2017 年 23 巻 4 号 p. 517-523

2017 年 23 巻 4 号 p. 517-523

Lysophosphatidic acid has a role in protecting the gastrointestinal tract, and is formed from the digestion of exogenous foodstuff-derived phosphatidic acid (PA) in the human digestive tract. Japanese mustard spinach (Komatsuna) is an important source of foodstuff-derived PA. PA does not accumulate at high levels in Komatsuna, but is abundantly released upon grinding of Komatsuna. To manufacture PA-rich food using Komatsuna, the characteristics of micro wet milling (MWM) and PA production of Komatsuna were investigated. The results show that after grinding, PA was found at sufficient levels in Komatsuna, and MWM could effectively decrease the particle size as well as release PA. As the particle size of Komatsuna tissues decreased, the measured amount of PA increased. This phenomenon can be explained by the high proportion of native Komatsuna PA released from the biomembrane due to particle disruption, and possibly by the release of endogenous phosphatidylcholine during grinding, which is then converted to PA by phospholipase D.

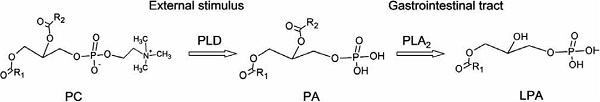

Phospholipids (PLs), the most important class of polar lipids in foods, are ubiquitous nutritional compounds because they are the major components of animal and plant cell membranes (Restuccia et al., 2012). Phosphatidic acid (PA) is a diacyl-glycerophospholipid that serves as a precursor for the biosynthesis of complex functional lipids and acts as a cellular signaling molecule (Ohlrogge and Browse, 1995; Testerink and Munnik, 2005). PA is hydrolyzed from phosphatidylcholine (PC) by phospholipase D (PLD), and is also a precursor of lysophosphatidic acid (LPA), a simple PL, which is generated by phospholipase A2 (PLA2). The transformation pathway of PC, PA and LPA, which mainly occurs during homogenization and digestion of plant tissues in the GI tract, is shown in Figure 1. Recent findings revealed that the supplementation of LPA shows a protective effect on the gastrointestinal (GI) mucosa (Tokumura, 2011).

The possible transformation pathway of PC, PA and LPA, which mainly occur during the homogenization and digestion of plants tissue in GI tract. Abbreviations used: PC, phosphatidylcholine; PLD, phospholipase D; PA, phosphatidic acid; PLA2, phospholipase A2; LPA, lysophosphatidic acid.

A large part of the LPA provided to the GI tract upon the ingestion of foodstuff may be attributed to PA hydrolysis (Tanaka et al., 2013; Uthe and Magee, 1971). A previous study showed that the ingestion of fresh cabbage juice reduced the period required for the healing of stomach ulcers (Cheney, 1949). PA-rich foodstuffs, such as cabbage leaves, radish root, and Japanese mustard spinach leaves, are thought to be good sources of LPA, which is effective against gastric ulcer or diarrhea (Li et al., 2005). PA is the major structural component of cell membranes but does not accumulate at high levels in the membrane under normal conditions (Tanaka et al., 2012). However, it is rapidly and transiently generated in response to biotic and abiotic stresses in plants, such as osmotic, salinity, water deficit and temperature stresses (Hou et al., 2016). Recent studies reported that a substantial amount of PA is produced from many plant foodstuffs, especially Brassica vegetables, by repeated grinding, and some herbs release high amounts of PA when they are mashed. The masticated cabbage leaves contained similar PA levels to those contained in mechanically homogenized cabbage leaves (Tanaka et al., 2009, 2012). These observations suggest that PLD is activated during grinding and mastication to form PA from endogenous phospholipids (Hanahan and Chaikoff, 1948). Thus, the development of PA-rich foodstuffs is expected to involve the use of processing techniques such as grinding or milling.

