2019 Volume 25 Issue 3 Pages 425-434

2019 Volume 25 Issue 3 Pages 425-434

The effect of soaking treatment before cooking on the hardness of soybeans and red kidney beans stored at 37 °C/75 % RH (aged beans) was evaluated by kinetic analysis using the softening rate constant. Based on the analysis results, softening behavior was separately examined as “softening due to water absorption” and “softening due to heating”, making it possible to predict the heating time and to quantitatively evaluate the effect of soaking treatment on hardness during cooking of beans. Interestingly, in both aged beans, prolonged soaking time remarkably suppressed softening during subsequent heating. In addition, in both aged beans, when the soaking time was longer, the value of the softening rate constant ks1 for pre-soaked beans decreased and the difference in the predicted heating time between pre-soaked and un-soaked beans was reduced. These results indicated that soaking treatment before cooking is not recommended for stored beans, as it suppresses their softening during cooking.

Dry legumes generally require soaking treatment to absorb sufficient water before cooking or processing. The purpose of pre-soaking before cooking is to shorten the subsequent heating time and soften the tissue evenly (Kon et al., 1979; Gandhi and Bourne, 1991; Abu-Ghannam and McKenna, 1997). Previously, using kinetic analysis with a softening rate constant, it was demonstrated that pre-soaking of soybeans and red kidney beans before cooking shortens the subsequent heating time up to approximately 1/2 for soybeans and 1/3 for red kidney beans (Koriyama et al., 2018). On the other hand, for beans pre-soaked at around 60 °C for 8 h or more, softening was suppressed during subsequent heating and hardening occurred instead, as observed in vegetables and fruits (Kasai et al., 1994; Koriyama et al., 2017).

It is known that storage of dry legumes at a high temperature and high humidity, such as 35 °C/75 % RH (Garcia et al., 1998; Yi et al., 2016), causes a hardening phenomenon, also known as the Hard-to-Cook defect. Softening of stored beans in which this phenomenon has occurred requires a long cooking time, making such beans less acceptable to consumers (Mattson, 1948; Garcia et al., 1998). The mechanism of hardening has been proposed to involve the formation of insoluble pectates based on the pectincation-phytate theory (Njoroge et al., 2014, 2016; Shiga et al., 2004, 2011) and/or inhibition of swelling and gelatinization of starch due to protein insolubility (Liu et al., 1992a, 1993; Koriyama et al., 2017). However, the hardening phenomenon of beans is complicated and has not been fully elucidated.

In regards to the influence of soaking treatment on the hardness of beans, many researchers have determined cooking behavior in different solutions such as Na2CO3, CaCl2, and NaCl (Kinyanjui et al., 2017; Njoroge et al., 2016; Liu et al., 1992; Makino et al., 1987). However, there are no reports focusing on “soaking treatment in water itself” as a softening-suppressive factor in stored beans. In addition, no study has compared the softening rate in the presence or absence of soaking treatment in the cooking of stored beans.

To ensure that dry beans are optimally edible and soft when cooked, they must go through the process of storage, soaking, and heating, with each condition affecting the hardness and cooking time. However, it is difficult to quantitatively show the influence of different factors in each of the processes on the change in hardness. Moreover, to date, this has not been considered. Previously, we designed experiments to distinguish the softening behavior of stored beans as either “softening due to water absorption” or “softening due to heating” and to obtain the rate constant of each softening process (Koriyama et al., 2018).

In this study, we aimed to quantitatively evaluate the influence of soaking treatment on hardness in the cooking of stored beans.

Samples Two types of dry beans, soybeans (Glycine max L. Merrill, Yukihomare, Tokachi, Hokkaido) and red kidney beans (Phaseolus vulgaris L., Taisho-Kintoki, Tokachi, Hokkaido), were purchased immediately after harvest in 2015 (Futami Seika, Kushiro City, Hokkaido, Japan) and used for the study. Storage conditions were determined according to the results of our previous study. The hardening phenomena occurred in both soybeans and red kidney beans by storage at 37 °C/75 % RH, and these beans, hardened by storage, were referred to as aged beans. Beans refrigerated at 4 °C, the condition in which the smallest change in hardness was observed during storage, were used a control.

