2016 Volume 22 Issue 5 Pages 655-664

2016 Volume 22 Issue 5 Pages 655-664

Glycogen branching enzyme contributes to the process of glycogen synthesis by creating α (1→6) branches through cleaving the α-1, 4-glycosidic bonds. An intracellular glycogen branching enzyme (named PsGBE) from Paenibacillus sp. SSG-1 was cloned and expressed. The recombinant enzyme was purified by metal-affinity chromatography, exhibited a molecular mass of 84.9 kDa. PsGBE was optimally active at pH 6.6 and 35°C. PsGBE showed high specificity to amylose, soluble starch and amylopectin. PsGBE could attack and change the structures of starch granules. Addition of PsGBE (40 U/100 g of flour) to wheat bread increased specific volume (5.85 mL/g) and decreased crumb firmness (8.16 N) during bread storage. In addition, PsGBE could significantly retard the retrogradation and improve the quality of bread. Therefore, these properties make PsGBE highly potential application in the starch-related industries.

Glycogen is a major storage carbohydrate in bacteria. It is a polysaccharide composed of α-1, 4-linked glucans and highly branched by α-1, 6-glycosidic linkages (Kim et al. 2008, Roussel et al. 2013). Branches have 8–13 glucose residues on average which are more or less regularly distributed alongside the glycogen particle. In bacteria, the glycogen accumulates especially under carbon-abundant and nitrogen-deficient environment (Eydallin et al. 2010, Preiss 1984). The synthesis of glycogen requires ADP- or UDP-glucose pyrophosphorylases (EC 2.7.7.27 or EC 2.7.7.9), synthases (EC 2.4.1.11 or EC 2.4.1.21) and glycogen branching enzymes (Okita et al. 1981). Glycogen branching enzyme (GBE; EC 2.4.1.18) is a carbohydrate-active enzyme which plays an important role in the formation of glycogen branches (Ball et al. 2003, Okita et al. 1981), like the starch branching enzyme (SBE) in the plant. Some GBEs are recently described as members of the glycoside hydrolase family 57 (GH57) (Murakami et al. 2006, Palomo et al. 2011). However, most GBEs belong to subfamily 8 or 9 of GH13, which are also known as the α-amylase family (Stam et al. 2006).

So far, GBEs are known to catalyze the formation of branch points in glycogen by cleavage of α-1, 4-glycosidic bonds and subsequently transfer of the cleaved oligosaccharide to α-1, 6 positions (Boyer et al. 1977, Van Der Maarel et al. 2002). However, the minimal chain length (CL) of donor α-glucan substrate and branching pattern of the reaction products are also different with different GBEs (Palomo et al. 2009, Guan et al. 1997). The GBEs have been identified and biochemically characterized from Cyanobacterium synechococcus (Kiel et al. 1989), Neurospora crassa (Kawabata et al. 2002), Rhizomucor miehei (Wu et al. 2014), Bacillus stearothermophilus (Takata et al. 1994), Neisseria denitrificans (Büttcher et al. 1999), Streptococcus mutans (Kim et al. 2008) and Rhodothermus obamensis (Roussel et al. 2013), but only few of them have been purified and characterized. Most of GBEs display maximal activity within the mesophilic temperature range and neutral pH (Kiel et al. 1989, Lee et al. 2010, Thiemann et al. 2006).

GBEs have been applied in starch-related industries for their unique α-1, 6 transglycosylation activity. GBEs can specifically catalyze the α-1, 4-glycosidic linkages of starch, changing its structure and decreasing amylose percentage in starch, to reduce the retrogradation. Starch modified by GBEs is applied to improve the quality of food products, such as cookies, cakes and breads (Spendler et al. 1997, Wu et al. 2014, Oliveira et al. 2014). GBE from N. crassa can increase the solubility and stability of starch solutions (Kawabata et al. 2002). GBE from S. mutans could retard rice starch's retrogradation (Kim et al. 2008). GBE from Rhizomucor miehei could improve quality and increase shelf life of wheat bread (Roussel et al. 2013). However, there are few reports about the applications of bacterial GBE, and the detailed mechanisms require further investigation.

