2018 年 24 巻 6 号 p. 1111-1119

2018 年 24 巻 6 号 p. 1111-1119

Based on our recent finding that the “kokumi” taste components, γ-glutamyl-tyrosine, γ-glutamyl-phenylalanine, raffinose, and stachyose, are present in soybean seeds, we aimed to understand whether thermal treatment of soybean seeds can enhance the “kokumi” taste in soymilk or not. Heating was carried out prior to the grinding step in the soymilk production process. The extraction efficiency of the “kokumi” taste components changed with the type of thermal treatment. Autoclave and microwave heating of soybean seeds before grinding caused a high extraction efficiency of “kokumi” taste components compared to unheated and dry heat heating. Traditional methods, such as the thermal treatment at 90°C during grinding, also increased the “kokumi” taste components, but the efficiency and nitrogen yield were low compared to the thermal treatment before grinding. Enhanced extraction of “kokumi” taste components may be originated from the disruption of cell walls of soybean seeds induced by thermal treatment, and the degree of cell damage was closely related with the extraction efficiency of the “kokumi” taste components. Thus, instead of the traditional processes, the thermal treatment before grinding can contribute to the production of soymilk with greater “kokumi” taste components.

In Japan, soybeans (Glycine max (L.) Merr.) have long been regarded as an important food material. Various types of soy-products, such as miso, soy sauce, tofu, yuba, and soymilk, are widely utilized in many kinds of Washoku (Japanese cuisine) or Japanese-style meals. In these soy-products, the consumption of soymilk has increased by 40% over the last five years in Japani). In many cases, soymilk is added to or blended with various types of beverages to serve consumers, but recently, the opportunities to use soymilk during cooking have been gradually increasing in order to impart or enhance the palatability of cuisine in restaurants and at home. Soymilk is added to not only Japanese cuisine but also Western and Asian cuisine to enhance the “kokumi” taste. The “kokumi” taste is distinct from the five basic tastes and is defined as a function of imparting properties of enhanced thickness, continuity, and mouthfeel (Dunkel et al., 2007). Specifically, in Japan, “kokumi” is thought to be a key factor increasing palatability in foods by modifying a certain mouthfeel. In this context, it is worth identifying “kokumi” taste components and increasing them in soymilk in order to improve the palatability of food using soymilk as a seasoning ingredient. We recently reported that soybean seeds contained “kokumi” taste components, such as γ-glutamyl-tyrosine and γ-glutamyl-phenylalanine. We also found oligosaccharides are present in soybean seeds, exhibiting a synergistic or enhancing effect on the “kokumi” taste sensation evoked by γ-glutamyl peptides (Shibata et al., 2017). The content of the “kokumi” taste components in soymilk, such as γ-glutamyl peptides and oligosaccharides may change depending on the soybean variety and processing method. In the previous study, we investigated the diversity of “kokumi” taste components in soymilk from various soybean seeds of mini-core collection, and found some accessions that contained higher “kokumi” taste components in seeds (Shibata et al., 2018). This result indicates the possibility that the breeding contributes the development of soybean variety with high content of “kokumi” taste components. The another approach for increasing the “kokumi” taste components in soymilk is to improve the processing methods of soymilk production. However, there are no reports about this approach.

There are wide variations in the production process of soymilk around the world. A traditional process comprises the following steps. First, whole soybeans are soaked for more than 10 hours. Thereafter, soybeans are ground to a slurry and heated. Soymilk is then obtained by filtration of the slurry (Piper and Morse, 1923). This process generates lipid peroxide derivatives like n-hexanal by lipoxygenase and other related enzymes, and these derivatives are responsible for off-flavors (beany flavors). Off-flavors have been a serious problem in soymilk production, and many works have been dedicated to controlling lipoxygenase activity to reduce these flavors (Wilkens et al., 1967; Badenhop and Hackler, 1970; Kon et al., 1970; Nelson et al., 1976; Mizutani and Hashimoto, 2004; Tripathi et al., 2015). One of the most effective treatments for preventing the lipoxygenase activity is to grind water-soaked soybeans at high temperatures (Mizutani and Hashimoto, 2004), but this thermal treatment affects protein solubility, which is an important index of soymilk quality. In these studies, the thermal treatments are normally carried out during grinding or after filtration of the soymilk. However, there are few reports on the direct thermal treatment of soybeans prior to the preparation of soymilk.

