2019 年 25 巻 3 号 p. 391-397

2019 年 25 巻 3 号 p. 391-397

Whipped cream consists of air bubbles, fat-globule aggregation, and a water phase; thus, knowledge of the effects of foam and fat-globule aggregation is important in understanding the physical properties of the produced whipped cream. A 45 (wt%) fat-content dairy cream and a batch whipping machine were used in this study to explore the shape-retention ability. The mean diameter of bubbles was also measured in optical microscopy images to evaluate the effects of bubble size. In constant-beating-speed tests, increasing the beating speed decreased the whipping time and overrun, which increased the shape-retention ability. On the other hand, changing the beating speed during the whipping process maintained a high shape-retention ability while reducing the whipping time. A high initial overrun might induce a shape-retention ability at a constant beating speed, and small initial bubbles might maintain a high shape-retention ability.

Various types of cream are used in applications such as whipping cream, coffee whitener, and cooking cream. Whipped cream must gain a shape-retention ability so that it can be used for decorative purposes, such as on cakes. The whipping process involves introducing air bubbles into the cream and then aggregating the fat globules; the combination of bubbles and fat-globule aggregate makes the cream firm, ultimately becoming a whipped cream (Noda and Shiinoki, 1986; van Aken, 2001; Hotrum et al., 2005). However, whipped creams are unstable, which makes it difficult to control their physical properties to produce desirable characteristics such as mouthfeel, flavor release, and appearance.

Hotrum et al. (2005) defined three stages of the whipping process: (1) air bubbles are introduced and proteins are simultaneously adsorbed onto their surfaces, (2) fat globules are adsorbed onto the surface and accumulate, and (3) a network of fat-globule aggregates is formed. Noda and Shiinoki (1986) defined a four-stage process, and investigated the influences of demulsification and bubble introduction at each stage on the firmness of the produced cream. Jackubczyk and Niranjan (2006) reported that introducing air bubbles influenced the firmness of whipped cream. Air bubbles are known to be stabilized by the adsorption of fat globules (Dickinson and Stainsby, 1982; Anderson and Brooker, 1988), and some of the fat globules on the surface of the air bubbles are needed to produce the structure of the whipped cream. These reports indicate the importance of controlling the aggregation of fat-globules and the introduction of bubbles on the physical properties of whipped cream.

An appropriate whipping condition is needed in each phase to produce good-quality whipped cream, however, many factors affect the quality. Ihara et al. (2010) studied the influence of cream temperature on the whipping properties and concluded that a high cream temperature conferred firmness, which might be caused by the promotion of fat-globule aggregation. Besner and Kessler (1998) found that tempering the cream improved the quality of the produced whipped cream, making it firm via surface-mediated partial coalescence (Drelon et al., 2006; Gravier et al., 2006). Ihara et al. (2015) studied the effects of emulsifying components in the water phase and concluded that the large amount of emulsifying component resulted in a softer whipped cream after refrigeration. This phenomenon might be caused by a decrease in fat-globule aggregation. Moens et al. (2016) found that tempering cream promoted partial coalescence of the fat globules and increased the stability of whipped cream during cold storage. Ihara et al. (2005, 2007) studied the influence of beating speed on the physical properties of whipped creams. Those studies found that creams that are whipped at a low speed were relatively stable during storage, and suggested that the stability of the air bubble surface influenced the total stability of whipped creams. However, it was unclear which stage of whipping was influenced the most by changes in speed, as was the underlying mechanism.

The present study compared the physical properties of whipped creams produced using constant beating speeds and those produced when changing the beating speed during the whipping process. We also analyzed the factors that influence the whipping properties and the shape-retention ability during refrigeration.

Creams A 45 (wt%) fat dairy cream (Morinaga Milk Industry, Tokyo, Japan) was used, with 32 g of sucrose added to 400 g of cream for whipping.

Whipping conditions A standard mixer (Kitchen Machine Chef Classic KM4005, Delonghi, Treviso, Italy) was used for cream whipping. The beating speed as prescribed in each experiment refers to the orbital speed of the beater. The whipping time was defined as the time when the cone-penetration depth (PD) (see the next section) reached in the range of 20.5 to 22.5 mm. At the time of production, the whipped cream showed a good texture for cake-making. The whipped creams were stored at 5 °C to evaluate their shape-retention ability, while other measurements were carried out immediately. Each experiment involving the whipping process was conducted independently. The whipping rate was defined as the percentage of the beating time to the whipping time.

Cone-penetration test A cone penetrometer equipped with a cone having the following characteristics was used to measure the cream firmness: front-edge angle, 40°C; weight, 12 g; upper diameter, 24 mm; and length, 33 mm. The firmness was defined as the cone-penetration depth (PD) of the cone at 5 s after dropping under its own weight from the surface of the whipped cream.