Japanese mustard spinach (Brassica rapa var. perviridis) is also known as Komatsuna in Japanese. It is a common and popular leafy vegetable in the Japanese diet. Komatsuna contains low energy and high nutrient components that are highly effective in reducing serum cholesterol (Aiso et al., 2014). Moreover, the PL content of Komatsuna is high in the genus Brassica (Tanaka et al., 2012), and the hydrolysis of endogenous PLs such as PC by PLD is suggested to be triggered during grinding, increasing the amount of PA. On the other hand, knowledge of the lipid signaling targets and their physiological consequences in plants is limited (Hou et al., 2016), and the mechanism responsible for the abundant PA observed in mashed foodstuff is unclear.

Based on the aforementioned issues, in this study, through measurements of particle size and PA contents of Komatsuna under different processing conditions, the effects of steaming and milling on the PA contents of Komatsuna with inactivated and activated PLD were investigated, and the mechanism responsible for abundant PA formation in Komatsuna during grinding was also revealed. In order to characterize the milling and PA production of Komatsuna, a new processing method, namely the micro wet milling (MWM) system, was adopted. In MWM, a small particle size is achieved by processing the wet material using an electric stone mill (Koyama and Kitamura, 2014), allowing the more effective release of bioactive compounds. Information presented here will contribute to the processing of PA-rich foods from Komatsuna, which are potentially beneficial for the restoration or prevention of certain GI disorders.

Materials Japanese mustard spinach (B. rapa; named Komatsuna in Japan) was purchased from a local market. Standard PA of 98% purity was purchased from Sigma-Aldrich (St. Louis, MO, USA). Chemicals, including chloroform, methanol, HCl, and 28% ammonia solution, were from Wako (Osaka, Japan). TLC Silica gel 60 was from Merck (Darmstadt, Germany).

Steaming and grinding of Komatsuna To investigate the effects of steaming and grinding on the particle size and PA content of Komatsuna, preparations were conducted using whole Komatsuna. After washing with tap water, Komatsuna (100 g of wet weight) was steamed (99.7 ∼ 100.4°C) for different durations ranging from 1 to 30 min, and quickly cooled to 4°C. The steamed Komatsuna was mixed with water (100 g, 4°C) and ground using a blender (SBC-1000J; Cuisinart, Tokyo, Japan) for 2 to 25 min at room temperature. The obtained Komatsuna juice samples were analyzed for the following properties.

PLD assay of Komatsuna PLD activity was detected in vitro using the Amplex Red assay kit (Molecular Probes, Eugene, OR, USA). For the PLD assay, Komatsuna was steamed for 1 to 5 min and ground for 2 min as above. The mixture was centrifuged at 1300 × g for 5 min at 4°C, and the supernatant was incubated with 250 µM PC, 1 unit/mL horseradish peroxidase, 0.1 unit/mL choline oxidase, and 50 µM Amplex Red reagent in 200 µL of a reaction buffer consisting of 5 mM CaCl2 and 50 mM Tris-HCl (pH 8.0). PLD activity was measured after 2 h and 10 h incubation using a Benchmark Plus microplate reader (Bio-rad, Hercules, CA, USA) at 530 nm excitation and 590 nm emission (Kato et al., 2005; Vogt et al., 2002). Non-steamed raw Komatsuna was used as the control.

Particle size and particle size distribution The particle size (D50) and particle size distribution were determined using a laser diffraction particle size analyzer (SALD-2200; Shimadzu Corporation, Japan) in wet measurement mode. The D50 value was chosen as the particle size, termed the median diameter, and is defined as the average particle size by mass. The particle size distribution profile was described by the particle size and the frequency (Koyama and Kitamura, 2014).

