2022 年 28 巻 3 号 p. 235-244

2022 年 28 巻 3 号 p. 235-244

Fish sauce is a liquid condiment prepared by fermenting fish at room temperature and high salt concentration (> 20%) for more than six months. We examined whether the application of pressurized CO2 (pCO2), mild heating, and acid protease (1%) would produce reduced-salt fish sauce in a short fermentation period. Optimal fermentation temperature and NaCl concentration were determined to be 45°C and 7%, respectively, at a fixed fermentation period (one week). Treatment with pCO2 (1 MPa), mild heating (45 °C), and acid protease (ORYENTASE AY) decreased biogenic amine content, increased free amino acid content, and enriched umami flavor. This treatment did not induce bacterial growth, and the changes in organic acid content and smell were minimal. In the presence of protease, browning was suppressed under pCO2 compared to atmospheric pressure. Thus, the application of pCO2 and protease with mild heating enabled reduced-salt fish sauce production in a short fermentation period.

Fish sauce, especially in Southeast Asia, is a widely used liquid seasoning, and is a valuable source of protein (Xu et al. 2008). It is produced by fermenting fish in high-salt concentrations (> 20%) for more than 6 months. During this period, endogenous proteases hydrolyze fish meat protein, yielding enriched free amino acids. The addition of approximately 20% NaCl during the fermentation process of fish sauce aims to suppress the growth of undesirable microorganisms. However, such high-salt concentrations decrease the attractiveness of seasoning for low-salt diets, and shortening the manufacturing time is important.

Electrodialysis has been applied for desalination of fermented foods. Sasaki (2014) reduced the NaCl concentration of fish sauce from 25% to 13% by electrodialysis with maintaining amino acids. Chindapan et al. (2013) simulated electrodialysis desalination of fish sauce using artificial neural networks and genetic algorithm electrodialysis, and found that desalination to 14.3% is optimum for preserving aroma compounds and free amino acids. Fidaleo et al. (2013) reported that desalination of soy sauce can be mathematically reconstructed using Nernst–Planck equation. However, loss of amino acid and polar odor compounds should be concerned in desalination by electrodialysis.

Salt reduction by inhibiting microbial proliferation during fermentation has also been addressed. Previous studies have reported that increasing the fermentation temperature induces shortening of the fermentation period and reduction of salt concentration because high temperatures enhance endogenous protease activity and inhibit mesophilic microorganisms present in the fish body (Utagawa 2012). Protease addition was found to accelerate fish meat protein proteolysis (Chaveesuk et al., 1993).

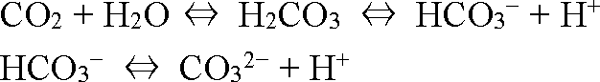

We considered that carbon dioxide (CO2) could suppress the growth of microorganisms and the Maillard reaction in the fermentation process of fish sauce. Dissolving CO2 in water decreases the pH according to the following reaction formula:

|

In addition, replacing air with CO2 in the pressure vessel creates an anaerobic environment inside the container. Such conditions are expected to inhibit the proliferation of many microorganisms. Conveniently, these conditions can be cancelled by CO2 pressure release. We have previously shown that applying pressurized CO2 (pCO2) conditions during fermentation at 30 °C for 6 months enables the production of high-quality reduced-salt (10%) sardine fish sauce (Noma et al. 2020).

In the present study, a mildly heated temperature and a salt concentration optimal for fish meat degradation was determined, then the effect of protease addition during fermentation on the quality of fish sauce prepared under pCO2 and atmospheric pressure at the optimized temperature was evaluated.

Determination of optimum preparing conditions of fish sauce The optimum fermentation temperature for fish meat degradation and growth inhibition of mesophilic bacteria under atmospheric pressure was determined. Sardines (Sardinops melanostictus) were purchased from a local supermarket in Saga city, Japan. The sardines were washed with tap water, and their internal organs, bones, heads, and tails were removed. The resultant fish were cut into round slices with approximately 1 cm thick, and 50 g of sardines were placed in a polyethylene bag. To obtain a final NaCl concentration of 10%, 50 mL of NaCl solution was added. The polyethylene bags containing the fish meat and NaCl solutions were heat-sealed, placed in a plastic container, and incubated for fermentation at 40, 45, and 50°C under atmospheric pressure for 1 week. After incubation, the prepared fish sauce moromi was filtered with a cooking mesh to remove undecomposed bones and meat, centrifuged at 1 000 ×g at 4 °C for 15 min, and the obtained supernatant was used as fish sauce. The fish sauces were serially diluted with 0.85% NaCl solution, plated onto tryptic soy agar (TSA, BD Difco, Franklin Lakes, NJ, USA) plates, and incubated at 30°C for 48 h to count viable bacteria.

