2021 Volume 27 Issue 3 Pages 483-489

2021 Volume 27 Issue 3 Pages 483-489

The yeast strain Hanseniaspora vineae TW15 derived from local wine grapes lacks sucrose fermentation ability, confers palatable aroma and taste in breads made from dough with monosaccharides added instead of sucrose. In this study, strain TW15 was applied along with the baking strain Saccharomyces cerevisiae to the conventional dough containing sucrose. The liquid fermentation ability of sucrose was elevated with the increasing ratio of S. cerevisiae, which synthesizes external invertase. The baking strain was then inoculated along with H. vineae TW15 and the two strains were grown on sucrose. When the mixed cells were used for the conventional dough formula comprising sucrose, the baked breads showed a distinct and acceptable quality similar to those made using H. vineae TW15 alone. Thus, H. vineae TW15 can be applied to the conventional bread making method in mixed culture with a baking strain.

The apiculate yeast Hanseniaspora vineae TW15 is a fermentable strain isolated from the wine grape ‘Yamasachi’ that is unable to ferment sucrose (Takaya et al., 2019) . When this strain is used in bread making, the baked goods have desirable aroma and taste; however, the dough formulation requires addition of monosaccharides from high-fructose corn syrup (HFCS) instead of sucrose. HFCS is controversial and likely to be avoided by consumers who regard it as an artificial sweetener from industrial processes of enzymatic reactions (Parker et al., 2010). Additionally, HFCS has been shown to have negative effects on health, including involvement in the pathogenesis of obesity, mercury contamination during manufacture, and is toxic to honey bees (Parker et al., 2010).

The yeast Saccharomyces cerevisiae, which includes most of the baking strains, secretes invertase that hydrolyzes sucrose to fructose and glucose extracellularly (Carlson, 1987). Thus, TW15 may be able to utilize monosaccharides hydrolyzed from sucrose in the presence of S. cerevisiae. The produced breads are expected to possess the desirable aroma and taste of TW15 baked products, without the inclusion of HFCS.

So far S cerevisiae strain lacking sucrose fermentation ability has been cultured with the baking S. cerevisiae to obtain yeast incapable of hydrolyzing fructooligosaccharides for supply of a bifidus factor. However, the co-cultured cells cannot ferment sucrose because the gene encoding invertase has been eliminated (Nakatomi, 1987).

In the present study, strain TW15 was co-cultured on sucrose with a baking S. cerevisiae strain, and the mixed culture was applied to a conventional dough containing sucrose, to investigate its effects on the quality of baked breads.

Yeast strain Hanseniaspora vineae TW15 is a strain isolated from the wine grape, ‘Yamasachi’. Saccharomyces cerevisiae NBRC 2044 is a baking strain that shows high invertase activity and was obtained from the NITE Biological Resource Center (Kisarazu-shi, Chiba, Japan).

Cultures H. vineae and S. cerevisiae strains were cultured aerobically in 10.0 mL of preculture containing 1.0 % yeast extract, 2.0 % polypeptone, and 2.0 % glucose; then, 1.0 mL of the seed culture was inoculated into 100 mL of medium composed of 1.0 % Bacto-yeast extract (Difco), 2.0 % Bactopeptone (Difco), 2.0 % glucose, 0.2 % KH2PO4, 0.1 % MgSO4·7H2O, and 0.05 % Adekanol LG-294 and grown for 24 h at 30 °C with shaking (150 rpm) (Takaya et al., 2019) . Precedingly, 1.0 mL each cell harvested suspension was transferred to microtube and dried by heating for 3h at 80 °C to determine dry matter for baking tests. The cell suspension was mixed at various ratios and then used in the test. Further, using a medium containing 2.0 % sucrose instead of 2.0 % glucose, these strains were then co-cultured with seed cultures inoculated at a ratio of TW15:NBRC 2044 =80:20, 99.9:0.1, 99:1, 90:10, and 0:100.

The populations of strains TW15 and NBRC 2044 were determined using two discrimination methods: the microscopic method by cell shape and the lysine plate method by colony formation (Viana et al., 2011).

