2014 Volume 56 Issue 6 Pages 498-504

2014 Volume 56 Issue 6 Pages 498-504

Objectives: When an air current flows from behind a worker, the contaminant level in the breathing zone may increase due to the wake around the worker. Researchers have been investigating about this wake, and much knowledge has been provided about the wake that appears around a standing worker. However, the wake around a squatting worker has not been addressed. This study aimed to describe the wake in front of a worker squatting in a confined space by using a model worker and a chamber and investigate the conditions in which this wake develops easily. Methods: A mannequin was employed as a model worker and was placed in the chamber to simulate a squatting worker in a confined space. Then, air was sent from behind under various conditions with a fan, and the wake was observed. Results: A wake appeared when smoke was emitted at 0–0.1 m from the point just below the breathing zone, and most of the wake region was in the range between the point just below the model worker's breathing zone and body. A wake did not appear when a fan of 0.15 m in diameter was used. The flow rate and velocity of the airflow were almost irrelevant with respect to wake development. Conclusions: The following are recommended based on the results of the present study. i) The distance between a source of contaminants and the point just below the breathing zone should be more than 0.2 m. ii) An air duct with a cross-section of less than 0.02 m2 is desirable to avoid producing a wake.

(J Occup Health 2014; 56: 498–504)

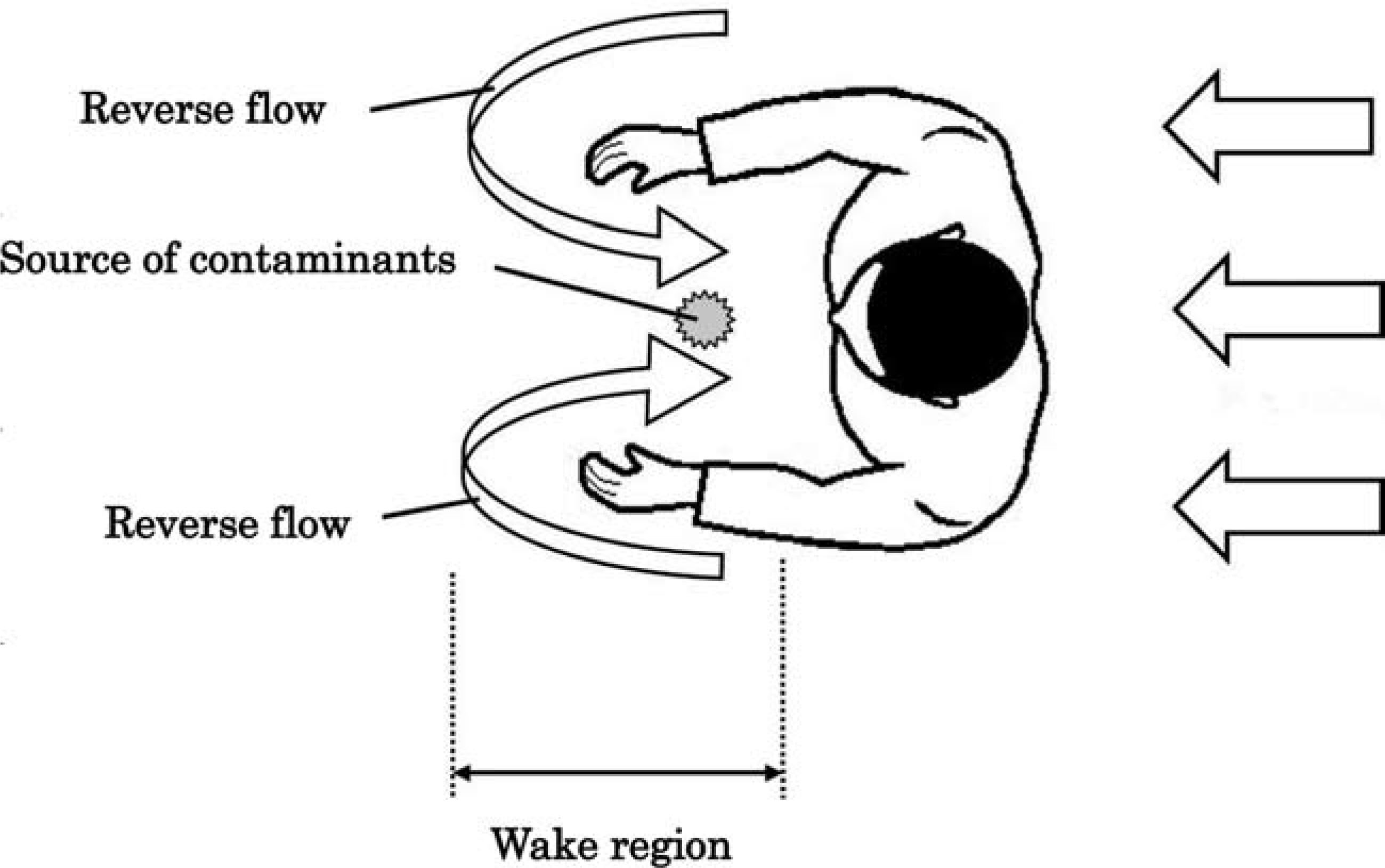