Overrun Overrun (OR) was calculated using the following equation:

|

where ρ0 is the density of unwhipped cream and ρw is the density of whipped cream. The density was obtained using a weighing cup filled with 100 mL of the sample.

Serum viscosity Serum viscosity was measured using a method described by Ihara et al. (2010). A 3-g sample of whipped cream was defoamed using a vacuum pump at 10 Pa to prepare a serum sample. Its viscosity was measured using a cone-plate rotational viscometer (HAAKE RotoVisco 1, Thermo Electron, Karlsruhe, Germany) at a shear rate of 300 s−1. Each obtained value was the average of three measurements. A difference in viscosity between unwhipped cream and serum means that fat-globule aggregation is not present, and so the serum viscosity can be used to evaluate the degree of fat-globule aggregation. Serum viscosity increased with the progress of the whipping process and influenced the firmness of the whipped cream (Ihara et al., 2010).

Observation of bubbles in whipped cream Bubbles in whipped creams were observed using an optical microscope (BX53, Olympus, Tokyo Japan). Cover glasses (0.15-mm thick) were placed around the sample to avoid bubble deformation due to the pressure of the top cover glass. Bubbles were also observed using synchrotron-radiation X-ray scanning in the BL19B2 beam line at the SPring-8 facility (Hyogo, Japan). Sato et al. (2016) developed a method for observing the structure of foodstuffs in open air using liquid nitrogen spattering equipment. This method was applied in the present study by collecting a whipped-cream sample in a straw (ca. 7 mm in diameter) and immersing the straw in liquid nitrogen to fix the structure of the whipped cream. The temperature of the frozen samples was maintained by spattering them with liquid nitrogen during scanning. The sample was kept in the open air in this way based on the assumption that its structure would remain relatively unchanged compared to making observations in a vacuum condition.

Mean diameter of bubbles in whipped cream Individual diameters of bubbles were obtained from the optical microscope images. As the bubbles were not exact circles, the diameter was calculated as an equivalent circle diameter in this study. The Sauter mean diameter (d32) was calculated from the obtained images using imaging software (Image Pro Plus 7.0 J, Media Cybernetics, Rockville, MD USA) by applying the following equation:

|

where di is the diameter of each bubble. d32 has the same specific surface area as the parent population.

Shape-retention ability of whipped cream The shape-retention ability can be described as the difference in the firmness of whipped cream measured immediately after whipping and after 1 day of refrigeration. The difference of the PD between immediately after whipping and after 1 day of refrigeration, known as the delta penetration depth (ΔPD), quantifies the degree to which the firmness of whipped cream is maintained. A low ΔPD means that the whipped cream has a good shape-retention ability.

Effect of beating speed on whipping properties To assess the effects of beating speed, we measured the beating time at the end of whipping (whipping time), overrun, and ΔPD. The whipping time became shorter as the beating speed increased and showed an exponential correlation (Fig. 1). A high beating speed supplies the cream with a large amount of energy, thus promoting the incorporation of foam into the cream. Moreover, the shear rate increases with the beating speed, which makes the fat globules aggregate more rapidly (Fredrick et al., 2010). This mechanism affects the whipping time. On the other hand, there was a correlation between overrun and whipping time. This correlation was higher than that between overrun and beating speed (data not shown); thus, whipping time might affect overrun directly. ΔPD decreased as the beating speed decreased. These results were in accordance with the findings of Ihara et al. (2005). The correlation was higher than that between whipping time and ΔPD (data not shown), indicating that beating speed itself affected ΔPD. The properties of bubble and fat-globule aggregation of the whipped cream might cause this phenomenon. A slow beating speed would result in a narrow distribution of air-bubble size in the cream (Ihara et al., 2005), which might be one of the underlying reasons. Decreasing the beating speed decreased ΔPD but increased the whipping time, which reduced the productivity of making whipped cream. To solve this problem, we investigated the effect of changing the beating speed during the whipping process.

Effect of beating speed on whipping time. R2 is determination coefficient, and P is significance level.

