2023 Volume 29 Issue 2 Pages 113-122

2023 Volume 29 Issue 2 Pages 113-122

Connective tissue and fat are often removed from meat during processing. Their removal requires skilled butchery techniques; however, few methods are available for batch processing a large number of meat pieces. In this study, we aimed to develop a pretreatment method that promotes the flow of connective tissue and fat from meat so that they are removed during cooking. When meat samples pre-treated with protease (immersion in papain solution) and quick freezing (with thawing after immersion in liquid nitrogen) were cooked, connective tissue and fat disintegrated; the amount of outflow was significantly higher than when each treatment was applied individually. This combination reduced treatment time and did not severely damage the muscle tissue in the meat. This method has the potential to produce value-added meat products in terms of sensory quality and nutrition.

Meat, such as beef and pork, is primarily composed of muscle tissue, connective tissue, and fat. Muscle tissue is mainly composed of myofibrillar proteins, such as actin and myosin, and they account for the majority of commercial meat (Ahmad et al., 2018). If the meat is hard, it is subjected to chemical treatment using proteases such as papain or bromelain, or physical treatment such as tenderizing (cutting), and is moderately softened (Ketnawa and Rawdkuen, 2011; Bekhit et al., 2014; Warner et al., 2022). Connective tissue is mainly composed of proteins such as collagens and elastins. When connective tissue is untreated and hard to chew, it is softened or removed as appropriate (Reico et al., 1986; Zhao et al., 2012). Proteases are used to soften connective tissue as well as muscle tissue. However, there are few proteases that specifically degrade connective tissue proteins. Prolonged protease treatment results in excessive softening of not only connective tissue, but also muscle tissue, resulting in poor taste (Bureros et al., 2020). Fat contributes to the aroma and taste of meat (Arshad et al., 2018). However, excessive ingestion of veterinary fats causes albuminuria, a risk factor for chronic kidney disease (Abbate et al., 2020). In addition, fat is often complexly intertwined with connective tissue and contributes to the hardness of meat (Aaslyng et al., 2002). The addition of kiwi fruit- and ginger-derived proteases to chicken and pork results in lipid efflux (Sugiyama et al., 2006). Lipid efflux is accelerated in yellowtail fillets rapidly frozen with liquid nitrogen (Takeuchi et al., 2021).

Therefore, the meat industry often sells the muscle tissue of the animal meat after carefully removing the connective tissue and fat (Hendricks et al., 1977; Olcay, 2020). This removal requires a skilled technique, and there are few methods for batch processing a large number of meat pieces. Hence, techniques to efficiently remove connective tissue and fat from meat should be developed. Most studies on meat focus on homogeneous muscle tissue, and connective tissue and fat are often removed during the sample preparation (Zhang et al., 2019). A possible reason for this removal is that meat with connective tissue and fat is heterogeneous, making it difficult to reproduce experimental data (Fraeye et al., 2020; Soren and Biswas, 2020).

In this study, we aimed to develop a meat pretreatment method in which connective tissue and fat are disintegrated and removed during cooking by appropriately combining the protease and the quick-freezing treatments. The relatively homogenous beef tallow (comprising connective tissue and fat) and beef thigh (comprising muscle tissue) were used as samples to ensure reproducibility. Beef tallow was used to verify the conditions under which connective tissue and fat outflow increased; beef thigh was used to verify the effects of each treatment on the eating quality of muscle tissue for evaluating the results independent of the heterogeneity of the meat. Pork loin meat was used only for tissue observation because it is heterogeneous and cannot be quantitatively evaluated. Papain, a cysteine protease produced by Carica papaya used as a meat tenderizer, was used for protease treatment (Bekhit et al., 2014).

Materials and reagents Commercial products were used for beef tallow, beef thigh, and pork loin. Papain (papain-W40, powdered, food additive) was purchased from Amano Enzyme (Nagoya, Japan).

Protease treatment (PrT) Papain (Molecular weight: 23 000) solution was used for PrT. Papain preparations were dissolved in distilled water and the solutions were prepared immediately prior to use. Protein concentration was determined using Protein assay CBB solution (Bio-Rad, Hercules, California, U.S.), with bovine serum albumin (FUJIFILM Wako Pure Chemical Corporation, Osaka, Japan) as the standard. The livestock meat samples were immersed in 10 µM papain solution and incubated for 1 to 24 h at 4 °C. The sample was thoroughly washed with distilled water at 4 °C. For the control, the same procedure was performed; however, the samples were immersed in distilled water instead of papain solution.

