2016 Volume 22 Issue 3 Pages 317-323

2016 Volume 22 Issue 3 Pages 317-323

Isada krill (12.5 kg) was first treated under subcritical water conditions at 140°C or 160°C by injecting steam into a large pressure-resistant vessel, and it was then separated into liquid extract and solid residue. The solid content, salt concentration, protein content, antioxidative activity, and odor intensity of the extract, as well as the color and odor of the residue, were determined. The preference score and flavor characteristics of both the extract and the residue were assessed by sensory evaluation. The results for the extracts and residues prepared by the large-scale treatment were roughly the same as those for the extracts and residues prepared using a 117-mL small vessel operated at similar severity factors. Both the extracts and residues exhibited a pleasant shrimp-like flavor, and would be promising as seasonings.

Isada krill (Euphausia pacifica) is a small crustacean found mainly on the Sanriku Coast of Japan. Because of rapid deterioration catalyzed by endogenous enzymes (Kawamura et al., 1981) and the development of bad smell and color after harvesting, Isada krill is mostly used in animal feed and aquaculture. However, the krill contains beneficial compounds for human diet, such as fatty acids (Cripps et al., 1999), proteins (Chen et al., 2009), and amino acids (Ali-Nehari et al., 2011). The shrimp-like flavor has been used as a savory flavor enhancer in seafood sauce, soup, and surimi (Kim et al., 2010). 2-Acetyl-1-pyroline and 2-acetylthiazole (Morita et al., 2001) and 2,5-dimethylpyrazine and 3,5-dimethylpyrazine (Tachihara et al., 2004) were found to have shrimp-like flavors. The shrimp-like flavors of roasted shrimp were extracted and concentrated by distillation (Kubota et al., 1986).

Subcritical water occurs in the liquid state between 100°C to 374°C under pressurized conditions. The water has two distinct features: a high ion product and a low relative dielectric constant. Due to these features, the water is used to obtain useful materials from marine sources, such as scallop (Tavakoli and Yoshida, 2006), squid (Uddin et al., 2010; Yoshida and Tavakoli, 2004; Kim et al., 2013), and defatted krill (Ali-Nehari et al., 2011). We also reported that treatment of the semi-dried and raw krill (Koomyart et al., 2015a, 2015b) under subcritical water conditions could produce liquid extracts and solid residues with a pleasant flavor, and may be prospective seasoning ingredients.

In the previous reports, we used a small pressure-resistant vessel with an inner volume of 117 mL, and the vessel was heated using either an external mantle heater or by immersion in an oil bath (Koomyart et al., 2015a, 2015b). However, such heating methods would be inadequate or inconvenient for treating the krill in large quantities. In this study, heating by direct injection of steam into a large vessel was used to treat a 12.5 kg batch of raw krill, and the properties of the liquid extract and solid residue prepared using the large vessel were compared with the material prepared using the 117-mL small vessel.

Materials Isada krill used for large-scale treatment was caught near Ishinomaki (Miyagi, Japan), and was supplied by Kinoya Ishinomaki Suisan (Miyagi). The krill used for small-scale treatment was caught from the Sanriku Coast and was obtained from Hamaichi (Wakayama, Japan). The average weight and length of the latter krill were 35.9 ± 10.5 mg and 17.9 ± 2.7 mm (n = 20), respectively. Folin-Ciocalteu reagent, bovine serum albumin (BSA), 1,1-diphenyl-2-picrylhydrazyl (DPPH), and 6-hydroxy-2,5,7,8-tetramethylchromane-2-carboxylic acid (Trolox) were purchased from Wako Pure Chemical Industries (Osaka, Japan). Raffinose and Dextran T-10, which were used to prepare the calibration curve for size exclusion chromatography, were purchased from Nacalai Tesque (Kyoto, Japan) and GE Healthcare Japan (Tokyo, Japan), respectively. Powdered instant coffee, which was used to refresh the sense of smell, was a product of Key Coffee (Tokyo).

