2021 Volume 27 Issue 4 Pages 551-557

2021 Volume 27 Issue 4 Pages 551-557

In this study, the shear and heat milling machine (SHMM), which was developed to produce amorphous rice flour, was applied to indica and japonica rice varieties. The grain shape of indica rice differs from that of japonica rice. We examined the effect of shape differences of rice grains on amorphization by SHMM. Pre-crushed samples were also used alongside the rice grain samples to control for differences in grain shape between indica and japonica rice varieties. Rice flour was produced from indica and japonica rices, and the effect of milling temperature at 80, 100, 120, and 140 °C on amorphization was examined. Crystallinity, moisture content, and particle size distribution were compared between the rice varieties. The effect of milling temperature on indica rice was qualitatively similar to that of japonica rice. The longer grain shape of indica had a negative effect on amorphization by SHMM.

In Asia, people also eat westernized processed foods, such as bread, pasta, and so on, which are made from wheat (Pingali, 2006). However, the number of people with celiac disease (gluten intolerance) is increasing, and a trend to avoid gluten in wheat products is spreading around the world (Gallagher et al., 2004). Therefore, gluten-free foods in which wheat has been replaced with rice or other cereals are attracting attention. Pregelatinized or amorphous starch has been reported to improve the quality of gluten-free rice flour breads. Amorphous starch, which is a main component of amorphous rice flour, works as a thickening agent (Pongjaruvat et al., 2014). The crystallinity of rice flour is related to the thickening effect or the strain hardening property of amorphous rice starch (Murakami et al., 2015). The particle size of rice flour also contributes to the quality of foods, especially pure rice bread (Araki et al., 2009; Murakami et al., 2016).

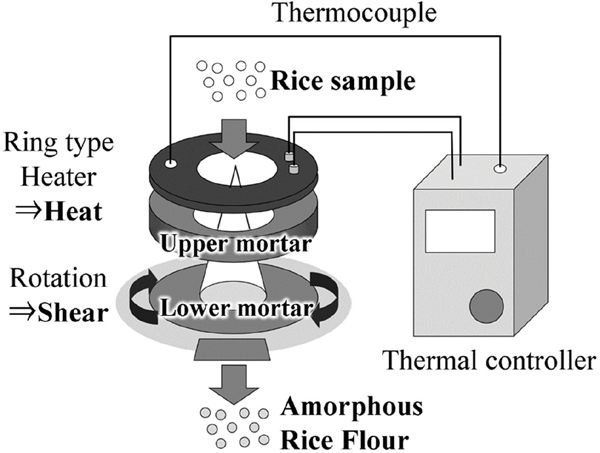

One of the easiest methods to produce amorphous starch is with the shear and heat milling machine (SHMM) developed by our research group (Katsuno et al., 2010). Figure 1 is a schematic description of the SHMM. The SHMM method is simple and produces high quality amorphous starch at a reduced cost, with a short processing time and lower energy consumption (Katsuno et al., 2010). SHMM has been, so far, applied only to japonica rice, which is produced throughout Japan (Murakami et al., 2018).

Schematic Illustration of the Shear and Heat Milling Machine (SHMM) (Katsuno et al., 2010).

In this study, we used SHMM to produce amorphous rice flour from indica rice. The production of amorphous rice flour from indica rice, which is widely cultivated in Asia, will contribute to the spread of the gluten-free concept (developed mainly in Europe and the United States) to Asia. Importantly, the grain shape of indica rice is obviously longer compared to japonica rice. One of our research interests is how differences in rice shape affect SHMM processing. Thus, amorphous rice flour was produced from indica and japonica rice varieties using SHMM, and the properties of crystallinity, water content, and particle size distribution were compared. The main purpose of this study is to examine the equivalence of indica and japonica rice varieties when applied to SHMM processing.

Materials Khao Hom Mali (Thailand) and Haenuki (Japan) were used as representatives of indica and japonica rices, respectively, and are both non-glutinous varieties. Indica and japonica rice samples were refined into starch and evaluated using Amylose/Amylopectin Assay Kit (K-AMYL, Megazyme Ltd., Bray, Ireland). The evaluated amylose content of indica and japonica rices were 11% and 9%, respectively. The two rice samples were considered to have similar amylose content. Grain shapes of indica and japonica rices are shown in Figure 2. The grain shape of indica rice is longer and more slender compared to japonica rice.

Grain shapes of (a) indica rice and (b) japonica rice.