In our previous study, we found an agar-degrading strain Paenibacillus sp. SSG-1 which was isolated from the soil of Sichuan, China (Song et al. 2014). As far as we have known, the intracellular glycogen branching enzyme of Paenibacillus sp. SSG-1 had not been reported. In this work, we cloned and expressed a new glycogen branching enzyme PsGBE from Paenibacillus sp. SSG-1. Biological characteristics and characterization of the substrate specificity of the recombinant PsGBE were reported. Moreover, we investigated the influence of PsGBE on wheat bread quality and the staling process. To our knowledge, it is the first report to dealing with Paenibacillus sp. enzymes as a bread improver.

Strains, plasmids and culture conditions Paenibacillus sp. SSG-1 was deposited at China Center for Type Culture Collection (CCTCC) under the preservation number CCTCC CB 2015001. The strain was grown in Luria-Bertani (LB) medium at 37°C. Escherichia coli BL21 (DE3) were used as the host for protein expression. E. coli harbouring the recombinant plasimid was grown in LB broth at 37°C with kanamycin (50 µg/mL). The plasmid pET-28a (+) (Invitrogen, China) was used as vector for gene cloning and protein expression.

Cloning and sequence analysis of the PsGBE The nucleotide sequence of PsGBE was retrieved from the result of whole genome sequence annotation. The gene was amplified by PCR with the genomic DNA as a template. The primers which used to clone the gene were designed as PsGBE-PF 5′-CGCGGATCCATGCACTATATTCC-3′ and PsGBE-PR 5′-CCGCTCGAGTTCATTGATCCG-3′ (restriction enzyme sites BamH I and Xho I were underlined), respectively. The purified PCR products were ligated to pET28a(+) vector and transformed into E. coli BL21 (DE3) for sequencing and protein expression. BLAST analysis was performed at the NCBI server (http://blast.ncbi.nlm.nih.gov/Blast.cgi). Signal peptide was analysed by the SignalP 4.1 server (http://www.cbs.dtu.dk/services/SignalP/). Multiple-alignment analysis was performed by MEGA 6.06 (Takata et al. 1994). The subcellular location was analysed by Gpos-mPLoc (http://www.csbio.sjtu.edu.cn/bioinf/Cell-PLoc-2/). The analysis of homologous protein domains was performed at the ProDom database (http://prodom.prabi.fr/prodom/current/html/home.php).

Expression and purification of the recombinant glycogen branching enzyme The single colony of E. coli BL21 (DE3) transformant harbouring pET-28a(+)-PsGBE was grown in LB medium containing kanamycin (50 µg/mL) on a rotary shaker (80 ×g) at 37°C until the optical density at 600 nm reached 0.6. Then cell culture was induced with 0.4 mM isopropyl thiogalactoside (IPTG) at 16°C for 24 h, resulting in overproduction of the recombinant PsGBE. The transformant cells were harvested by centrifugation (10,000 ×g for 10 min at 4°C), resuspended in 20 mM phosphate lysis buffer (pH 7.4) and disrupted by ultrasonic broken instrument. The cell extract was acquired by centrifugation twice at 10,000 ×g for 10 min at 4°C. The supernatant which contained the His-tagged recombinant PsGBE was loaded onto and purified by nickel-nitrilotriacetic acid (Ni-NTA) affinity column chromatography (QIAGEN, Germany).

SDS-PAGE and protein determination The purified recombinant PsGBE was estimated by SDS-PAGE in an 8% (w/v) acrylamide gel to analyse the molecular mass of the recombinant protein. The sample was separated for 90 min at 15 V·cm−1 under the conditions described in the method of Laemmli (Laemmli 1970), and subsequently stained by Coomassie Blue R-250. The protein concentration was determined according to Bradford's method with bovine serum albumin as a standard (Bradford 1976).