Treatment of Isada krill under subcritical water conditions A large-scale treatment using the Isada krill caught near Ishinomaki was conducted by Communication Link (Sendai, Japan). The frozen krill (12.5 kg) was thawed at room temperature, and was then pressure-filled by N2 gas into a large pressure-resistant vessel. The pressure in the vessel was reduced to atmospheric pressure, and high-pressure steam was injected into the vessel to increase the temperature to the desired level (140°C or 160°C). After maintaining the temperature at 140°C and 160°C for 17 min and 4 min, respectively, the liquid extract was withdrawn into a cooler with a water jacket by introducing steam into the tracing line. The extract was cooled down to room temperature (ca. 30°C) and then weighed. The temperature inside the vessel was recorded every minute. The extract was filled into polyethylene bags and stored in a freezer. The solid residue in the vessel was gathered up by using a scraper and was kept frozen in bags. The treatments using the large vessel at 140°C and 160°C were designated as L140 and L160, respectively, and the extract and residue were abbreviated E and R, respectively. The crude extract and residue were further refined. The crude extract was filtered through a No. 2 Advantec filter paper (Tokyo, Japan) under reduced pressure, and the crude residue was put into a Teflon mesh bag (MS-150, 144 µm mesh opening, 25 × 100 mm, Semitec, Tokyo, Japan) and was further pressed by a hydraulic machine at 7.86 MPa to obtain the compressed residue and the filtrate. The filtrate was combined with the liquid extract, and this mixture was designated solely as the extract (E). The residue remaining in the bag was called the residue (R).

The small-scale treatment was carried out in the same manner as previously reported (Koomyart et al., 2015b). In brief, the thawed krill (20 g; Hamaichi) was put into a 117-mL batch-type vessel (Taiatsu Techno, Osaka, Japan) together with distilled water (20 g). The vessel was tightly sealed and then heated to 140°C or 160°C by immersion in an oil-bath (MH-5E, Rikagaku Sangyo, Chiba, Japan), which was regulated at 230°C. The temperature in the vessel was monitored using a TXN-700B thermometer (As One, Osaka, Japan). After the temperature reached 140°C or 160°C, the vessel was transferred to another EO-200 oil-batch (As One), which was regulated at 153°C (or 173°C) and kept for 17 min (or 4 min). During this period, the temperature was maintained at nearly 140°C or 160°C. After that, the vessel was immediately cooled by immersion in ice water. The treatments using the small vessel at 140°C and 160°C were designated as S140 and S160, respectively. Based on preliminary experiments, the treatment conditions were determined to give almost the same temperature profiles as for L1 and L2, as shown later.

As a control experiment, the ambient-pressure boiling treatment was carried out. The thawed krill (30 g; Hamaichi) and water (30 g) were put in an open aluminum pot and boiled at atmospheric pressure for 10 min. This treatment was designated as C.

The mixture from the small vessel or pot was also separated into the solid residue and liquid extract by the same method as for the crude extract and residue from the large vessel.

Properties of solid residue The wet solid residue (ca. 2 g), which had been weighed precisely, was put in a Petri dish and dried at 135°C for 2 h in a DNF-400 oven (Yamato Scientific, Tokyo). The moisture content of the solid residue was calculated from the difference in the weight between the wet and bone dry residues. The moisture content was expressed on the basis of the dry material in units of kg-water/kg-dry residue.

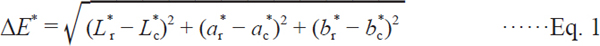

The color of the solid residue, when put in a glass cup (16 mm I.D. × 28 mm) to a height of ca. 10 mm, was characterized using an SA4000 color-difference meter (Nippon Denshoku Industries, Tokyo, Japan) with a D65 light source at a view angle of 10°. The color distance, ΔE*, between the krill residues treated under subcritical and cooking (control) conditions, which are labeled r and c, respectively, was calculated by the following equation:

|

Properties of liquid extract The solid content of the liquid extract (0.4 mL) was measured using a PAL-1 digital hand-held refractometer (Atago, Tokyo, Japan), and was expressed in units of Brix. The salt concentration of the extract (0.4 mL) was measured using a PAL-ES1 digital salt-meter (Atago). The freezing point depression, ΔTf, of the extract was measured using an OM802 osmometer (Vogel, Kevelaer, Germany) as an indicator of the overall molality of the extract.