A “wake” is defined as the region of reverse flow (recirculating flow) immediately behind a moving or stationary solid body caused by the flow of surrounding fluid around the body. This phenomenon is well known to happen in various industrial scenes and often causes problems with respect to occupational hygiene. When a moderate airflow originates from behind a worker facing a source of contaminants, a wake may occur in front of the worker and transport airborne contaminants back toward the worker, which will cause higher exposure (Fig. 1). In some cases, even the exhaust airflow of a local exhaust ventilation (LEV) system or some other system may have an adverse effect on the control of contaminants due to the effect of a wake1–3). From the view point of flow dynamics, many researchers have been studying air movements around a worker empirically by using a wind tunnel, a fume hood and a model worker (human or mannequin worker) to reveal the effect of a wake on worker exposure4–10). In these experiments, a source of contaminants was positioned in front of a standing model worker. In contrast, however, a wake around a squatting worker does not seem to have been adequately investigated yet even though many workers have to squat in a confined space. When work is performed in a confined space such as a tunnel or the inside of a structure, air duct ventilation that supplies fresh air into the space is commonly used to prevent anoxia and contaminant exposure, since an ordinary LEV system is inapplicable to these situations. Therefore, the supply of fresh air from behind a worker handling harmful substances in a confined space might cause accidental high exposure. So in this study, the author aimed to describe the appearance of a wake in front of a worker squatting down in a confined space by using a model worker (life-sized flexible mannequin) and a small chamber and to investigate the conditions in which this wake easily develops.