Enzyme assay and determination To assay the PsGBE, an iodine-staining assay with slight modifications was performed as described by Takata et al. (Takata et al. 1994). Mixtures of 0.2 mL containing 0.1% (w/v) type III amylose (Sigma-Aldrich, MO, USA) dissolved in 50 mM citrate buffer (pH 6.6) and 1.10 µg purified PsGBE were incubated at 35°C for 20 min. The reaction was terminated by adding 1.6 mL of 0.4 mM HCl, and then 2 mL of iodine reagent which was made daily from 0.125 mL stock solution (0.26 g iodine and 2.6 g potassium iodide in 10 mL water), 0.5 mL of 1 M HCl, and deionized water to a final volume of 65 mL was added to the solution. The absorbance of the amylose-iodine complex was measured at 620 nm (A620). One unit of enzyme activity was defined as the decrease of 1% the amylose-iodine complex absorbance per minute. Wave scans of the amylose-iodine complexes were also performed from 400 to 800 nm, which were used to determine the change in the shape and maximal wavelength.

Biochemical properties of PsGBE The optimal pH of PsGBE was determined at 35°C in various buffers (50 mM) of citrate buffer (pH 3.0–6.6), sodium phosphate buffer (pH 6.0–8.0), Tris-HCl buffer (pH 7.5–9.0) and glycine-NaOH buffer (pH 8.5–10.5). The effect of pH on PsGBE stability was measured under the standard conditions described above after incubated in the above pH buffers for 1 h at 35°C. The optimal temperature was compared in a temperature range of 0 – 65°C in 50 mM citrate buffer (pH 6.6). To determine thermal stability, the PsGBE was pre-incubated at different temperatures for 1 h and residual activity was measured under the optimum conditions.

The effect of various reagents and metal ions on PsGBE was determined by assaying for residual activity after incubating the enzyme with 1 mM each reagent dissolved in 50 mM citrate buffer (pH 6.6) for 20 min at 35°C. The remaining activity was assayed using amylose and compared with the control (enzyme without the addition of reagent).

Substrate specificity of PsGBE The substrate specificity of PsGBE was tested using several different polysaccharide substrates (0.1%, w/v): soluble starch, amylose, amylopectin, β-cyclodextrin, glycogen, pullulan, wheat starch, corn starch and pea starch. The soluble starch and amylase were gelatinized and dissolved in the buffer by heating in the 100°C water bath before use. After the reaction of the PsGBE and different substrates, the enzyme's activity was determined by measuring the decrease in 620 nm as described above.

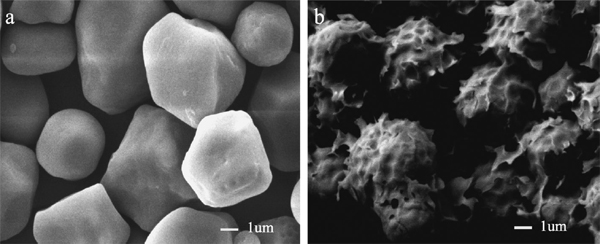

Scanning electron microscopy (SEM) A mixture of 1% (w/v) wheat starch and 11 µg purified PsGBE to a final volume of 0.2 mL in 50 mM citrate buffer (pH 6.6) was incubated at 35°C for 48 h. The pellet was harvested by centrifugation, then washed twice with 95% ethanol and dried at 35°C for 24 h. The treated starch granules were coated with Au using Cressington 208HR SPUTTER COATER (America) and photographed using SEM (JSM-7500F).