Aged beans were placed in a container, maintained at 75 % RH with saturated saline, and stored in a thermostatic chamber controlled at 37 °C. Control beans were kept in a sealed bag and stored in a chamber controlled at 4 °C/80 % RH. The storage period was 0–120 days. Broken or immature beans were removed by visual inspection before experiments.

Cooking conditions The cooking procedure was previously described by Koriyama (2018). Changes in bean hardness during heating were compared between un-soaked and soaked beans. Un-soaked dry beans were incubated at constant temperatures between 10 and 99.5 °C for 0–24 h, whereas soaked beans were heated at constant temperatures between 80 and 99.5 °C for 0–3 h. For the preliminary soaking, both soybeans and red kidney beans were soaked in a 20-fold (w/w) volume per sample of distilled water at 20 °C for 8 h. Subsequently, for heating, the soaked beans were placed in a beaker containing a 20-fold volume (w/w) of distilled water and were maintained isothermally at predetermined temperatures. Un-soaked beans were treated using an incubator (IN600, Yamato, Santa Clara, CA) at 10 and 20 °C, a thermostat-controlled water bath (Isotemp model 228, Fisher Scientific, Waltham, MA) at 30–90 °C, or an electric cooking stove (HP-634, HP-635, TOSHIBA, Tokyo, Japan) at 99.5 °C. The temperature was adjusted to be within ± 1 °C of the predetermined temperature over the experimental period.

Hardness measurement Textural properties were measured using a texture analyzer (TA.XT. Plus, Stable Micro Systems, Ltd., Surrey, UK) and hardness was expressed as the maximum load value (N) determined from the peak height of the force-deformation curve. Measurement conditions were as follows: load cell, 30 kg; probe, ϕ 3 mm cylindrical shape; probe speed, 1 mm/s; and compression ratio, 80 %. The average hardness was calculated from the results obtained from the evaluation of ten beans in each experiment. The experiment was performed in triplicate.

Kinetic analysis To determine the softening rate at each temperature, we defined the softening ratio x (Kasai and Shimada, 1985) as a dimensionless value for the change in hardness, as follows:

|

In this equation, y0, ye, and y represent values for initial hardness, equilibrium hardness, and hardness (N) at time t, respectively. Based on experimentally determined values, the equilibrium hardness values for soybeans and red kidney beans were 1.5 and 1.0 N, respectively (Koriyama et al., 2018).

Assuming that approximation to a first-order rate equation is possible, the softening ratio x, as defined by equation 1, can be expressed by the following equation:

|

|

The temperature dependencies of the water absorption rate and softening rate were described using the Arrhenius equation.

|

where A is the frequency factor (min−1), E is the apparent activation energy (J/mol), R is the gas constant (8.314 J/mol·K), and T is the absolute temperature (K). E and A were calculated in the temperature range in which the data were concordant with the Arrhenius equation.

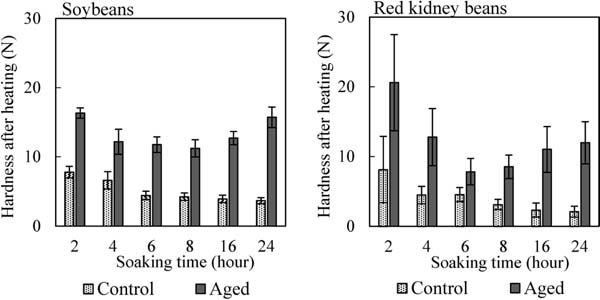

Influence of soaking time on hardness of cooked beans Generally, the hardening phenomenon appears clearly in cooked beans. Therefore, all of the beans with different soaking times were heated at 99.5 °C for 40 min and their hardness values were compared. The soaking temperature was 20 °C. As shown in Fig. 1, in control beans, both soybeans and red kidney beans became softer after heating with a longer soaking time. On the other hand, the aged beans became softer with a longer soaking time up to 8 h for soybeans and 6 h for red kidney beans; and they became harder when the soaking time exceeded these times. Interestingly, these observations suggested that the control beans tended to soften during heating due to soaking treatment, whereas in aged beans, exceeding a certain soaking time suppressed softening during heating.