Proteases selected were suitable for decomposing fish meat under pCO2 conditions. The proteases commercially available for food processing tested in this study are listed in Table 1. Once the internal organs, bones, heads, and tails were removed, the sardines were minced using a food processor (Tiger, Osaka, Japan). The fish meat and 9% of final concentration NaCl solution were mixed at a 1:5 weight ratio, left to stand for 24 h, and centrifuged at 1 000 ×g and 4 °C for 30 min. The obtained supernatant was used as the sardine protein extract. Test tubes containing 2 mL of the sardine protein extract and 20 mg of protease were placed in a pressure vessel (ϕ 50 mm × 255 mm, Taiatsu Techno, Tokyo, Japan), as shown in Fig. 1. The sample setting method in the pressure vessel was as described in our previous paper (Noma et al., 2020). CO2 gas was introduced into the vessel at 1 MPa pressure, and the tubes were incubated at 45°C for 24 h. After incubation, the moromi was centrifuged at 8 000 ×g at 4°C for 5 min, and the supernatant was subjected to amino acid analysis.

| pH | Temperature (°C) | specific activity (unit/g) | Origin | manufacture | |

|---|---|---|---|---|---|

| SUMIZYME AP | 2.5∼4 | 40∼60 | 50 000 | Aspergillus niger | Shin Nihon CEMICAL CO., LTD., Aichi, Japan |

| Kokulase · P | 4.5∼10 | 50∼60 | 48 000∼62 000* | A. oryzae | Mitsubishi Chemical Co., Tokyo, Japan |

| PROTEASE YP-SS | 2.5∼5.0 | 40∼60 | 80 000* | Aspergillus sp. | Yakult Pharmaceutical Industry Co., Ltd. Tokyo, Japan |

| PANCIDASE NP-2 | 3.0∼11.0 | 30∼60 | 32 000* | Aspergillus sp. | Yakult Pharmaceutical Industry Co., Ltd. Tokyo, Japan |

| ORIENTASE AY | 2.5∼4 | 45∼55 | 200 000 | A.niger | HBI Enzymes Inc., Hyogo, Japan |

These data were cited from each manufacture's brochure.

Pressure vessel

To optimize the NaCl concentration during fermentation, fish sauce was prepared with final NaCl concentrations of 4%, 7%, and 10% under pCO2. Fish sauce was prepared using the method used for the determination of temperature selection. A mixture of 50 g of NaCl solution was prepared to give final concentrations of 4, 7, and 10% and 50 g of minced sardine in a glass container was placed in the pressure vessel (Fig. 1) and subjected to pCO2 at 45°C and 1 MPa for 1 week.

The degree of degradation was evaluated by the free amino acid concentration obtained after hydrolysis of the extracted sardine protein. Lipids and proteins were removed from the sardine protein extract, and free amino acid analysis was performed as described by Noma et al. (2020). Briefly, the amino acids in the fish sauce were derivatized with phenyl isothiocyanate and analyzed using a PTC-Amino Acid Analysis Kit (Fujifilm Wako, Tokyo, Japan).

Fish sauce production under pCO2 conditions Fish sauce was produced under pCO2 conditions in the presence and absence of ORIENTASE AY using the same method used to determine the optimum preparation conditions for fish sauce at 45°C for 1 week. To produce fish sauce under atmospheric conditions, 50 g of both fish and NaCl solutions prepared to give a final concentration of 7% taking the water content of the fish body into consideration were placed in two polyethylene bags. One was supplemented with 1 g of protease, whereas the other was not. The bags were sealed with a heat sealer, placed in a plastic container, and incubated at 45°C for 1 week. After incubation, the resulting fish sauce moromi was filtered with a cooking mesh to remove large bones and meat, centrifuged at 1 000 ×g at 4 °C for 15 min, and the obtained supernatant was used as fish sauce.

