2019 Volume 25 Issue 3 Pages 373-381

2019 Volume 25 Issue 3 Pages 373-381

Wood ear (Auricularia polytrica) powder (WE) was used to substitute 10%–40% of wheat flour to make icebox cookies. Contents of fiber, polysaccharide, and total phenols in WE were 2.73%, 66%, and 2.49%, respectively. Hunter L, a, b, hardness, moisture, and water activity of cookies decreased with the increased WE percentages, while ash and carbohydrate contents showed a reverse effect. With the increased WE replacement, dimension of cookies became shorter, narrower and thicker. Total phenols content in WE40 extract was the highest among extracts, and had the best effect on 1,1-diphenyl-2-picrylhydrazyl radical scavenging ability. On a seven-point hedonic test, the score of color, sweetness, hardness, flavor and overall liking of cookies made with 0%–30% replacement of wheat flour with WE were moderately acceptable. Overall, a partial replacement of wheat flour with WE in cookies making could be developed as a novel food with more bioactive components and effective antioxidant activity.

Dietary fiber (DF) is defined as “the edible constituent of analogous carbohydrates or plants which is resistant to digestion and absorption in the human small intestine, with partial or complete fermentation in the large intestine” (AACC, 2001). Furthermore, dietary fiber is further divided into crude polysaccharide and crude fiber (Lin et al., 2016). Several studies have showed that a greater intake of DF can bring many beneficial health effects against cardiovascular diseases, diabetes, hyperlipidemia, hypocholesteremia, gut diseases, certain cancer especially colon cancer (Bosaeus, 2004; Kaczmarczyk et al., 2012). Consequently, DF is one of the dominant components in a human health-promoting diet.

Wheat flour, fat and sugar are principal ingredients in the manufacture of cookies, which are one of most popular bakery products consumed all over the world. Several studies showed that biscuits are used as a source for incorporation with different functional ingredients for their diversification (Gandhi et al., 2001; Hooda and Jood, 2005; Sudha et al., 2007). As a result, cookies can also act as a satisfactory carrier for providing DF and other functional ingredients to human. Effect of DF on the cookie and biscuit quality characteristics has been studied for soluble fiber such as resistant starch, inulin, beta-glucan, nutriose, and polydextrose (Brennan and Samyue, 2004; Laguna et al., 2011; Mancebo et al., 2018) or insoluble fiber from fruit, wheat fiber, bamboo, potato and pea (Bilgiçli et al., 2007; Sudha et al., 2007; Ajila et al., 2008; Reyes-Pérez et al., 2013; Laguna et al., 2014; Mancebo et al., 2018). Mushrooms are rich in fiber and have been used in the biscuit studies, such as Pleurotus sajor-caju, Pleurotus colombinus, other oyster mushrooms, and dehydrated shiitake (Abou-Zaid et al., 2012; Wan et al., 2012; Sonkar and Singh, 2015; Singh et al., 2016; Ng et al., 2017a; Ng et al., 2017b). These studies have shown the potential for developing cookies with rich dietary fibers and other nutrients of functional properties.

Auricuralia polytricha (Montagne) Saccardo (Auriculariaceae) is known as red wood ear or hairy wood ear mushroom. The wood ear mushroom is listed in traditional Chinese medicine and commonly used as food. This wood ear mushrooms could rehydrate readily from a dried state, and impart a unique and pleasing texture to most meals and impart a soups and sauces with strong umami taste (Mau et al., 1998). Therefore, these ear mushrooms are highly valued as a centerpiece of Asian cooking. Wood ear could provide abundant amount of no-volatile taste components for taste, especially the umami taste, and bioactive components for human health such as dietary fiber. Besides, this wood ear showed several beneficial effects such as antioxidant, anticancer and hypolipidemic effects (Mau et al., 2001; Yang et al., 2002; Yu et al., 2014). Wood ear can be added to food as an ingredient to provide the beneficial health effects through various food products. When wood ear is formulated into icebox cookie, the benefits expected would be its antioxidant and hypolipidemic effects. However, there is no information about wood ear icebox cookie, which was becoming popular in Taiwan recently. Furthermore, the market value of smaller wood ear in Taiwan is very low.