Influence of soaking time on bean's hardness after heating. Control and aged beans were heated at 99.5 °C for 40 min after soaking at 20 °C for 0, 2, 4, 6, 8, 16, and 24 h. Each value represents the mean ± standard deviation.

Control: beans stored at 4 °C/80 % RH for 90 days. Aged: beans stored at 37 °C/75 % RH for 90 days.

As shown in Fig. 2, both pre-soaked soybeans and red kidney beans at 0 min of heating were softer in aged beans than controls. However, the softening curve after the start of heating showed a tendency for decreased likelihood of softening in aged beans compared to the control. These results indicated that the hardening phenomenon of the aged beans was unclear in the preliminary soaking alone but became apparent in the subsequent “softening during heating”.

Change in hardness of pre-soaked control and aged beans during heating. Sample beans were heated at 99.5 °C after soaking at 20 °C for 8, 16, and 24 h.

Control: beans stored at 4 °C/80 % RH for 90 days; Aged: beans stored at 37 °C/75 % RH for 90 days.

Therefore, to quantitatively evaluate the influence of soaking time on the softening ratio in stored beans, changes in hardness during heating were evaluated, and a kinetic analysis was attempted using a first-order rate equation. Subsequently, the softening ratio x was obtained from these measured values of hardness, and the logarithmic values were plotted against the heating time as a first-order kinetics. As shown in Fig. 3, the softening behavior during heating of both soybeans and red kidney beans showed a linear relationship in the first-order plots. Moreover, the first-order plots for both beans presented two straight lines at all soaking conditions. It has been reported that the hardness of beans after pre-soaking decreased in a two-step reaction during heating (Gandhi and Bourne, 1991; Koriyama et al., 2018). Therefore, the softening rate constant of soaked beans, as obtained from the slope in the first half was set as ks1, while that in the latter half was set as ks2.

First-order plot of softening rate of pre-soaked control and aged beans during cooking. Sample beans were heated at 99.5 °C after soaking at 20 °C for 8, 16, and 24 h.

◊: Control, soaked for 8 h; ◆: Aged beans, soaked for 8 h; ▲: Aged beans, soaked for 16 h; ■: Aged beans, soaked for 24 h; Control: beans stored at 4 °C/80 % RH for 90 days; Aged: beans stored at 37 °C/75 % RH for 90 days.

As shown in Table 1, the softening rate constants ks1 and ks2 of both aged beans were smaller than those of the control. In particular, the value of ks1 decreased remarkably as the soaking time increased. In soybeans, the ks1 values of aged beans soaked for 8 and 24 h were approximately 1/4 and 1/7 of those of control beans, respectively. In red kidney beans, the ks1 values of aged beans soaked for 8 and 24 h were approximately 1/2 and 1/4 of those of control beans, respectively. These results demonstrate that the suppressed softening of aged beans during heating due to prolonged soaking time was indicated by the corresponding rate constant values.

| Soaking time | Soybeans | Red kidey beans | |||

|---|---|---|---|---|---|

| ks1 | ks2 | ks1 | ks2 | ||

| Control | 8h | 0.1061 | 0.0283 | 0.1042 | 0.0508 |

| 8h | 0.0231 | 0.0063 | 0.0452 | 0.0137 | |

| Aged | 16h | 0.0174 | 0.0050 | 0.0307 | 0.0122 |

| 24h | 0.0145 | 0.0052 | 0.0269 | 0.0115 | |

Sample beans were soaked at 20 °C for 8, 16, and 24 hours.