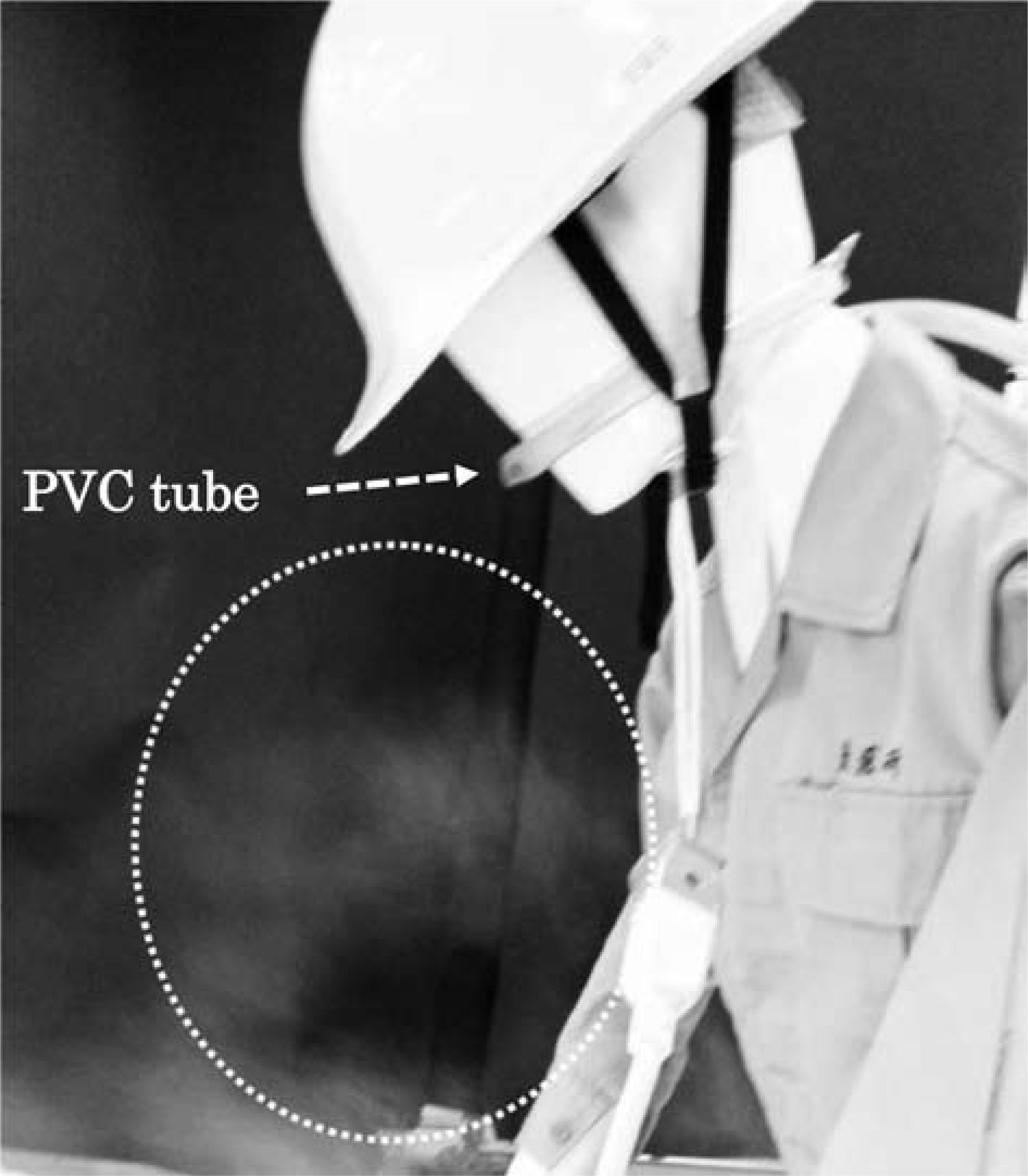

Wake in front of a worker standing in an airflow.