Quick-freezing treatment (QFT) Meat samples were placed in a refrigeration resistant bag and frozen either through immersion in a refrigerant (liquid nitrogen at −196 °C or 99.9 % ethanol at −80 °C) or by cooling in a freezer at −80 °C. They were allowed to cool for 10 min to 24 h and then were thawed either quickly in 25 °C water for 10 min or slowly in a 4 °C refrigerator for 24 h. A thermocouple temperature data logger (Misumi Group Inc., Tokyo, Japan) was used to measure the temperature of the samples. A sensor was inserted into the beef tallow, and the temperature change in the center over time was measured.

Combination treatment (QFT-PrT, PrT-QFT) For QFT followed by PrT (QFT-PrT), samples were immersed in liquid nitrogen for 10 min, quickly thawed, and then immersed in 10 µM papain solution at 4 °C for 1 h. For PrT followed by QFT (PrT-QFT), samples were immersed in 10 µM papain solution for 1 h at 4 °C and then frozen using the indicated methods and times (10 min or 1 h), followed by quick or slow thawing.

Cooking with heat In the case of grilling, the samples were grilled in a hot plate at 200 °C, 1 min on each side, for a total of 2 min. The samples were grilled on a small aluminum dish; the weight of the solids and the liquid that flowed out was measured individually after heating. The value obtained by dividing the weight after grilling by the weight before grilling was defined as the solid weight change (%) and the liquid efflux rate (%), respectively. In the case of boiling, the sample was boiled with boiling water for 2 to 120 min, and the weight of the remaining solid was measured to calculate the solid weight change (%).

Preparation and staining of tissue sections Meat samples subjected to PrT, QFT, or PrT-QFT were immersed in 10 % neutral formalin buffer (FUJIFILM Wako Pure Chemical Corporation) for 24 h and fixed. The samples were embedded in paraffin and sliced in 2 µm-thick slices using SM2010 R Sliding Microtome (Leica Biosystems, Wetzlar, Germany). The connective tissue was stained blue using Azan stain, as described previously (Schipke et al., 2017). Connective tissue and adipocyte were observed using BX53 microscope (OLYMPUS, Tokyo, Japan).

Hardness measurement using a texture analyzer The hardness was measured using a texture analyzer TA. XT plus (EKO Instruments, Tokyo, Japan); a blade-set HDP/BS was used for the plungers. The plunger was lowered at a pre-measurement lowering speed of 3 mm/sec, during-measurement lowering speed of 5 mm/sec, and a displacement of 30 mm, as described previously; the value (g) of the maximum load at the time of cutting the grilled beef thigh meat was measured (Huidobro et al., 2005).

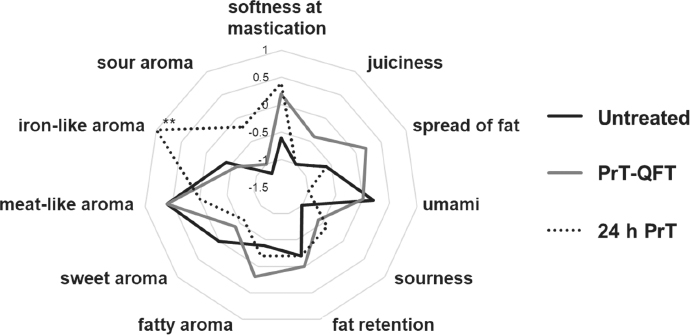

Sensory evaluation Samples were evaluated by five trained panels consisting of men and women of ages 21–50. In compliance with the sensory evaluation guidelines of meat (National Livestock Breeding Center, Tokyo, Japan), a total of 11 parameters, including six parameters of texture and taste (softness at mastication, juiciness, spread of fat, umami, sourness, and fat retention), and five parameters of aroma (fatty, sweet, meat-like, iron-like, and sour aroma), were evaluated in five grades: −2, −1, 0, 1, and 2; and averages were calculated.

Statistical analysis All tests were performed at least thrice. Error bars indicate the standard deviations. GraphPad Prism 7 (MDAF, Tokyo, Japan) was used for the statistical analysis. One-way analysis of variance (ANOVA) was performed for all analyses, except for boiling time and treatment combinations, for which two-way ANOVA was used. Tukey's multiple tests were performed in both cases, when differences were observed at a 5 % significance level.