As described above, the thermal treatment is considered to be one of the most important processes in soymilk production to reduce the generation of off-flavor. However, it is possible that thermal treatment improves soymilk quality by increasing taste-related components, such as the “kokumi” taste components. Therefore, the objective of this study was to evaluate the effectiveness of thermal treatments as a tool for increasing “kokumi” taste components in soymilk without reducing protein solubility. Thermal treatment was carried out before or during the grinding process. We compared the effectiveness of three heating methods (steam autoclave, microwave heating, and dry heating) of soybean seeds to establish a suitable method to produce soymilk containing plenty of “kokumi” taste components.

Chemicals γ-Glutamyl-tyrosine and γ-glutamyl-phenylalanine were purchased from BACHEM (Bubendorf, Switzerland). Saccharides and other materials in the control solution were purchased from WAKO Pure Chemical Industries (Osaka, Japan). All solvents were of LC-MS grade and were purchased from WAKO Pure Chemical Industries (Osaka, Japan). Dehulled soybeans (Glycine max (L.) Merr.) were provided by Fuji Oil Holdings Inc.

Preparation of heated soybean seeds Soybean seeds were subjected to heat treatments under the following conditions (Table 1). Steam autoclave heating (AC) was carried out using an Autoclave MAC-601 (TOKYO RIKAKIKAI, Tokyo, Japan). Soybean seeds (80 g) were placed in a 1 L beaker and the beaker was set in the autoclave for heating. For AC treatment, the humidifying step (“Preparation of humidified soybean” in the left line of Fig. 1) was skipped, because soybean seeds absorbed about 10% water per sample seed weight during AC treatment. To obtain the same water absorption for the three heating methods, we prepared soybean seeds that absorbed the same percentage of water by weight before heat treatment for microwave heating (MW) and dry heat heating (DH) (“Preparation of humidified soybean”). That is, soybean seeds (80 g) were spread out on a stainless steel tray and sprayed uniformly with 8 mL of water prior to thermal treatment (“Thermal treatment” step in Fig. 1).

| Treatment | Treatment code | NSI |

|---|---|---|

| Control | ||

| Unheated fresh soybean | Unheated | 82.1 ± 1.3 |

| Thermal treatment | ||

| Dry heat (110°C_60 min) | DH60 | 65.6 ± 2.1 |

| Dry heat (110°C_120 min) | DH120 | 54.3 ± 2.2 |

| Dry heat (110°C_150 min) | DH150 | 39.2 ± 2.5 |

| Dry heat (110°C_180 min) | DH180 | 36.7 ± 2.6 |

| Autoclave (110°C_3 min ) | AC3 | 65.3 ± 2.3 |

| Autoclave (110°C_5 min ) | AC5 | 54.2 ± 1.1 |

| Autoclave (110°C_7 min ) | AC7 | 38.5 ± 1.9 |

| Microwave (500W_10 s) | MW10 | 74.1 ± 2.5 |

| Microwave (500W_20 s) | MW20 | 67.6 ± 1.3 |

| Microwave (500W_30 s) | MW30 | 53.6 ± 1.8 |

| Microwave (500W_40 s) | MW40 | 40.4 ± 1.2 |

Data are presented as mean ± SE (n = 3)

Overview of the preparation of soymilk.

MW: Microwave, AC: Autoclave, DH: Dry Heat

The process of “Unheated” treatment is shown by dotted arrow in left line.

Microwave heating (MW) was carried out using a household microwave oven (NE-EH211, Panasonic, Osaka, Japan). Humidified soybean seeds prepared as described above (40 g) were spread out on a dish with a diameter of 20 cm and were heated in the microwave oven. To prevent uneven heating, the amount of raw materials is different from the other treatment methods.

Dry heat heating (DH) was carried out using dry oven DX302 (Yamato Scientific, Tokyo, Japan). Soaked soybean seeds (80 g) were spread out on a stainless-steel tray (20 cm × 30 cm), and the tray was set in the dry oven and heated.

All heating processing were repeatedly five times. The prepared samples using these three methods were dried by heating in dry oven at 80°C for 20 min (“Drying” in the left line of Fig. 1) and then used for the preparation of soymilk.

Preparation of soymilk samples Preparation of soymilk was carried out as previously described with some modifications (Mizutani and Hashimoto, 2004). After thermal treatment, dried soybean seeds (50 g) were soaked in water (250 mL) at 3°C for 12 h (“Soaking soybean seeds” in the left line of Fig. 1). Then the soaked soybeans and water were homogenized at 8,000 rpm for 10 min with an EXCEL AUTO HOMOGENIZER (Nihon Seiki Seisakusyo, Tokyo, Japan) with the temperature adjusted to 25°C (“Grinding” step in Fig. 1). The resulting slurry was immediately heated in boiling water and maintained above 95°C for 5 min (“Heating in boiling water” in Fig. 1). The heated slurry was immediately cooled in an ice bath for 30 min and then centrifuged at 13,420 × g at 4°C for 30 min. The supernatant collected was the soymilk. For soybean seeds without thermal treatment, soaked soybean seeds were ground at various temperatures (“Heat grinding” step in the right line of Fig. 1). The following steps were carried out according to the same method that was used for the seeds thermally treated.