Biogenic amines, free amino acids, and organic acids in the fish sauces were analyzed after removing lipids and proteins. A combination of 1 mL of each fish sauce and hexane was mixed with a vortex and centrifuged (4 °C, 3 000 × g, 5 min), and 500 µL of the lower layer was transferred to a new centrifuge tube. Subsequently, 1.15 mL of ethanol was added to the separated lower layer, and the mixture was vortexed and centrifuged (4 °C, 3 000 × g, 5 min). The resulting upper layer was filtered using a 0.45-µm syringe filter (ADVANTEC Co., Ltd. Tokyo, Japan).

Bacterial counts The fish sauces were serially diluted with 0.85% NaCl solution, and 100 µL of each was plated onto TSA plates and incubated at 30 °C for 48 h to count mesophilic bacteria. Clostridia medium and an anaerobic pouch (Sugiyama-gen, Tokyo, Japan) were used to detect Clostridium spp. according to the manufacturer's protocol. Briefly, fish sauce was heated at 70°C for 20 min before diluting it 10 times with 0.85% NaCl solution. Subsequently, 10 mL of the diluted sample and 15 mL of the Clostridia medium were poured into an anaerobic pouch, heat-sealed, and incubated at 35 °C for 24 h.

Biogenic amine content Amine contents were analyzed according to Noma et al.'s (2020) method using putrescine, cadaverine, histamine, tyramine, and spermidine as standards. Briefly, after removing lipids and proteins, the fish sauce amines were derivatized with dansyl chloride, passed through a 0.45-µm membrane filter, and transferred to another tube for HPLC analysis.

Organic acid content Following the manufacturer's instructions, a Nexera XR HPLC organic acid analysis system (Shimadzu, Kyoto, Japan) was used to analyze the organic acid content of the fish sauce. Formic acid, pyruvic acid, succinic acid, malic acid, lactic acid, acetic acid, citric acid, butyric acid, and isovaleric acid were used as standards. Lipids and proteins were excluded from the standard solutions and fish sauce before analysis.

pH and browning A pH meter (HORIBA, F-52) measured the pH of the fish sauce. The browning of fish sauce was evaluated by measuring absorbance at 420 nm.

Sensory test The two-point preference method on the smell of prepared fish sauce was adopted by 10 untrained panelists (7 men and 3 women, 21–62 years old). The panelists received two fish sauce samples (all combinations of four kinds of fish sauce samples), each with a random three-digit number identifier, at the same time and were asked, “Which sample do you prefer?”. They selected the preferred sample and the ratio of their responses was determined.

Taste sensor analysis A taste sensing system TS-5000Z (Intelligent Sensor Technology, Kanagawa, Japan) was used to analyze the taste of the fish sauce. First, the AAE, CT0, CA0, C00, and AE1 sensors analyzed the aftertaste after diluting the fish sauce 10-fold with deionized water and then, the taste was analyzed. Ultrapure water (200 mL) was added to 100 mL of the reference solution of 30 mM KCl and 0.3 mM tartaric acid. The reference solution was mixed with 2 mL of the aftertaste sample (20-hold diluted fish sauce), and the AAE sensor analyzed 35 mL of it in a sample cup. The data were analyzed using the software “taste recognition device analysis application” (Intelligent Sensor Technology, Kanagawa, Japan).

Statistical analysis All experiments, except for the organic acid analysis (duplicate), were performed in triplicate. Statistical analyses for bacterial count, biogenic amine content, free amino acid content, and taste sensor analysis were performed using Tukey's test (p < 0.01 and 0.05).

Determining fish sauce preparation conditions To date, attempts have been made to produce fish sauce outside traditional methods and in a short period by raising the temperature during fermentation. Lopetcharat et al. (2002) showed that fermentation at 50°C shortened the preparation period of Pacific whiting fish sauce. Yoshinaka et al. (1983) revealed that fish sauce fermented at 50°C for 15 days with sardine-visceral enzymes had comparable sensory qualities to commercial products. Further, amino acid-enriched fish sauce can be fermented for 1 day at 55°C (Utagawa, 2012). Previous studies determined the optimum temperature by considering digestive enzyme activity in the internal organs of fish and the degree of decomposition of fish meat. In this study, we determined the optimum temperature by evaluating the mesophilic bacterial counts, appearance, odor impression, and free amino acid concentration in fish sauce.