Bread-making The bread recipe involved the following ingredients: yeast (2%), salt (1.5%), sugar (4%), butter (3%) and water (60%), which were all in fresh weight relative to the amount of wheat flour. PsGBE was added into the flour at concentrations of 10, 20, 30 and 40 U/g of flour before mixing. Bread made without PsGBE served as the control. Bread dough was prepared by a mixing machine (Oumeijia, SMF25, China) with mixing condition for 10 min for gluten development, rested for 10 min, divided into 50 g portions, shaped, allowed to rest for 15 min, panned in baking pans and proofed at 80% relative humidity for 1 h at 35°C. The dough was baked at 180°C for 10 min. After baking, the bread was cooled for 2 h at room temperature, packaged in polyethylene bags and stored at 4°C for 0, 1, 3, 5 and 7 days for staling studies.

Effects of PsGBE on bread quality The specific volume of the bread was measured according to the AACC method (Committee 2000) and calculated as the ratio between volume and weight (mL/g).

The crumb firmness of the bread was determined on a texture analyzer (TMS-PRO, USA) according to the AACC method (Committee 2000). The test speed was 1 mm/s. Samples of the bread (25 mm thickness) were compressed for 5 s until the sample deformation reached 40%. The force was defined as the firmness value of the crumb.

Water content in bread crumb Crumb moisture contents of the bread stored for different days were analyzed using an infrared moisture analyzer (Fenxi, CSY-H1, China). About 1 g each of crumb was used for the analysis. Three replicates of all samples were analyzed.

Measurement of retrogradation by differential scanning calorimetry (DSC) Thermal analysis of PsGBE treated the bread was performed using a differential scanning calorimeter (DSC2, Mettler-Toledo, Switzerland) as described by Oliveira et al. (Oliveira et al. 2014). Each 1 mg of sample and 9 mg of distilled water were directly weighed into DSC silver pan, dispersed by a needle, sealed hermetically, and left for 3 h to equilibrate. The pan with sample was scanned from 30 to 110°C (5°C /min) to complete gelatinization. A pan containing 9 mL of deionized water was used as a reference. The melting enthalpy (ΔH) of retrogradation was measured.

Nucleotide sequence accession number The nucleotide sequence of PsGBE gene in Paenibacillus sp. SSG-1 has been submitted to DDBJ (DNA Data Bank of Japan) under accession no. LC102186.

Cloning and sequence analysis of PsGBE We successfully amplified and sequenced the entire PsGBE gene by PCR using PsGBE specific oligonucleotide primers (PsGBE-PF and PsGBE-PR). The putative full-length ORF of PsGBE was 2145 bp, encoding a single polypeptide of 714 amino acids. The molecular mass of purified recombinant PsGBE was 84.9 kDa. The result of SignalIP showed PsGBE had no signal peptide and the prediction of subcellular location also show the same result. So, PsGBE was an intracellular protein with no signal peptide.

The results of homology search by BLAST revealed that Paenibacillus sp. SSG-1 PsGBE had about 56% identity with branching enzyme from Halothermothrix orenii H168 (ACL69450.1), 54% from Geobacillus stearothermophilus (AAA22482.1), 54% from B. anthracis (AIF59015.1), 54% from B. cereus G9842(ACK97294.1), and 53% from B. weihenstephanensis KBAB4(ABY45863.1), respectively. PsGBE shared significant similarity with α-1, 4-glycogen branching enzymes from bacteria. The phylogenetic tree of Paenibacillus sp. SSG-1 PsGBE was shown in Figure 1. The protein domain of PsGBE showed obvious difference with other branching enzymes. There was a trehalose domain found in the PsGBE.