Determination of the nitrogen solubility index (NSI) The NSI of each thermally treated sample was analyzed as previously described according to the AOCS official method (Samoto et al., 2007). Initially, a 3.5 g soybean seeds were powdered by a grinder (MicroPowder, WEST Co., Ltd. Niigata, Japan), and the powdered sample was added to 100 mL of water. The mixture was then stirred for 1 h at 25°C and centrifuged at 1,000 × g for 10 min to obtain a supernatant and pellet. The pellet was extracted with 100 mL water for 1 h at 25°C and then centrifuged at 1,000 × g for 10 min again to obtain another supernatant and pellet. The resultant supernatants were combined and made up to 250 mL by adding water. The nitrogen levels were determined after filtration by the Kjeldahl method. The NSI was calculated as the percentage of the nitrogen extracted of the total nitrogen in the sample.

Quantitative analysis of γ-glutamyl peptides and oligosaccharides The prepared soymilk samples were diluted 100 times in a 1:1 volume ratio of water to acetonitrile containing 0.1% formic acid, filtered using a membrane (Vivaspin Turbo 15 VS15T01, Sartorius, Göttingen, Germany), and analyzed by Ultra Performance Liquid Chromatography-quadrupole-time-of-flight-mass spectrometry (UPLC-Q-TOF-MS/MS) using the parameters as previously described with some modifications (Takahashi et al., 2015). UPLC-MS was performed using a Waters Acquity UPLC system (Milford, MA) coupled to a Xevo QTOF-MS equipped with an electrospray source operated in a negative ion mode (ESI negative mode) with a lock-spray interface for accurate mass measurements. Leucine enkephalin was employed as the lock-mass compound and was directly infused into the MS at a flow rate of 20 µL/min. The concentration of leucine enkephalin was 200 ng/mL (in 50% acetonitrile, 50% water, 0.1% formic acid). The capillary, sampling cone, and extraction cone voltages were set at 2700 V, 20 V, and 1 V, respectively. The source and desolvation temperatures were 120°C and 450°C, respectively. The cone and desolvation gas flow rates were set at 50 and 800 L/h, respectively. An aliquot of the extracted sample (3 µL) was injected into an Acquity UPLC BEH amide column (column size, 2.1 × 100 mm; particle size, 1.7 µm). Mobile phases A (water and 0.1% formic acid) and B (acetonitrile and 0.1% formic acid) were used. The column temperature was set to 40°C. The buffer gradient consisted of 75% to 55% B for 0–10 min, 55% to 50% B for 10–10.1 min, 50% B for 10.1–15 min, and 75% B for 5 min, at a flow rate of 300 µL/min. Quantitative analysis was performed in triplicate by comparing the peak areas of the corresponding mass traces with those of the defined standard solutions of each reference peptide and oligosaccharide. Data were acquired with MassLynx software (Waters). External mass calibration was performed following the manufacturer's provided protocol. The relative extraction efficiency of the “kokumi” taste components (γ-glutamyl-tyrosine, γ-glutamyl-phenylalanine, raffinose and stachyose) in each of the thermal treated soybeans was calculated according to the following equation:

Relative extraction efficiency of “kokumi” taste components = Cthermal / Cunheated

where Cthermal is the content of “kokumi” taste components when thermal treated soybeans were used as the source material (mg / 100 g), and Cunheated is the content of the “kokumi” taste components when unheated fresh soybeans were used as the source material (mg / 100 g)

Extraction efficiency of the nitrogen The nitrogen extraction ratio showed the relative value of extraction efficiency of the nitrogen for soymilk samples. Nitrogen content was measured by Kjeldahl method using the following equation:

Nitrogen extraction ratio = NCthermal / NCunheat

where NCthermal is the total extractable nitrogen content in soymilk when thermal treated soybeans were used as the source material or when soybeans were grinded at 3°C, 60°C and 90°C (g / 10 g), and NCunheat is the total extractable nitrogen content in soymilk when unheated fresh soybeans were used as the source material or when soybeans were grinded at 25°C (g / 10 g)

“Kokumi” taste components / nitrogen Extraction ratio (K/N ratio) The K/N ratio showed the relative value between the extraction efficiency of “kokumi” taste components and nitrogen in each of the thermal treated soybeans. The content of “kokumi” taste components and nitrogen were analyzed as described above.