Liquid fermentation ability The cell suspensions strains TW15 and NBRC 2044 were used for assay of liquid fermentation ability and invertase activity.

The cell suspensions containing 40 mg of dry matter per mL were prepared from the cultured cells. The fermentation medium (20.0 mL) containing 2.5 g of sucrose, 0.25 g of asparagine monohydrate, and some minerals and vitamins in citrate buffer (pH 5.5) was mixed with 5.0 mL of cell suspension. After incubation for 3 h at 30 °C with shaking (80 rpm), the reduced weight was measured as the fermentation ability of sucrose (mg/3 h).

Invertase assay A reaction mixture (0.25 mL) containing 150 mM sucrose and the cell suspension in 80 mM acetate buffer (pH 5.0) was incubated at 30 °C and was terminated after 3 min by adding 0.25 mL of 3,5 dinitrosalicylic reagent and heating in boiling water for 5 min. The mixture was then diluted with 5.0 mL of deionized water to determine the reducing sugars derived from sucrose. Specific activity was expressed as nmol of sugar equivalent to glucose/min/mg cells.

Baking test Standard white breads including sucrose were prepared using yeast cake containing 33 % (w/w) of cells as dry matter as described elsewhere (Takaya et al., 2019). Breads were prepared using a bread machine SD-BMT1000 (Panasonic Corp., Osaka, Japan). Bread made using strains TW15 and NBRC 2044 were prepared in 2 h using the setting for ‘quick’ baking of white bread preparation for the quick experiments. In contrast, bread using co-cultured yeast was prepared in approximately 4 h using the setting for ‘standard’ white bread preparation. Extracts prepared from bread crumbs were used for the determination of volatile compounds, amino acids, organic acids, and sugars as described previously (Takaya et al., 2019).

Yeast cake used was prepared by pressing centrifuged cells in centrifuge tube containing polyethylene bag to porous plate.

Reproducibility All experiments were carried out more than three times independently, and the obtained data are shown as the average values ± standard deviations. Significant differences were determined using ANOVA and Tukey's multiple range tests.

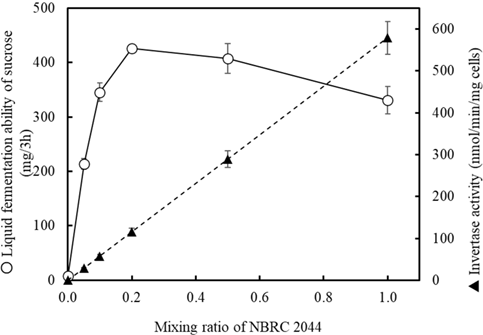

Compensation with invertase secreted by strain NBRC 2044 The two strains were grown separately on glucose and the rate of sucrose fermentation was determined by mixing strain NBRC 2044 with strain TW15 at various ratios (Fig. 1). Invertase activity was lower than that reported previously (Oda et al., 2010). In the experiments, the sugar in the culture medium was sucrose, which induced the expression of invertase. Sucrose fermentation was observed to be absent in TW15 because this strain showed undetectable invertase activity. In the mixed ratio with strain NBRC 2044 up to 0.1, sucrose fermentation ability was elevated, and reached the highest level at a ratio of 0.2, when the invertase activity was 116 (nmol/min/mg cells). These observations indicate that invertase secreted by strain NBRC 2044 could supply sufficient monosaccharides for TW15 without the use of HFCS.

Liquid fermentation ability of sucrose and invertase activity.