Control: beans stored at 4 °C/80 % RH for 90 days; Aged: beans stored at 37 °C/75 % RH for 90 days.

It has been reported that unfavorable storage induced deterioration in cell membrane function of beans, insolubilization of proteins, and changes in cell wall polysaccharides (Liu et al., 1992b; Koriyama et al., 2017). Moreover, the mechanism by which the hardening phenomenon occurs is explained as follows: a loss of integrity of the cellular membrane allows intracellular electrolytes (predominantly K) to contact cell wall materials, thereby activating pectin methylesterase. The enzyme increases the amount of free carboxyl groups of cell wall pectin, and Ca and Mg from the cell interior increases the number of metal bridges (Bartorole and Hoff, 1972; Manabe, 1980). From these results, it is determined that aged beans have reduced cell membrane function, and mass transfer tends to occur when the soaking time is prolonged; thus, structural changes progressed and the beans became difficult to soften.

Changes in hardness of aged beans during heating without preliminary soaking Since suppression of softening of pre-soaked aged beans was suggested, the change in hardness of un-soaked aged beans during heating was investigated for comparison. Changes in the hardness of un-soaked aged beans measured during incubation at 10–99.5 °C are shown in Fig. 4.

Changes in hardness of aged soybeans and aged red kidney beans during incubating at constant temperatures between 10 °C to 99.5 °C. Sample beans were directly treated without soaking. Aged beans were stored at 37 °C /75 % RH for 90 days.

At 10–50 °C, both beans were rapidly softened during the beginning of incubation; however, almost no changes in hardness were observed after reaching 22 N for soybeans and 26 N for red kidney beans, even when incubation was continued further. Softening at 10–50 °C is considered to be “softening due to water absorption” because 10–50 °C is the temperature range at which β-elimination of pectin hardly occurs by heating. On the other hand, the water absorption rate continued to rise even after hardness reached the equilibrium state, and water absorption reached equilibrium after 8 h in soybeans and after 16 h in red kidney beans (Fig. 5). These results indicate that the lower limit value for hardness for “softening due to water absorption” is approximately 22 N for aged soybeans and 26 N for aged red kidney beans.

Changes in water absorption rate of aged soybeans and aged red kidney beans during soaking at constant temperatures between 10 °C to 50 °C. Aged beans were stored at 37 °C/75 % RH for 90 days.

◊: 10 °C, △: 20 °C, □: 30 °C, ○: 40 °C, ×: 50 °C

As shown in Fig. 4, at 60 °C or higher, both soybeans and red kidney beans were rapidly softened by heating for 30–40 min after the start of incubation, and thereafter, the softening became gradual. The hardness at which the softening curves changed from rapid to gradual was approximately 22 N for soybeans and 26 N for red kidney beans, and these values were constant at any temperature. Moreover, these values were close to the apparent equilibrium value of hardness for “softening due to water absorption” at 10–50 °C. Therefore, when incubation was performed without pre-soaking, “softening due to water absorption” was considered to occur dominantly up to approximately 22 N for aged soybeans and 26 N for aged red kidney beans, even at 60 °C or higher.

In our previous study using soybeans and red kidney beans refrigerated at 4 °C, a softening curve model was proposed, and it was clarified that the softening behavior during cooking of dry legumes can be distinguished as either “softening due to water absorption” or “softening due to heating.” This previous report showed that “softening due to water absorption” preferentially occurs from the initial hardness value to approximately 30 N, regardless of the temperature, even after heating without pre-soaking and that after reaching 30 N, “softening due to heating” occurs preferentially depending on the temperature.

