2019 Volume 25 Issue 3 Pages 399-404

2019 Volume 25 Issue 3 Pages 399-404

Preparation of GABA (γ-aminobutyric acid)-rich sourdough using rice bran and raisin was investigated. Preparation of sourdough began with pre-fermented raisin liquid, which is a widely used source of wild yeast and lactic acid bacteria. The number of naturally occurring cells in the liquid was 3.5×107 CFU/mL for yeast cells and 3.4×107 CFU/mL for lactic acid bacteria. The liquid was added to rice bran and then used to make sourdough via a three-stage fermentation process for 42 hours. The numbers of yeast (2.1×108 CFU/g) and lactic acid bacteria (1.3×108 CFU/g) in sourdough increased gradually with repeated fermentation. We also confirmed that the GABA and polyphenol contents of sourdough significantly increased during fermentation. Thus, sourdough enriched with GABA could be rapidly and easily obtained through a three-stage natural fermentation process using rice bran and raisin. These findings also provide useful information for the effective use of milling rice by-products.

Commercialization of sourdough bread is difficult since activation of yeast is time-consuming, and a high level of technology is required to produce standardized bread. However, as yeast fermentation technologies have become standardized, sourdough production has gradually reached its practical potential (Hamelman 2004; Chung et al., 2011; Cho et al., 1999). Current features of sourdough include improvement of unique flavors using naturally obtained bacteria (Thiele et al., 2002; Kim, 2001) and a prolonged storage period (Beak, 1990). Activation of natural yeast is a very important process. In general, sourdough starters are made from rye or fermented liquid using raisins. In other words, the process of sourdough development or standardization is considered to be one of the most important processes for making sourdough bread.

Previous studies on natural sourdough bread have focused on the separation of fermentation microorganisms from the bioactivity of sourdough (Banu et al., 2010; Chung et al., 2011), making of sourdough bread using hongguk (red rice-fermented Monascus sp.) (Lee et al., 2007), and the development of starters using probiotics and Saccharomyces cerevisiae (Chae et al., 2011). Likewise, the main ingredients used to make sourdough are mostly derived from edible agricultural products such as wheat flour, rye flour, or functional materials.

We first gained evidence of the superiority of rice bran while seeking materials for the development of new sourdough starters (Bhanwar et al., 2013; Moon et al., 2010; Kwak, 2010; Leventhal et al., 2003). We learned that rice bran, a by-product of the rice milling process, is often disposed of without any further use except as an animal feed, even though it contains various bioactive materials such as phenolic compounds and GABA. Functional activities of GABA are known to include protective effects against streptozotocin-induced diabetes, cardiovascular diseases, stimulation of alcohol metabolism, and prevention of obesity (Nakagawa T et al., 2005; Lin KH et al., 2014; Stanley BG, 2012). In recent years, interest in GABA as a functional material for bread making has increased. Bhanwar S. et al., (2013) suggested Lactococcus lacitis as a lactic acid bacteria starter for the production of GABA-enriched bhatura (fried sourdough bread), but there has been little research on GABA–rich sourdough made from fermented rice bran and raisin liquid.

Based on these findings, this study investigated the efficacy of natural GABA-rich sourdough made from rice bran and raisins.

Raw materials Rice bran was prepared fresh by processing Brown-gaba rice through a rice milling machine within 7 days and purchased from an organic farm (Gyeongsan, Korea). Raisins used in this study were a product of Liberty Farms and Sales (TS corporation co., Ltd, Korea), wheat flour was hard flour (Daehan flour co., Korea), and sugar was white sugar (CJ Cheiljedang co., Korea). All other materials were used after purchase from a nearby market.