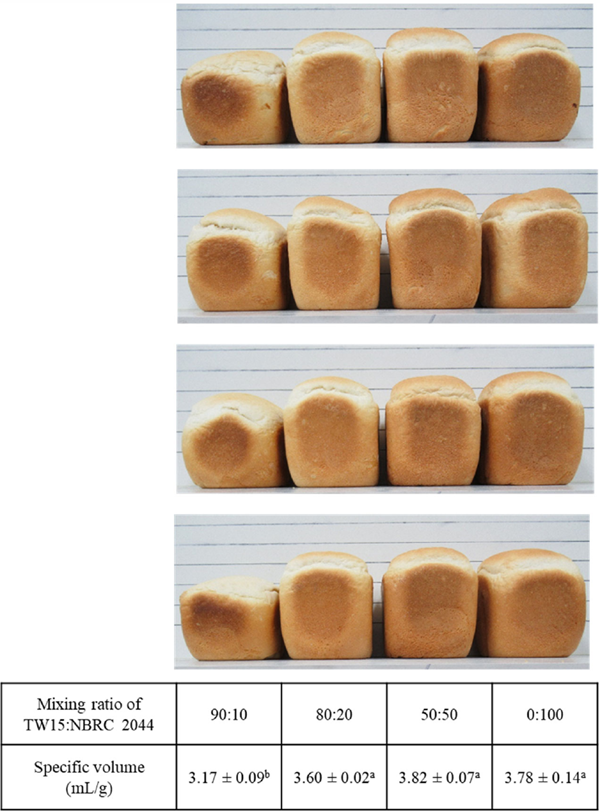

Preliminary baking tests First, baking tests were conducted using cells grown individually on glucose with four mixing ratios of TW15:NBRC 2044. The specific volume of the product with a ratio of 80:20 was lower than those of the others but no significant difference was observed among them (Fig. 2) The comments of for preliminary sensory evaluation of each product by three panels are summarized as follows: 90:10 (mixing ratio of TW15:NBRC 2044), low volume with sake-like flavor; 80:20, sweet smell with the most desirable flavor and taste showing the features of strain TW15; 50:50, slightly high volume, less flavor and taste characteristics of strain TW15, slightly unsatisfactory; 0:100, unsatisfactory in flavor and taste with slightly dark crumb color.

Appearance and specific volumes of baked breads prepared from dough leavened using mixtures of Hanseniaspora vineae TW15 and Saccharomyces cerevisiae NBRC 2044.

The results of four independent baking tests are shown from the top to bottom.

To confirm these organoleptic differences, water-soluble compounds were analyzed. The relative peak areas of acetoin and 2-phenylethyl acetate, the characteristic volatile compounds in the baked bread prepared with strain TW15 (Takaya et al., 2019), were significantly higher in the product with the TW15:NBRC 2044 ratio of 80:20 compared to that with the TW15:NBRC 2044 ratio of 0:100 (Table 1).

| Compound | Relative peak area (%) | |||

|---|---|---|---|---|

| Mixing ratio of TW15:NBRC 2044 | ||||

| 90:10 | 80:20 | 50:50 | 0:100 | |

| Acetic acid | 0.490 ± 0.071b | 0.589 ± 0.163 b | 0.652 ± 0.151 b | 0.854 ± 0.160 a |

| Acetoin | 2.725 ± 0.633 b | 4.329 ± 0.516 a | 2.874 ± 1.198 b | 1.915 ± 0.961 b |

| Benzaldehyde | 0.199 ± 0.028 b | 0.250 ± 0.040 b | 0.387 ± 0.088 ab | 0.379 ± 0.081 a |

| Diacetyl | 0.052 ± 0.039 a | 0.054 ± 0.019 a | 0.032 ± 0.025 ab | 0.017 ± 0.006 b |

| Dodecane | 0.185 ± 0.069 | 0.132 ± 0.015 | 0.133 ± 0.013 | 0.191 ± 0.075 |

| Furfural | 0.029 ± 0.015 | 0.021 ± 0.010 | 0.042 ± 0.023 | 0.061 ± 0.059 |

| Hexanoic acid | 0.178 ± 0.077 | 0.140 ± 0.039 | 0.140 ± 0.054 | 0.165 ± 0.073 |

| Hexanol | 0.596 ± 0.065 a | 0.472 ± 0.093 b | 0.400 ± 0.029 b | 0.435 ± 0.102 b |

| Isoamyl alcohol | 8.905 ± 0.913 a | 6.933 ± 0.699 b | 6.619 ± 0.584 b | 7.255 ± 0.818 b |

| Isoamyl butyrate | 0.083 ± 0.008 | 0.078 ± 0.018 | 0.071 ± 0.005 | 0.070 ± 0.021 |