Effects of changing the beating speed during the whipping process In experiments involving changing the beating speed, we first set the beating speed to 210 rpm, which is the maximum speed of the whipping machine employed. We hypothesized that the timing of the speed change played an important role in the whipping properties. In particular, we thought it was important to consider at which stage of the whipping process the timing change was performed. Therefore, we adopted the whipping progress rate at first beating speed (WRF) to indicate the timing of the speed change. This was defined as the percentage of beating time to the whipping time for a test at a constant speed of 210 rpm (first beating speed): a 0% WRF test meant a constant-beating-speed test at the second speed (e.g., 140 or 160 rpm), and a 100% WRF test meant a constant-beating-speed test at the first speed (210 rpm). Among the tests in which the second speed was 140 or 160 rpm, the whipping time shortened linearly as WRF increased (Fig. 3). The overrun also decreased as WRF increased (Fig. 4). However, in the tests in which the second speed was 140 rpm, the overrun was higher for WRF v50% than for WRF >50% (Fig. 4a). There were some potential physical differences in the whipped cream between WRFs of 50% and 75%. The serum viscosity remained low for WRF T50% and then began to increase for WRF >50% (data not shown). Beating high-viscosity cream at a low speed might lower the speed at which bubbles are introduced into the cream, and the overrun at the end of whipping could become low. The tests in which the second speed was 160 rpm showed a similar tendency to the data for a second speed of 140 rpm (Fig. 4b). However, the decrease in the overrun of the tests was smaller for a second speed of 160 rpm than for that of 140 rpm, which could be due to more air being introduced at 160 rpm.

Effects of beating speed on (a) overrun and (b) ΔPD. R2 is determination coefficient, and P is significance level.

Effects of the timing to change the speed (a) from 210 to 140 rpm, and (b) from 210 to 160 rpm on the whipping time. WRF is defined as the percentage of beating time at the speed changes to the whipping time for a test at a constant speed of 210 rpm. R2 is determination coefficient, and P is significance level.

Effects of the timing to change the speed (a) from 210 to 140 rpm, and (b) from 210 to 160 rpm on overrun. R2 is determination coefficient, and P is significance level.

ΔPD was relatively low for WRF between 0 and 80% in tests with second beating speeds of 140 and 160 rpm (Fig. 5). This meant that these whipping conditions yielded whipped cream with good physical properties. Whipped cream consists of air bubbles, fat-globule aggregation, and a water phase, and thus these factors might affect this phenomenon.

Effects of the timing to change the speed (a) from 210 to 140 rpm, and (b) from 210 to 160 rpm on the gap of the firmness after 1-day refrigeration (ΔPD).

Influences of overrun and serum viscosity on the shape-retention ability of whipped cream The foam represents >50% of the total volume of whipped cream; thus, foam is likely to be one of the most important factors affecting the physical properties of whipped cream. Fat-globule aggregation forms into a network that gives firmness to whipped cream (Hotrum et al., 2005). We therefore investigated the influence of overrun and serum viscosity on ΔPD. Fig. 6a shows the relationship between the overrun at the end of whipping and ΔPD. A correlation was present in the constant-beating-speed tests, but not in the tests in which the beating speed was changed. Fig. 6b shows that there was no correlation between the serum viscosity and ΔPD, which is consistent with the findings of Ihara et al. (2007). The difference in ΔPD between the constant speed and the speed change test was apparent in the range of overrun < 120%. These data were in the condition of WRF > 50%, in which the serum viscosity increased rapidly (data not shown). If beating speed became low in the stage, the speed of fat aggregation could be slow. We guessed that slow fat aggregation made the amount of free fat (unemulsified fat), which have an effect of defoaming, and might stabilize the bubbles. However, no correlation between serum viscosity andnΔPD. Ihara et al. (2005) also suggested that changes in the size of air bubbles during refrigeration can affect changes in the firmness of whipped cream in constant-beating-speed tests, and so we investigated the influence of the size of air bubbles in whipped cream.

Results of analyses of the effects of (a) overrun and (b) serum viscosity of the whipped creams on ΔPD. R2 is determination coefficient of the constant speed test. P is significance level of the constant speed test.