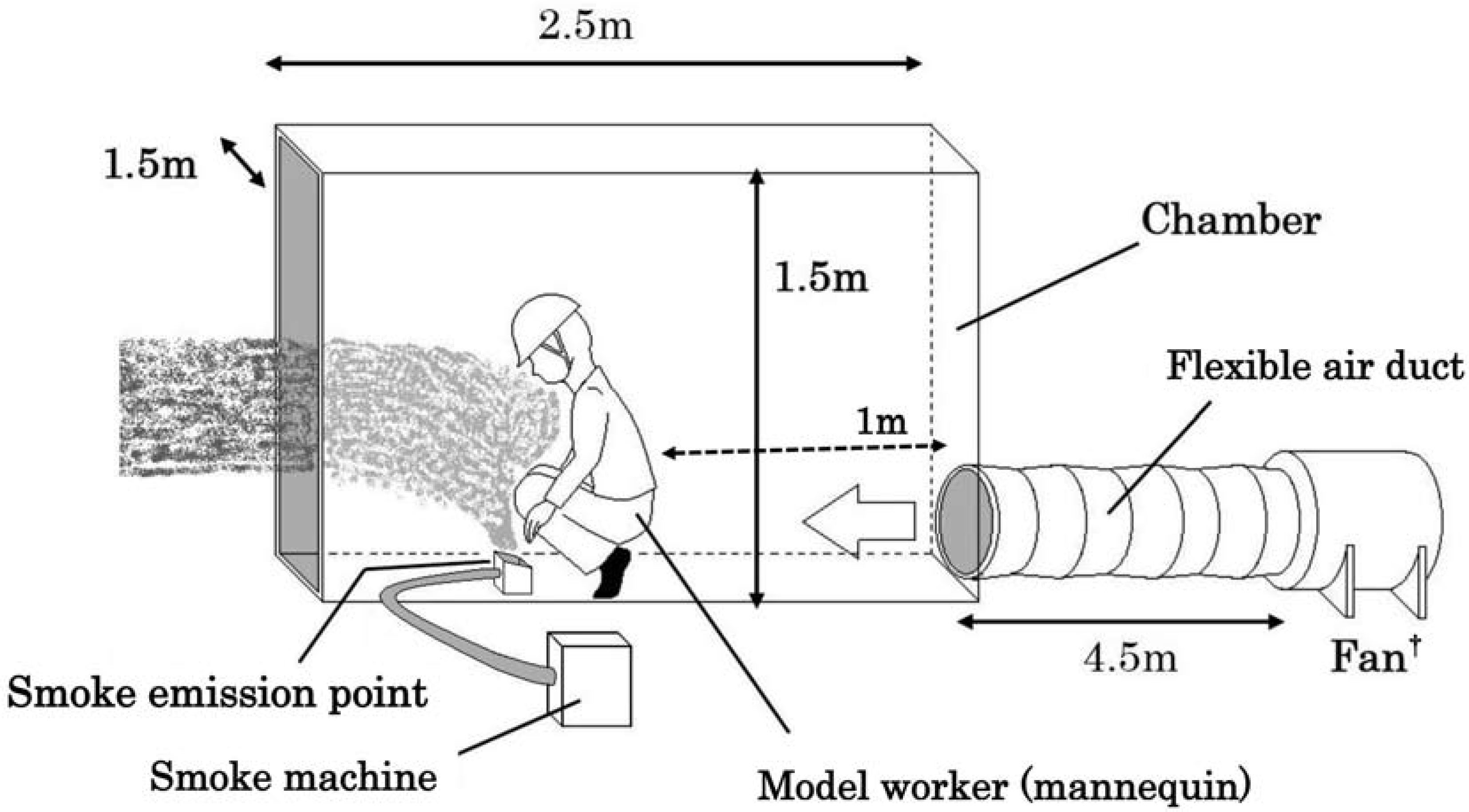

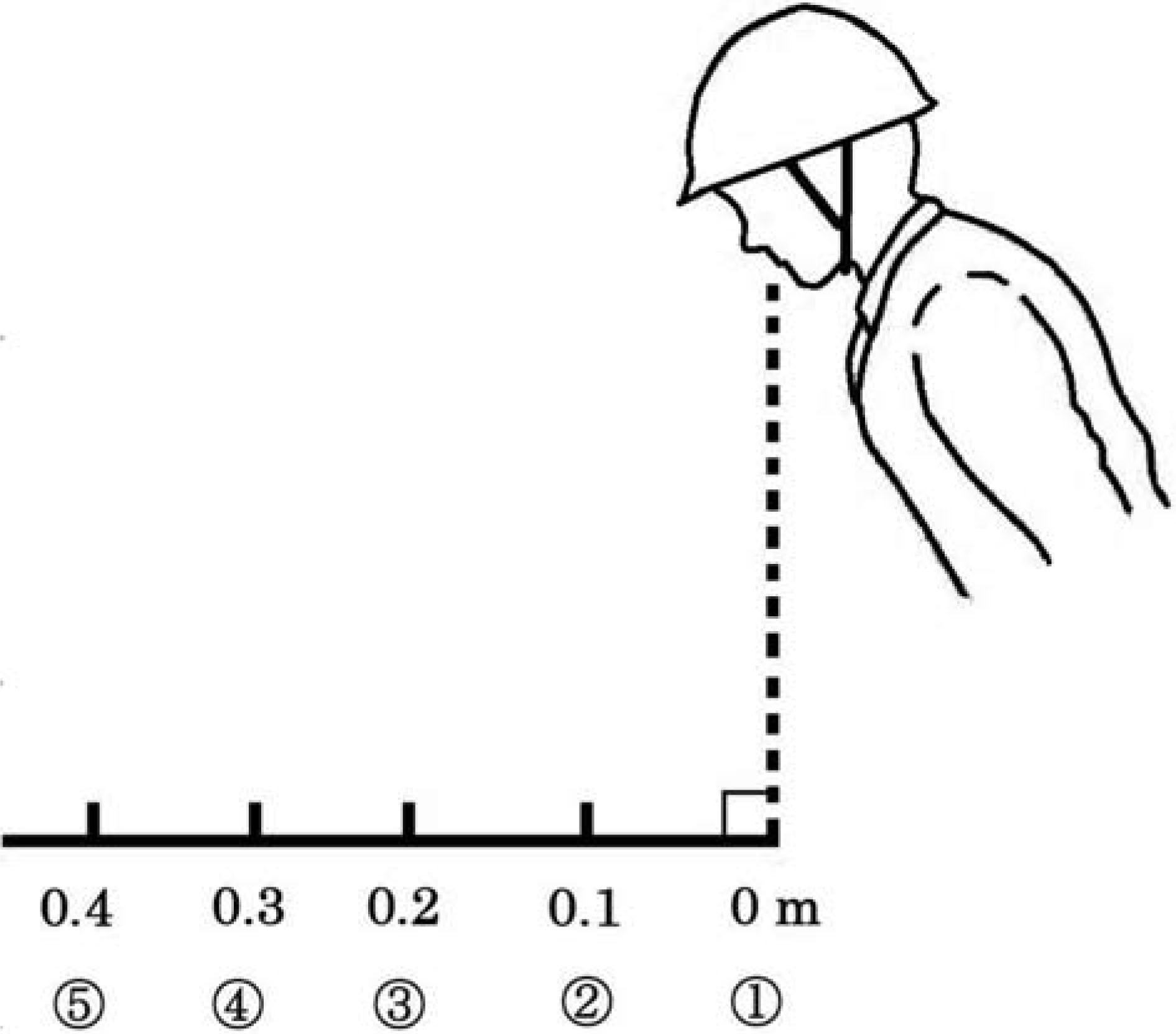

All experiments in this study were carried out with the experimental setup shown in Fig. 2. A confined space was simulated with a small chamber (W 2.5 m × D 1.5 m × H 1.5 m) with openings on two sides. Transparent plastic sheets were used for the walls in order to facilitate observation of the interior of the chamber. A commercial life-sized, breathing, heated, flexible polypropylene mannequin that could be put in virtually any pose was employed for the experiments and was placed in the center of the chamber to simulate a squatting worker in a confined space. The height of the mannequin was about 1 m when it was placed in a squatting position. The height of the breathing zone of the mannequin was about 0.7–0.8 m from the floor, and the shoulder width of the mannequin was about 0.45 m. With a PVC tube, the nose of the mannequin was connected to a simple piston-drive breathing apparatus that operated at 20 respirations per minute with a tidal volume of 1.5 liters, which was in accordance with the JNIOSH (National Institute of Occupational Safety and Health, Japan) technical recommendations for the structure standard of a PAPR11). The mannequin was also helmeted and was clothed in cotton pants and cotton work wear. Inside the work wear, a ribbon heater generating 100 watts of power was mounted around the mannequin's body to simulate a body temperature. Then air was directed at the mannequin with a fan (SJF-300RS, SJF-255, SJF-200L; Suiden Co., Ltd. and WB-II, Onishi Electric Industry Co., Ltd.) from behind through a 4.5 m flexible air duct. In the experiment, four kinds of fans that varied in size (diameter=0.3 m, 0.25 m, 0.2 m, 0.15 m) were used in turn. The