| Isobutyric acid | 0.093 ± 0.013 b | 0.074 ± 0.032 b | 0.103 ± 0.022 b | 0.196 ± 0.040 a |

| Isovaleric acid | 0.146 ± 0.082 b | 0.165 ± 0.040 b | 0.225 ± 0.063 b | 0.760 ± 0.274 a |

| 2-Pentylfuran | 0.224 ± 0.023 a | 0.185 ± 0.021 bc | 0.172 ± 0.013 c | 0.198 ± 0.021 b |

| 2-Phenylethyl acetate | 0.402 ± 0.033 a | 0.396 ± 0.028 a | 0.269 ± 0.024 b | 0.071 ± 0.011 c |

| 2-Phenylethyl alcohol | 2.052 ± 0.214 c | 2.304 ± 0.176 c | 2.775 ± 0.256 b | 3.073 ± 0.183 a |

| Valeric acid | 0.024 ± 0.006 | 0.026 ± 0.007 | 0.024 ± 0.014 | 0.041 ± 0.030 |

The values after the discriminated alphabet indicate that the difference in each row is significant (p < 0.05).

The contents of total free amino acids and organic acids seemed to be related to the metabolic activities of yeast cells. Consequently, strain NBRC 2044 might consume amino acids faster than strain TW15 and synthesize organic acids in greater quantities (Table 2).

| Compound | Contents (mg/100g dry matter) | |||

|---|---|---|---|---|

| Mixing ratio of TW15:NBRC 2044 | ||||

| 90:10 | 80:20 | 50:50 | 0:100 | |

| Total free amino acids | 245 ± 11 a | 211 ± 12 b | 160 ± 6 c | 116 ± 6 d |

| Organic acid | ||||

| Acetic acid | 53 ± 2 c | 80 ± 12 b | 95 ± 18 a | 105 ± 7 a |

| Succinic acid | 17 ± 2 c | 17 ± 2 c | 27 ± 4 ab | 23 ± 6 b |

| Sugar | ||||

| Fructose | 302 ± 90 d | 553 ± 166 c | 2 067 ± 216 b | 3 059 ± 85 a |

| Glucose | 182 ± 3 d | 307 ± 95 c | 921 ± 160 b | 1 673 ± 61 a |

| Lactose | 1 272 ± 20 b | 1 285 ± 28 ab | 1 330 ± 77 a | 1 285 ± 11 b |

| Maltose | 2 928 ± 138 ab | 2 897 ± 85 b | 3 050 ± 86 a | 3 059 ± 92 a |

| Sucrose | 5 087 ± 226 a | 3 629 ± 227 b | 1 208 ± 349 c | 123 ± 92 d |

The values after the discriminated alphabet indicate that the difference in each row is significant (p < 0.05).

Lower contents of glucose and fructose meant that monosaccharides hydrolyzed from sucrose by the action of invertase are immediately used for fermentation in the product with the ratio of 80:20, whereas in the product with other ratio of 50:50 and 0:100, excess amounts of reducing monosaccharides might participate in the Maillard browning reaction to increase the darkness of the crumb. These baking tests indicate that invertase secreted by strain NBRC 2044 supplied enough monosaccharides for dough leavening by TW15.