Measurement of PA content Lipids were extracted from the Komatsuna juice according to the Bligh and Dyer method with minor modifications (Bligh and Dyer, 1959; Tanaka et al., 2009). Komatsuna juice (8 mL, containing approximately 97% moisture) was added to a mixture consisting of 10 mL chloroform, 20 mL methanol and 0.24 mL water, in order to form a chloroform/methanol/water phase (10:20:8, V/V/V). The mixed homogenate was vortexed (Vortex Mixer, VM-96B; Jeio Tech, Daejeon, Korea) for 20 s and centrifuged at 1300 × g for 10 min, and the supernatant portion was then collected. The supernatant was diluted with 15 mL of chloroform and water (1:1, V/V) to produce a biphasic system for phase-separation. After adding 0.05 mL of 5N HCl for acidification, the mixed homogenate was vortexed for 20 s and centrifuged at 1300 × g for 10 min. The lipid extract was collected from the chloroform layer. PA was isolated from the lipid extract by TLC with a developing agent consisting of chloroform/methanol/28% ammonia (60:35:8, V/V/V). Then, two-phase separation was conducted to extract PA from the scraped silica gel. The recovered PA was first dissolved in 5.7 mL of a mixed solvent consisting of chloroform/methanol/water (10:20:8, V/V/V), then 3.0 mL of chloroform and water (1:1, V/V) were added for phase separation, and finally, 0.02 mL of 5N HCl was added. The mixture was vortexed, centrifuged, and the purified PA was collected from the lower phase. The amount of PA was spectrophotometrically quantified using a colorimetric method based on phosphomolybdenum-malachite green formation (Chalvardjian and Rudnicki, 1970).

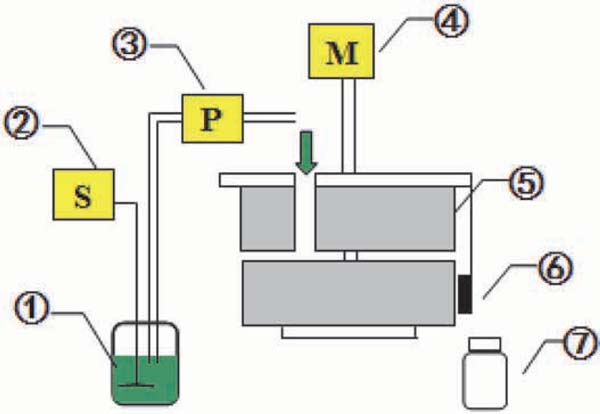

Characteristics of micro wet milling of Komatsuna Because the particle size of Komatsuna does not decrease obviously under long grinding times, the MWM system was used to produce smaller particles. Figure 2 shows the layout of the MWM system, which is a modified electric stone mill system. In this system, the pump feeds materials to the stone mill at an adjustable feeding rate, and the lower mill stone with grooves can efficiently chop the materials to smaller particles at a certain milling rotation. For detailed observation of the mechanisms of PA production, experiments were conducted using active and inactive PLD, and the particle size and PA content of Komatsuna between the two groups were comparisons. The two samples were subjected to different processing sequences. The first sample was processed by steaming for 5 min, mixed with water (4°C) at a ratio of 1:1 (w/w), and ground by a blender for 2 min, then milled by MWM at room temperature. The other sample was mixed with water, ground for 2 min and milled by MWM, and steamed for 5 min after the grinding process. The MWM parameters were as follows: feeding rate, 10 mL/min; milling rotation, 40 rpm; contact surface area of the mill stone, 207 cm2; groove width, 4.5 mm. The measurements of particle size distribution and PA content were conducted as described above.

Micro wet milling system, which is conducted by electric stone milling process of wet material to make the smallest particle size. (1) Raw material (2) Stirrer (3) Tubing pump (4) Motor (5) Stone mill (6) Rubber spatula (7) Sample bottle.

Statistical analyses Student's t-test was used for comparisons between two groups, and one-way ANOVA was conducted using SPSS software (version 22.0; IBM, Armonk, NY, USA). A p value of < 0.05 was considered to indicate statistical significance.