K/N ratio = K/N

where K is the relative extraction efficiency of extractable “kokumi” taste components in soymilk, and N is the nitrogen extraction ratio in soymilk.

Microstructure analysis Each sample of thermally treated soybean seeds was observed using a scanning electron microscopy (SEM) (SU8239, Hitachi, Japan) with an SE (U) detector equipped with a Cryo unit (Alto2500, Gatan Oxon, UK). A tiny metal tube including a thermally treated seed sample was rapidly frozen in slush nitrogen and then cleaved and sublimated at −95°C for 10 min. The cleaved surface was coated with platinum using an ion spatter and observed at 1.5 kV of acceleration voltage.

Statistical analysis All experiments were performed triplicate. In each analysis, differences between groups were compared with one-way repeated measures analysis of variance (ANOVA) followed. p values less than 0.05 were considered statistically significant.

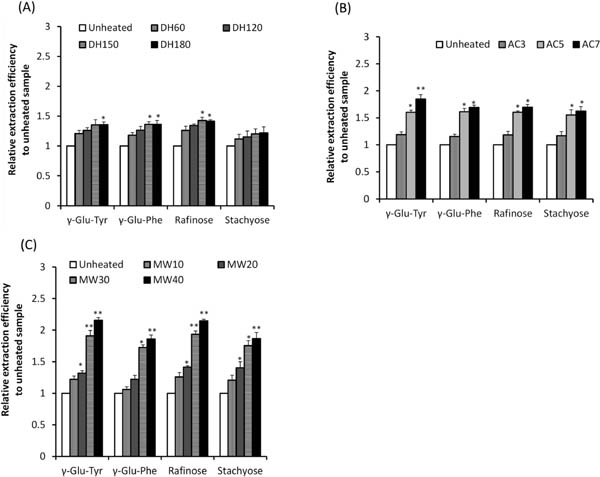

Effects of thermal treatment before grinding soybeans on the nitrogen solubility and extraction efficiency of “kokumi” taste components The NSI of thermal treated soybean seeds are shown in Table 1. The NSI of thermal treated samples decreased with the heating conditions compared with that of unheated fresh sample. The extraction efficiency of the “kokumi” taste components γ-glutamyl-tyrosine (γ-Glu-Tyr), γ-glutamyl-phenylalanine (γ-Glu-Phe), raffinose (Raf), and stachyose (Sta) in thermal and non-thermal treated soybean seeds are shown in Fig. 2. Regardless of the thermal treatment (AC, MW and DH), the extraction efficiency of the “kokumi” taste components increased with an increase in the heating time concomitant with a decrease in the NSI (see also Table 1). These data showed that the “kokumi” taste components were extracted more efficiently by heating soybean seeds. Of the three heating methods, the DH treatment extraction efficiency of “kokumi” taste components did not increase remarkably; the maximum value of the relative extraction efficiency of γ-Glu- Tyr, γ-Glu-Phe, Raf and Sta, obtained by long heating for 150 or 180 min, was 1.358, 1.362, 1.428, and 1.203, respectively (Fig. 2A). For the AC7 treatment exhibiting a NSI (38.5 in Table 1) similar to that (39.2 in Table 1) of DH150, the extraction efficiency of the “kokumi” taste components was higher than that of the DH150 treatment, that is, the values of γ-Glu-Tyr, γ-Glu-Phe, Raf, and Sta was 1.847, 1.692, 1.695, and 1.625, respectively (Fig. 2B). Furthermore, the MW40 treatment, which showed a NSI similar to that of DH150 and AC7, had the highest extraction efficiency of “kokumi” taste components of the three thermal treatments (Fig. 2C; the maximum value of γ-Glu-Tyr, γ-Glu-Phe, Raf, and Sta, attained by heating for 40 s, was 2.156, 1.859, 2.147, and 1.865, respectively). These results suggest that MW is the best way to increase the extraction efficiency of “kokumi” taste components. It should be noted that the higher extraction efficiency of the “kokumi” taste components was achieved by MW compared to the other methods with similar NSI values, which reflects the same degree of protein denaturation.

Effect of thermal treatment on the extraction efficiency of the “kokumi” taste components.

Extraction efficiency of each component is presented as mean ± SE (n = 3).

Notes: * p < 0.05, ** p < 0.01; one-way repeated measures ANOVA, when compared with the respective unheated control.