Analysis of physicochemical property The pH level was measured using a pH meter (Corning pH meter 240, U.S.A.) applied to 10 mL of raisin liquid, and the measurement was carried out three times (A.O.A.C, 1984). Measurement of acidity was performed using 10 mL of raisin liquid according to the method of AACC 2 to 31 (A.A.C.C., 1983). Briefly, raisin liquid was placed into a 250 mL beaker and diluted 10-fold with distilled water, after which two to three drops of 0.1% phenolphthalein indicator were added. The raisin liquid was then titrated with 0.1 N NaOH, and the endpoint was designated as the point at which pink color persisted for 30 seconds. The sugar content was measured three times using an Abbe Refractometer (Hand Refractometer, ATAGO, Japan).

Microbe count Yeast colonies were counted after cultivation at 30 °C for 48 hours on potato dextrose agar media (Difco, USA) to which 10% sterile tartaric acid was added in order to lower the pH of the medium to 3.5, so that bacterial growth is inhibited. Colonies of lactic acid bacteria were counted after cultivation at 30 °C for 48 hours on Lactobacilli MRS media (Difco, USA) to which 0.01% Bromocresol green was added (Oberg et al., 1986).

Analysis of total phenolics and GABA The content of total phenolic compounds was measured according to the methods of Folin and Denis (Folin and Denis, 1912) and Lee et al (Lee et al., 2006). Dough was used after adjustment of density to 1 mg/mL with distilled water. Folin-Ciocalteu's reagent (0.2 mL; Sigma, U.S.A.) was added after mixing 0.2 mL of sample with 1.8 mL of distilled water in a screw tube. Absorbance was measured at 725 nm as follows: sample was incubated at room temperature for 3 minutes, followed by vortexing, addition of 0.4 mL of 10% Na2CO3, and addition of 1.4 mL of distilled water for 1 hour. The content of total phenolic compounds was calculated from the standard curve using ferulic acid (Sigma, U.S.A.).

GABA content was measured by diluting 5 g of dough or fermented rice bran 10 times with distilled water, addition of 20 mL of distilled water, and addition of 20 mL of 20% TCA (trichloroacetic acid), after which the precipitated protein was centrifuged at 3,000 rpm for 20 minutes. The aqueous layer was decompressed and concentrated after addition of 30 mL of ethyl ether to the supernatant. After mixing, TCA and fat-soluble substances were removed. Citrate buffer (0.2 M; pH 2.2) solution was added to the concentrate to a total volume of 5 mL, filtered through a 0.22 µm membrane filter, and analyzed using an amino acid analyzer (L-8800, Hitachi, Ltd., Tokyo, Japan). The fermented rice bran mentioned above was prepared according to the procedure of a previous study (Kim and Han, 2011). Briefly, distilled water was added to the rice bran at about 25% (v/w) and then fermented with yeast of Issatchenkia orientalis MFST1 at RT for 5 days.

Preparation of fermented raisin liquid and rice bran sourdough Raisin mixture was prepared by adding 500 g of raisins to a sterile bottle, followed by mixing with 750 mL of sterile water and 10 g of sugar. The mixture was then kept in an incubator (HB-201SLI Han Baek Scientific co., Korea) at 28 °C for 7 days and then filtered through a 60-mesh sieve to produce fermented liquid.

Rice bran sourdough was prepared and cultured using a modified multi-stage method, as shown in Table 1. A three-stage fermentation process was required to manufacture sourdough, and the endpoint of fermentation was the point at which when the volume of dough became twice that of the original. Specifically, primary sourdough was manufactured using a stationary culture of 250 g of rice bran, 250 g of bread flour, and 500 g of fermented raisin liquid in a fermenter (HS-5001, Hwasung Machinery Co., Korea) at 28 °C. Secondary sourdough was manufactured using a stationary culture of 900 g of the primary sourdough with 450 g of rice bran, 450 g of flour, and 900 g of water at 28 °C. Final sourdough was manufactured using a stationary culture of 2,400 g of the secondary sourdough with 1,200 g of rice bran, 1,200 g of flour, and 1,680 g of water at 28 °C. This experiment for making sourdough through three-stage fermentation using rice bran and raisin was carried out two times independently in same condition.