Therefore, it would be beneficial to develop the new formulation of icebox cookie production with dried wood ear powder (WE). The purpose of this study was to investigate the proximate composition and active components of hot air-dried WE. Besides, the quality characteristics of icebox cookie with 0%, 10%, 20%, 30% and 40% of wheat flour replaced by hot air-dried WE were also determined.

Materials and reagents Fresh wood ear mushrooms (A. polytricha) (12 kg, diameter: 6.19 ± 1.20 cm/piece, weight: 3.72 ± 1.17 g/piece) was purchased from Pinrui Biotechnology Farm (Changhua, Taiwan). The wood ear (0.6 kg) was blanched in a boiling water bath (3 kg) for 5 min, and taken out to cool in a 5 °C water bath and drained for 10 min. Thereafter, washed wood ear was dried in a hot air oven at 70 °C for 22 h, and was ground and screened in a mill with 0.2 mm sieve (RT-30HS, Rong Tsong Precision Technology, Taichung, Taiwan). Dried WE powder thus obtained was sealed in a PET/Al/PE bag and stored at −20 °C before use. Unchlorinated and unheated wheat flour (8.03% protein) was purchased from Chia Fha Enterprise Co. (Taichung, Taiwan). Sucrose (Taiwan Sugar Corp., Tainan, Taiwan), sodium chloride (Taiyen Biotech, Tainan, Taiwan), fresh whole eggs (local supermarket), unsalted Anchor butter (Fonterra Brans (New Young), Taiwan Branch, Taipei, Taiwan), whole milk powder (Fonterra, Auckland, New Zealand) and shortening (Cheng I Food, Changhua, Taiwan) were purchased from the local market.

Hydrochloric acid, sulfuric acid, sodium dihydrogen phosphate, and sodium phosphate were purchased from Merck (Darmstadt, Germany). Methanol and acetone was purchased from Avantor Performance Materials (Radnor, PA, USA). Hexane was purchased from Tedia (Fairfield, OH, USA). Gallic acid, Folin-Ciocalteu's phenol reagent, 1,1-diphenyl-2-picrylhydrazyl (DPPH), 3,5-dinitrosalicylic acid, and glucose were purchased from Sigma-Aldrich (St. Louis, MO, USA). Cupric sulfate, anhydrous sodium carbonate and sodium hydroxide were purchased from Shimakyu's Pure Chemicals (Osaka, Japan). Phenol reagent was purchased from Wako Pure Chemical Industries Ltd. (Osaka, Japan). Ethanol (95%, v/v) was purchased from Taiwan Tobacco & Liquor Co. (Tainan, Taiwan). Potassium sulfite was purchased from Nihon Shiyaku Reagent (Tokyo, Japan). Methyl red pure was purchased from Koch Light Research Laboratories (Gauteng, South Africa). Methylene blue was purchased from Katayama Chemical Industries Co., Ltd (Osaka, Japan).

Icebox cookie preparation Control cookie was prepared following the recipe described previously by Lee et al. (2010). The formulae of icebox cookies were designed at 5 different WE percentages (Table 1). To make the cookie dough, the shortening and butter were mixed with whisk attachment in a mixer (K5SS, Kitchen Aid, St. Joseph, MI, USA) on speed 5 setting for 2 min to stir well together, and then sucrose and sodium chloride were added into the mixer and mixed for 3 min at the same speed. Afterwards, the eggs were poured into the mixer on speed 3 setting for 1 min, and then the sifted wheat flour, WE and whole milk powder were poured into the mixer on speed 5 setting for 5 min. The icebox cookie dough was immediately deposited into a rectangular mold (50 cm × 45 cm × 0.5 cm), pressed into 5 cm × 4 cm × 0.5 cm inside the mold, and then frozen at −20 °C for 24 h.