The total protein content of the extract was determined by the Lowry-Folin method (Lowry et al., 1951). For the determination, the extract required 1000-fold dilution with distilled water. A standard curve was prepared using BSA. The diluted extract or BSA solution (0.4 mL) was mixed with the Lowry reagent (2 mL) and 50% (w/v) Folin-Ciocalteu reagent (0.2 mL). The absorbance of the mixture was measured at 750 nm using a U-5100 spectrophotometer (Hitachi High-Tech Science, Tokyo, Japan). The content was expressed in units of g/L-extract.

The DPPH radical scavenging activity of the extract was determined after clarification by centrifugation at 1 × 104 rpm for 5 min and 100-times dilution with distilled water according to the method by Faithong et al. (2010) with slight modifications. Trolox was used as a reference compound. The diluted extract, 95% ethanol (control) or Trolox solution (0.75 mL), was mixed with 0.15 mmol/L DPPH in 95% ethanol (0.75 mL), and the mixture was then kept in the dark at ambient temperature for 30 min. The DPPH radical scavenging activity was evaluated by measuring the absorbance of the mixture at 517 nm using the U-5100 spectrophotometer. The percentage DPPH radical scavenging activity of the sample was compared with that of Trolox in order to express the DPPH radical scavenging activity as µmol Trolox equivalent (TE)/L-extract.

The liquid extract was appropriately diluted with distilled water to produce a solid content of Brix 6.0. The diluted solution was further diluted 20 times with water, and its absorption spectrum was measured in the wavelength range of 200 – 600 nm using the U-5100 spectrophotometer.

The extract was centrifuged at 1 × 104 rpm for 5 min. The supernatant (15 µL) was applied to a high-performance liquid chromatograph comprising an LC-20AD pump, an RID-10A refractive index detector (Shimadzu, Kyoto, Japan), and a YMC-Pack Diol-60 column (500 × 8.0 mm I.D., YMC, Kyoto, Japan). Distilled water was used as the mobile phase (flow rate: 1.0 mL/min). The mass distribution in the extract was determined using external molecular mass standards comprising glycerol (92 Da), glucose (180 Da), raffinose (595 Da), and Dextran T-10 (1.0 × 104 Da) dissolved in distilled water.

Sensory evaluation and odor intensity The overall preference of the extract and residue was evaluated using the extract (1 mL) or the wet residue (1 g) placed in a 10 mL amber glass bottle at room temperature by a sensory panel containing 12 members. The panelists were instructed to perform preference scoring using the 5-point hedonic scale (−2: dislike extremely, −1: dislike, 0: neither like nor dislike, +1: like, and +2: like extremely). The intensities of shrimp-like, fishy, rotten, burnt, and roasted flavors were also graded using a five-point intensity scale (0, unrecognizable; 4, strong) by the same panelists. The sense of smell was refreshed by smelling the coffee between samples because it was reported that coffee can refresh the olfaction (Dorri et al., 2007).

Odor intensity was measured using an XP-329IIIR odor concentration meter (Cosmos, Tokyo, Japan) and reported as an overall strength of perceived odor for the extract (1 mL) or residue (1 g) in a test tube (14 mm I.D. × 88 mm in height). The emitted odor compounds were detected by the integrated sensor of the meter and were reported in relative strength of odor between 0 to 2000.

Yields of extract and residue Table 1 summarizes the mass balance of the crude extract and residue obtained from the large vessel. Because the injected steam was condensed, the total mass of the crude extract and residue was greater than the initial mass of the krill (12.5 kg). More steam condensed during treatment at 160°C than at 140°C.

| Treatment temperature [°C] | Crude extract [kg] | Crude residue [kg] | Condensed water* [kg] |

|---|---|---|---|

| 140 | 8.88 | 5.37 | 1.75 |

| 160 | 17.18 | 2.25 | 6.93 |

Appearance of extract and residue Figure 1 shows the temperature profiles during the large- and small-scale treatments. Because the treatment was performed non-isothermally, the temperature history during treatment affected the properties of the extract and residue. We demonstrated that severity factor R0, which was defined by Eq. (2) (Overend et al., 1987), could assess the combined effects of temperature and time during subcritical water treatments of coconut meal (Khuwujitjaru et al., 2014) and passion fruit peel (Klinchongkon et al., 2015).

