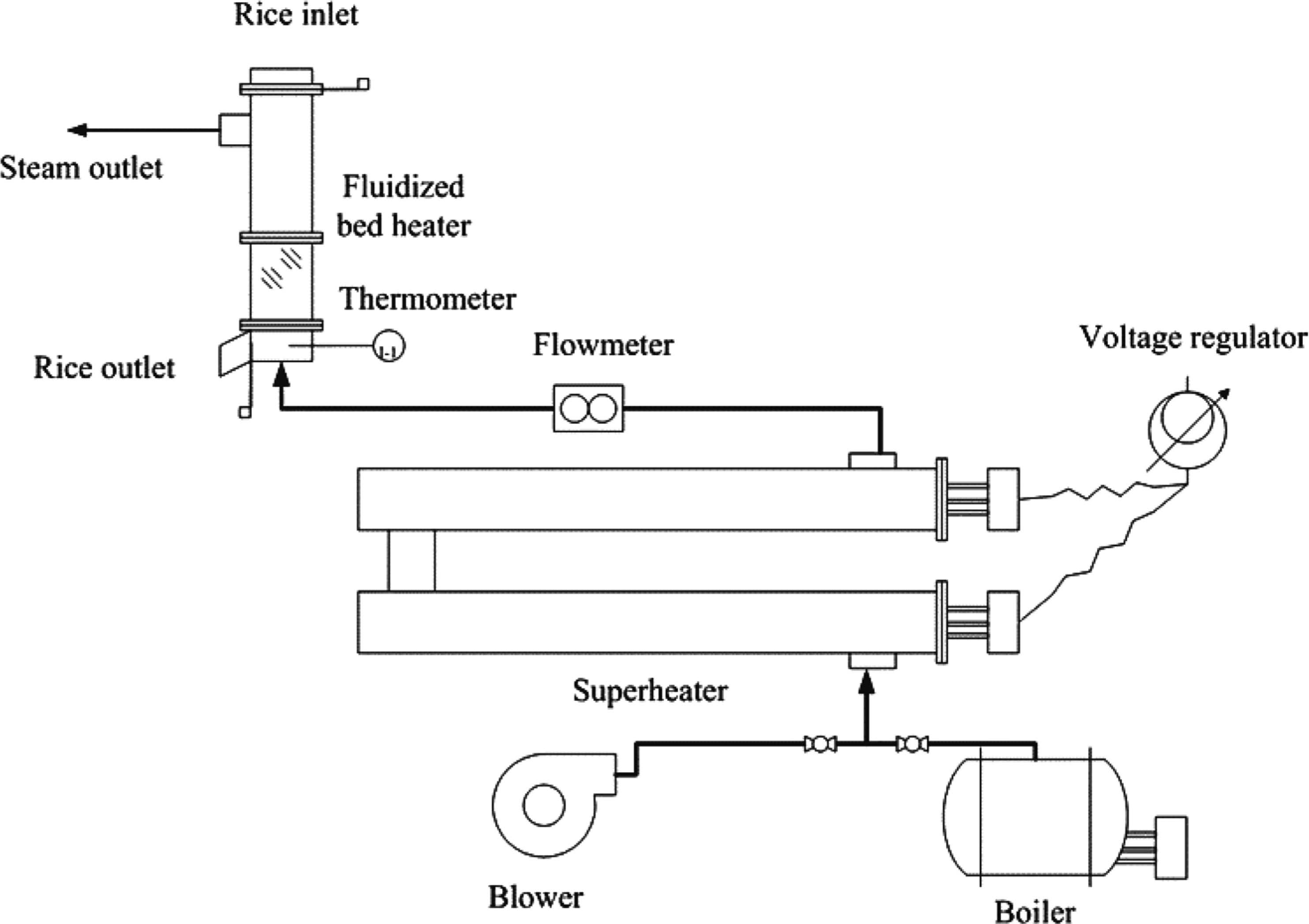

Experimental set-up The experimental set-up consists of a small fluidized-bed roasting device, which is shown in the flow diagram (Fig. 1). The steam from the steam generator enters through the electric heater and is heated at a pre-set temperature. The flow velocity of the superheated steam is controlled at 1.5 times the minimum superficial velocity for fluidization (Umf) or 4 m/s (Taechapairoj et al., 2003), and the diameter of the fluidized bed is 65 mm. Rice is placed on the roasting device at 10 g each time until the scheduled roasting duration is reached. The resulting samples are then discharged from the side gate at the bottom of the device.

Schematic diagram of experimental apparatus for heating rice using superheated steam or hot air.

The airflow from the draught fan enters the electric heater and then is heated at a set temperature. Subsequently, the airflow goes into the fluidized bed where the rice is roasted. The flow velocities of the hot air and the superheated steam are controlled at 1.5 Umf or 2.6 m/s (Taechapairoj et al., 2003) for comparison.

Materials One kind of non-waxy rice (JS-1) (Oryza sativa Linnaeus) and two kinds of waxy rice (JN-21 and N-32) (Oryza sativa var. glutinosa) are used in this study. The rice came from the Yixing City Grain and Oil Group Rice Co., Ltd., Jiangsu, China, which was harvested in 2009 and was stored at −20°C for standby application after polished and processing.

AnalysesRice roasting The optimum temperature for the superheated steam to roast the rice is 200°C (Chen et al., 2012). Three kinds of rice are roasted in this study at 200°C for different times: 5, 10, 15, 20, 30, 40, 50 and 70 s. Changes in the rice properties are studied during the whole roasting process, especially the differences between the two heating media and their effects on the properties of rice.

Determination of the degree of gelatinization Determination of the degree of gelatinization is based on the method described by Lee et al. (2005). Water is first added into the roasted rice ground for enzymatic saccharification. The DNS method is then employed to determine and restore sugar content for gelatinization.

Moisture content The moisture content of rice in the hot-air oven is determined at 103°C and is weighed after 72 h based on the method introduced by the American Association of Cereal Chemists (AACC, 1995).

Pasting properties The gelatinization curve of rice adopts the rapid visco analyzer (RVA, Newport Scientific, RVA-RECHMASTER, Australia), along with the usage mode and method 61 − 02 (AACC, 1995). Rice flour at 3 g is added into 25 mL distilled water. The mixture is placed in the blending device at a rotation speed of 960 rpm per 10 s and then at 160 rpm for the entire test phase. Temperature changes are observed through the following procedure: temperature initially set to 50°C for 1.5 min, increased to 95°C at a speed of 12°C/min for 2.5 min, and then decreased to 50°C for 2.1 min.

Scanning electron microscopy The micro-structure of rice is examined via SEM using FEI Quanta-200 from the Netherlands. The rice stalk is cut off from the middle to represent the natural fracture section and then subjected into a series of treatments before SEM analysis.

X-ray diffraction analysis The X-ray diffraction analysis uses a Bruker AXS DS Advance diffractometer with the following parameters: Cu Kα (λ=0.154 06 nm) with 1600 W power (40 kV × 40 mA), NaI crystal scintillation counter to measure the strength of X-ray diffraction with a scanning scope of 3° to 30°, a scanning speed of 4 °/min, and a step length of 0.02°. DS − SS − RS are respectively set as 1 mm − 1 mm − 0.1 mm.

Statistical analysis Analytic measurements were performed in triplicate in addition to the gelatinization curve of rice. The data were expressed as the mean ± SD. The mean values were compared using t-test and the analysis of variance was performed by ANOVA. The level of significance was 95%. Origin 8.0 is used for data analysis and for concrete illustrations.

Numerical proceduresGoverning equations Unsteady-state heat transfer takes place for the duration of the rice roasting in the fluidized bed. As larger internal thermal resistance, the internal temperature of rice is not uniform and there is the internal temperature distribution.

The heat transfer process of rice roasting is basically similar to the single-grain rice is heated in the hot gas stream. The heat transfer model is simplified in the following manner:

So rice grain is spherical, the rice equivalent diameter, dp can be calculated using equation (1)

|

where L, W, Th respectively is length, width and thickness of rice grain.

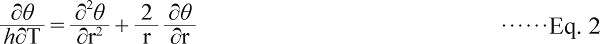

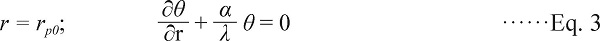

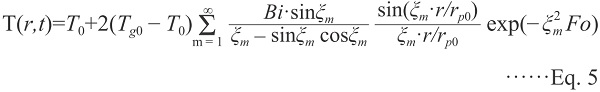

Heat transfer process between spherical grains and hot gas flow consists of the particle surface heat transfer and the internal grain conduction heat transfer, belongs to the one dimensional unsteady heat transfer process. The heat transfer process can use the following differential equation in spherical coordinate system:

|

Equation (1) was solved with the following inlet and boundary conditions:

|

|

Solution of differential equation The differential equation was solved using the separation of variables (Ozisik et al., 1993) and the solution of the equation was as follows:

|

|

|

|

Then, applying equation (5) the average temperature of rice, θ(t), heat transfer, Q(t) and gas outlet temperature, Tg is obtained.

|

|

|

where, ρs,cs respectively is the density and specific heat of rice. S is fluidized bed sieve area, u0 is gas velocity.

|

where, Nup is Nusselt number, Pr is Prandtl number, Rep is Reynolds Number.

|

|

|

where, ρg, cg, µg respectively is the density, specific heat and viscosity of gas.