| Ingredient (g) | Control1 | WE10 | WE20 | WE30 | WE40 |

|---|---|---|---|---|---|

| Wheat flour | 600 | 540 | 480 | 420 | 360 |

| Wood ear powder | 0 | 60 | 120 | 180 | 240 |

| Sucrose | 300 | 300 | 300 | 300 | 300 |

| Sodium chloride | 3 | 3 | 3 | 3 | 3 |

| Whole milk powder | 36 | 36 | 36 | 36 | 36 |

| Shortening | 150 | 150 | 150 | 150 | 150 |

| Unsalted butter | 210 | 210 | 210 | 210 | 210 |

| Whole egg | 120 | 120 | 120 | 120 | 120 |

| Total | 1419 | 1419 | 1419 | 1419 | 1419 |

The slice was deposited into the prepared baking sheets, and then baked at 180 °C for 15 min in a pre-heated oven (Sing Mine International, Taichung, Taiwan). The cookies were allowed to cool for 2 h and were packed in low density polyethylene (LDPE) packages at room temperature for physicochemical qualities analyses and sensory evaluation. Icebox cookie samples prepared with 0%, 10%, 20%, 30%, and 40% replacement of wheat flour with WE were coded as Control, WE10, WE20, WE30 and WE40, respectively. Five batches of baked icebox cookies were produced for each recipe, and icebox cookies were mixed before sampling for quality analysis. All treatments were randomly produced.

Proximate analysis Proximate compositions of dried WE, wheat flour and cookies, including ash, crude fat, moisture, and crude protein, were determined by American Association of Cereal Chemists (AACC, 2000) Approved Methods 08-01.01, 30-25.01, 44-40.01, and 46-11.02, respectively (AACC). The nitrogen conversion factor of dried WE, wheat flour and cookies used for crude protein calculation were 4.38 (Crisan and Sands, 1978), 5.70, and 5.70, respectively. Carbohydrate content (%) was calculated by subtracting the contents of ash, crude fat, moisture, and crude protein from 100% of dry matter.

Determination of crude fiber, reducing sugar and crude polysaccharide Crude fiber was determined according to the methods of the Association of Official Agricultural Chemists (AOAC) Method 14.111 (AOAC, 1990). Reducing sugar were determined using the 3,5-dinitrosalicylic acid method (James, 1995). Dried WE powder (5.0 g) was extracted with 150 mL of boiling water in a Corning PC-320 hot plate stirrer with a stirring bar for 2 h, and then centrifuged at 5470 ×g for 30 min. The residue was re-extracted with two extra 150 mL boiling water as described above. The combined water extract was precipitated by adding four-fold volume of 95% ethanol, and incubated at 4–6 °C for 24 h in a refrigerator. After centrifugation and vacuum freeze drying (40 h was performed using a freeze-dryer (FD-20L-6S, Kingmech Co., Taipei, Taiwan) with drying conditions of < 0.2 mmHg, chamber temperature of 25 °C and condenser temperature of −50 °C), the crude soluble polysaccharides content of freeze-dried sample was analyzed by phenol-sulfuric acid method (Dubois et al., 1956). The yield (%) of crude soluble polysaccharides in a dried WE was calculated using the equation: yield (%) = (weight of crude polysaccharides/weight of dried WE) ) 100%. Carbohydrate can be subdivided in to crude fiber, reducing sugar and soluble polysaccharide. Therefore, the sum of crude fiber, reducing sugar and soluble polysaccharide contents is also carbohydrate content.