As shown in Table 2, we observed 4.9 × 107 mesophilic bacteria at 40 ºC and no mesophilic viable bacterial count at 45 °C and 50 °C. Fish meat remained decomposed, and decomposition seemed to proceed in the order of 40 °C, 45 °C, and 50 °C, as summarized in Table 2. The odor impressions at 40°C, 45 °C, and 50 °C were putrefactive odor, favorable odor, and unfavorable oily odor, respectively. This may be due to the remarkable bacterial growth at 40 °C and the oxidation of fats and oils at high temperatures (50 °C). Based on these results, we found 45 °C to be the optimal fermentation temperature, whereas 50 °C, which has been widely used until now, was not suitable for fish sauce production in our research.

| Incubation temperature (°C) | General viable bacteria count (CFU/mL) | Odor impression | Appearance |

|---|---|---|---|

| 40 | 4.9×107 b | putrefactive | Fish meat was flaked and soft. The bone was also broken up. |

| 45 | ND* a | favorable | Decomposition was relatively high compared to 40 and 50°C. Fish meat was soft and elastic. it crumbled by touching. |

| 50 | ND a | unfavorable oily | Fish meat crumbled by touching, whereas it was firm, and it looks like simmered meat. |

Different characters show the significant difference determined by Tukey's test (p < 0.05).

In our previous study, pCO2 was performed at 30°C and pressures of 1, 3, and 5 MPa, and NaCl concentration of 10% for 6 months, and slight spoilage was observed at a pressure of 1 MPa (Noma et al., 2020). However, the availability of low pressure is important for the practical use of pCO2. Therefore, we set the CO2 pressure to 1 MPa in this experiment.

Proteases (Chaveesuk et al. 1993) and microorganisms can accelerate fish sauce production (Akolkar et al. 2010). As the pH was expected to decrease under pCO2 conditions, we tested five acidic proteases, which are used for proteolysis in some fermentation processes and have an optimum temperature of approximately 45 °C. They have varied specific activities; however, the activity evaluation method and optimum concentration for fish meat degradation were not disclosed. Therefore, a suitable protease for fish protein hydrolysis was determined at a protease concentration of 1% (w/v) by evaluating the free amino acid content after exposure to pCO2 at 1 MPa, 45 °C, and 9% NaCl (Table 3). ORIENTASE AY treatment resulted in the maximum total free amino acid content (per 100 mL), yielding 8 731 mg/100 mL. This may be because the pH of the fish sauce was lowered to the manufacturer-claimed optimum pH range during pCO2 treatment. The pH value is approximately 3.5 when CO2 is dissolved in water at 45ºC (Meyssami et al., 1992). In addition, ORIENTASE AY appeared to have the highest specific activity among the tested proteases.

| no addition | SUMIZYME AP | Kokulase · P | PROTEASE YP-SS | PANCIDASE NP-2 | ORIENTASE AY | |

|---|---|---|---|---|---|---|

| Total | 666 ± 39a | 3 418 ± 48b | 6 909 ± 97d | 2 903 ± 7b | 4 320 ± 48c | 8 731 ± 107e |

Final NaCl concentration was set at 9%. Data were shown as mean of triplicate experiments±standard error. Different characters show the significant difference determined by Tukey's test (p < 0.05).

To determine the optimal NaCl concentration in fish meat degradation by endogenous protease at 45 °C and pCO2, amino acid content was evaluated for fish sauce produced at 4, 7, and 10% NaCl concentrations. The total free amino acid content was the highest at 7% NaCl and lowest at 10% NaCl (Table 4). Generally, the higher the salt concentration, the more the protein degradation is suppressed. This is because the water activity decreases depending on the salt concentration, and the hydrolysis of the protein is inhibited. However, in this experiment, an increase in NaCl concentration from 4% to 7% appeared not to give a significant negative effect on free amino acid production, and the highest free amino acid content was observed at 7%. No significant difference was observed in the total free amino acid content between fish sauces produced under 4% NaCl and 7% NaCl. However, the optimal NaCl concentration was determined to be 7% for preventing spoilage of fish sauce. Based on these results, ORIENTASE AY was selected to produce fish sauce under pCO2 at 1 MPa and 45°C for 1 week in the presence of 7% NaCl.

| NaCl concentration (%) | 4 | 7 | 10 |

|---|---|---|---|

| Total | 725±12 b | 750±16 b | 489±8 a |

Data are shown as mean of triplicate experiments ± standard error. Different characters show the significant difference determined by Tukey's test (p < 0.05).