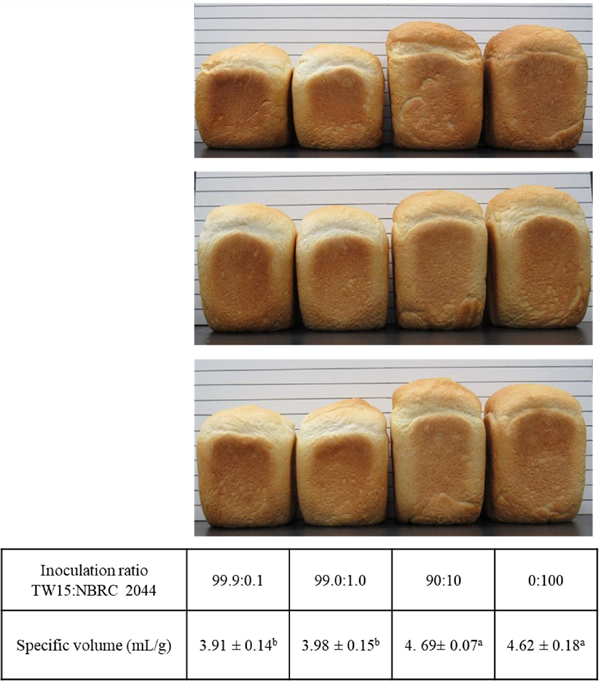

Baking tests using co-cultured cells Next, H. vineae TW15 was inoculated together with S. cerevisiae NBRC 2044 at four different ratios of 99.9:0.1, 99:1, 90:10, and 0:100, and cultured on sucrose. Cell yields increased with the proportion of strain NBRC 2044 accompanied, as did invertase activity (Table 3). Lysine plate analysis found the population of strain TW15 was approximately 96 % in the inoculation ratio of 99.9:0.1, 92 % in 99:1, 80 % in 90:10, and 0 % in 0:100. Compared with the results of liquid fermentation ability (Fig. 1), the baking test required higher invertase activity for higher specific volumes probably because sucrose diffusion in the dough is slower than that in liquid medium (Fig. 3).

| Inoculation ratio of TW15:NBRC 2044 | ||||

|---|---|---|---|---|

| 99.9:0.1 | 99:1 | 90:10 | 0 :100 | |

| Cell yield (mg dry matter/100 mL medium) | 4.9 ± 0.4c | 5.3±0.2bc | 5.7± 0.1ab | 6.1± 0.1a |

| Invertase (nmol/min/mg cells) | 111±51 c | 206±70 c | 1 120±156b | 2 140±195a |

| Discrimination methods | Proportion of TW15 (%) | |||

| Microscopy | 96.9 ± 0.1 a | 92.2 ± 0.4 b | 79.5 ± 0.1 c | 0.0 ± 0.0 d |

| Lysine plate | 96.3 ± 2.5 a | 91.7 ± 3.3 ab | 85.8 ± 6.5 b | 0.0 ± 0.0 c |

The values after the discriminated alphabet indicate that the difference in each row is significant (p < 0.05).

Appearance and specific volumes of baked breads prepared from dough leavened using mixed cultures of Hanseniaspora vineae TW15 and Saccharomyces cerevisiae NBRC 2044.

The results of three independent baking tests are shown from the top to bottom.

Preliminary sensory evaluation by three panels indicated that quality of the baked bread with an inoculation ratio of 99.9:0.1 and 99:1 resembled that prepared with the initial mixing ratio of 80:20 at the preliminary baking tests. Although there were differences in several soluble components in this study (Table 4), little effect was found compared with the previous report (Takaya et al., 2019), and it was considered that the characteristics of the flavor of bread by TW15 were not due to soluble components.

| Compound | Contents (mg/100g dry matter) | |||

|---|---|---|---|---|

| Inoculation ratio of TW15:NBRC 2044 | ||||

| 99.9:0.1 | 99:1 | 90:10 | 0:100 | |

| Total free amino acids | 133.2 ± 6.6 b | 164.3 ± 14.6 a | 97.4 ± 9.6 c | 90.0 ± 3.4 c |

| Organic acid | ||||

| Acetic acid | 186 ± 15 a | 176 ± 26 a | 161 ± 14 a | 121 ± 20 b |

| Succinic acid | 17 ± 2 b | 15 ± 4 b | 18 ± 5 b | 61 ± 13 a |

| Sugar | ||||

| Fructose | 0 ± 0 b | 0 ± 0 b | 330 ± 496 b | 1 436 ± 295 a |

| Glucose | 0 ± 0 | 0 ± 0 | 0 ± 0 | 0 ± 0 |

| Lactose | 1 150 ± 76 | 1 229 ± 162 | 1 112 ± 116 | 1 098 ± 56 |

| Maltose | 2 657 ± 416 | 2 777 ± 235 | 2 805 ± 228 | 2 426 ± 361 |

| Sucrose | 1 850 ± 340 a | 1 715 ± 287 a | 0 ± 0 b | 0 ± 0 b |

The values after the discriminated alphabet indicate that the difference in each row is significant (p < 0.05).