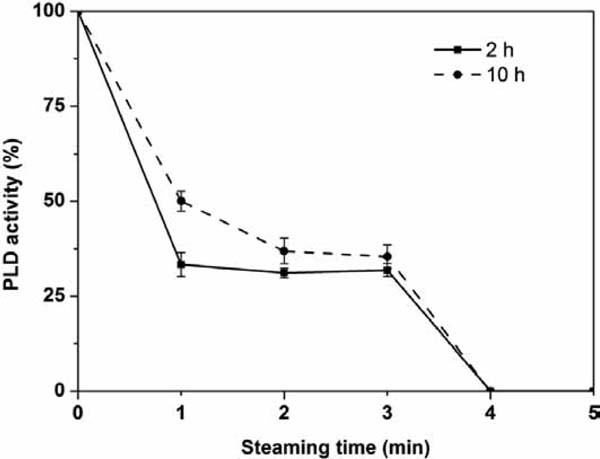

Effect of steaming time on PLD activity This study aimed to elucidate the relationship between the solid particle size of Komatsuna juice and the amount of PA available to the body when consumed. However, the amount of PA is also related to PLD activity, as PA is mainly converted from PC by the enzyme PLD. When PLD is inactivated, the influence of PLD on PA increase or content can be excluded. Therefore, in order to understand the inactivation conditions of PLD, the PLD activity of Komatsuna at different steaming times was investigated.

The production of PA is dependent on the different PLD isoforms and their catalytic properties (Ruelland et al., 2015). Previous studies showed different thermostable properties of PLD; for example, approximately 30% of PLD activity was retained following exposure to a temperature of 100°C for 15 min (Hanahan and Chaikoff, 1948), whereas Tanaka et al. (2009) adopted 3 min of heating time to inactivate PLD activity. Therefore, it is necessary to confirm the exact steaming time of Komatsuna for PLD inhibition. In this study, the steaming time ranged from 1 to 5 min, and PLD activity was measured after incubation for 2 h and 10 h at 37°C in darkness. The effect of steaming time on PLD activity is shown in Figure 3. Although the standard incubation time for the detection of PLD activity was 2 h, the results showed that the reaction of PC to PA by PLD was not completely finished at 2 h. Therefore, PLD activity was also detected after 10 h incubation, which is the time that the enzyme reaction remains stable. The PLD activity result of 10 h incubation was used to confirm the results observed at 2 h. The initial PLD activity of non-steamed raw Komatsuna was defined as 100%, and relative PLD activity of Komatsuna at different steaming times was determined. The effect of steaming on PLD activity at 2 h incubation was similar to that at 10 h. About 60% of PLD activity was inhibited following steaming for 1 min, whereas PLD was totally inactivated following steaming for 4 min.

Phospholipase D (PLD) activity was as a function of steaming time. Komatsuna was steamed from 1 min to 5 min, ground by a blender for 2 min. Non-steamed raw Komatsuna was as the control. The initial PLD activity of fresh raw Komatsuna was defined as 100%, the PLD relative activities of Komatsuna with different steaming time were determined. The supernatants were prepared as described in the Materials and Methods, incubated for 2 h and 10 h at 37°C, protected form light, and measured by microplate reader respectively.

The chemical reaction of PLD, which cleaves PC to choline, and PA continued after 2 h, because the excess PC stimulated PLD. The reaction was stable when incubated for 10 h, and this result was similar to that reported by Kato et al. (2005). Those researchers measured PLD activity with different incubation times and showed that PLD activity changed sharply in the first 3 h, reached a plateau at 6 h and lasted up to 24 h. In this study, from the combined results of PLD activity with 2 h and 10 h incubation, it was clearly observed that PLD was inactivated after steaming of Komatsuna for 4 min. The result of PLD inactivation differed with Tanaka (2009) and Hanahan (1948), who boiled and steamed cabbage for 3 min and 15 min respectively. In plants, PLDs comprise a large and diverse family of enzymes (Bargmann et al., 2009). The differences in PLD primary structure and isoforms contribute to the different enzymatic properties (Ruelland et al., 2015). The high amount of vegetable fiber in Komatsuna may also be the reason for the different results (Aiso et al., 2014).

Effect of steaming time on particle size and PA content of Komatsuna Steaming or heating not only inactivates PLD, but also influences the milling characteristics and resulting particle size of Komatsuna juice. Figure 4 shows the relationship between steaming time and particle size of Komatsuna juice. The particle size decreased with increasing steaming time. Steaming of Komatsuna resulted in tissue that was more degradable, making the tissues more amenable to breaking down to smaller fragments upon grinding.