The equation (12) that is the widely cited is the empirical formula of convective heat transfer coefficient between rice grain and heat flow by Ranz and Marshallis (1952). This formula in the dilute conditions is very effective. In this paper, the roasting experiment belongs to dilute phase fluidization.

Initial and boundary conditions and properties the initial and boundary conditions are described in Table 2. The properties of air are at 200°C, and properties of the rice are at about 14% humidity. These properties are assumed to be constant throughout the process. The same gas velocity in the calculation and experiment is 1.5 times the minimum fluidization velocity. Heat transfer coefficient h is calculated by the equation (12) based on these properties and the initial temperature of rice is 25°C.

| Parameter | Parameter name | Unit | Value |

|---|---|---|---|

| dp | rice grain equivalent diameter | m | 0.00291 |

| rp0 | rice grain equivalent radius | m | 0.001455 |

| h | gas-grain heat transfer coefficient | W/(m2·°C) | 131.935 |

| α | thermal diffusivity of rice | m2/s | 5.40468×10−8 |

| λ | thermal conductivity of rice | W/(m·°C) | 0.101533 |

| Tg0 | inlet temperature of gas | °C | 180,200,220 |

| T0 | initial temperature of rice | °C | 20 |

| ρs | density of rice | kg/m3 | 1429 |

| cs | specific heat of rice | kJ/kg | 1.2733 |

| ρg | density of gas | kg/m3 | 0.746 |

| cg | specific heat of gas | kJ/kg | 1.026 |

| µg | viscosity of gas | Pa·s | 2.6×10−5 |

| u0 | gas velocity | m/s | 2.6 |

Model calculation First of all, h was calculated by equation (12) and then ξm was calculated using equation (8). Temperature distribution function of rice which was heated respectively by 180°C, 200°C and 220°C air can be obtained by the equation (5) and Similarly, the average temperature of rice, θ(t), heat transfer, Q(t) and gas outlet temperature, Tg can be obtained by equation (9), (10) and (11). The model was programmed and calculated using Mathematica and calculation series is 5000 for precision.

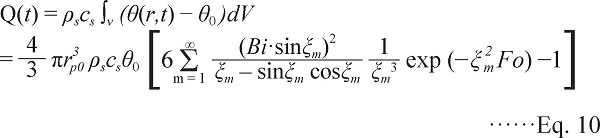

Rice Processing Analysis Roasting effects of air and superheated steam could be compared by two methods, i.e. by assuming identical gas velocity Konishi et al. (2004) or fluidized state Rordprapat et al. (2005). The present study employs the latter in view of the extremely remarkable difference between the two media in terms of their properties. If the same gas velocity is used, rice would exhibit striking differences in fluidized states that are impossible to use for comparison. A relatively high velocity of gas, i.e., 1.5 Umf (the minimum superficial velocity for fluidization) is used in experimental apparatuses for heat transfer reinforcement so that the gelatinization process could be completed within a relatively short period of time. Fig. 2 (a) to (c) shows that both heating media can realize a degree of gelatinization of over 90% within a relatively short period of time, which meets the requirements for the liquor brewing process. It can be concluded that the operating parameters for dry heating treatment have a greater impact on the degree of gelatinization while the heating medium shows a relatively small impact thereon.

Effect of superheated steam (○) and hot air (▵) on gelatinization of roasted rice. Error bar represents the standard deviation (N = 3).

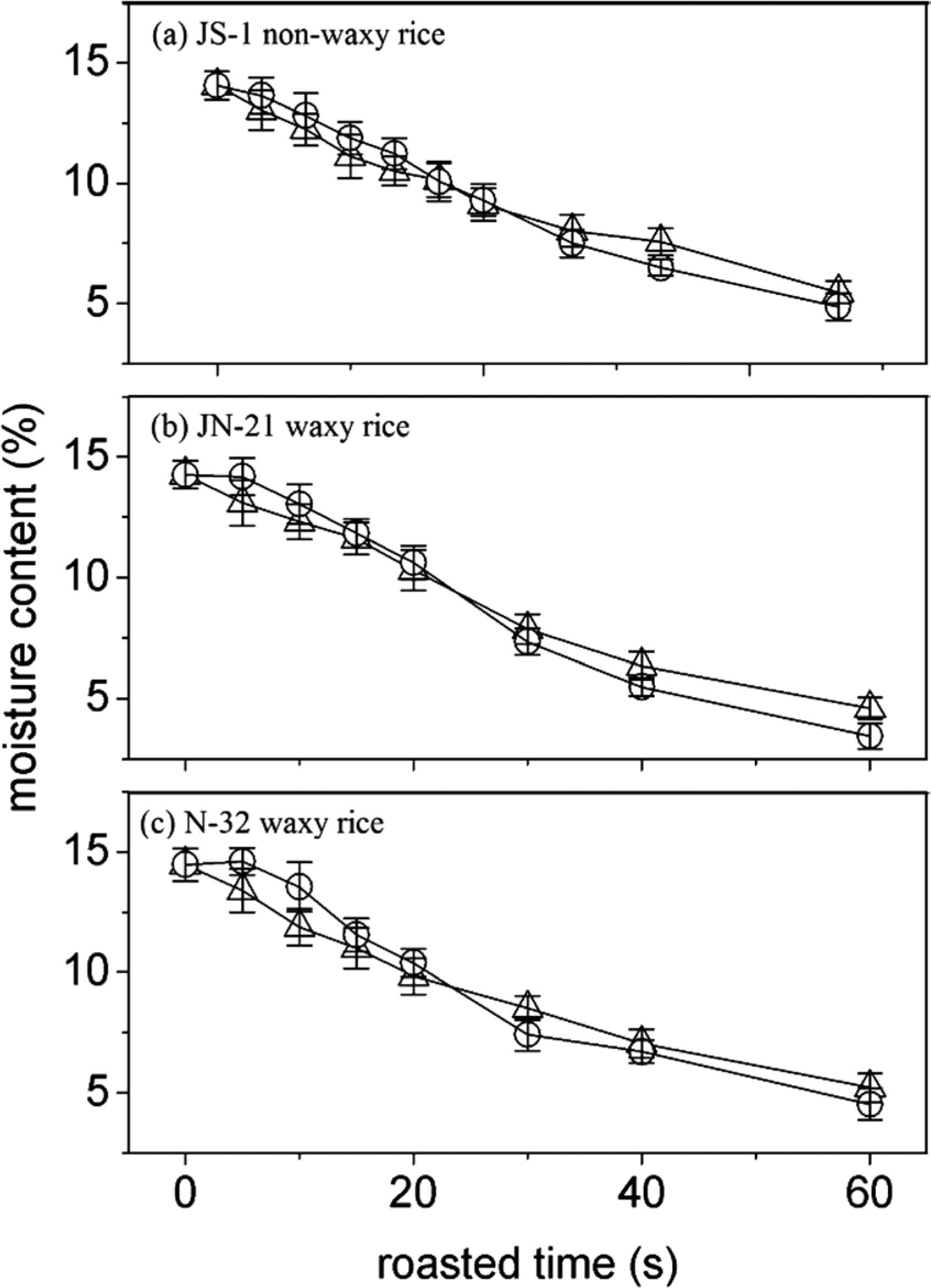

Secondly, among the three raw materials used for experiments, the degree of gelatinization in hot air-based processing is slightly lower than that in heating by superheated steam from the initial stage of heating. The cause of this phenomenon may be as follows: Superheated steam may condense on the surface of rice in the early stage of heating due to the material temperature's being lower than the boiling point of the steam. Condensation is a process of rapid heat transfer, during which the temperature of rice grains rises faster than heating by hot air. At the same time, the condensed moisture on grain surface brings about the increase in moisture content of the rice surface and reduces or even prevents the evaporation of moisture from inside rice grains, thereby maintaining a higher moisture content than that of hot air-heated rice (Fig. 3 (a) to (c)). Rice starch with higher moisture content has a relatively low melting point that could facilitate the process of gelatinization Biliaderis et al. (1986). From this point of view, the gelatinization effect of superheated steam processing is more favorable than that of hot air-based processing in initial stage.

Effect of superheated steam (○) and hot air (▵) on moisture content of roasted rice. Error bar represents the standard deviation (N = 3).

Fig. 3 (a) to (c) indicates that, although condensed water induced a higher moisture content of superheated steam-roasted rice than that of hot air-heated rice in the initial stage of heating, the moisture content of superheated steam-roasted rice decreases quickly as the heating time goes by and even drops below that of hot air-roasted rice in the end, which indicates superheated steam-based roasting contributes to a faster heat transfer and evaporation of moisture, thus bringing about more favorable gelatinization effect. The findings are similar to those of Rordprapat et al. (2005).