(A), (B), and (C): DH, AC, and MW treatment before grinding, respectively.

The number following each thermal treatment symbol (DH, AC, MW) means the duration of heating.

Relative extraction efficiency of “kokumi” taste components = Cthermal / Cunheated

Cthermal– The content of “kokumi” taste components in soymilk when thermal treated soybeans were used as the source material, Cunheated- The content of “kokumi” taste components in soymilk when unheated fresh soybeans were used as the source material (mg / 100 g)

The effects of heating on the extraction of intracellular components were previously investigated in tomato and carrot. Dewanto et al. reported that thermal processing enhanced the nutritional value of tomatoes by increasing the amount of bioaccessible lycopene extracted and total antioxidant activity despite insignificant changes in the total phenolic and flavonoid content as well as a decrease in Vitamin C contents in thermally treated tomatoes (Dewanto et al., 2002). Kidmose et al. reported that a significantly higher content of sucrose and carotene was obtained by thermal treated carrots (Kidmose and Martens, 1999). As in the case of thermally treated tomatoes and carrots, it is possible to enhance the extraction efficiency of the “kokumi” taste components by the AC and MW treatment, while preventing a decrease in the NSI and protein solubility, which is an important element of soymilk quality.

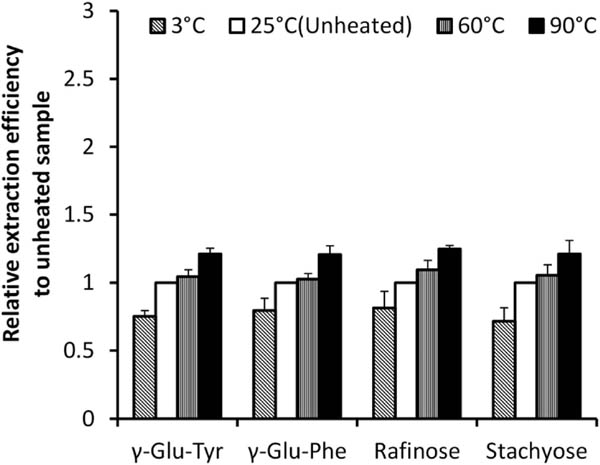

Effect of thermal treatment during the grinding of soybean seeds on the extraction efficiency of “kokumi” taste components The extraction efficiency of the “kokumi” taste components was investigated using soybean seeds, which were subjected to grinding at various temperatures (3°C, 25°C, 60°C, and 90°C). Results are shown in Fig. 3. In this figure, the experimental results of 25°C are the same as the ‘Unheated’ samples of AC, MW, and DH treatments in Fig. 2A, B, and C, respectively. The extraction efficiency of “kokumi” taste components from thermally treated samples increased depending on the heating condition (at 60°C, the values of γ-Glu-Tyr, γ-Glu-Phe, Raf, and Sta was 1.043, 1.024, 1.094, and 1.053, respectively; at 90°C, the value of γ-Glu-Tyr, γ-Glu-Phe, Raf, and Sta was 1.281, 1.280, 1.248, and 1.212, respectively), and in the case of cooling (3°C), the extraction efficiency significantly decreased compared to the thermal and non-thermal treatment conditions (the value of γ-Glu-Tyr, γ-Glu-Phe, Raf, and Sta was 0.751, 0.794, 0.812, and 0.715, respectively). Increases in extraction efficiency by the thermal treatment were lower than those of the AC and MW treated (Fig. 2). These data suggest that the extraction efficiency of “kokumi” taste components were affected more by the timing of the thermal treatment of soybean seeds i.e., heating before grinding had a greater effect than during grinding.

Effect of thermal treatment during grinding on the extraction efficiency of the “kokumi” taste components.

Relative extraction efficiency of “kokumi” taste components = Cthermal / Cunheated

Cthermal– The content of “kokumi” taste components in soymilk when soybeans were grinded at 3°C, 60°C and 90°C (mg / 100 g), Cunheated- The content of “kokumi” taste components in soymilk when soybeans were grinded at 25°C (mg / 100 g)