Effects of combined PrT and QFT on the outflow of beef tallow Standard treatment conditions were as follows; PrT: immersion in 10 µM papain solution at 4 °C for 1 h, and QFT: rapid thawing after immersion in liquid nitrogen for 10 min. No buffer was added in PrT because there were no suitable edible buffers that did not affect the taste. The pH of the papain solution in which beef tallow or beef thigh meat were immersed was measured over a period of time. The pH between 10 min and 24 h was stable in the range of 5.2–6.5 (Fig. S1), presumably because the meat has a buffering effect of pH 5.5–7.0 (Puolanne and Kivikari, 2000; Mennah-Govela et al., 2020). The optimal pH for papain activity is 5–8 and is stable over a wide range of pH conditions (Berger and Schechter, 1970; Arshad et al., 2016; Milošević et al., 2019). Therefore, sufficient enzymatic activity was exerted on both beef tallow and beef thigh in PrT.

The PrT-, QFT-, QFT-PrT-, and PrT-QFT-treated beef tallow (2 cm cubes) was grilled at 200 °C for 2 min. The tallow of QFT-PrT and PrT-QFT collapsed markedly after grilling (Fig. 1A). Comparisons of solid and liquid weights revealed that the values in PrT and QFT did not differ significantly from that in the untreated; however, QFT-PrT and PrT-QFT significantly decreased solid weight (Fig. 1B) and increased liquid efflux (Fig. 1C). The combination of PrT and QFT promoted the outflow of connective tissue and fat and reduced the solid weight. In addition, the order of the treatments did not influence the results.

Changes due to the grilling of beef tallow after each treatment. (A) Appearance of the beef tallow after each treatment and grilling. (B) Change in solid weight and (C) liquid efflux rate of the beef tallow after each treatment and grilling (n = 5). PrT: Immersion in 10 µM papain solution for 1 h at 4 °C. QFT: Immersion in liquid nitrogen for 10 min, followed by rapid thawing with water at 25 °C. Alphabetical letters indicate the significant differences at the 1 % level, evaluated using Tukey's multiple tests.

Effect of prolonged single treatment on the outflow of beef tallow The effect of the prolonged individual treatments was investigated. When beef tallow treated with PrT for 6 or 24 h was grilled, the solid weight decreased significantly with the increase in treatment time (Fig. 2). However, in QFT, there was no correlation between the change in solid weight and the treatment time in the range of 1–24 h. The change in the solid weight of beef tallow treated with PrT for 24 h was 43 %, which was comparable to that in beef tallow treated with the combination of 1 h PrT and 10 min QFT (38–39 %) (Fig. 1B). Therefore, a strong efflux effect can be obtained in a short treatment time using the combination treatment. In general, shorter treatment times contribute to improved safety, because prolonged treatment can cause spoilage and deterioration of meat (Borch et al., 1996).

Change in solid weight due to grilling of beef tallow following prolonged treatments (n = 5). PrT: Immersion in 10 µM papain solution at 4 °C for 6–24 h. QFT: Immersion in liquid nitrogen for 1–24 h, followed by rapid thawing with water at 25 °C. Alphabetical letters indicate significant differences at the 5 % level, evaluated using Tukey's multiple tests.

Effect of cooling rate and thawing method of QFT on the outflow of beef tallow For quick freezing of food, methods such as spray-type liquid nitrogen quick freezing or immersion in a refrigerant is used; immersion in cooled ethanol is also a common technique (Choi et al., 2018; Cheng et al., 2020; Park et al., 2021). We investigated the effects of cooling rate and thawing method on QFT. Beef tallow diced into 2 cm cubes were placed in bags and frozen in three different ways: (i) cooled in a freezer at −80 °C, (ii) immersed in 99.9% ethanol at −80 °C, and (iii) immersed in liquid nitrogen (−196 °C). Temperature changes in the core of the tallow frozen using the above methods were recorded; the cooling rates in the 0–5 °C range were −1.5, −7.5, and −150 °C/min, respectively (Fig. 3A). PrT alone or PrT in combination with each freezing treatment was used and the change in the solid weight of the tallow during grilling was compared. We also evaluated the effects of a quick thaw (immersed in water at 25 °C) and slow thaw (left at 4 °C for 24 h). The change in the weight of solids in (i) did not differ from that in the PrT alone; in addition, accelerated efflux was not observed (Fig. 3B). However, in the freezing method (ii) with quick thawing, the weight of solid matter decreased, and a significant difference from the untreated samples was observed. Freezing using method (iii) resulted in the greatest reduction in solid weight. These effects were similar when slow thawing was used. The cooling rate to freezing rate was important for the outflow; however, the thawing method did not have any effect.