In this study, the apparent equilibrium hardness values for “softening due to water absorption” in both aged beans were lower than 30 N; however, the softening behavior of aged beans showed a similar tendency to that of the previous study. This result suggests that “softening due to water absorption”and “softening due to heating” can be analyzed separately, even in aged beans. One of the reasons why the apparent equilibrium hardness value for “softening due to water absorption” was smaller for aged beans than for control is that certain changes in tissue structure possibly occurred in the aged beans. Details of changes in organizational structure during soaking will be the subject for future study.

Softening rate constant of “softening due to water absorption” and “softening due to heating” processes Softening ratio (x) was obtained from the measured values of hardness, and logarithmic values were plotted against heating time as per first-order kinetics.

As shown in Fig. 6, a linear relationship was obtained in the first-order plots of softening ratio in the 10–50 °C range, which represents “softening due to water absorption”, for both soybeans and red kidney beans. At ≥ 60 °C, the first-order plots for both beans were represented by curves comprising two or three straight lines. The hardness values when the slope of the first line changed were substantially constant at any temperature, as shown by the dotted lines, and these values were close to the lower limit hardness value for “softening by water absorption” at 10–50 °C. The second slope of each bean type changed in the shaded area, corresponding to hardness values of approximately 10 N for soybeans and 7 N for red kidney beans.

First order plot of softening ratio in aged soybeans and aged red kidney beans incubated at 10–99.5 °C. Sample beans were directly treated without soaking.

Aged beans were stored at 37 °C/75 % RH for 90 days. x: softening ratio.

◊: 10 °C, △: 20 °C, □: 30 °C, ○: 40 °C, ×: 50 °C,

: 60 °C,

: 60 °C,  : 70 °C, ◆: 80 °C, ▲: 85 °C, ■: 90 °C, ●: 95 °C, *: 99.5 °C

: 70 °C, ◆: 80 °C, ▲: 85 °C, ■: 90 °C, ●: 95 °C, *: 99.5 °C

Since the second and third slopes occurred after “softening by water absorption” in un-soaked beans, both slopes are presumed to be “softening due to heating.” Therefore, pre-soaked beans were also heated, and a first-order plot was generated for comparison. As shown in Fig. 7 and Fig. 8, the first-order plots of both beans showed one or two straight lines. The slope changed after reaching a hardness of approximately 11 N for soybeans and 7 N for red kidney beans, as shown by the shaded area. It was inferred that a two-step reaction with different rate constants occurred in the “softening due to heating” process of soybeans and red kidney beans, regardless of the presence or absence of pre-soaking.

Changes in hardness of aged soybeans and aged red kidney beans during cooking at constant temperatures between 80 °C to 99.5 °C. Sample beans were treated after presoaking at 20 °C for 8h. Aged beans were stored at 37 °C/75 % RH for 90 days.

First order plot of rate of “softening due to heating” in the aged soybeans and red kidney beans incubated at 80–99.5 °C. Sample beans were treated after presoaking at 20 °C for 8h. Aged beans were stored at 37 °C/75 % RH for 90 days. x: softening ratio.

From the above, regardless of temperature, the segment of the plot from the initial value to the point where the first slope change occurred was defined as kw, which was the rate constant for “softening due to water absorption.” Furthermore, the softening rate constants for “softening due to heating” were defined as ks1 and ks2 in either case of beans heated without pre-soaking and those with pre-soaking: for the rate constant for “softening due to heating” of soybeans, the slope from the hardness value of 26 N to that of 10 N was set as ks1, while the slope after reaching 10 N was set as ks2. In the same way, for the rate constant for “softening due to heating” of red kidney beans, the slope from 22 to 7 N was set as ks1, while the slope after reaching 7 N was set as ks2. These definitions made it possible to quantitatively evaluate the influence of pre-soaking on the cooking of aged beans using the softening rate constant.