It is observed from the comparison between different varieties of rice that waxy rice shows a higher degree and speed of gelatinization due to the compact crystallization of amylose in non-waxy rice, which is difficult to melt and scatter as amylase presents a high viscosity even after it melts. Furthermore, the compounds formed with such micromolecules as lipids make non-waxy rice more difficult to get gelatinized. It's true that higher energy necessary for gelatinization could be achieved at a higher temperature, but as a consequence, other undesirable changes such as non-biological browning could also speed up.

Fig. 2(a) to (c) shows the change in the degree of rice gelatinization over time during roasting. The overall process constitutes a relatively typical sigmoid curve because of its relatively slow change at the beginning and ending parts yet relatively fast change in the middle. In the event of hydrothermal treatment, the kinetics study of rice gelatinization indicates a first-order reaction process, where the rate of gelatinization is positively proportional to starch concentration Bakshi et al. (1980). Where as in dry heating treatment, starch gelatinization seems a much more complex process, during which a number of factors affecting the rate of gelatinization could be observed. Firstly, the influence of temperature variation: Hydrothermal treatment exhibits smaller temperature fluctuation and relatively short duration, while dry heating treatment shows significant temperature variation within tens of seconds. Accordingly, temperature changes almost simultaneously with the process of gelatinization in dry heating treatment. Secondly, the influence of moisture variation: As for hydrothermal treatment, gelatinization temperature and reaction energy are almost subject to no change since there's excessive moisture during the whole process; but in dry heating treatment, the drastic temperature changes lead to rapid changes of moisture, resulting in change in the temperature for starch gelatinization and the melting point for starch crystallization. That is to say, gelatinization in dry heating treatment is more of a dynamic process of change. Thirdly, the influence of puffing: Puffing leads to the drastic change in the internal macro structure of rice grains in a very short period of time, tremendously impacting the change in the molecular structure of starch. It can clearly be seen that during the processing of rice the gelatinization process in dry heating treatment involves various factors, some of which are observed in certain periods, while the others are observed throughout the whole process. From this point of view, rice starch gelatinization cannot be summarized by simple reaction orders during dry heating treatment, and its reaction curve is a typical S-shaped.

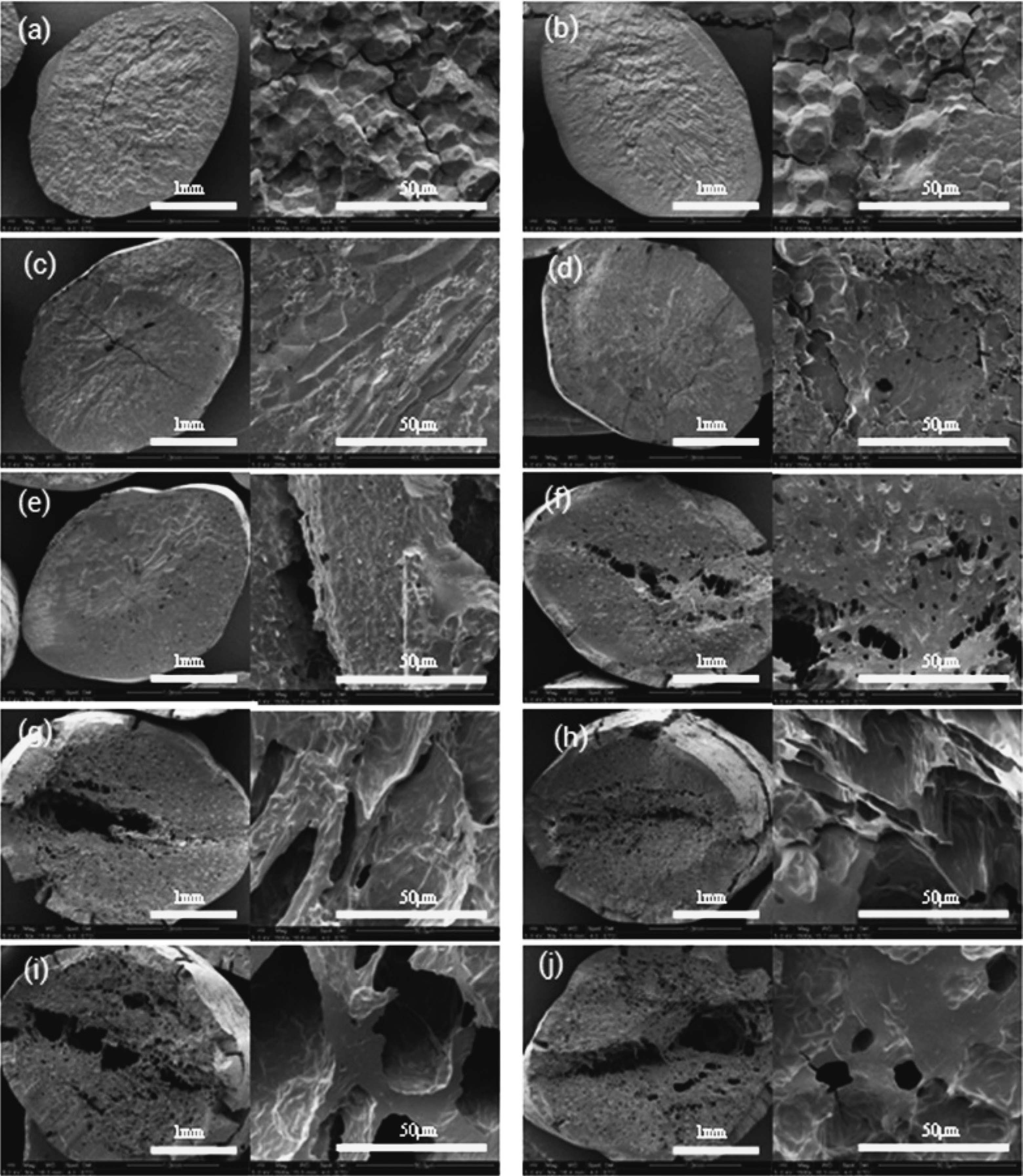

SEM During the roasting, rice gelatinization is basically considered a starch melting process due to its low moisture content. This is a process where heat transfer and phase transformation co-exist. Once the rice starch enters a soft state after glass transition at the high temperature, the starch molecules will be endowed with a certain freedom of movement and then pass into the molten state, where the starch turns into viscoelastic fluid. At the same time, the air and vaporized water in rice grains bring about a large number of increasingly expanding bubbles, among which coalescence and other phenomena can be observed. In general, this process witnesses both the change in structure of the starch molecules, and the puffing of rice grains. It is such processes as air expansion and bubble movement in rice that promotes the change in molecular microstructure of rice.

As a commonly used means for observing the microstructure of substances, scanning electron microscope is designed to learn about the fundamental changes in the internal structure of rice during the heating process. The Fig. 4 (a) to (j) shows such changes in the internal structure of non-waxy rice (JS-1) with heating time. As can be seen from the photographs, the change in microstructure of rice could be divided into two stages, i.e., heating and puffing. In the stage of heating, the original cube-shaped granular structure in rice gradually disappears, while tiny porous structure emerges and increases. This indicates that the solid content in rice is gradually softening. After 20 s to 25 s, the rice steps into the puffing stage, in which lots of large pores appear abruptly along with the rapid expansion of rice grains, indicate that the heating has transformed the solid content of the rice into viscoelastic fluid. As the viscoelastic intensity is lower than air pressure in pores, expansion happens rapidly, followed by a striking puffing process. Thereafter, the size of rice grain changes only by a small margin, indicating that the extraordinarily short puffing time of rice is correlated with the rapid increase of the degree of gelatinization. Thus, puffing could be considered to have contributed to the increased degree of rice gelatinization. Since the significant increase in surface area of puffed rice is conducive to starch enzymolysis by glucoamylase. But the biggest problem in the puffing stage is required from the temperature quickly rises to maintain the temperature stable. The only way to prevent thermal decomposition and abiotic browning that are not accepted in the brewing process.

Changes on the microstructure of JS-1(non-waxy rice) during roasting process by superheated steam. (a) to (j) denote respectively heated time 0 s, 5 s, 10 s, 15 s, 20 s, 25 s, 30 s, 40 s, 50 s, 70 s.

By reason of its limited space, this paper presents no photographs showing the waxy rice and the hot air-based heating of rice. Roasting by hot air or by superheated steam has basically the same effect on rice structure and shows no significant difference. The starting point of puffing of non-waxy rice is slightly later than that of waxy rice because non-waxy rice contains a certain amount of amylase whose melting point is higher than that of amylopectin. Moreover, the viscosity of molten non-waxy rice is higher than that of glutinous rice, bringing about a less favorable puffing effect. The number of pores in non-waxy rice grains is significantly smaller than in waxy rice, and this may constitute one of the causes of difference in puffing effect there-between.