Phylogenetic relationship of PsGBE. The substitution rate (0.1 amino acid replacements per site) is indicated by the bar (at the lower left corner). Bootstrap values (1000 bootstrap trials) are marked along each branch node. Abbreviations and accession numbers of the branching enzymes are as follows: Halothermothrix orenii H168 (ACL69450.1), Geobacillus stearothermophilus (AAA22482.1), Bacillus anthracis (AIF59015.1), Bacillus cereus G9842 (ACK97294.1), Bacillus weihenstephanensis KBAB4 (ABY45863.1), Bacillus caldolyticus (CAA78440.1), Marinobacter hydrocarbonoclasticus VT8 (ABM18520.1), Synechococcus sp. JA-3-3Ab (ABD00202.1), Francisella tularensis (KFJ37710.1), Aquifex aeolicus VF5 (AAC06895.1), Prochlorococcus marinus str. MIT 9301 (ABO17233.1), Mycobacterium sp. JLS (ABN99623.1), Mycobacterium tuberculosis H37Rv (3K1D A). The homologous protein domains were listed after the accession number. The trehalose domain was in the blue box.

Multiple alignments of PsGBE with other bacteria glycogen branching enzymes demonstrated that PsGBE shares four highly conserved sequences (I, II, III and IV) and several important invariant residues, which were common characteristics of the GH13 family (Fig. 2). On the basis of the sequence comparison between PsGBE and other branching enzymes, D358 in region II, E418 in region III and D487 in region IV are predicted to be the respective catalytic sites in GH13 family. The aforementioned results indicated that PsGBE was a new glycogen branching enzyme.

Multiple alignment of amino acid sequences for PsGBE with other branching enzymes. Identical residues are shown in red. Conserved residues are shown in black. The four highly conserved regions are shown in black boxes. Asterisks signify the putative catalytic triad. Branching enzymes from Halothermothrix orenii H168 (ACL69450.1), Geobacillus stearothermophilus (AAA22482.1), Aspergillus oryzae (BAB69770.1), Marinobacter hydrocarbonoclasticus VT8 (ABM18520.1), Neurospora crassa (CAB91480.2), Rhizomucor miehei (AGV00788.1).

Expression and purification of the recombinant PsGBE PsGBE protein was successfully expressed in E. coli BL21 (DE3) at 16°C in the presence of 0.4 mM IPTG for 16 h. The purified enzyme showed a single protein band on SDS-PAGE, and the molecular mass of purified recombinant PsGBE was estimated to be approximately 84.9 kDa (Fig. 3). The specific activity of the purified PsGBE was 98.63 Umg−1.

SDS-PAGE analysis of recombinant purified PsGBE. Lane M, Low molecular weight protein markers (Biomed, sizes are indicated); lane 1, crude extract; lane 2, purified PsGBE.

The branching action of PsGBE on amylose was investigated by analyzing the iodine-amylose complex. After the enzymatic reaction, there was an obvious decrease of absorbance at the optimal wavelength which shifted from 620 nm to 590 nm (Fig. 4a). The ability of amylose to form the iodine complex decreased rapidly in the progression of the enzymatic reaction (Fig. 4b). The α-1, 6-branching points increasing in the amylose could result in decline and left shift of the maximal absorption at wavelength (Kim et al. 2008).

(a) Wave scans of amylose-iodine complex before and after PsGBE treated. (b) Time-dependent changes in maximal iodine absorption. Absorbance at 620 nm (λmax of intact amylose-iodine complex) was measured.

Biochemical properties of PsGBE The biochemical properties of PsGBE were determined using amylose as the substrate. PsGBE displayed a maximum activity at pH 6.6 (Fig. 5a). The enzyme was fairly stable between pH 5.5 and 7.5, retaining more than 80% of its activity (Fig. 5b). The optimum temperature for PsGBE activity was 35°C (Fig. 5c), retaining about 80% of its activity at 0 – 45°C for 1 h (Fig. 5d). PsGBE showed favor similar conditions in the cytoplasm and less stable under in vitro conditions. Unlike other GBEs losing more than 50% activity below 30°C (Kiel et al. 1989, Lim et al. 2003), PsGBE exhibited more than 80% activity in the low temperature range of 15 – 30°C, which may have potential use in the food industry like the glycogen branching enzyme RmGBE from Rhizomucor miehei (Wu et al. 2014).