| Samples | Fermented dough | Fermented raisin liquid (g) | Rice bran (g) | Flour (g) | Water (g) | Total (g) |

|---|---|---|---|---|---|---|

| 0-step | - | 500 | 250 | 250 | 0 | 1000 |

| 1-step | - | 500 | 250 | 250 | 0 | 1000 |

| 2-step | 900 | - | 450 | 450 | 900 | 2700 |

| 3-step | 2400 | - | 1200 | 1200 | 1680 | 6480 |

Dough mixed with fermented raisin liquid and rice bran (0-step), dough after 24 hours of fermentation from 0-step (1-step), dough after 12 hours of fermentation from 1-step (2-step), and dough after 6 hours of fermentation from 2-step (3-step).

We confirmed a high reproducibility in the two times sourdough experiments with qualitatively similar results, and then we analyzed the results obtained from the last sourdough experiment.

Statistical analysis Data were obtained from triplicate measurement with three independent sampling from sourdoughs. Values are expressed as mean ± standard deviation (SD). One-way analysis of variance (ANOVA) and T-test were used for multiple comparisons. Treatment effects were analyzed using Duncan's multiple range test using SPSS 19.0 software. Differences are considered significant with p values <0.05.

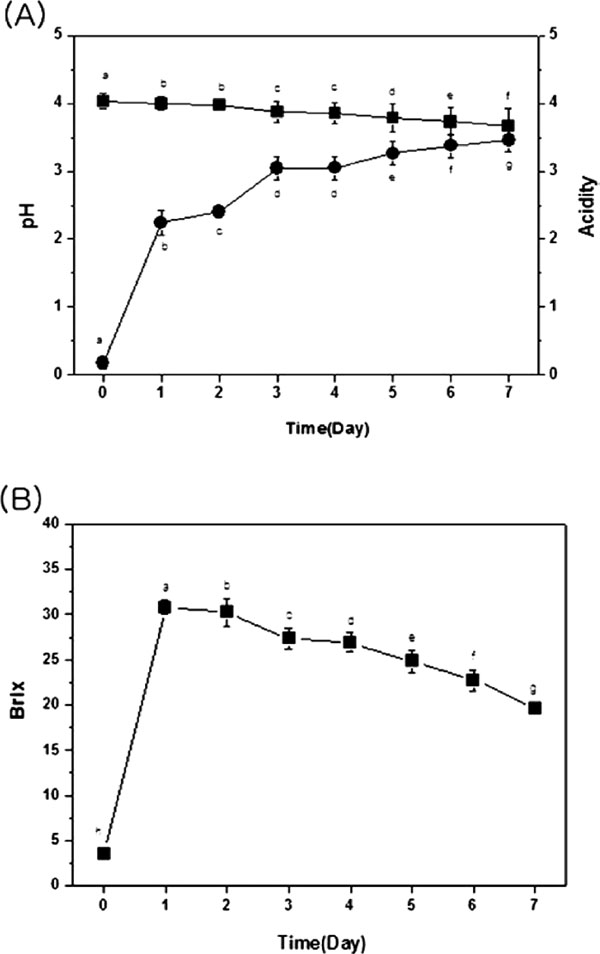

Physicochemical properties and microorganism conditions of fermented raisin liquid figure 1 (A) shows the pH and acidity results after fermenting raisins for 7 days. The pH level gradually decreased at the beginning of fermentation and then significantly decreased from day 5 of fermentation to a final pH level of 3.68. These results are consistent with the research results of Kim and Chun (Kim and Chun, 2008), who showed that the pH level decreases while acidity increases with a longer cultivation time of raisins. The acidity gradually increased over 7 days of fermentation after its significant increase on day 1 (p < 0.001). Changes in sugar content of the fermented liquid are shown in Fig. 1 (B). Sugar content significantly increased to 30.8 brix on day 1 of fermentation and gradually decreased as fermentation progressed, reaching a low point of 19.76 brix on day 7. These results suggest that the sugar in raisins was used by microbes during fermentation, resulting in increased acidity and decreased pH level. According to Kim and Chun (Kim and chun, 2008), the sugar content of sourdough continuously increased until day 2 of fermentation, after which it gradually decreased from day 3. In this study, sugar content gradually decreased after reaching its highest level on day 1.