Baked bread prepared with an inoculation ratio of 99.9:0.1 and 99:1 had a high relative peak area of acetoin (Table 5), similar to that in the bread prepared with the mixing ratio of 80:20. Therefore, acetoin may be a critical component for the desirable flavor of bread prepared using TW15.

| Compound | Relative peak area (%) | |||

|---|---|---|---|---|

| Inoculation ratio of TW15:NBRC 2044 | ||||

| 99.9:0.1 | 99:1 | 90:10 | 0 :100 | |

| Acetic acid | 1.790 ± 0.494 a | 1.770 ± 0.337 a | 1.797 ± 0.275 a | 0.957 ± 0.392 b |

| Acetoin | 3.919 ± 0.568 a | 3.950 ± 0.707 a | 2.068 ± 0.835 b | 0.686 ± 0.227 c |

| Benzaldehyde | 0.351 ± 0.049 a | 0.259 ± 0.034 b | 0.282 ± 0.048 b | 0.228 ± 0.046 b |

| Diacetyl | 0.051 ± 0.017 a | 0.050 ± 0.000 a | 0.030 ± 0.012 b | 0.011 ± 0.004 c |

| Dodecane | 0.144 ± 0.029 | 0.144 ± 0.025 | 0.127 ± 0.036 | 0.124 ± 0.022 |

| Furfural | 0.023 ± 0.029 | 0.021 ± 0.020 | 0.051 ± 0.056 | 0.028 ± 0.030 |

| Hexanoic acid | 0.308 ± 0.165 | 0.267 ± 0.110 | 0.213 ± 0.073 | 0.266 ± 0.112 |

| Hexanol | 0.156 ± 0.014 a | 0.147 ± 0.020 a | 0.119 ± 0.024 b | 0.075 ± 0.022 c |

| Isoamyl alcohol | 3.672 ± 0.870 | 3.856 ± 0.677 | 3.192 ± 1.104 | 3.771 ± 0.927 |

| Isoamyl butyrate | 0.087 ± 0.014 ab | 0.096 ± 0.019 a | 0.065 ± 0.024 bc | 0.057 ± 0.018 c |

| Isobutyric acid | 0.053 ± 0.010 c | 0.050 ± 0.008 c | 0.105 ± 0.015 b | 0.156 ± 0.020 a |

| Isovaleric acid | 0.115 ± 0.037 c | 0.103 ± 0.033 c | 0.376 ± 0.075 b | 0.461 ± 0.063 a |

| 2-Pentylfuran | 0.094 ± 0.009 a | 0.087 ± 0.015 a | 0.075 ± 0.030 ab | 0.058 ± 0.019 b |

| 2-Phenylethyl acetate | 0.758 ± 0.128 a | 0.696 ± 0.099 a | 0.746 ± 0.300 a | 0.117 ± 0.037 b |

| 2-Phenylethyl alcohol | 2.845 ± 0.501 c | 2.328 ± 0.238 c | 4.891 ± 0.388 b | 6.944 ± 0.698 a |

| Valeric acid | 0.063 ± 0.019 | 0.056 ± 0.016 | 0.056 ± 0.012 | 0.051 ± 0.009 |

The values after the discriminated alphabet indicate that the difference in each row is significant (p < 0.05).

Hanseniaspora vineae TW15, which lacks sucrose fermentation, can be applied to the conventional bread making method by mixed culture with a baking strain of Saccharomyces cerevisiae to obtain products with desirable qualities. The method developed in the present study will assist the engineering of yeast strains for baking which confer desirable aroma and taste characteristics to baked goods, without the addition of HFCS. Yeast strains incapable of sucrose fermentation had limited bakery applications previously because conventional dough contains sucrose as the fermentation substrate; we have demonstrated a method, which improves the potential applications of H. vineae in commercial baking.

Acknowledgements We would like to thank Editage (www.editage.com) for English language editing.