Bacterial count Bacterial counts were performed to evaluate the risk of food poisoning and food spoilage. No viable mesophilic bacteria were detected in fish sauces prepared under pCO2 at 45 °C, regardless of the presence of protease (Table 5). Fish sauce prepared under atmospheric pressure in the presence of protease contained no viable bacteria, although we observed 2.9 × 106 CFU/mL in the absence of protease.

| CO2 1 MPa | atmosphere | |||

|---|---|---|---|---|

| +*1 | −*1 | + | − | |

| Mesophilic bacteria | ND*2 a | ND a | ND a | 2.9×106 b |

| Clostridia | ND | ND | ND | ND |

The addition of protease suppressed the growth of viable bacteria, suggesting that protease addition contributed to a reduced risk of bacterial growth. The reason for this result is unclear and should be explored with a focus on the potential direct growth-inhibitory effects of proteases and the growth-inhibitory effects of the fish decomposition products.

No viable bacteria were observed in the fish sauce prepared under pCO2, even without the addition of protease. It is expected that the pH under pCO2 is approximately 3.5 (at 45 °C) at the beginning of the fermentation process (Meyssami et al., 1992), although fish sauce components produced during the progression of fish degradation reduce the lowering of pH under pCO2. Klangpetch et al. (2011) described that CO2 permeates into bacterial cells and generates H+, thereby impairing metabolism. Exposure to pCO2 at 1 MPa at 4 °C for 15 min decreased the heat resistance of various kinds of bacteria (Noma et al., 2010). Although the temperature of 45 °C used for fish sauce production may be sub-lethal for most non-injured mesophilic bacteria, acidification was expected to increase the sensitivity of bacteria to heating at 45 °C. Clostridia is one of the most notable anaerobic bacteria and has also been detected in fish sauce (i). However, we detected no Clostridia in any of the fish sauces produced, suggesting that the sardine used in this study contained no Clostridia. The minimum pH for the growth of C. butyricum was approximately 4.4 (Ghoddusi et al., 2013). It is expected that the pH downshift under pCO2 retards and/or inhibits growth in the case Clostridia contamination occurs during fish sauce production under pCO2. Therefore, applying pCO2 at 45 °C helps reduce the salt concentration from 20% or more, which is the usual salt concentration of the conventional preparation method, to 7%.

Free amino acid content Amino acids play an important role in the taste of fermented foods, such as fish sauce (Zhao et al. 2016). The presence of various amino acids gives it a rich taste of sweetness and bitterness; aspartic and glutamic acids lend to the umami flavors (Zhao et al. 2016). As shown in Table 6, the addition of protease increased the total amino acid content by approximately 10 times in both fish sauces prepared under atmospheric pressure and pCO2. The degree of total amino acid content was higher under pCO2 than under atmospheric pressure. It is considered that acidic conditions under pCO2 accelerated the degradation of proteins into free amino acids. Acidic proteases present in fish muscle are involved in maintaining the freshness and autolysis of fish meat. (Makinodan and Ikeda, 1969). In addition, acidic conditions under pressurization can alter the structure of major proteins in fish, such as the large molecular weight protein actomyosin, which is sensitive to endogenous proteases (Noma et al., 2020).