output (fan speed) of each fan was regulated by a transformer. A flexible duct with the same diameter as the fan was connected to each fan. The distance between the back of the mannequin and the end of the flexible duct was set at 1 m. In order to observe the wake visually, smoke (chemical mist) was generated by a smoke machine (Porta Smoke PS-2001; Dainichi Co., Ltd.). The generated smoke was gently emitted from the floor in front of the mannequin to visualize the wake. Several different positions for the smoke emission point were used and were within 0 m to 0.4 m from under the breathing zone of the mannequin (Fig. 3). The flow rate of the supplied air blown from the end of the flexible duct was measured by a Pitot tube flow meter (AMA-A 300D; Shibata Giken Co., Ltd.). The velocity of the supplied air was measured at the center of the opening at the end of the duct by a hot-wire anemometer (Anemometer Standard, Model 6035; Kanomax Japan, Inc.).

Experimental setup for wake observation. (†Diameter=0.3 m, 0.25 m, 0.2 m, 0.15 m)

Positions of the smoke emission point with respect to the model worker.

In this study, the author observed the state of the flowing smoke in front of the mannequin by viewing video and still images taken by a digital camera. With the situation that the smoke entered into the breathing zone of the mannequin, the author recognized the wake appeared in front of the mannequin. The test conditions of the experiment included every combination of the four fan sizes (diameter=0.3 m, 0.25 m, 0.2 m, 0.15 m), four fan speeds (100% [maximum], 80–90% [comparably high], 60–80% [comparably low], 30–75% [minimum]) and five smoke emission points (➀–➄; Fig. 3). The experiments were conducted in a laboratory without any ambient airflow.