Temperature profiles during the treatment of Isada krill using a large (solid curves) and small (broken curves) vessels at 140°C and 160°C. Labels L and S indicate the large and small vessels, respectively. Values 140 and 160 represent the treatment temperatures. The dotted curve labeled C shows the temperature profile during the boiling treatment (control).

|

where T(t) is the temperature at time t and 14.75 is an empirical constant. The R0 values for the large-scale treatments, L140 and L160, were calculated to be 284 and 304 min, respectively. The R0 values for the small-scale treatments S140 and S160, were 293 and 291 min, respectively, and were almost the same as those for the large-scale treatments because the profiles observed during the small-scale treatments well replicated the profiles during the large-scale treatments. The R0 value during the control experiment was evaluated to be 13, from its temperature history.

Figure 2 illustrates the appearance of the liquid extracts and solid residues obtained by the large- and small-scale treatments as well as that of the extract and residue in the control experiment. The extracts obtained by subcritical treatments were dark brownish, while the extract of the control experiment (C-E) was light brownish. In addition, small differences were observed between the colors of the extracts L140-E, L160-E, S140-E, and S160-E. This would be due to the differences in the raw materials (Isada krill), i.e., their origins, compositions (contents of protein, fat, etc.) were different; and also due to the fact that the condensed water formed during the large-scale treatment would affect the extraction behavior. The dark brownish color of the extracts L140-E, L160-E, S140-E, and S160-E, seem to be ascribed to the Maillard reaction during the treatments at high temperatures.

Appearance of the liquid extracts and solid residues obtained using the large and small vessels at 140°C and 160°C. Labels L and S and values 140 and 160 are the same as in Fig. 1. E and R indicate the extract and residue, respectively. C-E and C-R indicate the extract and residue, respectively, obtained from the boiling treatment (control).

Figure 3 shows the absorption spectra of the extracts. The absorbance of C-E was much lower than those of the extracts obtained by the subcritical treatments. Among the extracts obtained by the subcritical treatment, S140-E exhibited a slightly lower absorbance than others in the visible-light range. The low absorbance of S140-E coincided with its light appearance. Because the R0 values for the S140-E and S160-E are almost the same, some factors other than the R0 value would greatly affect the appearance.

Absorption spectra of the extracts from the large-and small-scale treatments at 140°C and 160°C, which are labeled as L140-E, L160-E, S140-E and S160-E, respectively. C-E is the same as in Fig. 2.

The solid residues obtained by the subcritical treatment, L140-R, L160-R, S140-R, and S160-R, were also dark brownish, while the residue of the control experiment, C-R, exhibited a light pinkish-brown color. The color of the residues, L140-R, L160-R, S140-R, and S160-R, was characterized by the color distance, ΔE*, from that of the residue, C-R (Table 2). The ΔE* of S140-R, whose extract exhibited a lighter brown color than the other extracts, was also a little smaller than those of other residues.

| Residue† | Yield [kg/kg-rnixture] | Moisture content [kg/kg-d.m] | ΔE* | Odor intensity |

|---|---|---|---|---|

| L140-R | 0.145 | 1.98 | 9.68 | 467 |

| L160-R | 0.138 | 1.98 | 8.60 | 248 |

| S140-R | 0.071 | 1.58 | 5.93 | 249 |

| S160-R | 0.083 | 1.97 | 8.51 | 300 |

| C-R | 0.065 | 1.13 | — | 14 |

Properties of extract The characteristics of all the extracts are summarized in Table 3. Yields L140-E and L160-E were calculated for the extracts refined from the crude extract and residue. The wet-basis moisture content of raw Isada krill was about 0.8. The yields of the L140-E and L160-E were lower than those of the S140-E and S160-E because the steam injected into the vessel condensed to dilute the extracts. Because less steam condensed during the treatment at 140°C than at 160°C, the L140-E had a higher solid content, salt concentration, protein content than the L160-E. The high solid content of the L140-E resulted in larger ΔTf than the L160-E. The L160-E had stronger radical scavenging activity than the L140-E despite the lower solid content. Although the R0 value for the treatment at 160°C was almost the same as that for the treatment at 140°C, compounds with higher activity were produced at the higher temperature.