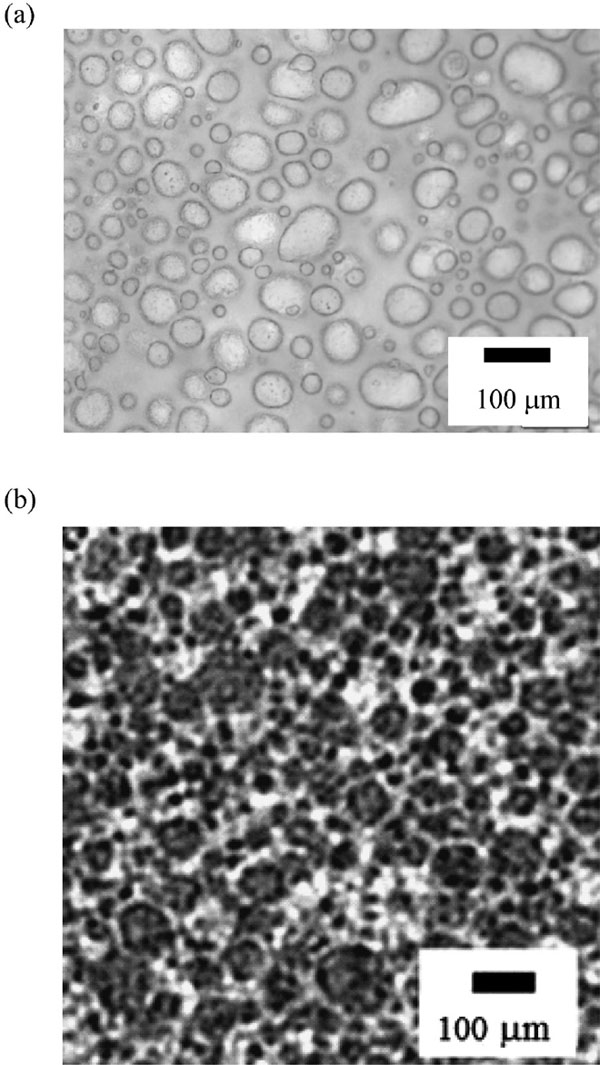

Observations of air bubbles in whipped cream Before investigating the influence of air-bubble size, we validated a method for observing air bubbles. The size of the bubbles ranged from 10 to 100 µm (Labbafi et al., 2007), and so we used an optical microscope for the observations since this provides a wide view of samples and is good for observing large (ca. 100 µm) bubbles. However, the sample will experience a compression force when a cover glass is placed over it, potentially deforming the bubbles. We therefore also observed the sample using synchrotron-radiation X-ray scans in order to validate the optical microscope observations. Synchrotron-radiation X-ray scans can also provide wide views of a sample within a short time without applying any physical pressure to the sample; thus, it is particularly suitable for observing bubbles. However, large facilities are needed to generate synchrotron-radiation X-rays, which limits its availability; thus, synchrotron-radiation X-rays were only used to validate the observation method.

Fig. 7a and b show images obtained using an optical microscope and synchrotron-radiation X-rays, respectively. The bubbles appeared to be of the same size in both types of image, and thus we subsequently used optical microscopy images to evaluate the sizes of air bubbles.

Observations of whipped cream using (a) optical microscopy and (b) X-ray scanning, in which the bubbles appear white and dark, respectively.

Influence of bubble diameter on the shape-retention ability of whipped cream We calculated d32 values for whipped cream in order to investigate how the mean diameter of their constituent bubbles influences the shape-retention ability. We adopted the conditions of beating at 120, 140, 160, 180, and 210 rpm in constant-beating-speed tests. For beating-speed-change tests, we chose a series of tests from 210 to 140 rpm and from 210 to 160 rpm. WRF in these tests was 25, 80, or 90%. The whipped cream with 25% WRF had a relatively low ΔPD, and ΔPD changed between the 80 and 90% WRF tests; thus, we proposed these data might be good for studying the relationship. Fig. 8 shows the correlation between d32 and ΔPD in the beating-speed-change tests. A smaller d32 at the end of whipping gave a lower ΔPD, which is accordance with the findings of Ihara et al. (2005). Fat globules attached to the surface of the air bubbles and constructed a fat-globule network (Dickinson and Stainsby 1982; Anderson and Brooker 1988; Walstra et al., 2006), and the bubble size, which influences the properties of the bubble surface, could affect the strength of the fat-globule network. Also, air bubbles themselves form a part of the network and furnish the whipped cream with a shape-retention ability. This means that the properties of the bubbles might play an important role in the shape-retention ability of whipped cream. This correlation was clear especially in the conditions of <120% overrun (data not shown). However, there was a weaker correlation between d32 after 1-day refrigeration and ΔPD. Further studies are needed to identify the underlying mechanisms.

Results of the analysis of the influence of Sauter mean diameter (d32) of the bubbles in the whipped creams on ΔPD. R2 is determination coefficient, and P is significance level.

We found that introducing a change in the beating speed during the whipping process of whipped cream shortened the whipping time while maintaining a high shape-retention ability of whipped cream. Moreover, overrun could be controlled by selecting an appropriate beating speed and timing of the speed change. The properties of the foam in the produced whipped creams played an important role in their shape-retention ability. The overrun at the end of whipping affected the change in the firmness of cream during refrigeration that had been whipped at a constant beating speed. On the other hand, the initial mean diameter of the air bubbles affected the shape-retention ability of whipped cream in the beating-speed-change tests. Changing the whipping conditions might be useful for manipulating the foam property of whipped cream in ways that allow the efficient production of high-quality whipped cream.

Acknowledgements The synchrotron-radiation X-ray scanning experiments were performed in the BL19B2 beam line at the SPring-8 facility with the approval of the Japan Synchrotron Radiation Research Institute (JASRI) (Proposal No. 2015B1896).