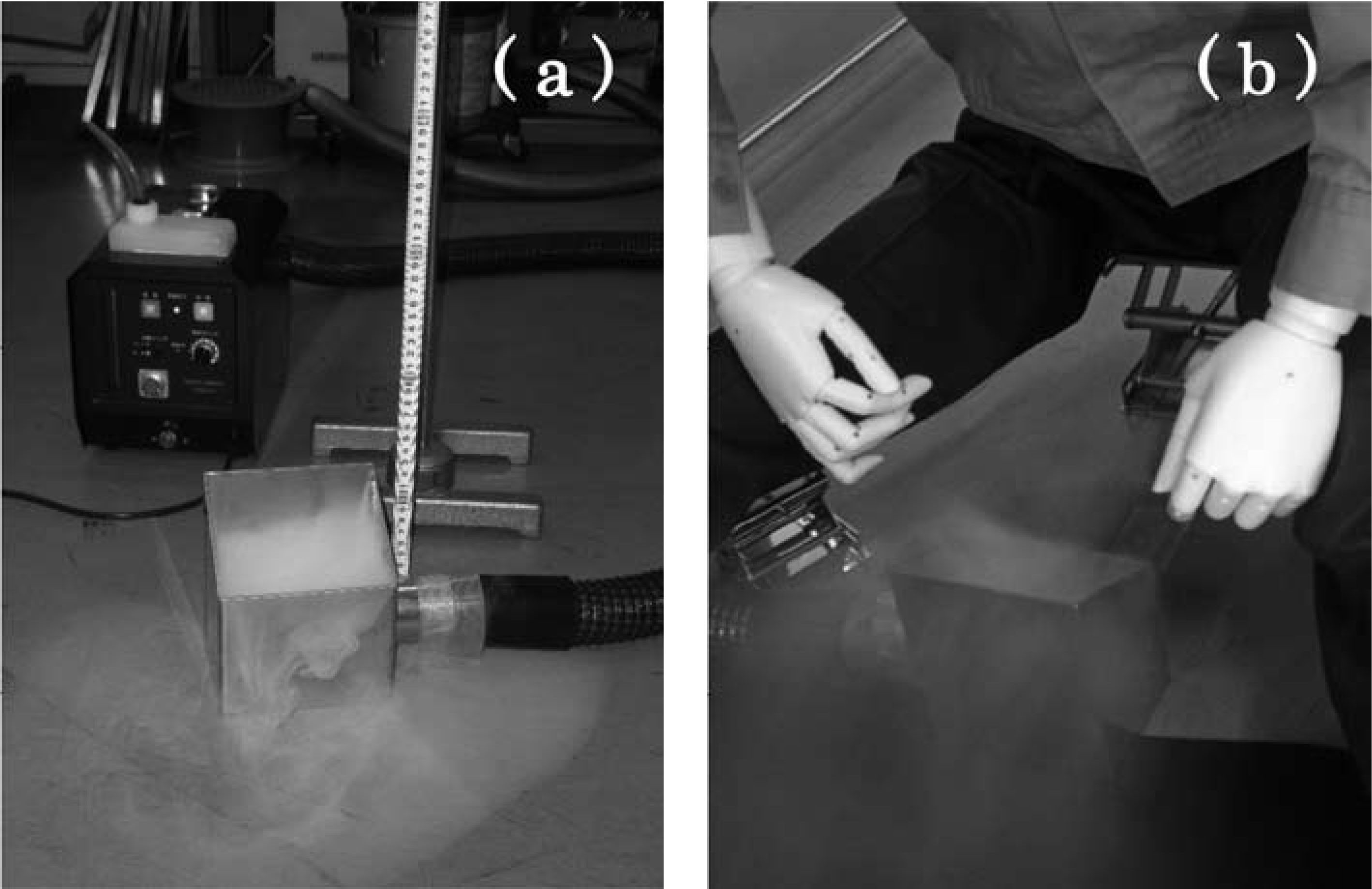

Although the emitted smoke could not rise higher in the air in the absence of a wake (Fig. 4), it could be pulled into the breathing zone by the wake in front of the mannequin. Figure 5 shows an image of the wake that appeared in front of the mannequin. In this case, a fan with a diameter of 0.3 m was used at the minimum fan speed (5.4 m/sec), and smoke was emitted from point ➀.