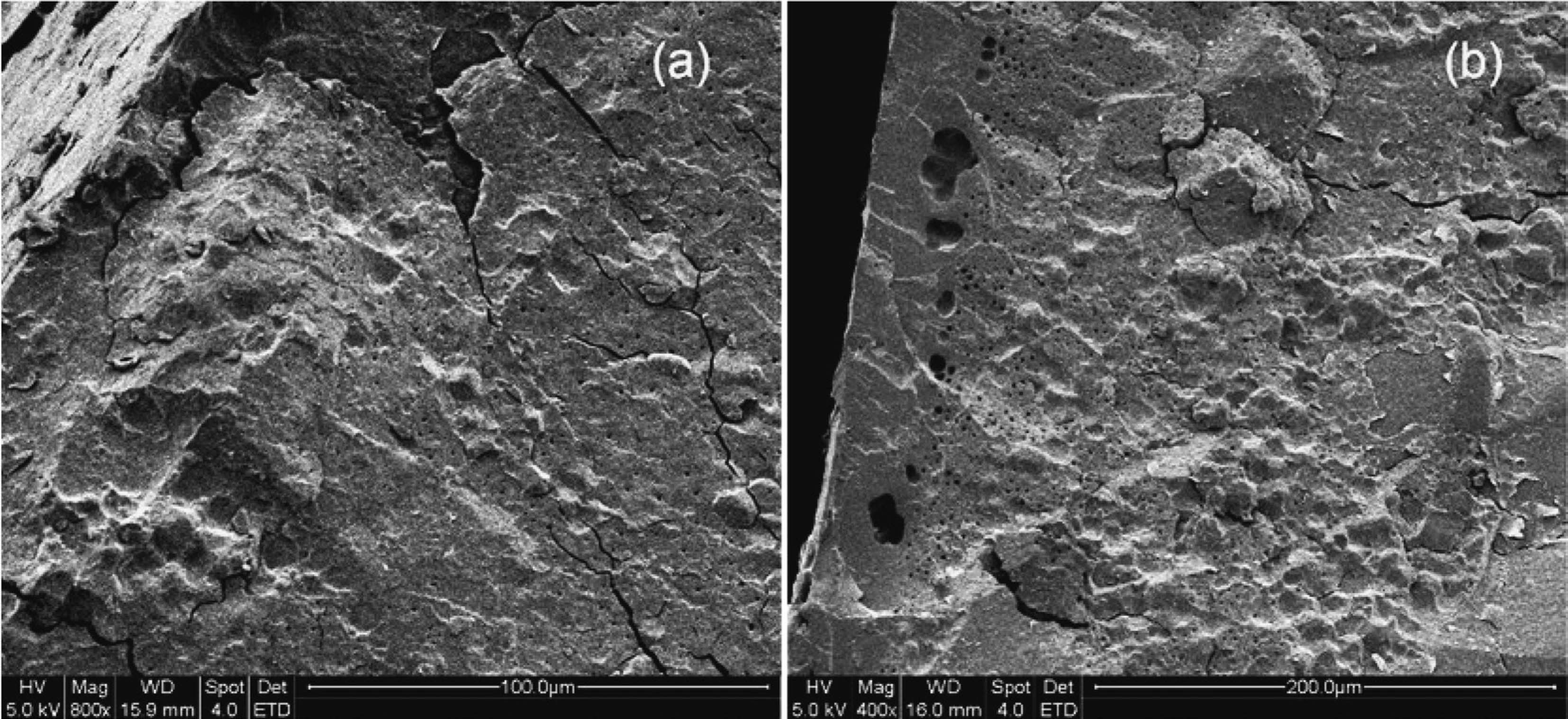

Figure 5 is the roasted rice surface after heated 10 seconds using different heating medium. Roasted rice surface with superheated steam have a thin dense layer, and the roasted rice surface by air has not. It leads to the formation of a dense layer that the starch of the rice surface is wetted with water during steam condensation and then the condensation is also the rapid evaporate. It is the direct evidence that steam is condensed on the surface of the rice and also shows that steam condensation effect on the surface of the rice.

waxy rice (N-32) surface in roasted 10 s. (a) Hot air, (b) Superheated steam

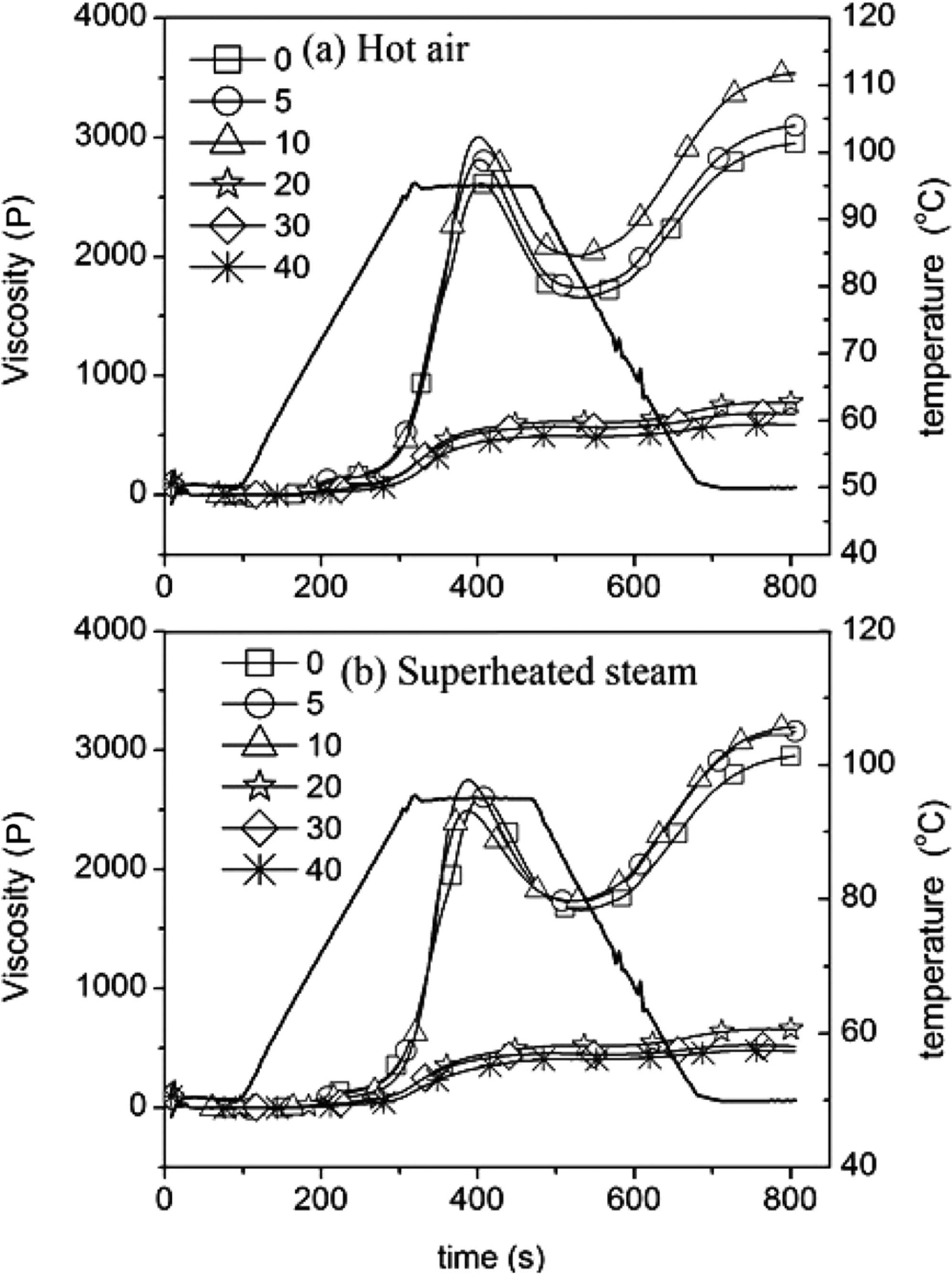

Pasting property Rice gelatinization brings about a series of changes in rice starch granules, starch molecules and crystallization that may affect the gelatinization properties of rice flour, which can be shown clearly with a Rapid Visco Analyzer (RVA). Furthermore, the RVA curve of rice flour could normally reflect the changes in molecular structure and microstructure in the process of gelatinization in a more accurately and detailed manner. From this point of view, gelatinization property analysis is considered very useful to reflect the internal changes of rice.