| Residue† | Yield [kg/kg-mixture] | Solid content [Brix %] | ΔTf [°C] | Salt concentration [%] | Protein content [%] | DPPH scavenging activity [mmol/TE/L] | Odor intensity |

|---|---|---|---|---|---|---|---|

| L140-E | 0.653 | 8.6 | 1.018 | 0.90 | 62.80 | 1.24 | 553 |

| L160-E | 0.746 | 7.4 | 0.875 | 0.76 | 50.70 | 1.51 | 387 |

| S140-E | 0.786 | 6.3 | 0.680 | 0.70 | 41.30 | 1.34 | 300 |

| S160-E | 0.782 | 6.8 | 0.708 | 0.71 | 46.90 | 2.18 | 453 |

| C-E | 0.443 | 9.2 | 1.234 | 0.72 | 54.60 | 1.43 | 193 |

| C-Ec | — | 5.2 | 0.698 | — | 30.9 | 0.81 | — |

Because the small vessel was a closed system, the solid content, ΔTf, salt concentration, and protein content of the S140-E were almost the same as those of the S160-E. The radical scavenging activity of the S160-E was higher than that of the S140-E due to the higher treatment temperature.

Because water evaporated during heating in the pan, the yield of C-E was much lower than those from the subcritical treatment. The mass of water lost during heating was added to the C-E to compensate for the loss. The compensated extract was designated as the C-Ec. The solid and protein contents of the C-Ec were much lower than those obtained by subcritical treatment. This indicated that some of solid materials in the krill were solubilized during the subcritical treatment. The radical scavenging activity of the C-Ec was much lower than those of the extracts from the subcritical treatment. This also indicated that the subcritical treatment of the krill was more severe than boiling for producing compounds with antioxidative ability.

Figure 4 illustrates the size exclusion chromatograms for the extracts. The extracts obtained from the subcritical treatment showed larger peaks in the high-molecular-mass range of 103 to 104 than the C-Ec. This coincided with the higher protein content of the extracts from the subcritical treatment. In addition, this indicates that there would be polymerized compounds formed during the treatment by the Maillard reaction. There seemed to be no significant difference in the peak area among the extracts.

Size exclusion chromatograms of the extracts. The labels are the same as in Fig. 3.

Properties of residue The properties of the solid residues are summarized in Table 2. It should be noted that the definition of yield for the residues treated using the large vessel, L140-R and L160-R, are different from that for other residues. The yields for the S140-R, S160-R, and C-R were ca. 0.07, indicating that 90% or more of the krill was recovered as the liquid extract. The color distance of the S140-R, which was a lighter shade of brown, was smaller than the others. Odor intensity was much stronger for the extracts from the subcritical treatment than the C-R. The odor characteristics of the residues were examined in detail by sensory evaluation, as shown later.

Sensory evaluation As shown in Table 4, the residues obtained by the subcritical treatment of the Isada krill had a higher preference score than the control residue, C-R. The liquid extracts obtained at 140°C, L140-E and S140-E, also exhibited a higher preference score than the control extract, C-E.

| Vessel | Treatment temperature [°C] | Extract | Residue |

|---|---|---|---|

| Large | 140 | 0.75 ± 1.01 | 0.75 ± 0.72 |

| 160 | 0.25 ± 0.72 | 1.17 ± 0.80 | |

| Small | 140 | 0.67 ± 1.03 | 1.00 ± 1.00 |

| 160 | 0.42 ± 1.26 | 1.08 ± 0.95 | |

| Boiling (control) | 0.25 ± 1.23 | 0.00 ± 0.82 | |

Values: mean ± S.D.

The smell characteristics evaluated were shrimp-like, fishy, rotten, burnt and roasted flavors for all the extracts and the residues (Figs. 5(a) and (b)). For both the extract and residue, the subcritical treatment weakened fishy and rotten flavors and strengthened shrimp-like, roasted, and burnt flavors compared with the boiling treatment (control). These changes in flavor characteristics are responsible for the improvement of the preference scores of the extracts and residues.

Five-axis cobweb charts for (a) extracts and (b) residues. The labels are the same as in Fig. 1.

In conclusion, large-scale treatment of Isada krill in subcritical water roughly showed the same results as the small-scale one although there were small differences in the properties between large-scale products and small scale ones. Success in the scale up would promise practical production of the seasonings from Isada krill.

Acknowledgments This study was performed under the project “The Creation of Innovative Technology for Marine Products Industry” of the Program for Revitalization Promotion, which was supported by Japan Science and Technology Agency (JST). The krill for the large-scale treatment was supplied by Kinoya Ishinomaki Suisan, Miyagi, Japan.