(A) Temperature change in beef tallow during cooling and (B) change in solid weight due to grilling of beef tallow frozen using different cooling methods (n = 3). PrT: Immersion in 10 µM papain solution for 1 h at 4 °C. QFT: (i) Cooling in a freezer at −80 °C for 1 h, (ii) immersion in 99.9 % ethanol at −80 °C for 1 h, and (iii) freezing by immersion in liquid nitrogen for 10 min, followed by quick thawing with water at 25 °C or slow thawing at 4 °C for 24 h. Alphabetical letters indicate significant differences at the 5 % level, evaluated using Tukey's multiple tests.

Evaluating the effects during boiling We investigated whether a similar outflow acceleration was observed when heated with boiling water instead of grilling. PrT-, QFT-, and PrT-QFT-treated beef tallow were boiled with boiling water for 2−120 min, and the change in solid weight was measured. Two-way ANOVA revealed an interaction between the boiling time and treatment (p = 0.036). Significant loss in solids weight was observed for PrT samples and PrT-QFT samples, when boiled for 120 min and 20–120 min, respectively (Fig. 4). In addition, a significant decrease in solid weight was observed in PrT-QFT after 120-min boiling compared with 2-min boiling, indicating that PrT-QFT is the most effective treatment for long boiling durations. Therefore, this pretreatment method might apply to both boiling and grilling.

Change in solid weight when beef tallow from each treatment is boiled for the stipulated time (n = 3). PrT: Immersion in 10 µM papain solution for 1 h at 4 °C. QFT: Immersion in liquid nitrogen for 10 min, followed by rapid thawing with water at 25 °C. Alphabetical letters indicate significant differences at the 5 %, evaluated using Tukey's multiple tests.

The effect of each treatment on tissue anatomy To examine the effect of PrT and QFT on connective tissue and fat, paraffin sections of ungrilled beef tallow from each treatment were prepared. The connective tissue was stained blue using Azan stain. Connective tissue and fat of pork loin were observed as meat other than beef. Connective tissue and adipocyte cell membranes were observed in both beef tallow and pork loin in the untreated group (Fig. 5A). In PrT, voids were found in the tissues of beef tallow, and connective tissue was cut in pork loin (Fig. 5B). Fruit-derived cysteine proteases, such as papain and ficin, cleave telopeptide regions of collagen molecules (Nishimura et al., 2020; Sato et al., 2020). Therefore, it was inferred that this void and cleavage were caused by the degradation of collagen. In QFT, adipocyte morphology was abnormal in both beef tallow and pork loin, and voids were observed in pork loin (Fig. 5C). Takeuchi et al. discuss the mechanism underlying accelerated lipid efflux by quick freezing; the fat in animal adipocytes is in an emulsion state and it precipitates when rapidly frozen, causing morphological abnormalities in cells (Takeuchi et al., 2021). In PrT-QFT, there were both connective and fat tissue injuries, with total tissue disruption (Fig. 5D). Therefore, the tissue skeleton became fragile following the pre-degradation and disruption of connective tissue by PrT; this was augmented by the breakdown of the fat tissue. QFT-PrT was not evaluated; however, it is speculated that the destruction of adipose tissue by QFT would facilitate protease penetration and promote connective tissue cleavage. Freeze impregnation generates voids in a tissue by freezing in advance to promote enzyme penetration; it is used for manufacturing products like nursing food (Sakamoto et al., 2021). PrT and QFT mainly degrade the connective tissue and the adipose, respectively; the efflux was promoted by a combination of these treatments.

Tissue structure of beef tallow and pork loin after each treatment. (A) Untreated, (B) PrT, (C) QFT, and (D) PrT-QFT. PrT: Immersion in 10 µM papain solution for 1 h at 4 °C. QFT: Immersion in liquid nitrogen for 10 min, followed by rapid thawing with water at 25 °C. Paraffin sections of each tissue were stained using Azan stain. The damage suspected to be caused by PrT or QFT is indicated using red and yellow arrows, respectively.