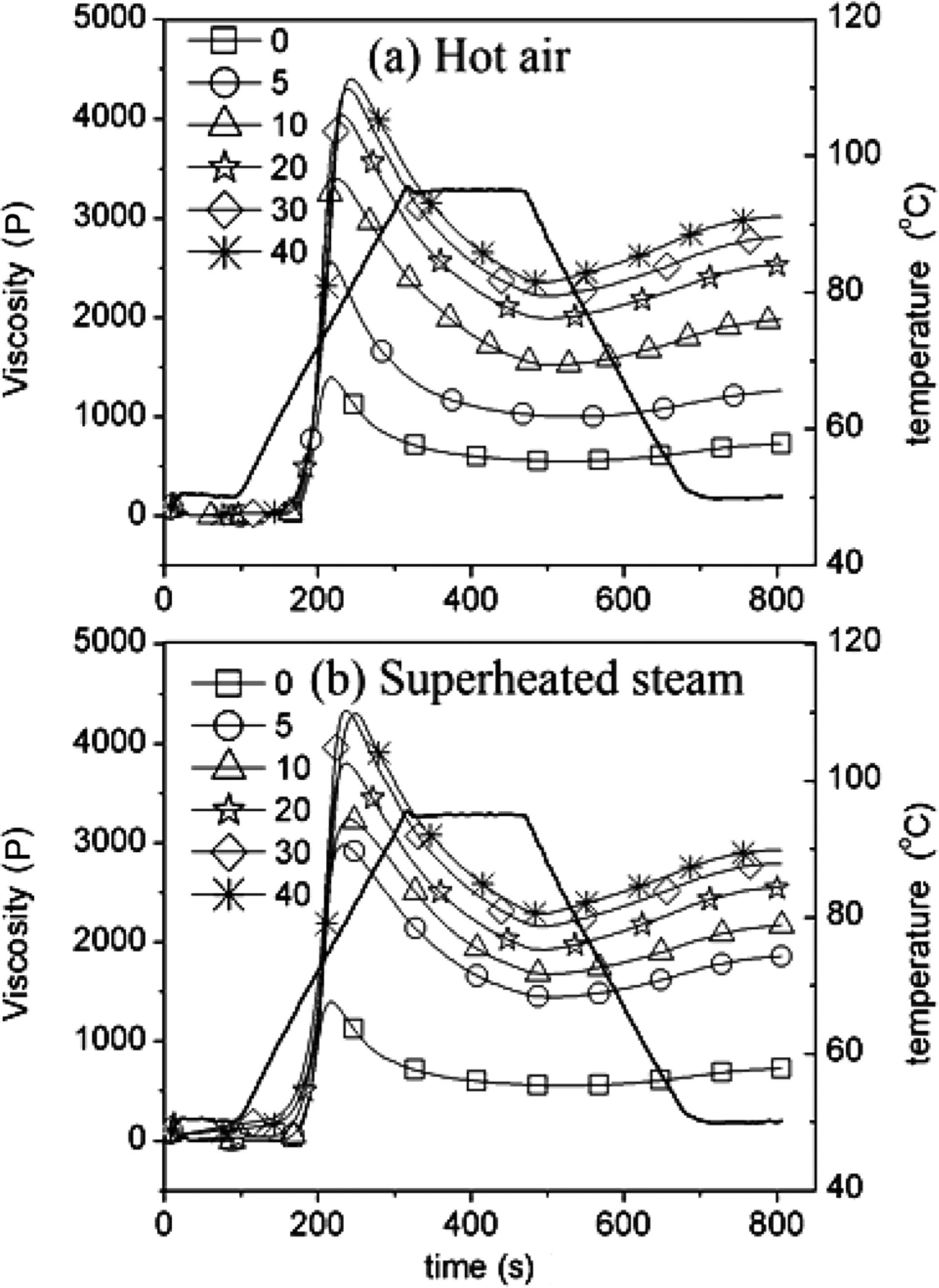

Fig. 6 and 7 shows the changes of RVA profile of different varieties of rice during roasting at 200°C by using air or superheated steam. As for non-waxy rice, the RVA profile and its parameters such as peak viscosity and final viscosity increase slightly and then drop within the first 10 s of the initial heating stage. After 10 s, they decrease sharply and the maximum falling range is observed between the 10 s and 20 s. After 20 s, the RVA profile change only by an extremely small margin. As for waxy rice, the RVA profile tend to increase gradually from low to high by a smaller margin within the first 20 s and a larger one after that. This illustrates that before the occurrence of puffing, the microstructure of macromolecules like rice starch has undergone great changes but it has not showed up on a macro scope. The puffing phenomenon that occurs after 20 s is, however, a manifestation of accumulated changes in the macromolecular structure of rice on the macro scope.

Viscograph of JS-1(non-waxy rice) heated by (a) hot air and (b) superheated steam with roasting time between 0–40 s.

Viscograph of JN-21(waxy rice) heated by (a) hot air and (b) superheated steam with roasting time between 0–40 s.

Another noteworthy point is the way of change of the RVA profile of non-waxy rice at initial stage of heating - dropping after a slight rise. This way of change is not reported in previous literature. This means the amylose and amylopectin in non-waxy rice may be compounded tightly, thus difficult to escape from starch granules in initial stage of heating. With the progress of processing, amylose would get out of starch granules. Normally, the entire RVA profile of non-waxy rice decrease with the development of processing in later stages, which leads to the misunderstanding that it is the way the RVA profile changes. Judgment error may thus occur if the level of rice gelatinization is estimated only based on the changes in RVA profile (Rordprapat et al., 2005).

In addition, the margin by which the RVA profile of superheated steam-heated rice change is greater than those of non-waxy rice heated for the same period of time, further demonstrating that the rice gelatinization effect of superheated steam-based roasting is more favorable than that of hot air-based roasting.