Optimal pH (a), pH stability (b), optimal temperature (c) and thermostability (d) of the purified PsGBE. The effect of pH and temperature on PsGBE activity was determined as described in Materials and Methods: citrate buffer (◆), sodium phosphate buffer (×) Tris-HCl buffer (▴), glycine-NaOH buffer (■).

The effects of various metal ions and chemical reagents on PsGBE activity were analysed (Table 1). The enzyme's activity was significantly enhanced by some metal ions, such as Na+ (132.47%), K+ (129.79%), Li2+ (121.74%), Ca2+ (130.68%) and Fe2+ (117.20%). Zn2+ (0.80%), Cu2+ (0.25%), Ni2+ (4.24%), Co2+ (42.70%) and Pb2+ (26.26%) strongly inhibited the enzyme activity. β-mercaptoethanol (29.65%) had a strong inhibitory effect, whereas urea had no effect on activity (Table 1). Obvious increase of activity was observed in the presence of DTT (116.92%), SDS (108.94%) and EDTA (115.43%), suggesting that metal ions or disulphide bonds was not required for activity of the recombinant enzyme.

| Metal ion or chemical reagent | Specific activity (U mg−1) | Relative activity (%) | Metal ion or chemical reagent | Specific activity (U mg−1) | Relative activity (%) |

|---|---|---|---|---|---|

| None | 51.71 ± 1.44 | 100.00 | Mn2+ | 41.61 ± 2.89 | 80.46 |

| Na+ | 68.50 ± 1.40 | 132.47 | Fe2+ | 60.60 ± 2.92 | 117.20 |

| K+ | 67.11 ± 0.77 | 129.79 | Co2+ | 22.08 ± 2.59 | 42.70 |

| Li2+ | 62.95 ± 2.90 | 121.74 | Pb2+ | 13.58 ± 1.04 | 26.26 |

| Zn2+ | 0.42 ± 0.21 | 0.80 | EDTA | 59.69 ± 1.97 | 115.43 |

| Cu2+ | 0.13 ± 0.06 | 0.25 | PMSF | 36.65 ± 4.96 | 70.88 |

| Ni2+ | 2.19 ± 0.79 | 4.24 | urea | 47.58 ± 2.23 | 92.02 |

| Mg2+ | 51.39 ± 3.23 | 99.38 | SDS | 56.34 ± 4.19 | 108.94 |

| Ca2+ | 67.58 ± 2.50 | 130.68 | β-mercaptoethanol | 15.33 ± 0.37 | 29.65 |

| Ba2+ | 43.49 ± 3.27 | 84.11 | DTT | 60.46 ± 0.12 | 116.92 |

Substrate specificity of PsGBE The substrate specificity of PsGBE was determined on various substrates (Table 2). PsGBE showed the highest specificity toward amylose (98.63 U/mg, 100%), followed by soluble starch (82.40%), amylopectin (61.16%), glycogen (37.06%), but exhibited low activity on corn starch (32.16%), wheat starch (30.56%), pea starch (28.55%), β-cyclodextrin (22.82%) and pullulan (11.21%). PsGBE displayed much higher activity toward amylose than amylopectin, which was similar to the glycogen branching enzymes from E. coli (Guan et al. 1997), Rhodothermus obamensis (Shinohara et al. 2001) and Rhizomucor miehei (Wu et al. 2014). The results of substrate specificities show that PsGBE prefers amylose rather than highly-branched amylopectin. Starch is composed of two macromolecules: amylose and amylopectin which are different in corn, potato and wheat starch (Tester et al. 2004). The amylose in starch could lead to high tendency for starch retrogradation, which results in many quality defects in food products, such as bread staling (Kawabata et al. 2002). The high specific activity of PsGBE toward amylose could reduce the retrogradation of starch, which could improve the quality of the food. Therefore, PsGBE may have a potential use in the starch-related industries, such as food, paper and pulp.