Changes in pH, acidity, and Brix in fermented raisin liquid. (A) pH  , Acidity

, Acidity  . (B) Brix

. (B) Brix  . Each value represents mean±SD (n=3), a–f Means with different superscripts are significantly different at a 5% significance level by Duncan's multiple range test. F-value of pH is 191.006***, F-value of acidity is 14457.033*** (***p < 0.001).

. Each value represents mean±SD (n=3), a–f Means with different superscripts are significantly different at a 5% significance level by Duncan's multiple range test. F-value of pH is 191.006***, F-value of acidity is 14457.033*** (***p < 0.001).

The numbers of naturally occurring yeast cells and lactic acid bacteria in the final fermented raisin liquid were determined. The numbers of lactic acid bacteria and yeast cells were similar at 7.531 log10 CFU/g (3.4×107 CFU/mL) and 7.531 log10 CFU/g (3.5×107 CFU/mL), respectively (Table 2 Raisin F-L).

| Raisin F-L | 0-step | 1-step | 2-step | 3-step | |

|---|---|---|---|---|---|

| Yeast cells | 7.531 ± 0.30bc | 7.505 ± 0.50bc | 7.114 ± 0.30c | 8.079 ± 0.20ab | 8.322 ± 0.09a |

| Lactic acid bacteria | 7.531 ± 0.50bc | 7.505 ± 0.29bc | 7.230 ± 0.23c | 7.763 ± 0.10ab | 8.114 ± 0.11a |

Fermented raisin liquid (Raisin F-L), dough mixed with fermented raisin liquid and rice bran (0-step), dough after 24 hours of fermentation from 0-step (1-step), dough after 12 hours of fermentation from 1-step (2-step), and dough after 6 hours of fermentation from 2-step (3-step). Each value represents mean±SD (n=3),

F-value of yeast cell is 7.265**, F-value of Lactic acid bacteria is 6.082**. (**p < 0.01).

Fermentation time of sourdough added with rice barn was reduced by three-stage fermentation Primary sourdough was made by adding rice bran and flour to the fermented raisin liquid after fermentation for 7 days, whereas secondary sourdough was made by fermentation after addition of rice bran, flour, and water to the primary sourdough. Final sourdough was made by fermentation after addition of rice bran, flour, and water to the secondary sourdough. Each stage of the fermentation process was carried out when the volume of dough reached twice that of the original. The time required for the 1-step fermentation of sourdough was about 24 hours, 12 hours for 2-step, and 6 hours for 3-step. Thus, the time required to ferment sourdough was reduced by half with each additional step to obtain the same volume of dough, indicating this three-step process efficiently reduced the time required to prepare sourdough.

Changes in microorganisms during fermentation of sourdough with adding rice bran Changes in yeast and lactic acid bacteria during fermentation of sourdough with added rice bran are shown in Table 2. The number of yeast colonies in the fermented raisin liquid was 7.531 log10 CFU/g (3.5×107 CFU/g), whereas the number slightly decreased to 7.114 log10 CFU/g (1.3×107 CFU/g) after addition of rice bran and flour in the 1-step fermentation. The numbers of yeast colonies in the second and final step sourdoughs increased to 8.079 log10 CFU/g (1.2×108 CFU/g) and 8.322 log10 CFU/g (2.1×108 CFU/g), respectively, upon addition of rice bran and flour. The pattern of lactic acid bacteria in sourdough was similar to that of yeast as shown above. Based on these results, the numbers of yeast and lactic acid bacterial colonies continuously increased upon addition of rice bran and flour. Similarly, Hanne and Ase (Hanne and Ase, 2000) measured the numbers of yeast and lactic acid bacterial colonies to be 6.0–8.04 log10 CFU/g and 8.43–9.14 log10 CFU/g, respectively, in sourdough made from conventional or organic rye. Many reports have shown that the natural appearance of lactic acid bacteria and yeasts is the most important factor in making sourdough (Hanne and Ase, 2000; Meignen et al., 2001; Carnevali et al., 2007; Emanuele et al., 2009). Our results are the first to investigate the efficacy of a sourdough starter made from rice bran and raisins without artificial additives.