The particle sizes and phosphatidic acid (PA) contents of Komatsuna juice with different steaming time. Komatsuna was steamed from 0 min to 30 min, and ground by a blender for 2 min. Particle size was determined by SLAD-2200 in wet measurement mode, and expressed by median diameter; PA in Komatsuna juice was extracted by modified Bligh and Dyer method, and quantified by phosphomolybdenum-malachite green method. Values are the mean ± standard deviation (SD), from experiments performed in three independent experiments. Data with the different letters reflect the significant of differences in particle size and PA content (p < 0.05), respectively.

In order to confirm the inactivation of PLD, PA content was also determined at different steaming times. The result of PA content obtained at different steaming times is also shown in Figure 4. The PA content of steamed Komatsuna was much lower compared to non-steamed Komatsuna. When PLD was inactivated, the conversion of PC to PA by PLD was prevented, and the PA content was the lowest after Komatsuna was steamed for 4–5 min. However, after 5 min of steaming, PA content increased. Although PLD was inactivated, the particle size of Komatsuna decreased slightly with longer steaming times, allowing more PA to be released.

It is assumed that when biomembranes are broken down to smaller particles, the structural membrane PA is released. In order to investigate this assumption, Komatsuna was processed using various grinding times in the next experiment.

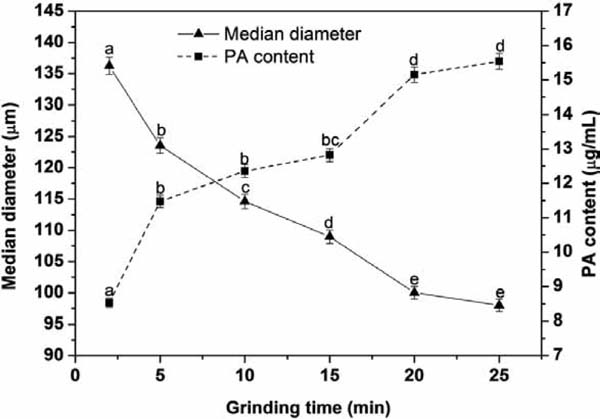

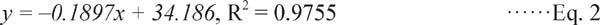

Effect of grinding time on particle size and PA production of Komatsuna The particle size and PA content of steamed Komatsuna at different grinding times were quantified (Figures 5 and 6). As shown in Figure 5, particle size generally decreased with increasing grinding time, and the relationship can be expressed with a logarithmic function. The equation is as follows:

|

The particle sizes and phosphatidic acid (PA) contents of steamed Komatsuna juice with different grinding time. Komatsuna was steamed for 5 min, and ground by a blender for 2 min to 25 min. Values are the mean ± SD of three replicates. Data with the different letters are significantly different in particle size and PA content (p < 0.05), separately.

The relationship of phosphatidic acid (PA) content and particle size (PLD inactive). Under the condition of inactive PLD, a linear equation between PA content and particle size was established. And, the smaller particle size, the more PA.

where Y is the particle size (µm) and X is the grinding time (min).

Figure 5 also shows that PA content increased gradually with grinding time. With longer grinding times, the fluid has sufficient time to break all bonds of the inner structure within the flocs (Blaser, 2000), and the fragments are degraded to smaller particles. Since PA is a structural component of many cell membranes, PA is released upon membrane disruption. In other words, with increasing grinding time, the particle size of Komatsuna decreased and the PA content increased. Moreover, the relationship between PA content and particle size was observed (Figure 6). With PLD inhibition, the particle size and PA content showed a linear relationship; in other words, the smaller the particle size, the larger the PA content. The linear equation is as follows:

|

where y is the PA content (µg/mL) and x is the particle size (µm).