Physical quality analyses Water activity (Aw) of the samples was determined by an AquaLab CX-2 water activity meter (Decagon Devices, Pullman, WA, USA). Length, width, and thickness of baked icebox cookies were measured using a Vernier caliper (Mitutoyo, Kanagawa, Japan). Spread ratio of the baked cookies was calculated using the average width (diameter) divided by the thickness of the cookies. Data were averaged from 10 replicates. Surface color determinations of cookie samples from the midsection of the cookies were determined by a color measurement spectrophotometer (ColorFlex-Diffuse, Hunter Associates Laboratory, Reston, VA, USA) set for Hunter L, a and b values with a D65 illuminant at 10°. The hue angle (h, arctan (b/a)), chroma (C, (a2+b2)1/2), and ΔE (total color difference) values were calculated from Hunter L, a, b values. Total color difference (ΔE) of WE cookies in comparison to control was calculated using the equation: ΔE = [(Lc − Ls)2 + (ac − as)2 + (bc − bs)2]1/2, where L, a and b are the color coordinates in control (c) and WE biscuits (s). The results of color values were averaged from the midsection of ten cookies.

Hardness of baked cookie samples was determined according to the method of Lee et al. (2010). A texture analyzer (TA-XT2, Stable Micro Systems, Surrey, UK) with a cylinder probe (P/5, 5 mm diameter) was used for texture evaluation. The hardness was determined by penetration. The results of hardness were averaged from 10 baked icebox cookies.

Determination of total phenols and antioxidant activity Each of dried WE powder and icebox cookie powder (10 g) was extracted with 100 mL of 95% ethanol at 75 °C in a shaking water bath (SB302, Kansin Instruments, Kaohsiung, Taiwan) at 100 rpm for 30 min and then filtered through Advantec No.1 filter paper (Toyo Roshi Kaisha, Tokyo, Japan). The residue was then extracted with one extra 100 mL portions of 95% (v/v) aqueous ethanol as described above. The combined ethanolic extract was rotary-evaporated at 40 °C, and then freeze-dried. Extraction yield (%) = (dried extract weight/sample weight) × 100%. The resulting dry extract was stored at −20 °C before use. Total phenols of the extracts were determined the method described by Mau, Lee, Chen, and Lin (2017), and their content was calculated on the basis of the calibration curve of gallic acid and expressed as milligram of gallic acid equivalents (GAE) per gram of freeze-dried extract (the equation of standard curve: absorbance at 760 nm = 0.0009 CGA [µg/mL] / 0.0009, R2 = 0.9995). Scavenging ability of freeze dried cookie extracts (0–10 mg/mL) on DPPH radicals was determined according to the method of Shimada et al. (1992). The effective concentration (mg/mL) at 50% (EC50) is the concentration at which DPPH radicals was scavenged by 50%.

Sensory evaluation Surface color, sweetness, hardness, flavor and overall liking degrees of the icebox cookies was determined following the hedonic scale test used in Lee et al. (2010). The untrained consumers (totally 90, 37 males and 53 females) were recruited from the students, staff and faculty at Hungkuang University. Each of the consumers received five samples and were asked to rate them based on degree of liking on a seven-point hedonic scale (1 = dislike extremely, 4 = neither like nor dislike, 7 = like extremely). Samples were placed on white plates and were identified with random three-digit numbers. Consumers evaluated the samples in a testing area, and were instructed to rinse their mouths with warm water between samples to minimize any residual effect.

Statistical analysis Each measurement was conducted in triplicate, except for the dimension (n = 10), surface color (n = 10), hardness (n = 10), and hedonic test (n = 90). The experimental data were subjected to an analysis of variance for one way classification design using a Statistical Analysis System (SAS Institute, Inc., Cary, NC, 2000). Duncan's multiple range tests were used to determine the difference among means at the level of 0.05.