The flow of the emitted smoke. (a) Without the mannequin and the fan. (b) Without the generation of a wake.

Appearance of the wake in front of the model worker.

The results of the wake observations are summarized in Table 1. Regarding the wake at the front of a squatting worker, the following issues were noted based on the results.

| Fan size [cm] | Velocity [m/sec]* | Flow rate [m3/min] | Smoke emission point | Wake appearance** |

|---|---|---|---|---|

| 30 | 16.4 | 53.5 | ➀ | ○ |

| ➁ | × | |||

| ➂ | × | |||

| ➃ | × | |||

| ➄ | × | |||

| 13.0 | 42.4 | ➀ | ○ | |

| ➁ | × | |||

| ➂ | × | |||

| ➃ | × | |||

| ➄ | × | |||

| 9.5 | 31.0 | ➀ | ○ | |

| ➁ | △ | |||

| ➂ | × | |||

| ➃ | × | |||

| ➄ | × | |||

| 5.4 | 17.6 | ➀ | ○ | |

| ➁ | △ | |||

| ➂ | × | |||

| ➃ | × | |||

| ➄ | × | |||

| 25 | 10.3 | 23.3 | ➀ | ○ |

| ➁ | △ | |||

| ➂ | × | |||

| ➃ | × | |||

| ➄ | × | |||

| 8.9 | 20.2 | ➀ | ○ | |

| ➁ | △ | |||

| ➂ | × | |||

| ➃ | × | |||

| ➄ | × | |||

| 7.7 | 17.5 | ➀ | ○ | |

| ➁ | × | |||

| ➂ | × | |||

| ➃ | × | |||

| ➄ | × | |||

| 5.9 | 13.4 | ➀ | ○ | |

| ➁ | × | |||

| ➂ | × | |||

| ➃ | × | |||

| ➄ | × | |||

| 20 | 6.6 | 9.5 | ➀ | ○ |

| ➁ | △ | |||

| ➂ | × | |||

| ➃ | × | |||

| ➄ | × | |||

| 5.9 | 8.6 | ➀ | ○ | |

| ➁ | △ | |||

| ➂ | △ | |||

| ➃ | × | |||

| ➄ | × | |||

| 5.2 | 7.6 | ➀ | ○ | |

| ➁ | △ | |||

| ➂ | × | |||

| ➃ | × | |||

| ➄ | × | |||

| 4.8 | 7.0 | ➀ | ○ | |

| ➁ | △ | |||

| ➂ | × | |||

| ➃ | × | |||

| ➄ | × | |||

| 15 | 11.8 | 9.6 | ➀ | × |

| ➁ | × | |||

| ➂ | × | |||

| ➃ | × | |||

| ➄ | × | |||

| 10.6 | 8.6 | ➀ | × | |

| ➁ | × | |||

| ➂ | × | |||

| ➃ | × | |||

| ➄ | × | |||

| 9.3 | 7.6 | ➀ | × | |

| ➁ | × | |||

| ➂ | × | |||

| ➃ | × | |||

| ➄ | × | |||

| 8.9 | 7.2 | ➀ | × | |

| ➁ | × | |||

| ➂ | × | |||

| ➃ | × | |||

| ➄ | × |

A wake that brings about an accidental high exposure to a contaminant may be dangerous not only to a standing worker but also to a squatting worker. However, such an exposure has often been ignored because many workers tend to think intuitively that the windward area of a source of contaminants is almost completely free from contaminants.

In addition to training in work practices and education of workers about the concept of a wake, the following recommendations will be beneficial in avoiding accidental exposures caused by a wake.

Karaismail10) mentioned that a worker's movements could be one of the most important factors affecting the level of exposure in real work. For example, a human worker's arm movements can enhance mixing, which may lead to higher exposure8, 12). However, a squatting worker does not seem to make large arm movements like a standing worker using an industrial-type benchtop enclosing hood10). Therefore, an experiment with a stationary mannequin and source is thought to be applicable for most cases of a squatting worker.

In this study, a dispersing contaminant was simulated with smoke that was emitted upward gently. However, when the temperature of a source of contaminants is so high that it produces a significant ascending current, it would impact the flow pattern around a worker and change the wake conditions drastically. Work tasks such as arc welding, in which welding fumes and CO gas disperse with a rapid ascending current, should be considered in a future study.