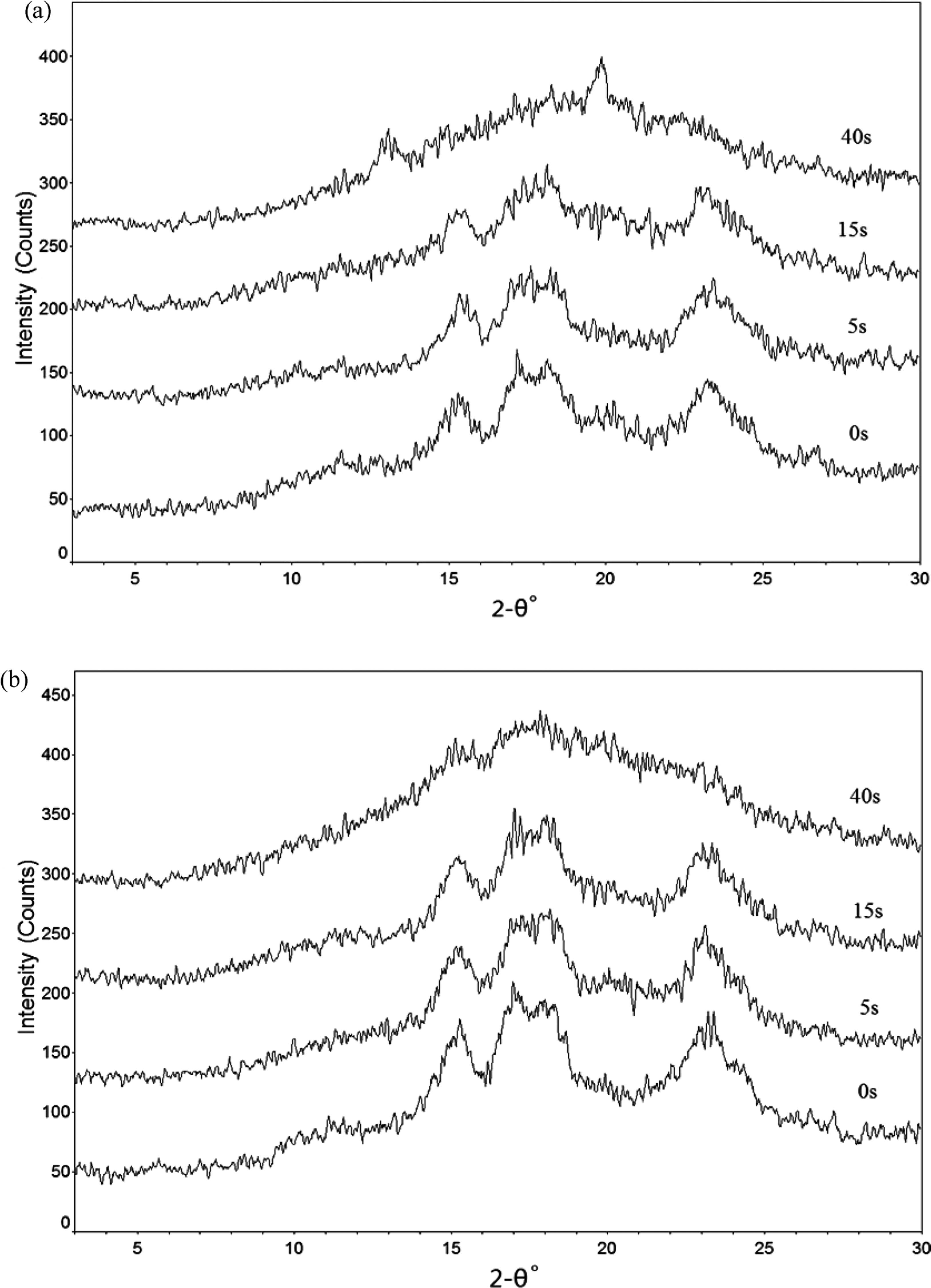

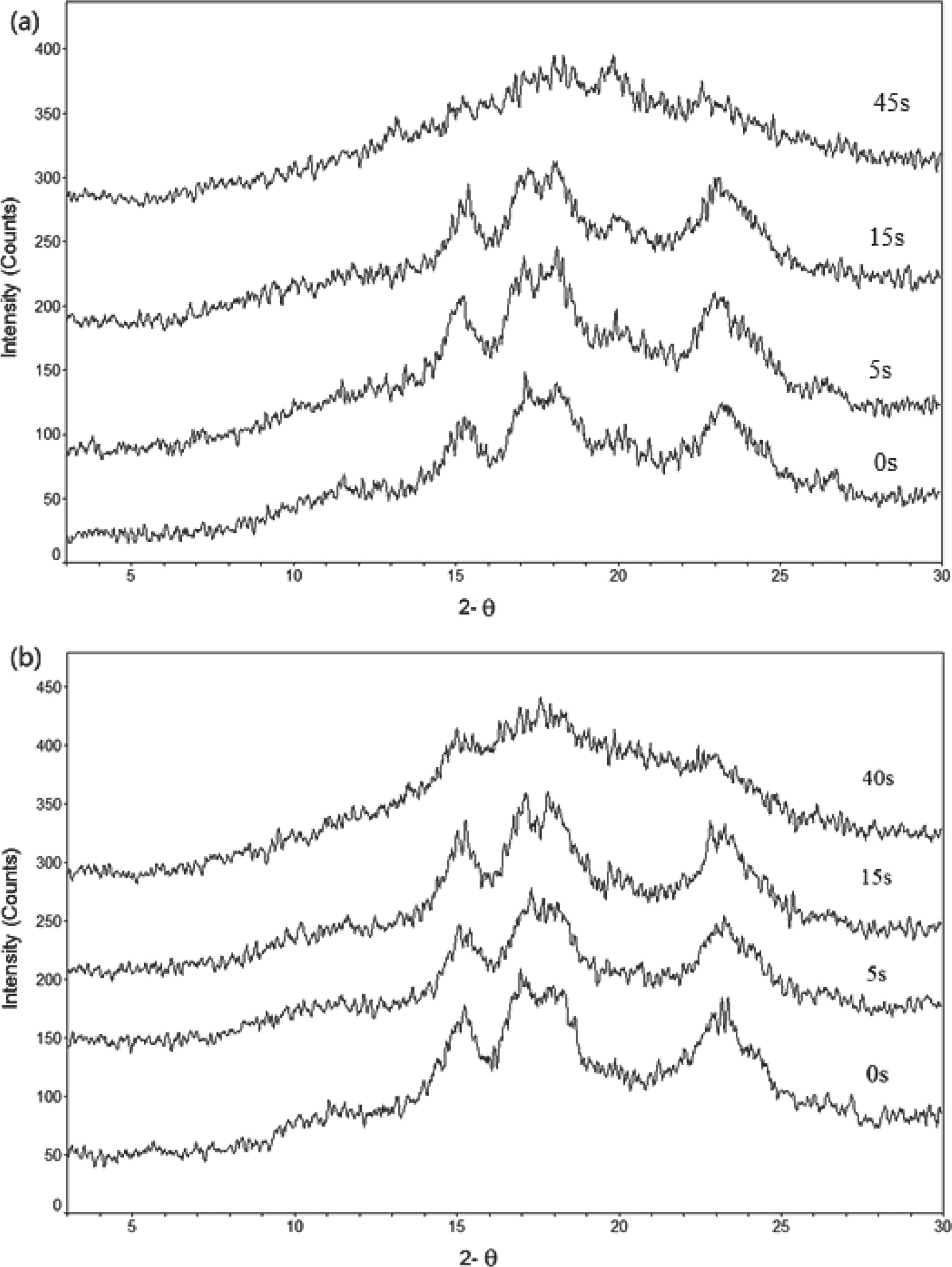

X-ray Diffraction X-ray diffraction images can help learn about the changes in internal starch crystallization of rice during roasting. X-ray diffraction analysis is performed on rice in its baking stage and for rice heated for 40 s. Fig. 8 and 9 show the X-ray diffraction patterns of three varieties of rice heated by superheated steam or air at 200°C to make race flour. Raw rice and rice heated for 5 s, 15 s and 40 s are used as samples. As can be seen from the illustrations, by reason that relatively strong diffraction peaks are detected at 15° and 23° and double peaks are observed at 17° and 18° and that all samples have a type-A starch structure (Biliaderis et al., 1993; Derycke et al., 2005), the molecular array of starch remains unchanged during the heating process although the peak intensity changes by small amplitude, reflecting that the starch crystal primarily maintains its original crystalline structure in the initial stage of heating in roasting and that little starch crystal exists at the 40 s in the end. That is to say, the crystal disappears between the 15 s and 40 s, which means the crystalline portion of rice changes only by a small margin in the initial stage of heating despite the remarkable change in starch molecules. This further demonstrates the importance of rice temperature for disintegrating starch crystalline in rice during the heating process, proving that the crystal is destroyed after rice gets molten.

X-ray diffraction pattern of rice heated by superheated steam. (a) JS-1, (b) JN-21

X-ray diffraction pattern of rice heated by Air. (a) JS-1, (b) JN-21 (roasting time: 0 s, 5 s, 15 s, 40 s).

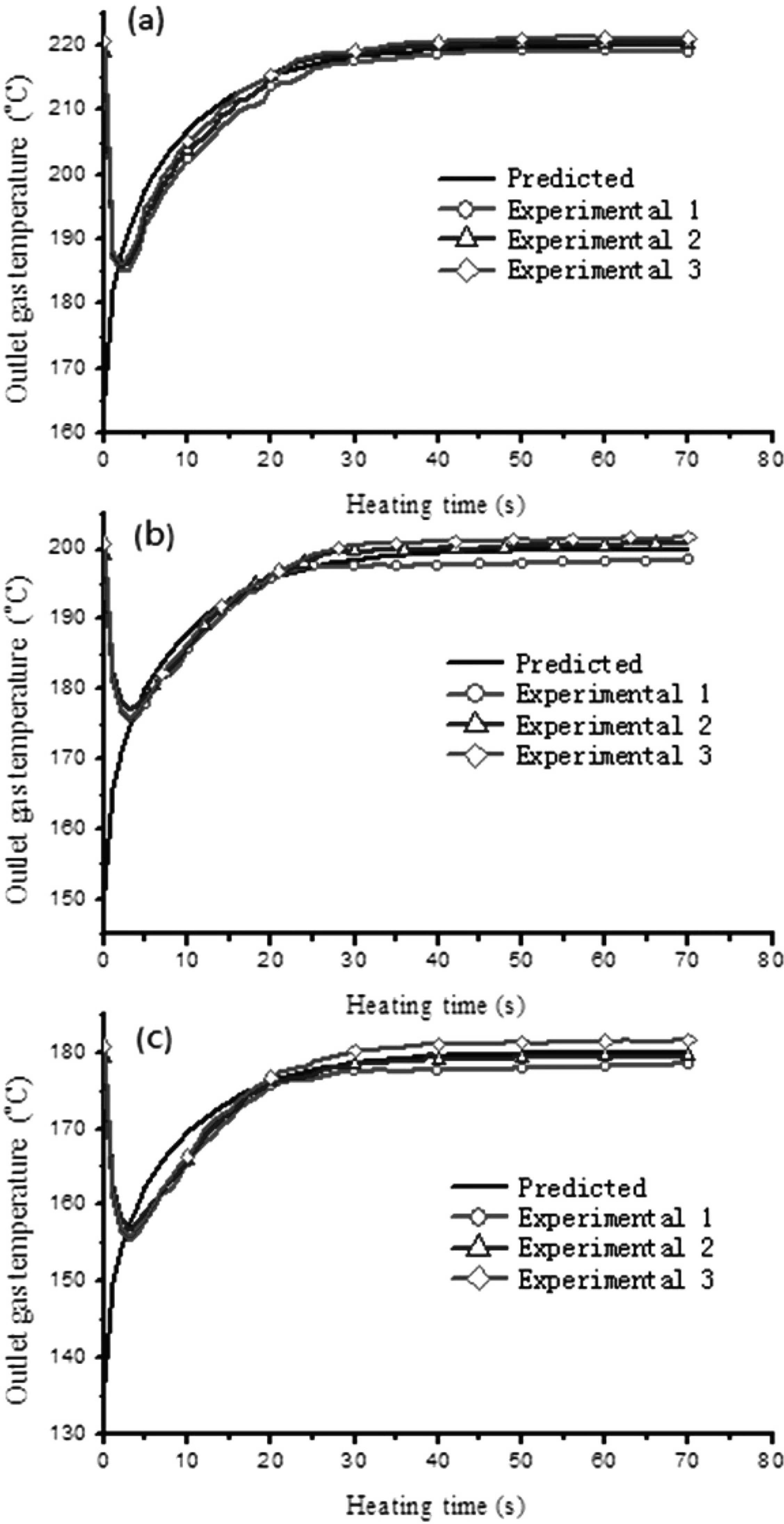

Analysis of rice temperature change during roasting During the roasting process of rice, the temperature variation of fluidized-bed outlet gas over time could be easily measured; meanwhile the variation of outlet gas could also be calculated by the model. By comparing the calculated results and the measured values, it would be possible to determine whether the model is suitable for the roasting process of rice. Fig. 10 provided the calculated values and the measured values of fluidized-bed outlet gas temperature respectively under the air temperatures of 180°C, 200°C and 220°C. It could be observed that the actually measured outlet gas temperature has a decreasing process due to the lag of thermal resistance for temperature measurement. Therefore, the measured values are inconsistent with the corresponding calculated values during the initial heating process, while the measured values and calculated values are comparable with each other subsequently. It could be concluded that the model was successfully established and could be applied to the roasting process of rice.