We also checked changes in the pH of sourdough with added rice bran and flour. The pH level of fermented raisin liquid was 3.68 and increased to 5.62 just after addition of rice bran and flour, and the pH levels of sourdough were not significantly different during fermentation of sourdough (5.92 for 2-step, and 6.02 for 3-step).

Changes in polyphenol and GABA contents during fermentation of the sourdough Figure 2 shows that repeated fermentation significantly increased the polyphenol content of sourdough (Fig. 2 (A)), possibly due to fermentation of raisins. Polyphenols are present at a higher level in raisins compared to grapes, and lactic acid fermentation allows increased concentrations of total phenols, flavonoids, and anthocyanins in fruits (Williamson and Carughi 2010; Curiel et al., 2015). However, we could not exclude the possibility that polyphenol content might be affected by fermented rice bran in sourdough. In our previous study, polyphenol content of rice bran significantly increased after fermentation with yeast (Kim et al., 2011). Changes in the GABA content of sourdough during fermentation were similar to that of polyphenols (Fig. 2 (B). Flours itself have very low GABA level and their concentrations are various depending on their species. Coda et al. (2010) have been reported that the GABA content of twelve different flours had various endogenous concentrations of GABA, which varied from 3±1 to 78±13 mg/kg. Rice bran is known to be good source of GABA. GABA production significantly increased by fermentation with lactic acid bacteria and rice bran extracts (Kook et al., 2010). We also confirmed that GABA content in rice bran was increased by yeast fermentation. Rice bran fermented by yeast of I. orientalis MFST1 showed higher GABA content (1002.8±18.2 mg/100 g) compared to those of non-fermented normal rice bran (634.0±15.1 mg/100 g). Taken together, these findings led us to hypothesize that the increased GABA contents of sourdough may be mainly due to rice bran fermented in the sourdough.

Changes in polyphenol and GABA contents during fermentation of rice bran sourdough. (A) Polyphenol content. (B) GABA content. Dough mixed with fermented raisin liquid and rice bran (0-step), dough after 24 hours of fermentation from 0-step (1-step), dough after 12 hours of fermentation from 1-step (2-step), and dough after 6 hours of fermentation from 2-step (3-step). Each value represents mean±SD (n=3), abcd Means with different superscripts are significantly different at a 5% significance level by Duncan's multiple range test. F-value is 1741.559*** (***p < 0.001).

As shown in Fig. 2, the GABA volume of sourdough using rice bran in this study is thought to be higher compared to general sourdough. There are several reports about GABA content in non-rice bran sourdough. Diana et al. reported that the GABA concentration in sourdough prepared using Lactobacillus brevis CECT 8183 was 98.2 mg/100 mL and similarly Coda et al. also showed GABA content of 103 mg/100 g in a study on the use of Lactococcus lactis subsp lactis PU1. (Diana et al., 2014; Coda et al., 2010).

Taken together, sourdough enriched with GABA could be rapidly and easily prepared through three-stage fermentation using rice bran and raisin liquid without artificial additives. These findings may enhance the health benefits and commercial value of rice bran as well as provide useful information for the effective use of milling by-products of rice.

Acknowledgements This work was supported by the 2012 Yeungnam University Research Grant