| CO2 1 MPa | atmosphere | |||

|---|---|---|---|---|

| protease | +* | −* | + | − |

| Asp | 113 ± 2 a | 27 ± 1 b | 106 ± 5 c | 9 d |

| Glu | 280 ± 9 a | 59 ± 2 b | 239 ± 5 c | 27 d |

| Ser | 322 ± 7 a | 31 ± 1 b | 261 ± 2 c | 9 ± 1 d |

| Gly | 443 ± 10a | 16 ± 1 b | 323 ± 7 c | 7 ± 1 b |

| His | 372 ± 13a | 117 ± 5 b | 264 ± 6 c | 83 ± 3 b |

| Arg | 788 ± 20 a | 171 ± 2 b | 691 ± 6 c | 138 ± 1b |

| Thr | 392 ± 6 a | 28 ± 1 b | 286 ± 8 c | 13 b |

| Ala | 853 ± 33a | 56 ± 1 b | 686 ± 3 c | 35 b |

| Pro | 605 ± 32 a | 13 ± 1 b | 420 ± 9 c | 12 ± 1 b |

| Tyr | 320 ± 10 a | 27 ± 1 b | 379 ± 7 c | 13 ± 1 b |

| Val | 589 ± 17a | 34 b | 442 ± 7 c | 20 b |

| Met | 311 ± 6 a | 29 b | 181 ± 2 c | 12 d |

| Cys | 221 ± 63 a | 29 ± 6 b | 120 ± 14 ab | 10 ± 1 b |

| Ile | 519 ± 19a | 31 ± 1 b | 351 ± 1 c | 15 b |

| Leu | 957 ± 23a | 76 ± 2 b | 711 ± 17c | 39 ± 1 b |

| Phe | 649 ± 33a | 45 ± 5 b | 378 ± 6 c | 17 ± 1 b |

| Lys | 345 ± 8 a | 64 ± 1 b | 342 ± 2 c | 40 d |

| Total | 8 080 ± 292 | 854 ± 13 | 6 180 ± 17 | 499 ± 7 |

Aspartic acid and glutamic acid, known as umami amino acids, increased about 10-fold under pCO2 with protease compared to fish sauce prepared under atmospheric pressure in the absence of protease. Therefore, pCO2 promoted fish meat proteolysis, which was further accelerated by addition of exogenous proteases, increasing the free amino acid content. Park et al. (2001) reported that the free amino acid content is 7 532 mg/100 mL in commercially available fish sauce produced in Japan. In addition, free amino acid content increased from 3 515 mg/100 mL in 1 month of fermentation to 8 685 mg/100 mL after 18 months (Zhu et al. 2021). The fish sauce produced in this study in a week had a free amino acid content of 8 080 mg/100 mL, which is consistent with previous reports.

Biogenic amine content Biogenic amines are produced by the decarboxylation of amino acids by microorganisms (Ibe, 2014). They are indicators of food spoilage because of their toxicity and odor. As shown in Table 7, putrescine and cadaverine production was observed in all the fish sauces prepared. Histamine was detected in the presence of protease. However, the concentrations were below the stipulated concentration by the Codex standard 302-2011 (ii, 40 mg/100 g). The total amine content of fish sauce produced with protease appeared to be lower in the pCO2 fish sauce than in the atmospheric pressure fish sauce.

| CO2 1 MPa | atmosphere | |||

|---|---|---|---|---|

| +* | −* | + | − | |

| putrescine | 541 ± 1 a | 831 ± 15 b | 583 c | 813 ± 2 d |

| cadaverine | 110 ± 1 a | 83 b | 115 ± 1c | 83 ± 1 b |

| histamine | 28 ± 1 a | ND b | 22 c | ND b |

| tyramine | ND | ND | ND | ND |

| spermidine | ND | ND | ND | ND |

| total | 678 ± 3 | 914 ± 5 | 720 ± 1 | 896 ± 3 |

Putrescine, cadaverine, and histamine detected in fish sauces are produced from ornithine, lysine, and histidine (Ibe, 2014). The cadaverine and histamine contents were significantly higher in the presence of protease, and the contents of their precursor amino acids, i.e., lysine and histidine were also increased upon treatment with protease. In addition, the contents of histamine and its precursor histidine were higher under pCO2 than under atmospheric pressure in the presence of protease. Therefore, there seems to be a correlation between the biogenic amine content and the corresponding precursor amino acid content.

Various bacteria, including Morganella, Enterobacter, Hafnia, Raoultella, and others, produce histamine (Satomi, 2016). In addition, Kluyvera intermedia produces histamine, putrescine, and cadaverine, and Enterobacter asburiae produces cadaverine and putrescine (Fadhlaoui-Zid et al., 2012). Therefore, it is not easy to clarify the contribution of microorganisms to biogenic production; however, a flora analysis should be performed in the future.