Grinding soybeans at high temperature (90°C) has been selected as the appropriate method to produce soymilk with less off-flavor, which was found by Mizutani and Hashimoto (Mizutani and Hashimoto, 2004). In our case, too, it is likely that the generation of the off-flavor was inhibited by grinding at 90°C compared to grinding at 3°C, 25°C, or 60°C. Furthermore, grinding soybeans at 90°C resulted in greater amount of “kokumi” taste components as shown in Fig. 3. This suggests that grinding of soybean seeds under high temperatures improves the quality of soymilk with respect to taste as well as flavor. However, in this study, the heating of soybeans, especially using MW, prior to grinding more effectively enhanced the amount of extracted “kokumi” tastes components compared to heating at 90°C during the grinding process. This indicates the possibility that the heating of soybean prior to grinding is superior to the heating during the grinding process as a processing method for obtaining soymilk with high amount of “kokumi” taste components. To promote the application of thermal treatment of soybeans prior to grinding in order to produce high-quality soymilk, we should test if the generation off-flavors during the preparation process of soymilk is prevented by such a thermal treatment of soybean seeds prior to the grinding step in future studies. We had preliminary results that lipoxygenase, including lipoxygenase-2, which is thought to be mainly responsible for the generation of the off-flavor (Axelrod et al., 1981; Matoba et al., 1985; Furuta et al., 1996), is deactivated by the thermal treatment of soybean, thereby reducing off-flavor production during the grinding process.

Extraction efficiency of nitrogen As the protein content in soymilk is of great importance from nutritional viewpoints, the amount of nitrogen in soymilk was measured. A comparison of the nitrogen extraction efficiency for each thermal treatment is shown in Table 2. As a control, unheated fresh soybeans were ground at 25°C and the amount of nitrogen in the soymilk was determined (the sample correspond to that of “Unheated fresh soybeans in Thermal treatment before grinding” and that of “25°C of Thermal treatment during grinding” in Table 2). The amount of nitrogen in this control was 0.094 g/10 g soymilk. This value was in accordance with the value described in the literature (Mizutani and Hashimoto, 2004) and set as a reference value. Other data are expressed as the relative value against this control. In the case of thermal treatment before grinding, nitrogen extraction efficiency gradually decreased with an increase in heating time, and a decrease in NSI was observed regardless of the heating method. Similarly, in the case of thermal treatment during grinding, the nitrogen extraction efficiency decreased with the increase in the grinding temperature. The decrease in the nitrogen extraction efficiency by thermal treatment was assumed to be caused by the denaturation of glycinin and β-conglycinin, which are the main components of the soluble protein fraction, and the resultant formation of insoluble aggregates of denatured protein molecules (Sirison et al., 2017). Interestingly, for the thermal treatment before grinding, the degree of the decrease in the nitrogen extracted was slightly lower than that of heating at 90°C during grinding even though temperatures more than 100°C were employed in the case of thermal treatment before grinding. This can be explained by the effects of the water content on the heat-induced denaturation of proteins. Previous reports indicated that the denaturation temperature of protein is normally elevated by the decrease of the water content (Kitabatake et al., 1989: Kitabatake et al., 1990). In the case of thermal treatment during grinding, soybeans absorbed water sufficiently, and the protein denaturation temperature was lower than 100°C. However, in the case of heating before grinding, the low amount of adsorbed water should cause an increase in denaturation temperature above 100°C. Therefore, we can speculate that heating before grinding under low moisture conditions prevents excess protein denaturation, leading to higher nitrogen content in soymilk.

| Treatment | Nitrogen Extraction Efficiency1 | “kokumi” taste components / nitrogen extraction ratio (K/N ratio)2 | |||

|---|---|---|---|---|---|

| γ-Glu-Tyr | γ-Glu-Phe | Raf | Sta | ||

| Thermal treatment before grinding | |||||

| Unheated fresh soybean (Control) | 1.00 ± 0.00 | 1.00 ± 0.00 | 1.00 ± 0.00 | 1.00 ± 0.00 | 1.00 ± 0.00 |

| Dry heat (110°C_60 min) | 0.96 ± 0.06 | 1.26 ± 0.11 | 1.23 ± 0.09 | 1.32 ± 0.12 | 1.17 ± 0.11 |

| Dry heat (110°C_120 min) | 0.93 ± 0.04 | 1.40 ± 0.12 | 1.40 ± 0.10 | 1.49 ± 0.11 | 1.28 ± 0.13 |

| Dry heat (110°C_150 min) | 0.92 ± 0.04 | 1.60 ± 0.12 | 1.60 ± 0.11 | 1.68 ± 0.13 | 1.42 ± 0.13 |

| Dry heat (110°C_180 min) | 0.91 ± 0.03 | 1.68 ± 0.13 | 1.69 ± 0.12 | 1.76 ± 0.15 | 1.51 ± 0.14 |

| Autoclave (110°C_3 min) | 0.98 ± 0.04 | 1.22 ± 0.14 | 1.18 ± 0.11 | 1.21 ± 0.11 | 1.20 ± 0.09 |