Proximate composition and bioactive components of wood ear and wheat flour Wood ears used in the research were small in size, rich in carbohydrate and crude protein, but lower in crude fat and ash (Table 2). The size used in Mau et al. (1998) was regular and its protein and carbohydrate contents were 5.70% and 88.24%, respectively. It seems that small size wood ears contained higher amount of protein. Besides, wood ears contained 68.73% total dietary fiber (Table 2), which was the combined contents of crude fiber and crude polysaccharide (Lin et al., 2016), and were the bioactive components provided. Contents of total dietary fiber and reducing sugar together were carbohydrate content (81.1%), which was comparable to the carbohydrate content (83.31%) in Table 2 calculated by subtraction of crude protein, fat, ash and moisture from 100%. In addition, contents of moisture and crude fat of wheat flour were higher than those of WE (Table 2). However, crude protein, ash, carbohydrate, crude fiber and total phenols of wheat flour showed a reverse trend. Besides, the polysaccharide of wheat flour was not determined, because its major component is starch in this study. Overall, the substation of wheat flour with WE could provide its bioactive components-total dietary fiber through cookies.

| Content (%) | ||

|---|---|---|

| Quality characteristics | Wood ear powder | Wheat flour |

| Moisture | 3.09 ± 0.351 | 12.13 ± 0.18 |

| Crude protein | 9.99 ± 0.26 | 8.03 ± 0.21 |

| Crude fat | 0.53 ± 0.01 | 1.04 ± 0.05 |

| Ash | 3.08 ± 0.03 | 0.53 ± 0.02 |

| Carbohydrate | 83.31 ± 0.53 | 78.27 ± 0.57 |

| Crude fiber | 2.73 ± 0.26 | 0.23 ± 0.02 |

| Soluble polysaccharide | 66 ± 3 | ---2 |

| Reducing sugar | 12.37 ± 0.86 | --- |

| Total phenols | 2.492 ± 0.141 | 0.076 ± 0.005 |

Physicochemical quality characteristics of baked cookies Usually, the initial moisture content could be a very important factor influencing the cooking process. Although the moisture contents of WE powder (3.09%) and wheat flour (12.13%) significantly differed (Table 2), those of the cookies were ranged from control (2.82%) to WE40 (1.04%) (Table 3). The differences in cookies were significant but the difference was relatively small as compared to the difference in ingredients. Besides, the moisture contents (1.04–2.82%) were small numbers in a cookie (100%). Water activity of icebox cookies ranged from 0.308 to 0.212, respectively (Table 3). Lower moisture content and water activity ensures that cookies are generally not susceptible to microbiological spoilage and inhibition of lipid oxidation (Wade, 1988; Arimi et al., 2010). Furthermore, these cookies would have longer shelf life if the storage environment is at low relative humidity condition since cookies are hygroscopic in nature. Contents of crude protein and crude fat in samples were not varied notably. However, carbohydrate and ash contents increased with the replaced WE percentages, because the contents of ash (3.08%) and carbohydrate (83.31%) of WE powder in Table 2 were higher than those of wheat flour (0.53% and 78.27%) in this study.

| Physicochemical characteristics | Control1 | WE10 | WE20 | WE30 | WE40 |

|---|---|---|---|---|---|

| Proximate composition | |||||

| Moisture (%) | 2.82 ± 0.09A2 | 1.98 ± 0.02B | 1.84 ± 0.01C | 1.44 ± 0.01D | 1.04 ± 0.02E |

| Crude protein (%) | 7.66 ± 0.29A | 7.69 ± 0.14A | 7.72 ± 0.03A | 7.74 ± 0.16A | 7.77 ± 0.3A |

| Crude fat (%) | 28.02 ± 0.19A | 27.98 ± 0.15A | 27.94 ± 0.2A | 27.91 ± 0.29A | 27.87 ± 0.39A |

| Ash (%) | 0.73 ± 0.03E | 0.84 ± 0.02D | 0.94 ± 0C | 1.05 ± 0.01B | 1.15 ± 0.03A |

| Carbohydrate (%) | 60.77 ± 0.28D | 61.51 ± 0.27C | 61.56 ± 0.19C | 61.86 ± 0.12B | 62.17 ± 0.13A |

| Water activity | 0.308 ± 0.007A | 0.297 ± 0.006B | 0.270 ± 0.003C | 0.241 ± 0.002D | 0.212 ± 0.002E |

| Dimension | |||||

| Length (cm) | 6.13 ± 0.07A | 5.89 ± 0.09B | 5.78 ± 0.06C | 5.68 ± 0.06D | 5.71 ± 0.12CD |