It is assumed that “softening due to water absorption” was influenced by the characteristic water absorption of the beans; for example, soybeans absorb moisture from the entire epidermis (Tagawa et al., 1998). On the other hand, “softening due to heating”, which was caused by gelatinization of starch and change of cell wall polysaccharides, is considered to be influenced by differences in the component composition of beans: soybeans contain high levels of protein and lipids, but little starch, while red kidney beans contain high starch levels.

Arrhenius plot The logarithmic values of the softening rate constants kw, ks1, and ks2 were plotted against the reciprocals of temperature to construct the Arrhenius plot. The results for ks1 are shown in Fig. 8. In soybeans, the slope of the straight line of the Arrhenius plot with pre-soaking was smaller than that without pre-soaking; however, the ks1 value at 99.5 °C (actual temperature of cooking) showed no clear difference between pre-soaking and without pre-soaking. In red kidney beans, the slopes for pre-soaking and without pre-soaking almost overlapped with each other. These results indicated that pre-soaking aged beans did not substantially promote softening. In general, pre-soaking treatment before cooking of beans is effective for shortening the heating time, and our previous study on control beans (refrigerated at 4 °C) showed that the slope of the line of the Arrhenius plot with pre-soaking was steeper than that of the line of the plot without pre-soaking. However, the current study using aged beans has shown different results from the control.

Arrhenius plot of softening rate constant ks1 for aged soybeans and aged red kidney beans between 80–99.5 °C.

ks1 means the rate constant of “softening due to heating.”

▲: Softening rate constant of un-soaked beans; △: Softening rate constant of pre-soaked beans; Aged beans were stored at 37 °C/75 % RH for 90 days.

From the slope of each Arrhenius plot, the apparent activation energy Ea and frequency factor A of kw, ks1, and ks2 were calculated. As shown in Table 2, Ea of ks1 for pre-soaked soybeans was approximately 0.7-fold smaller than that for un-soaked beans. Ea of ks1 for pre-soaked red kidney beans was 0.9-fold smaller than that of ks1 without pre-soaking. These results indicate that the temperature dependency of the ks1 value of both aged beans was smaller in the case of pre-soaking than without pre-soaking. Generally, the cause of softening during heating is considered to be β-elimination of pectin (Albersheim et al., 1960); however, pre-soaking in aged soybeans and red kidney beans stored at a high temperature and high humidity was suggested to make β-elimination of pectin less likely at high temperatures such as 99.5 °C compared to that in un-soaked beans. Several changes such as the loss of cell membrane integrity and protein denaturation during storage of beans might cause hardening by pre-soaking, followed by the suppression of softening during cooking.

| Soybeans | Red kidney beans | ||||

|---|---|---|---|---|---|

| Ea (kJ/mol) | A (min−1) | Ea (kJ/mol) | A (min−1) | ||

| Un-soaked | kw | 21.8 | 1.3 ×102 | 2.0 | 0.12 |

| ks1 | 125.9 | 9.1 ×1015 | 185.4 | 4.2 ×1024 | |

| ks2 | 142.3 | 1.1 ×1018 | 19.6 | 3.8 | |

| Pre-soaked | ks1 | 88.5 | 6.0 ×1010 | 168.1 | 1.4 ×1022 |

| ks2 | 107.6 | 1.0 ×1013 | 238.2 | 6.1 ×1031 | |

Sample beans were stored at 37 °C/75 % RH for 90 days.

Un-soaked samples were directly treated without soaking treatment.

Pre-soaked samples were treated after soaking at 20 °C for 8h.

kw: the rate constant of “softening due to water absorption.”

ks1, ks2: the rate constant of “softening due to heating.”

Influence of storage time on softening rate constant and cooking time of dry beans The changes in hardness of aged beans with different storage times were predicted using the softening rate constants for each bean, and the cooking time at 99.5 °C to obtain the optimal hardness of 3 N (Murakami et al., 2008) was calculated. The rate constants were calculated using Ea and A in Table 2.