| Substrates | Specific activity(Umg−1) | Relative activity(%) |

|---|---|---|

| soluble starch | 81.27 ± 0.22 | 82.40 |

| amylose | 98.63 ± 1.73 | 100.00 |

| amylopectin | 60.32 ± 2.39 | 61.16 |

| β-cyclodextrin | 22.51 ± 1.49 | 22.82 |

| pullulan | 11.05 ± 1.01 | 11.21 |

| glycogen | 36.56 ± 1.29 | 37.06 |

| corn starch | 31.72 ± 1.03 | 32.16 |

| wheat starch | 30.14 ± 0.48 | 30.56 |

| pea starch | 28.16 ± 0.43 | 28.55 |

Scanning electron microscopy Scanning electron microscopy of PsGBE treated granules showed that wheat starch granules surface changed after enzyme incubation (Fig. 6). Large potholes with a corrugated appearance were found on the surface of wheat granules. SEM showed that PsGBE could attack and change the structures of starch granules.

SEM analysis of untreated (a) and treated (b) wheat starch granules by PsGBE.

Effects of PsGBE on bread quality The specific volume of the bread made with the addition of PsGBE increased when compared to the control (4.47 mL/g, without PsGBE) (Fig. 7). There was a significant effect on bread specific volume with a maximal 30.9% increase in volume (5.85 mL/g) when 40 U/100 g of flour PsGBE was added. However, there were no significant differences in specific volume (4.61 mL/g) when the addition of PsGBE was 10 U/100 g of flour. So, high concentrations of PsGBE could increase the specific volume of bread. Fungal glycogen branching enzyme also could increase the specific volume of bread (Wu et al. 2014). BSuA, an effective antifirming β-amylase widely used in breadmaking, could increase the bread volume only to 6.72% (Goesaert et al. 2009). PsGBE may help forming a more flexible and stable dough which would have a greater ability to expand during baking.

Specific volume (a) and photograph (b) of breads with and without added PsGBE. From left to right: control, bread with concentrations of 10, 20, 30 and 40 U/g of flour PsGBE.

The crumb firmness of the bread was used to analyze the staling effects in both control and enzyme added breads (Fig. 8). The crumb firmness of all bread samples increased progressively during 7 days of storage. However, the PsGBE-added samples were markedly less firm. On the seventh day of storage, hardness of the bread with 40 U/100 g of flour PsGBE were significantly lower than that of the control bread, and no texture profile difference with the sample with 30 U/100 g of flour PsGBE. The crumb firmness was only 8.16 N which decreased 57.8%. Goesaert et al. found amylase BSuA could decrease crumb firmness by 56.37% (Goesaert et al. 2009). It was reported that GBEs could convert amylose into branched amylopectin, decreasing the content of amylose, and change the structure of starch (Takata et al. 1996a, Takata et al. 1996b). The results indicated that PsGBE could considerably retard bread staling, and increase bread quality.

Effect of PsGBE on crumb firmness during bread storage at 4°C.

Moisture content of bread The moisture of fresh bread is directly related to its softness. Table 3 showed the moisture contents of the bread crumb with or without PsGBE after storage at 4°C for up to 7 days. The crumb moisture content of fresh bread with or without enzyme was approximately 43%. The moisture content of control samples decreased from 43.45% to 34.65%, whereas the samples with added PsGBE decreased to 36%-38%. The moisture loss from bread crumb increased the bread staling (Rogers et al. 1988). Piazza and Masi concluded that slowing the dehydration rather than increasing the initial moisture content prevented staling (Piazza et al. 1995). During the bread storage, the extent of decrease in bread moisture was lower than the samples with PsGBE, suggesting that PsGBE slowed down the dehydration rate during storage. Thus, PsGBE considerably affected the quality of the bread.