Organic acid content Organic acids also greatly influence taste by contributing to the flavor, acidity, and odor of the food (Wang et al., 2019), and odor impression. The total organic acid content was highest in fish sauce prepared without protease under atmospheric pressure and the lowest in fish sauce prepared with protease under pCO2 (Table 8). Lactic acid accounted for most of the organic acids under both atmospheric pressure and pCO2, regardless of the presence of protease. In our previous study, the lactic acid content was notably higher than that of the other organic acids measured (Noma et al., 2020). Michihata et al. (1997, iii) reported that lactic acid and pyroglutamic acid were the major organic acids and the lactic acid content did not change from the beginning to the final stage of fermentation in sardine fish sauce produced using the conventional method. They described that glycogen present in the sardine muscle was converted to lactic acid through the glycolytic pathway, and the lactic acid accumulated in fish tissue was transferred to fish sauce. pCO2 decreased the levels of acetic acid in the presence and absence of protease. Butyric acid and isovaleric acid were rarely detected in fish sauce prepared using each method. The impact of protease on the total organic acid content was limited.

| CO2 1 MPa | atmosphere | |||

|---|---|---|---|---|

| protease | +* | −* | + | − |

| Citric | 0.2 | 0.7 | 0.1 | 0.1 |

| Pyruvic | 1.9 | 0.6 | 1.7 | 1.3 |

| Malic | 1.1 | 1.2 | 1.6 | 0.3 |

| Succinic | 0.6 | 0.2 | 0.6 | 1.1 |

| Lactic | 90.4 | 94.4 | 88.5 | 85.7 |

| Formic | 1.0 | 1.4 | 8.0 | 6.9 |

| Acetic | 1.5 | 0.7 | 3.4 | 22.1 |

| Butyric | 0.1 | 0.2 | 0.1 | 0.1 |

| Isovaleric | 0.1 | 0.1 | 0.2 | 0.1 |

| Total | 96.9 | 99.4 | 104.2 | 117.6 |

pH and color Table 9 shows the pH and absorbance of the fish sauces at 420 nm. The pH of the prepared fish sauces appeared to be similar. This suggests that the application of pCO2 did not affect the pH value of fish sauce after preparation. As mentioned above, the pH of fish sauce decreases upon application of pCO2, and the original pH can be recovered after the release of CO2 pressure. Gidberg et al. (1984) reported that fish sauce with low salinity could be produced by acidification with acetic acid and hydrochloric acid during fermentation and subsequent neutralization. This study shows that lowering the pH during fermentation is an effective method for producing reduced-salt fish sauce, and the application of pCO2 enables the production of fish sauce under acidic conditions without post-neutralization.

| CO2 1 MPa | atmosphere | |||

|---|---|---|---|---|

| protease | +* | −* | + | − |

| pH | 5.47 ± 1.53×10-2 a | 5.77 ± 6.11×10-2 b | 5.47 ± 5.77×10-2 a | 5.71 ± 3.46×10-2 b |

| absorbance (420 nm) | 1.70 ± 2.02×10-3 c | 0.79 ± 3.48×10-4 a | 3.06 ± 2.25×10-2 d | 1.30 ± 3.71×10-4 b |

The degree of browning, estimated by absorbance at 420 nm, was lower in fish sauces prepared under pCO2 than in those under atmospheric pressure (Table 9). Proteases promoted browning in the pCO2 and atmospheric pressure conditions, where the degree was greater under atmospheric pressure than under pCO2. It is desirable to produce light-colored fish sauce because dark-colored fish sauce can change the color of processed foods, such as dressings and soups, when used in food manufacturing. Although the addition of protease and the high incubation temperature promoted the formation of a brown color under atmospheric pressure, applying pCO2 suppressed it. This is because acidic conditions inhibited the Maillard reaction progress.

Sensory evaluation of odor impression There was no significant difference in all combinations of the four tested samples using the two-point preference method with 10 untrained panelists, showing no difference in smell. This suggests that fish sauce odor quality does not decrease with the addition of protease or application of pCO2. Jiang et al. (2011) reported that dimethyl disulfide, dimethyl trisulfide, propanoic acid, butanoic acid, 3-(methylthio)-propanol, 2-methylbutenal, and some nitrogen-containing compounds were the major volatile compounds that contribute to the characteristic odor of Yu Lu, a traditional Chinese fish sauce. In the future, we will investigate the reason for the lack of significant effects of pCO2 and protease on sensory evaluation of odor impression with respect to the similarity of their odor profiles.