Outlet gas temperature of fluidized bed with model predicted and experiment measurement. (a) 220°C, (b) 200°C, (c) 180°C

The ultimate objective of establishing a model for the roasting process of rice was to discover the temperature variation during roasting. Six spherical surfaces were selected from the inside part to the outside to calculate the temperature variation. There were two key points needed to be understood when analyzing the temperature variation. Firstly, the melting point of rice starch was around 180°C, corresponding to the initial moisture content (14%) of rice. Therefore, it could be considered that the starch has been substantially gelatinized when the rice was heated up to 180°C. Secondly, previous studies have shown that there was no browning on rice surface after heating for 40 s and only slight browning after roasting for 70 s at 200°C; while there was significant browning only after heating for 25 s at 220°C. Therefore, the temperature of rice should not exceed 200°C during process. Moreover, the surface temperature of rice was highest, and keeping the surface temperature of rice below 200°C was the only one that was necessary to be done.

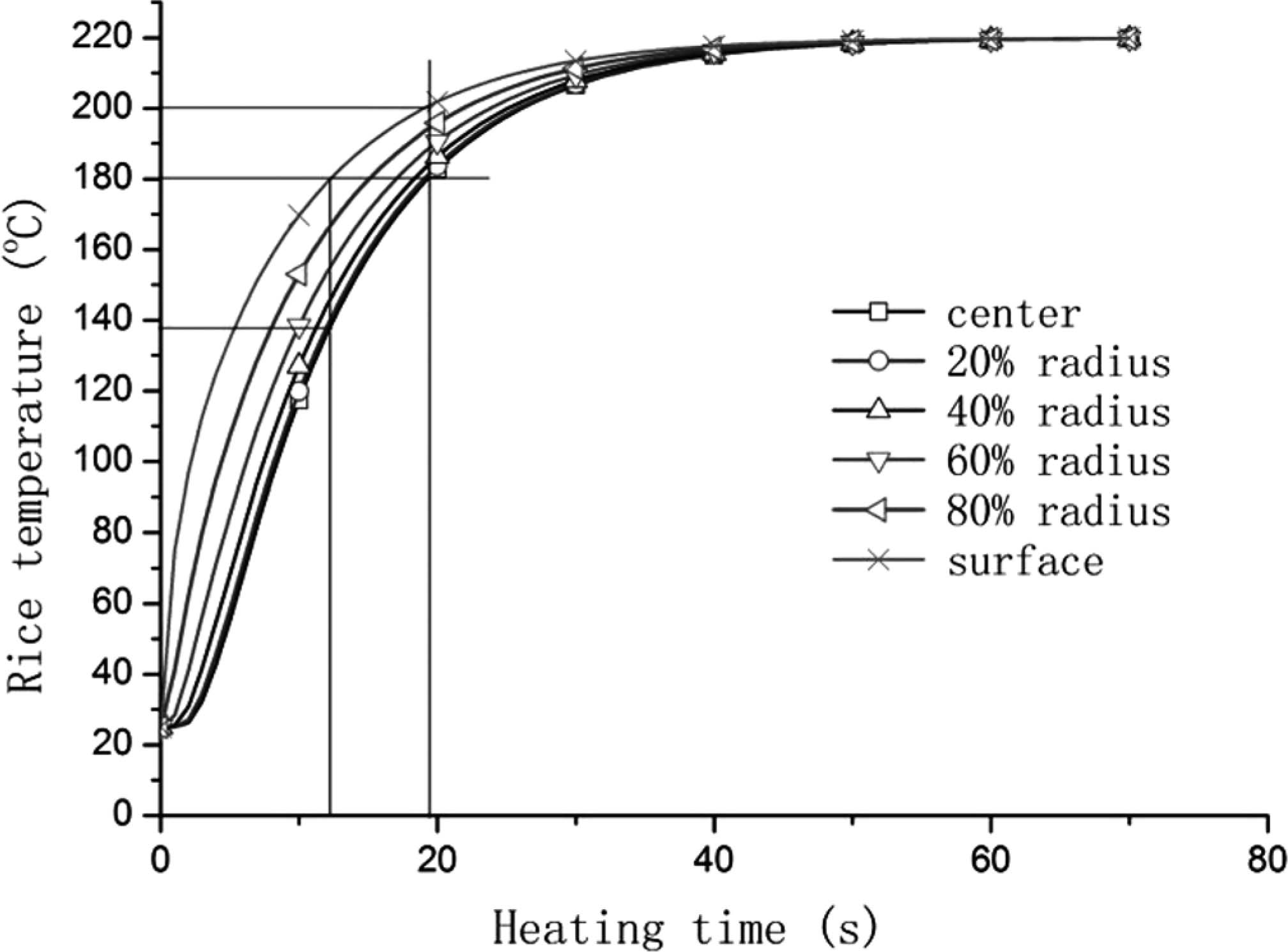

Fig. 11 provided the temperature variation for every spherical surface at 220°C. The surface temperature of rice reached up to the melting point of rice starch (180°C) at 12 s, meanwhile the center temperature of rice was only up to139°C, and the temperature difference between the inside and the outside was 40°C or so. After about 7 s, the center temperature of rice reached up to 180°C, meanwhile the surface temperature of rice was around 200°C, and there was still a temperature difference of 20°C. Finally, the temperature difference decreased gradually, close to the gas temperature of 220°C. During the whole process, the rice was performed along with a higher temperature difference, and the temperature difference led to browning of rice surface despite the fast heating speed. Moreover, the temperature variation around the melting point of rice starch was very quick, and the residence time was difficult to control. So that often resulted in unsatisfactory gelatinization or serious browning.

Internal temperature distribution of rice during roasting at 220°C by model predicted

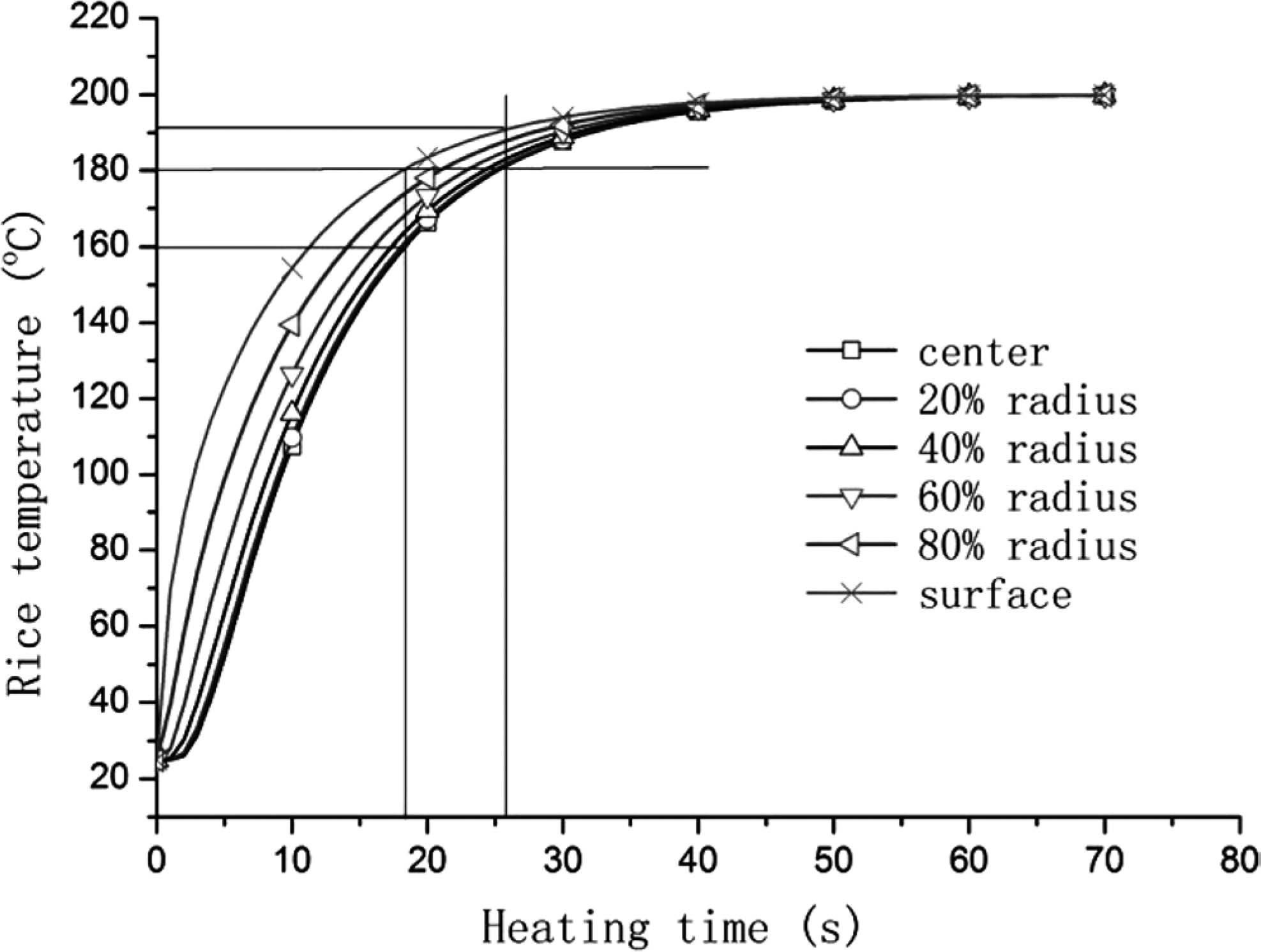

Fig. 12 provided the temperature variation of rice at 200°C. The surface temperature of rice reached up to 180°C at 18 s, meanwhile the center temperature of rice was 160°C, and the temperature difference between the inside and the outside was around 20°C. After about 8 s, the center temperature of rice reached up to 180°C, meanwhile the surface temperature of rice was around 191°C, and the temperature difference was 11°C. The subsequent temperature variation rate was more slowly and roasting process more easily controlled. This proves that the roasting process was divided into two stages are correct and suitable.