| Width (cm) | 5.32 ± 0.15A | 5.04 ± 0.07B | 4.96 ± 0.09C | 4.88 ± 0.07CD | 4.83 ± 0.08D |

| Thickness (cm) | 0.71 ± 0.01C | 0.78 ± 0.02B | 0.82 ± 0.02A | 0.83 ± 0.03A | 0.84 ± 0.03A |

| Spread ratio | 7.49 | 6.46 | 6.05 | 5.88 | 5.75 |

| Color property | |||||

| L | 70.76 ± 0.80A | 57.28 ± 0.93B | 48.93 ± 0.50C | 41.49 ± 0.59D | 39.43 ± 0.29E |

| a | 4.80 ± 0.72A | 3.05 ± 0.27B | 3.01 ± 0.22BC | 2.67 ± 0.20CD | 2.49 ± 0.18D |

| b | 22.63 ± 0.54A | 11.84 ± 0.37B | 8.72 ± 0.61C | 6.84 ± 0.36D | 5.90 ± 0.36E |

| h (°) | 78.06 ± 1.59A | 75.56 ± 1.01B | 70.97 ± 1.11C | 68.74 ± 0.79D | 67.15 ± 0.83E |

| C | 23.14 ± 0.64A | 12.23 ± 0.40B | 9.23 ± 0.62C | 7.34 ± 0.40D | 6.40 ± 0.39E |

| ΔE | 17.36 ± 0.91D | 25.95 ± 0.61C | 33.33 ± 0.53B | 35.60 ± 0.34A | |

| Hardness (g) | 2064 ± 440A | 1738 ± 596AB | 1389 ± 294BC | 1331 ± 187C | 1303 ± 217C |

Length (5.68–6.13 cm), width (5.83–5.32 cm) and thickness (0.71–0.84 cm) of all baked cookies were larger than the dimension of cookie dough slice (5.0 cm × 4.0 cm × 0.5 cm) before baking (Table 3). Length and width decreased significantly with the increased WE percentages in these baked cookies, while the thickness showed a reverse effect. The total volumes (length × width × thickness) of the baked cookies were almost constant independent from the content of WE (<1%). This means that if the cookies are elastic, decreasing of length and width might reflect on the increase in thickness. Spread ratio also decreased with the increased WE percentages in these baked cookies. Dimension and spread ratio of samples is strongly influenced by the water binding capacity (Pareyt and Delcour, 2008), and the higher the water holding capacity, the lower the final width and the higher the thickness were observed (Mancebo et al., 2018). Li (2003) had supplemented silver ear and shiitake-stipe in the form of powder to bread and found that the water holding capacities of silver ear, shiitake-stipe and wheat flour ingredients were 8.18, 5.14% and 0.6%, respectively. It seems that mushrooms had good water holding capacity in nature. Therefore, dimension results in this study might be due to the good water binding capacity provided by WE polysaccharides. Consequently, WE gave rise to lower dimension results of WE cookies than those of control cookie made with only wheat flour. In addition, WE also provided beneficial dietary fiber. The dietary fiber contents in the WE cookies could be simply calculated from Table 2 as 2.92%, 5.83%, 8.75% and 11.66% for WE10, WE20, WE30 and WE40 cookies, respectively.

Several studies had indicated that the product color was one of the important attributes contributing to choices made by consumers (Fernández-Vázquez et al., 2011; Huang et al., 2018). The significantly difference on the surface color of baked icebox cookies could be visualized in Fig. 1. Moreover, the surface color changed in baked cookies could also be determined in terms of Hunter L, a, b, h, C and ΔE values (Table 3). The L, a, b values indicate the brightness of the color (black (0)/white (100)), the green (a < 0) or red (a > 0) color and the blue (b < 0) or yellow (b > 0) color, respectively. The L, a, b values of cookies were seriously affected by the replacement of wheat flour with WE, and decreased significantly with the increased WE replacement. The decreased L, a, b values indicated that the cookies became darker, less red and yellower after addition of WE. Wheat flour contained no soluble sugars whereas contents of fructose, glucose, mannitol and trehalose in shiitake stipe flour were 83.55, 87.70, 100.50 and 39.75 mg/g, respectively (Lin et al., 2008). Besides, the total contents of free amino acids in wheat flour and shiitake-stipe flour were 1.32 and 23.68 mg/g, respectively (Lin et al., 2008). Therefore, the Maillard reaction and caramelization occurred during baking and the pigment of WE gave rise to the cookies with darker color.