| Autoclave (110°C_5 min) | 0.95 ± 0.03 | 1.87 ± 0.17 | 1.79 ± 0.12 | 1.81 ± 0.16 | 1.78 ± 0.15 |

| Autoclave (110°C_7 min) | 0.91 ± 0.05 | 2.12 ± 0.19 | 1.94 ± 0.14 | 1.89 ± 0.17 | 1.85 ± 0.17 |

| Microwave (500W_10 s) | 0.99 ± 0.03 | 1.23 ± 0.11 | 1.07 ± 0.11 | 1.27 ± 0.11 | 1.22 ± 0.11 |

| Microwave (500W_20 s) | 0.96 ± 0.04 | 1.39 ± 0.12 | 1.29 ± 0.13 | 1.49 ± 0.12 | 1.48 ± 0.12 |

| Microwave (500W_30 s) | 0.94 ± 0.04 | 2.07 ± 0.21 | 1.87 ± 0.13 | 2.09 ± 0.21 | 1.90 ± 0.14 |

| Microwave (500W_40 s) | 0.91 ± 0.05 | 2.39 ± 0.22 | 2.06 ± 0.19 | 2.38 ± 0.23 | 2.07 ± 0.19 |

| Thermal treatment during grinding | |||||

| 3°C | 1.28 ± 0.03 | 0.59 ± 0.01 | 0.62 ± 0.02 | 0.63 ± 0.02 | 0.56 ± 0.04 |

| 25°C (same as control) | 1.00 ± 0.00 | 1.00 ± 0.00 | 1.00 ± 0.00 | 1.00 ± 0.00 | 1.00 ± 0.00 |

| 60°C | 0.96 ± 0.06 | 1.08 ± 0.10 | 1.06 ± 0.09 | 1.14 ± 0.08 | 1.09 ± 0.09 |

| 90°C | 0.86 ± 0.05 | 1.41 ± 0.11 | 1.40 ± 0.11 | 1.45 ± 0.12 | 1.41 ± 0.11 |

Data are presented as mean ± SE (n = 3)

NCthermal – Total extractable nitrogen content in soymilk when thermal treated soybeans were used as the source material or when soybeans were grinded at 3°C, 60°C and 90°C (g / 10 g), NCunheat - Total extractable nitrogen content in soymilk when unheated fresh soybeans were used as the source material or when soybeans were grinded at 25°C (g / 10 g)

K– The relative extraction efficiency of extractable “kokumi” taste components in soymilk, N– the nitrogen extraction ratio in soymilk.

Commercial soymilk is supplied to consumers after adjusting the content of the soluble materials, i.e., Brix. Considering this commercial requirement, the amount of “kokumi” taste components determined in this study should be standardized by Brix to evaluate the actual “kokumi” taste in soymilk. We did not measure the Brix of soymilk, but the value of extracted nitrogen in Table 2 can be used instead of Brix. In this context, the ratio of the “kokumi” taste components to extracted nitrogen (K/N) was calculated for all the samples. All K/N values are shown in Table 2. Grinding soybeans at a low temperature (3°C) resulted in the highest extraction efficiency (1.28) for nitrogen in soymilk as shown in Table 2, but had the lowest extraction efficiency of the “kokumi” taste components (Fig. 3). Therefore, this sample had the lowest K/N ratio, which suggests that grinding soybeans at 3°C was not suitable for producing soymilk with desired “kokumi” taste. Grinding soybeans at 90°C, which is the standard process for commercial soymilk production, had a higher K/N ratio than other temperature conditions and is regarded as more suitable method for getting soymilk with a “kokumi” taste. However, the K/N ratios of soymilk prepared from soybeans heated at 90°C during grinding were not greater than the K/N ratios of soymilk prepared from soybeans thermally treated before grinding, particularly with long heating times (150 and 180 min for DH, 5 and 7 min for AC, 30 and 40 s for MW).

Moreover, the K/N ratio reached values twice that of the control by AC and MW heating for 7 min and 30 s, respectively. These data suggest that the thermal treatment of soybeans before grinding is a suitable method for producing soymilk with high “kokumi” taste components while maintaining protein levels.