Internal temperature distribution of rice during roasting at 200°C by model predicted

By comparing the temperature distribution inside the rice at two different gas flow temperatures, it could be realized that selecting a proper gas flow temperature could effectively control the temperature and temperature distribution of rice during the heating process, and the optimized operating conditions not only ensure the fast heating of rice, but also not result in the excessive temperature difference and too high temperature inside the rice. Desirable gelatinization ratio of rice could be obtained at the gas flow temperature of 200°C; meanwhile the particle temperature remained at lower level, effectively overcoming the negative effects including non-living browning. At the gas flow temperature of 220°C, a higher gelatinization ratio of rice was obtained within a shorter time; however, the subsequent temperature continued to rise quickly, which would cause coking easily. Therefore, that condition was more difficult to control. The gelatinization ratio was unsatisfactory if the heating time was too short; and the negative effect was serious if the heating time was too long.

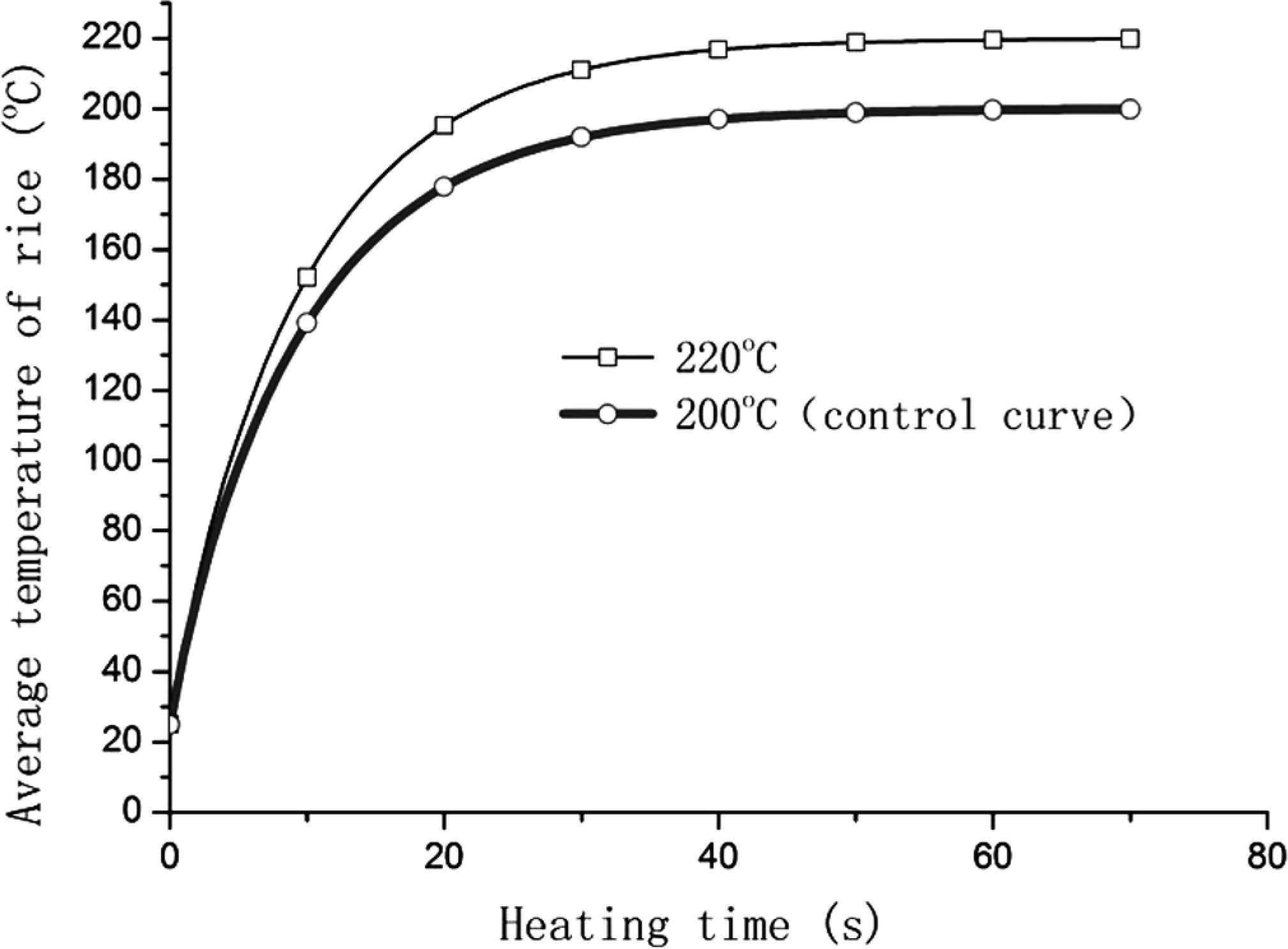

It was particularly necessary to point out that the temperature variation of rice itself at the gas flow temperature of 200°C was an ideal process through experiment and model analysis. Under that condition, the heating rate of rice could meet requirements, and the temperature difference and final temperature could be controlled ideally. Fig. 13 provided the average temperature curves of rice accordingly at the gas flow temperature of 200°C and 220°C. The curve of 200°C provided the average temperature variation of rice in the optimized operating condition, and that curve was determined to be the standard temperature control curve for the rice roasting. So it could be determined whether the operation of fluidized-bed was successful based on the curve in future. If the average temperature variation curve obtained on the basis of the pre-established fluidized-bed operating parameters was the same as or close to the standard temperature control curve, the operating conditions were considered to be successfully established; otherwise the operating conditions were unsatisfactory. Once the standard temperature curve was obtained, researchers could focus on the temperature variation of rice itself rather than the establishment of external optimized operating conditions during fluidized-bed research and design. In other words, superheated steam of 200°C could result in favorable roasting effects in experiment research, but in industrialized system, as long as the temperature variation of rice matched with the standard temperature curve, the gas flow temperature could vary to specific conditions.

Average temperature of rice during roasting by model predicted

The curve of degree of rice gelatinization that changes over time during the rice roasting is a S-shaped curve that shows fast changes in the middle while slow ones at both ends. Due to the fact that the gelatinization process is influenced by a combination of factors, it could not be classified as a first-order or zero-order reaction.

The roasting process is divided into two stages, i.e., the stage before the melting of rice starch and the puffing stage of rice. In the first stage, the molecular structure of rice changes greatly as the temperature increases and a large number of bubbles are observed, which paves the way for the puffing process of rice. In the puffing stage, rice turns into thermoplastic fluid due to the melting of solid substance in rice at high temperature, and swells rapidly under the internal pressure of bubbles. Therefore, this stage is where the macroscopic structure of rice changes. The overlapping period between the above-mentioned two stages is between the 20 s and 25 s. The key to the whole process is pre-puffing stage in which molecular changes have been basically completed as the efficient heat transfer between airflow and rice in this stage ensures the rapid heating of rice. In the puffing stage, to prevent the temperature of rice continues to rise is critical at this stage, in order to avoid side effects.

By numerical simulation, it is found that temperature gradient in rice is relatively low and temperature changes in a small range in the late during rice roasted at 200°C, therefore, roasted rice that have both high gelatinization and lower surface browning rice, and be allowed to have broad residence time distribution in the fluidized bed. In comparison, rice roasted at 220°C, the temperature rises faster, but larger temperature difference in rice and temperature is too high in the late. This will make the rice browning, therefore, must accurately control the residence time of the rice in the fluidized bed. The results further support the view on the rice roasting process was divided into two stages, at the same time, thought that the best temperature change pattern of rice in the roasting process was obtained.

The average temperature curve during roasting can reflects the temperature change patterns of rice, therefore, rice average temperature curve when roasted at 200°C is determined as the standard temperature control curve. Temperature of roasted rice should be based on the standard temperature control curve as a benchmark. The temperature change of rice during roasting should be control similar to the curve, in order to ensure the quality of the roasted rice. Since differences in equipment and operating conditions, the temperature of the heating medium is not necessarily 200°C, as long as the temperature change of the rice itself and the standard temperature control curve can be similar.

Acknowledgements This project was funded by the Priority Academic Program Development of the Jiangsu Higher Education Institution. The authors would like to thank Cai Zhen Duan, for useful comments and assistance in proofreading the manuscript.