Color of baked wood ear icebox cookie.

From left to right: Control, WE10, WE20, WE30 and WE40: prepared with 0%, 10%, 20%, 30% and 40% replacement of wheat flour with dried wood ear powder, respectively.

Parameter h describes the color wheel in such a way that 0/360° value corresponds to the red-purple color, 90° for yellow, 180° for green and 270° for blue (Kirca et al., 2007). From the h results in the baked cookies, the progressions of color from yellow towards red-purple in correlation with increased WE replacement were observed (Table 3). Chroma (C) presents the color intensity and the higher the value, the more intense and vivid the color is perceived. However, cookies with more WE replacement had a lower value of this parameter.

The color difference sensation of the two samples can be concluded from ΔE. Several studies (Rogowska, 2015; Korus et al., 2017) had indicated that the implication of ΔE value can be interpreted as follows: for 0 < ΔE < 1, the difference in color is unrecognizable by standard observer; for 1 < ΔE < 2, only an experienced observer can recognize the difference; for 2 < ΔE < 3.5, inexperienced observer can spot the difference; for 3.5 < ΔE < 5, any observer can easily notice the differences; and for ΔE > 5, an observer can notice two different colors. The ΔE of the WE cookies and control cookies ranged from 17.36–35.60 (Table 3) and all WE cookies could be easily distinguished from the control cookies. For WE cookies, values of ΔE between WE10 and WE20, WE20 and WE30, and WE30 and WE40 were 8.59, 7.38 and 2.27, respectively, indicating that all WE cookies were different in color and could also be distinguishable by naked eyes.

Hardness of baked cookies became softer with increased WE replacement (Table 3). Hardness values of the WE cookies were found to be significantly lower than that of the control cookie, implying a softer eating characteristic and easier to chew. The result might be due to the dietary fiber-rich WE could interfere with or interrupt the gluten formation.

Total phenols and antioxidant activity of cookie extracts Using 95% (v/v) aqueous ethanol as the extracting solvent, the extraction yields were in the range of 14.20–14.49% (Table 4). Total phenols content of freeze-dried extracts significantly increased with increased WE percentages. It might be due to the fact that content of total phenols (24.92 mg GAE/g) of WE was higher than that of wheat flour (0.76 mg GAE/g). Scavenging ability on DPPH radicals of cookie extracts was summarized in Table 4 and the results were expressed as EC50 values for comparison. Effectiveness of scavenging ability on DPPH radicals of cookie extracts was inversely correlated with their EC50 values and in the descending order: WE40 ≈ WE30 > WE20 ≈ WE10 > Control. The result showed that supplemented WE greatly enhanced antioxidant activity of the icebox cookie. Besides, WE also contained small amounts of other bioactive components such as lovastatin, γ-aminobutyric acid and ergothioneine (16.1, 281.6 and 1.4 mg/kg dry matter, respectively) (Lo et al., 2012). However, since the amounts in baked WE cookies would be relatively low, icebox cookies supplemented with WE still provided with trace amounts of these bioactive components.