Taste sensor analysis Taste sensors are used to characterize foods by objectively assessing taste, regardless of the subjectivity of the panel (Tahara and Toko 2013). The taste sensor evaluates taste by responding to taste-related chemical substances (Hayashi et al. 2006). Taste sensor analysis was used to investigate the effects of pCO2 and enzymes on the taste of fish sauce. Umami, bitterness, and saltiness could be evaluated as an impression just after putting fish sauce into the mouth, and umami koku (aftertaste) can also be measured as a sustainable taste after swallowing (Table 10).

| CO2 1 MPa | atmosphere | |||

|---|---|---|---|---|

| +* | −* | + | − | |

| Umami | 6.5 ± 0.04 d | 5.5 ± 0.05 c | 5.9 ± 0.03 b | 4.7 a |

| Umamikoku | 2.0 ± 0.04 d | 1.6 ± 0.02 c | 1.3 ± 0.02 b | 1.1 a |

| Saltiness | 9.9 ± 0.03 c | 12 ± 0.09 b | 8.1 ± 0.01 a | 8.9 a |

| Bitterness | 0.88 ± 0.04d | 0.67 ± 0.09 c | 1.3 ± 0.01 b | 1.2 a |

The difference in analytical data of taste that human can distinguish can be expressed as 1.0 unit (iv; Kobayashi et al., 2010). Some preparation conditions induced variable data of 1.0 unit or more. Protease addition increased the umami more than 1.0 unit in fish sauce produced under atmospheric pressure and pCO2. Protease also increased umami koku by approximately 1.0 unit. These results can possibly be attributed to the concentration of free amino acids in the fish sauce.

Saltiness increased by more than 1.0 unit in fish sauces prepared under pCO2 regardless of protease addition, while the degree was larger in fish sauce without protease. In general, at high salt concentration, saltiness is sensorily decreased with an increase in the content of umami components. However, this conflicts with our results. Taste sensors evaluate each taste not only by reacting to individual substances, but also by electrostatic and hydrophobic interactions with various taste substances. Anions such as Cl- and SO42- are two of the detectors of the sensor CT0 used to evaluate saltiness. Well-progressed degradation may have released these anions into fish sauce. It is necessary to investigate the components that affect the saltiness in pCO2 fish sauces using the sensor.

Bitterness of pCO2 fish sauces was lower than that of atmospheric pressure fish sauces. Peptides containing hydrophobic amino acids often exhibit bitterness. The combination of pCO2 and protease may result in protein hydrolysis, because the almost all types of hydrophobic amino acids are liberated to a greater degree by the combination treatment. However, the degree of reduction was smaller than 1.0 unit.

Taste sensory analysis creates an expectation that simultaneous application of pCO2 and protease enhances umami, umami koku, and saltiness. These are positive changes for enhancing commercial value of fish sauce. In the future, it will be necessary to relate the results of the taste sensor to those of the sensory test.

We have previously produced reduced-salt (10%) fish sauce with the following properties: amino acid enrichment; no putrefaction; and sensorially low rancidity under pCO2 at 3 and 5 MPa and 30°C for 6 months. In this study, we successfully produced a further reduced-salt (7%) fish sauce under pCO2 at 1 MPa in a short period (1 week) by using a combination of an acid protease and mild heating. The resultant fish sauce showed similar tendencies with respect to improvement in the quality of amino acid content and suppression of browning. In addition, the combined treatment strategy used in this study improved umami, umami koku, and enhanced saltiness. Therefore, combining these techniques can promote increased consumption of reduced-salt fish sauce.

Acknowledgements This work was supported by the Japan Society for the Promotion of Science (grant number 20K02406). Taste sensor analysis was performed using research equipment shared in the MEXT Project for promoting public utilization of advanced research infrastructure (Program for supporting the introduction of a new sharing system; grant number JPMXS0422400021).

Conflict of interest There are no conflicts of interest to declare.