Effect of thermal treatments on microstructure of soybean seeds To evaluate the effect of thermal treatments on the microstructure of soybean seeds before grinding, we observed SEM images of thermally treated soybean. The microstructure of unheated fresh soybeans (control) and DH120, AC5, and MW30 treated soybean samples are presented in Fig. 4. Thermal treated samples which are selected in this figure show almost the same NSI ( ≠ 54). Cells of unheated fresh soybeans exhibited elongated shapes and have nearly straight cell walls. Lamellar structure, which plays an important role in cell-to-cell binding, was observed in the middle of cell walls. This demonstrated that the organelles and cytoplasm in fresh soybean cells were firmly protected by the matrix. Soybean seeds subjected to DH120 treatment showed partially distorted cell walls, but the middle lamellar structure remained in the gap between walls. With AC5 and MW30 treatment, cell structures were more damaged than in DH120 treated samples. For the cell structure of AC5 seeds, the cell walls were widely distorted, and the middle lamellar structure partially disappeared. MW30 treated seeds had the most drastic changes with irregular cell structures, cracked cell walls, and disappearance of the middle lamella.

Effect of thermal treatment before grinding on the microstructure of soybean seeds by SEM analysis. (A): Unheated, (B): DH120, (C): AC5, (D): MW30. Bars = 10 µm

These structural changes might be caused by degradation of pectinacious materials during the thermal treatment as previously reported in the case of cooked carrots (Rastogi et al., 2008). Once the middle lamella disappears after the thermal treatment, the cell wall may be easily broken by the grinding process. In addition, MW treatment causes rapid dehydration in tissues, resulting in the collapse and folding of cell walls (Kidmose and Martens, 1999). Cells expanded by water absorption are dehydrated by internal heating from microwaves, which causes the rapid removal of water from the cytoplasm and the rapid reduction of the cytoplasmic volume. This mechanism may account for the damage to some cells observed in the SEM image. “Kokumi” taste components, such as γ-glutamyl peptides and oligosaccharides, are synthesized during the ripening period of soybean seeds, and degradated during germination. Because these components are not changed during germination in case that the seeds are thermally treated (data not shown), it is thought that the enzymes involved in the synthesis and/or degradation of these components may be deactivated. Therefore, we can speculate that these “kokumi” taste components are not synthesized newly by the thermal treatment of soybean seeds. Based on this speculation, changes in cell structure depicted by electron-micrography may cause the release of these components, which are thought to be located originally in the vacuole or cytosol (Paulose et al., 2013), to the cell matrix. As described above, under the same NSI conditions, the MW treatment exhibited the most efficient extraction of the “kokumi” taste components of the three treatments. Such efficient extraction of “kokumi” taste components can be attributed to the severe deformation and destruction of cell structures in soybean seeds subjected to MW treatment.

Our results suggest that the degree of cell damages derived from the heat treatment is closely related to the extraction efficiency of the “kokumi” taste components. Previous studies found the same tendency in thermally treated tomatoes and carrots (Dewanto et al., 2002; Kidmose and Martens, 1999). Furthermore, in a recent study, Jayathunge et al. reported that the extraction efficiency of lycopene increased more in tomato juice when using both thermal and non-thermal processing tools, such as ultrasonic and pulsed electric fields techniques than only use of thermal processing (Jayathunge et al., 2017). Combined use of thermal and non-thermal processes could cause dramatic changes to the cell structure and extract lycopene more effectively. By applying these technologies to soybean, it will become possible to produce soymilk with more of “kokumi” taste components.

Results of this study demonstrated that the thermal treatment of soybean seeds before grinding was effective in enhancing the amount of the “kokumi” taste components in soymilk while maintaining the nitrogen yield. The extraction efficiency of the “kokumi” taste components changed with the type of thermal treatment. The AC and MW treatments had higher extraction efficiency than the DH treatment or thermal treatment during grinding. In particular, the extraction efficiency of the “kokumi” taste components of MW40 treatment increased more than twice as much as the unheated control. Thermal treatment of soybean seeds disrupted cell walls and deformed cell structures. The degree of cell damage derived from the heat treatment was closely related to the extraction efficiency of the “kokumi” taste components. These findings suggest that instead of the standard processes, thermal treatment before grinding can contribute to the production of a soymilk with more “kokumi” taste components. This ‘new’ soymilk may meet the diverse needs of consumers and play a role in the creation of a new food culture.

Acknowledgements We thank members of the R&D division of Fuji Oil Company for their assistance with the study. We also would like to thank Editage (www.editage.jp) for English language editing.

Autoclave heating

MW heatingMicrowave heating

DHDry Heat heating

UPLC-Q-TOF-MSUltra Performance Liquid Chromatography-quadrupole -time-of-flight-mass spectrometry

HPLCHigh performance Liquid Chromatography

HILICHydrophilic Interaction Chromatography

γ-Glu-Tyrγ-glutamyl-tyrosine

γ-Glu-Pheγ-glutamyl-phenylalanine

RafRaffinose

StaStachyose

NSINitrogen Solubility Index