As shown in Table 3, in soybeans, the softening rate constant kw of Aged I to III was close to that of the control. On the other hand, the kw value of red kidney beans decreased with storage time; the value of Aged III was 0.57-fold compared with that of the control.

| Soybeans | Red kidney beans | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Control | Aged | Control | Aged | ||||||

| I | II | III | I | II | III | ||||

| Un-soaked | kw | 0.084 | 0.080 | 0.098 | 0.085 | 0.087 | 0.075 | 0.047 | 0.050 |

| ks1 | 0.037 | 0.023 | 0.018 | 0.016 | 0.045 | 0.039 | 0.031 | 0.023 | |

| ks2 | 0.020 | 0.015 | 0.010 | 0.007 | 0.031 | 0.016 | 0.011 | 0.009 | |

| Θ (min) | 108 | 148 | 196 | 206 | 73 | 112 | 166 | 196 | |

| Pre-soaked | ks1 | 0.088 | 0.034 | 0.023 | 0.013 | 0.103 | 0.052 | 0.040 | 0.028 |

| ks2 | 0.026 | 0.019 | 0.010 | 0.006 | 0.098 | 0.035 | 0.018 | 0.013 | |

| Θ (min) | 48 | 92 | 161 | 249 | 23 | 54 | 96 | 128 | |

Control: Stored at 4 °C/80 % RH for 90 days.

Aged I: Stored at 37 °C/75 % RH for 45 days.

Aged II: Stored at 37 °C/75 % RH for 90 days.

Aged III: Stored at 37 °C/75 % RH for 120 days.

For the softening rate constants ks1 and ks2, both beans showed a tendency to decrease with a longer storage period, regardless of the soaking treatment. In soybeans, the ks1 value for un-soaked beans was 0.037 for the control and 0.016 for Aged III, whereas that for pre-soaked beans was 0.088 for the control and 0.013 for Aged III. In red kidney beans, the ks1 value for un-soaked beans was 0.045 for the control and 0.023 for Aged III, whereas that for pre-soaked beans was 0.103 for the control and 0.028 for Aged III. In other words, the reduction in the ks1 value for Aged III relative to that for the control was 0.42-fold for un-soaked beans and 0.15-fold for pre-soaked beans in soybeans, and 0.47-fold for un-soaked beans and 0.27-fold for pre-soaked beans in red kidney beans. These results clearly indicate that the longer the storage time, the lower the rate constant for “softening due to heating” with pre-soaking.

In addition, the predicted heating time until attaining optimal hardness was compared with or without pre-soaking treatment. In control beans, in the case of soybeans, the heating time was 108 min for un-soaked beans and 48 min for pre-soaked beans, and in the case of red kidney beans, the heating time was 73 min for un-soaked beans and 23 min for pre-soaked beans. However, in the aged beans, the differences in the heating time between pre-soaked and un-soaked beans became smaller when the storage time was longer in both beans. Particularly, in Aged III of soybeans, the heating time for beans with preliminary soaking was longer than that for un-soaked beans. These facts indicated that preliminary soaking shortens the heating time during cooking of soybeans and red kidney beans in cases where these beans are not affected by storage; however, pre-soaking of aged beans affected by storage suppresses softening by subsequent heating, and this tendency is enhanced with longer storage. Based on the softening rate constant and heating time, it is indicated that the hardening phenomenon of beans after storage was accelerated by preliminary soaking. In other words, in the case of aged beans, soaking treatment before heating is not recommended.

As mentioned above, our study makes it possible to compare the influence of pre-soaking and/or storage with the rate constants of softening and cooking time and is expected to be practically applicable to cooking.

In the hardening of aged beans (stored at a high temperature and humidity), tissue changes during soaking greatly affect the suppression of softening during subsequent heating, as shown by the softening rate constant. In addition, the longer the storage period, the smaller the effect of pre-soaking treatment in “softening due to heating.” It can be concluded that preliminarily soaking before heating is not desirable for the cooking of aged beans.