Effect on muscle tissue hardness The change in the solids weight after grilling was approximately 40% in the beef tallow subjected to PrT for 1 h and QFT for 10 min (PrT-QFT) or PrT for 24 h (24 h PrT); a large amount of outflow was observed (Fig. 1B and Fig. 2). However, treatment of meat under conditions that soften connective tissue results in excessive softening of muscle tissue and poor taste (Bureros et al., 2020). To determine whether these two treatment methods (PrT-QFT, 24 h PrT) would damage muscle tissue, muscle tissue hardness was measured. Beef thigh composed of homogeneous muscle tissue and substantially free of connective tissue and fat were used. The maximum load required for cutting beef thighs 2 mm thick and 2 cm wide, which had been grilled after each treatment, with a blade-type plunger was measured using a texture analyzer. The magnitude of the maximal load when cutting perpendicular to the muscle fibers was in the order of untreated, PrT-QFT, and 24 h PrT (Fig. 6A). The magnitude of this maximal load represents the hardness of the muscle fiber; therefore, the muscle fiber was softened by PrT-QFT, but not as much as that by 24 h QFT. However, there were no significant differences in the magnitudes of the maximal load when cutting parallel to the muscle fibers (indicating the ease of separation between the muscle fibers) (Fig. 6B). Papain strongly degrades myofibrillar proteins in animal meat (Ha et al., 2012). We speculate that papain degraded the muscle tissue in the same way it degraded the connective tissue in Fig. 5. QFT hardly reduces the quality and breaking stress of livestock meat (Jo et al., 2014; Zhang and Ertbjerg, 2018). Therefore, the degree of softening of the beef thigh was less in PrT-QFT, where the PrT duration was short.

Hardness of grilled beef thigh in different treatments. The values of the maximum load when cutting in (A) perpendicular and (B) parallel to the muscle fiber were compared (n = 12). PrT-QFT: Immersion in 10 µM papain solution at 4 °C for 1 h, followed by immersion in liquid nitrogen for 10 min and quick thawing with water at 25 °C. 24 h PrT: Immersion in 10 µM papain solution at 4 °C for 24 h. Different alphabets indicate significant differences at the 1 % level, evaluated using Tukey's multiple tests.

Effect on sensory quality of muscle tissue Similar to the hardness measurements, sensory evaluations were performed using five trained panels to evaluate the sensory quality of PrT-QFT or 24 h PrT beef thigh. Samples were presented immediately after grilling to the panel, and the average value was calculated for 11 parameters evaluated in five grades: −2, −1, 0, 1, and 2. The “iron-like aroma” of the 24 h PrT samples was significantly higher than that of the samples in the other groups (Fig. 7). There were no significant differences among the other parameters; however, the mean values of “softness at mastication” were higher at 24 h PrT and PrT-QFT in that order, when compared with that of the untreated group. This was in line with the results of the hardness measurements (Fig. 6). Compared with that in the other groups, 24 h PrT samples tended to have a lower umami and higher sour aroma. In livestock meat, degradation of proteins results in the production of off-flavor, including bitterness and sourness (Zhao et al., 2020). Therefore, long time PrT caused deterioration in the taste and the aroma. However, these tendencies of taste deterioration were not observed in PrT-QFT. The combination of short-duration PrT and QFT did not degrade the sensory qualities of muscle tissue more than long-duration PrT (Fig. 6 and Fig. 7). Therefore, the combination of PrT and QFT was effective for removing connective tissue and fat without damaging muscle tissue in general meat products.

Sensory evaluation of grilled beef thigh subjected to different treatments (n = 5). The reaction conditions for PrT-QFT and 24 h PrT are the same as that in Fig. 6. **Tukey's multiple tests show that there are significant differences between the 24 h PrT group and other groups at the 1 % level.

Quantitative and reproducible results were obtained using beef tallow and beef thigh as samples. A combination of PrT and QFT on livestock meat promoted the outflow of connective tissue and fat during cooking. The combination greatly shortened the treatment time while minimizing the deterioration of the sensory qualities of the muscle tissue. This could be attributed to the differences in the target component of each treatment. Obtaining high value-added livestock meat, devoid of connective tissue and fat could be possible using this pretreatment method. However, optimization of the size and cooking conditions of meat samples is essential for the efficient practical application of this method.

Conflict of interest There are no conflicts of interest to declare.

Quick-freezing treatment

ANOVAAnalysis of variance

PrTProtease treatment

Time course of pH of the papain solution in which beef tallow or beef thigh were immersed. Each sample was immersed in 10 µM papain solution at 4°C for the stipulated time. Mean values of triplicate tests are indicated at each point and standard deviations are indicated using error bars.