In the food sciences, a food particle is deemed fit for consumption when it is smaller than 20 µm (Inoue, 2011). Using Eqs. 1 and 2, it was calculated that to obtain a particle size of 20 µm, a grinding time of 4556 min would be required, with a predicted PA content of 29 µg/mL. Not only is this PA content considered to be low, the grinding time is too long for industrial production. Therefore, a new technique, namely micro wet milling (MWM) was applied to produce smaller sized particles in a short time.

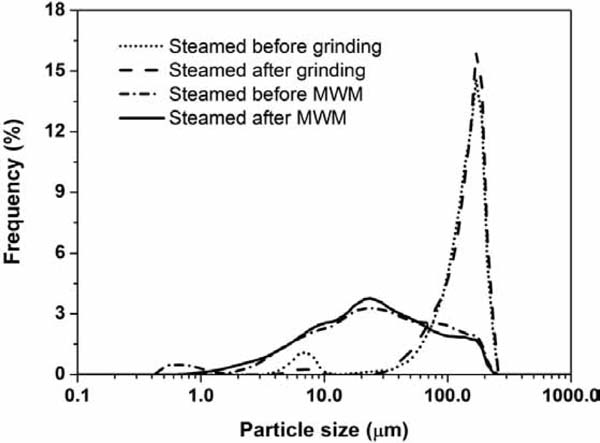

Characteristics of micro wet milling of Komatsuna MWM involves electric stone milling of wet material to minimize the particle size. With MWM processing, the PA content improved obviously and the particle size decreased to approximately 20 µm (Figures 7 and 8). The particle size distributions of Komatsuna following ordinary blender grinding and MWM are shown in Figure 7. The different processing sequences (steaming of Komatsuna before or after milling) had a minimal effect on particle size; in another words, compared to the differences between grinding and milling, the effect of steaming on particle size was small. Most particles of Komatsuna processed by ordinary blender grinding were 140 µm∼170 µm, whereas the majority of particles following MWM were 20 µm. These results indicate that the MWM system is more efficient than ordinary blender grinding for producing smaller particles.

Particle size distributions of Komatsuna juice steamed before or after blender grinding/Micro Wet Milling (MWM). Komatsuna was steamed (5 min) before blender grinding (2 min)/MWM or after blender grinding/MWM. The ordinary blender grinding rotation is 13000–17000 rpm. Procedures of MWM system were operated as follow: Komatsuna was mixed with water (4°C) at a ratio of 1:1 (w/w), grind by a blender for 2 min, and milled by MWM at room temperature. MWM parameters: feeding rate: 10 mL/min; milling rotation: 40 rpm; contact surface area of mill stone: 207 cm2; groove width: 4.5 mm. The particle size distribution profile was described by the particle size and frequency, which were measured by SLAD-2200 in wet measurement mode.

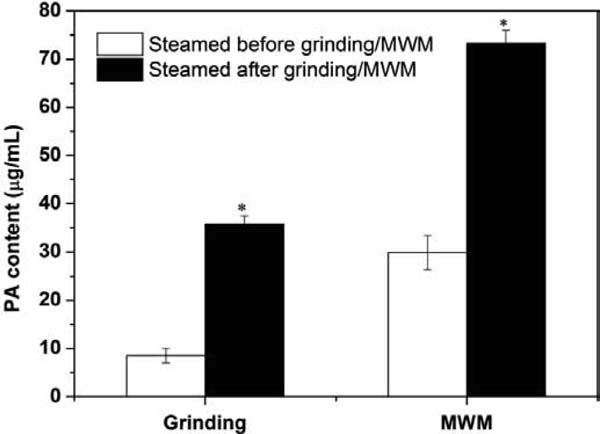

The phosphatidic acid (PA) contents of Komatsuna steamed before or after grinding/Micro Wet Milling (MWM). Komatsuna was steamed (5 min) before grinding (2 min)/MWM (unfilled column) or after grinding/MWM (filled column). Values are the mean ± SD, from three independent experiments. *, p < 0.05 (student's t-test).