| PsGBE (U/100 g of flour) | Moisture content (%) | ||||

|---|---|---|---|---|---|

| Day 0 | Day 1 | Day 3 | Day 5 | Day 7 | |

| 0 | 43.45 ± 0.33 | 42.62 ± 0.26 | 39.82 ± 0.34 | 35.34 ± 0.27 | 34.65 ± 0.18 |

| 10 | 43.14 ± 0.16 | 42.81 ± 0.17 | 40.48 ± 0.25 | 37.79 ± 0.32 | 35.95 ± 0.43 |

| 20 | 43.32 ± 0.25 | 42.66 ± 0.32 | 40.65 ± 0.42 | 38.94 ± 0.18 | 36.13 ± 0.31 |

| 30 | 43.56 ± 0.31 | 42.57 ± 0.42 | 41.28 ± 0.35 | 40.67 ± 0.37 | 38.85 ± 0.11 |

| 40 | 43.21 ± 0.17 | 42.56 ± 0.40 | 41.35 ± 0.32 | 40.48 ± 0.14 | 38.90 ± 0.26 |

Effects of PsGBE on retrogradation of bread According to measure the increase in the enthalpy (ΔH) of the retrogradation endotherm during the storage period, the effect of PsGBE on staling of bread was evaluated (Table 4). The ΔH of both control and PsGBE-treated samples increased in the process of storage, which due to the starch retrogradation. However, compare with the control, the ΔH of PsGBE-treated samples had different degree of reduced. On the seventh day of storage, the ΔH of sample with 40 U/100 g of flour PsGBE was 2-fold lower than the control. The starch retrogradation is an important factor in the staling process of bread (Gray et al. 2003). High amylose content and amylopectin with longer chain lengths in starch inevitably aggravate the degree of retrogradation (Kohyama et al. 2004, Varavinit et al. 2003). The addition of PsGBE could significantly decrease the retrogradation enthalpy ΔH by 50.7% during seven days of storage. Amylase BSuA addition also could lead to lower retrogradation enthalpy values (Goesaert et al. 2009). The ΔH could decrease 41.1%, which was of recrystallized amylopectin, which was below PsGBE. The significant reduction in bread retrogradation might be attributed to PsGBE which catalyzed branching and changed the content of amylose and amylopectin in the bread.

| PsGBE (U/100 g of flour) | ΔH (J/g) | |||

|---|---|---|---|---|

| Day 1 | Day 3 | Day 5 | Day 7 | |

| 0 | 1.93 ± 0.08 | 2.08 ± 0.02 | 2.43 ± 0.10 | 2.98 ± 0.06 |

| 10 | 1.66 ± 0.03 | 1.84 ± 0.04 | 2.18 ± 0.05 | 2.54 ± 0.05 |

| 20 | 1.42 ± 0.02 | 1.67 ± 0.10 | 1.94 ± 0.07 | 2.13 ± 0.05 |

| 30 | 1.11 ± 0.04 | 1.19 ± 0.02 | 1.32 ± 0.03 | 1.48 ± 0.03 |

| 40 | 1.03 ± 0.01 | 1.16 ± 0.02 | 1.34 ± 0.01 | 1.47 ± 0.05 |

This work reported a novel intracellular glycogen branching enzyme PsGBE which was cloned and expressed in E. coli. It was the first time to report an intracellular GBE in Paenibacillus sp.. Biochemical properties and the activity of PsGBE were investigated. PsGBE showed higher specificity for amylose. PsGBE could increase specific volume of the bread, reduce the bread crumb firmness, and decrease the bread retrogradation. These results clearly present evidence that PsGBE could improve the properties of the bread and retard staling. Thus, PsGBE possesses great potential in the food and starch industries.

Acknowledgments This work was supported by National Twelfth Five-year Science and Technology support program (2014BAD02B02), National Natural Science Foundation of China (31272659), National Infrastructure of Natural Resources for Science and Technology Program of China (NIMR-2014-8) and Sichuan Science and Technology Bureau (2014GXZ0005, 2013GZ0058, 2012GZ0008, 2015JCPT0003).