| Samples | Extraction yield2 (%) |

Total phenol content (mg GAE/g dried extract) |

EC50 value3 (mg extract/mL) scavenging ability on DPPH radicals |

|---|---|---|---|

| Control1 | 14.43 ± 0.71 a4 | 7.57 ± 0.37 e | 11.42 ± 0.37 a |

| WE10 | 14.34 ± 0.62 a | 8.45 ± 0.08 d | 9.04 ± 0.44 b |

| WE20 | 14.49 ± 0.41 a | 9.62 ± 0.48 c | 8.45 ± 1.06 b |

| WE30 | 14.28 ± 0.22 a | 10.71 ± 0.20 b | 8.22 ± 1.34 bc |

| WE40 | 14.20 ± 0.71 a | 11.65 ± 1.08 a | 7.08 ± 0.13 c |

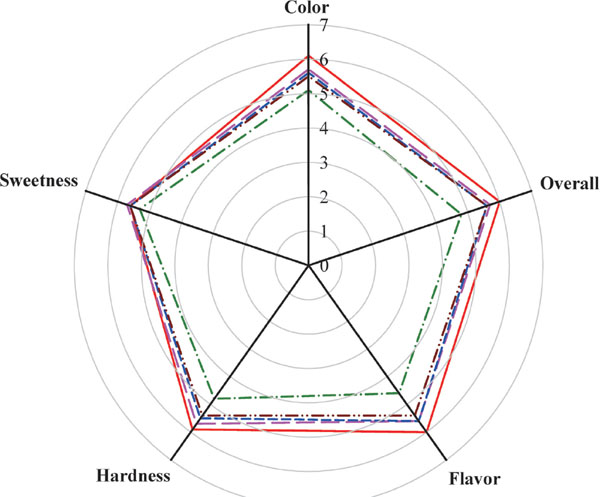

Hedonic scale test Control had yellowish brown color while its color became darker after addition of WE (Fig. 1). The color scores of cookies were found in the descending order of Control (6.1 ± 0.7), WE10 (5.7 ± 0.9), WE20 (5.6 ± 1.1), WE30 (5.5 ± 1.0), and WE40 (5.1 ± 0.9). The color liking degree of all cookies was up to like slightly (5.0) rated by the untrained consumers. No statistically significant differences were found in the sweetness, hardness, flavor and overall liking scores among Control, WE10, WE20 and WE30 (Fig. 2). However, sensory scores of WE40 was the lowest, especially in the hardness, flavor and overall liking scores (4.8 ± 0.7, 4.6 ± 0.8, and 4.8 ± 0.7, respectively) were lower than the degree of like slightly (5.0). On a seven-point hedonic scale, the sensory quality characteristics results of the Control, WE10, WE20, and WE30 were in the range of 5.4 to 6.1 (5 = like slightly, 6 = like), indicating that these icebox cookies were moderately acceptable. The sensory results indicated that a partial replacement of WE for wheat flour in icebox cookies is satisfactory.

Radar plot of sensory evaluation result of baked wood ear icebox cookie.

Control, WE10, WE20, WE30, and WE40: prepared with 0%, 10%, 20%, 30%, and 40% replacement of wheat flour with dried wood ear powder, respectively. Seven-point hedonic scale with 1, 4 and 7 representing extremely dislike, neither like nor dislike, and extremely like, respectively.  Control;

Control;  WE10;

WE10;  WE2;

WE2;  WE30;

WE30;  WE40.

WE40.

Hot air-dried wood ear powder could provide several bioactive components in this study, such as crude fiber, crude polysaccharides and total phenols. Baked cookie is well-known by consumers all over the world, and it is a potential candidate to become a carrier of functional ingredients was resulted from its tremendous consumption. Based on the hedonic scale test results obtained, the icebox cookies formulated with partial replacement of wheat flour with up to 30% WE had sensory quality characteristics comparable with control cookies prepared with 100% wheat flour. Moreover, substantial amount of crude fiber, crude polysaccharides and total phenols remaining in the wood ear icebox cookie would be beneficial and provide consumers with the alleged physiological properties. Accordingly, a successful and novel formulation of icebox cookie substituted with WE was developed.

Acknowledgements The authors would like to thank Ministry of Science and Technology of Taiwan, ROC for the financial support under Grant No. NSC 101-2221-E-241-016.