The PA contents of Komatsuna with ordinary blender grinding and MWM system before and after steaming were quantified respectively (Figure 8). The PA content of Komatsuna milled before steaming was much higher than that after steaming. The low PA content of Komatsuna steamed before milling suggests that steaming inhibited the PLD activity. High PA content was obtained when Komatsuna was milled before heating, which can be explained by the conversion of PC to PA by PLD, which was activated during grinding and milling. Similar results have also been observed in cabbage. Tanaka et al. (2009) reported that the PL profile of cabbage leaves boiled after grinding was characterized by high PA and low PC contents. PLs contain PA, PC and other phospholipids, which are major components of cell membranes (Hou et al., 2016). When structural membranes are disrupted, PA is released, and a similar situation is also expected with PC. PC serves as a substrate for the generation of PA by PLD, and the released endogenous PC stimulated PLD activity during milling. This suggestion is in agreement with the observations reported by Hanahan and Chaikoff (1948), in which repeated grinding of raw cabbage leaves activated PLD to form PA from endogenous PLs. Nguyen et al. (2014) also observed that the concentrations of PC and PA are complementary, and inversely proportional to each other. In future work, the amount of PC in Komatsuna subjected to different processes should be determined, which could clarify the conversion of PC to PA, and the mechanism responsible for PA increases during grinding would be explained more directly.

The PA contents of Komatsuna processed by MWM were much higher compared to ordinary blender grinding, and the particles following MWM were smaller compared to ordinary grinding. This result was obtained for samples that were steamed both before and after milling. Therefore, the MWM system was shown to be more effective than ordinary blender grinding in reducing particle size and increasing PA content, and could be developed as an efficient processing technology to produce Komatsuna juice with high PA content.

The bioavailability of a component is a fundamental issue in nutrition as opposed to the supply of a sufficient amount in the diet, which can be influenced by exogenous factors such as the properties of the bioactive ingredients, and endogenous host factors such as genetic conditions and physiological status (Klobukowski et al., 2014). Ghaid et al. (2009) examined the influence of milled grain particle size on starch digestion, and observed a decrease in the digestion rate with increasing particle size. The digestion and absorption of phospholipids in the GI tract are also determined by their physicochemical characteristics (Thomson et al., 1993). Moreover, lipids are generally absorbed via diffusion in a monomolecular state rather than the bulk transfer of lipid molecules from mixed micelles to the brush border membrane of the enterocyte (Simmonds, 1972; Westergaard and Dietschy, 1976). Therefore, the amount of dissociated PA that is released from the cell membrane or micelle, rather than the total PA including that inside the intact plant cell, is directly connected to the LPA content that can be produced and utilized for the restoration or prevention of GI disorders. This study shows that by decreasing the particle size of Komatsuna by effective milling, the amount of PA available to the body increases.

For the manufacture of Komatsuna PA-rich food, Komatsuna was processed using different steaming and milling conditions, and the particle size and PA content of Komatsuna juice were quantified. The study's main findings are as follows: (i) with longer grinding times, Komatsuna tissues were cleaved into smaller particles; (ii) sufficient amounts of PA were released from Komatsuna; and (iii) the smaller the particle size, the higher the PA content; and (iv) the MWM system more effectively manufactured PA-rich Komatsuna juice. Taken together, these findings suggest that the high PA content was primarily due to the release of native PA from the Komatsuna biomembrane by particle disruption, and secondarily, to the release of endogenous PC during the grinding process, which resulted in the conversion to PA by PLD. Foodstuff-derived PA is an efficient exogenous source of LPA for the human body, which has potential use as a dietary treatment for the restoration or prevention of GI disorders. Therefore, the application of milling for increasing PA content is worthy of further investigation.

Acknowledgement This study was supported by a scholarship to Xinyue Li from the China Scholarship Council.

phospholipids

PCphosphatidylcholine

PLDphospholipase D

PAphosphatidic acid

PLA2phospholipase A2

LPAlysophosphatidic acid

GI tractgastrointestinal tract

MWMmicro wet milling

The authors confirm that there are no conflicts of interest.