Milling by SHMM To examine effect of rice grain shape on SHMM processing, two types of milled samples were employed. The first was amorphous rice flour milled directly from rice grains (AFG), while the second was amorphous rice flour milled from pre-crushed rice flour (AFP). Pre-crushing was performed using an electric crusher (PM-2005, OSAKA CHEMICAL Co., Ltd., Osaka, Japan).

A commercial milling machine (KGW-G015, West Co., Ltd., Niigata, Japan) was modified and used as the SHMM, as described previously (Katsuno et al., 2010). The SHMM consists of two metal mortars and a ring heater. Both mortars have a diameter of 90 mm, and the gap between the upper and lower mortars was 10 µm. The lower mortar rotated at 150 rpm. The ring heater was put on the upper mortar and the temperature was set at 80, 100, 120, and 140 °C for AFG. A milling temperature of 120 °C is typical for japonica rice. AFP was milled at the typical temperature of 120 °C.

Characterization of materials Wide-angle X-ray diffraction analysis was performed for rice flour and pre-crushed samples using an automated multipurpose X-ray diffractometer (Ultima IV, Rigaku Co., Tokyo, Japan) with Cu-Kα radiation (λ=1.54 Å). Diffraction data was collected over a 2θ range of 5–35° at a scanning speed of 10°/min. Crystallinity was estimated from the ratio of the peak areas originating from starch crystalline structures to the total area of the X-ray diffractogram using peak analysis software (PeakFit, SeaSolve Software Inc., Framingham, Massachusetts, USA). Moisture content was measured for rice flour and precrushed samples using an infrared moisture analyzer (FD-720, Kett Electric Laboratory, Tokyo, Japan). The Pre-crushed material prior to SHMM processing was considered as the untreated control sample for the X-ray and moisture content analyses.

Particle size distribution was measured for rice flour samples using a laser diffraction particle size analyzer (Mastersizer 2000, Malvern Instruments Ltd., Malvern, Worcestershire, UK). Particle shape of the rice flour samples was examined using a scanning electron microscope (SEM) (VE-9800, KEYENCE Japan, Osaka, Japan). The samples were coated with a thin film of gold and then examined at an accelerating voltage of 1.3kV.

Crystallinity analysis of SHMM-processed indica and japonica rice flours X-ray diffractograms of untreated and treated indica and japonica rice samples are shown in Figure 3. Starch crystals are typically categorized as A- or B-type (Lopez-Rubio et al., 2008). Figure 3 (a) and (b) show that untreated rice of both varieties showed A-type crystalline diffraction patterns, with main diffraction peaks at 2θ of 15, 17, 18, and 23°. The crystallinity of the untreated rice was 26% and 23%, respectively, for indica and japonica samples. Figure 3 (c) and (d) show the diffractograms of SHMMprocessed indica and japonica rice flours at a milling temperature 120 °C, respectively. All main diffraction peaks of both rice varieties decreased after SHMM processing. The results showed that SHMM can be used for amorphization of indica rice as well as japonica rice. Figure 4 shows the crystallinity and moisture content of rice flours after milling at various temperatures. The indica rice flour had about 1–3 points higher crystallinity than the japonica rice flour in the range of studied temperatures. We propose that the higher crystallinity of untreated indica rice was one of the reasons for this difference.

X-ray diffractogram of (a) untreated indica rice, (b) untreated japonica rice, (c) amorphous rice flour milled from rice grain (AFG) of indica rice, and (d) AFG of japonica rice. AFG was obtained by SHMM processing at a milling temperature 120 °C.

Crystallinity and moisture content of amorphous rice flours milled from rice grain (AFG) in relation to the milling temperature. Closed circles and closed squares are crystallinities of indica and japonica rice, respectively. Open circles and open squares are moisture contents of indica and japonica rice, respectively.

Since indica rice is characterized by a long grain shape, it was necessary to determine its suitability for amorphization by SHMM. To examine this, the results of milling of pre-crushed rice flour samples (AFP) were used. Table 1 shows the results of crystallinity analysis of AFG and AFP milled at 120 °C in comparison to untreated rice. In AFP, the pre-crushing treatment controlled for grain shape differences between indica and japonica rice. AFP had higher crystallinity than AFG. We propose that the shear applied to the small precrushed flour was insufficient compared to that applied to the large rice grains. These results indicate that the shape of the samples before milling affected amorphization by SHMM. When the shape difference between indica and japonica rice grains was eliminated by pre-crushing, similar results were obtained for both rice varieties, as indicated by AFP in Table 1. From these results, we suggest that differences in the grain shape of indica and japonica rice varieties affected crystallinity, resulting in differences between indica and japonica AFG. The shape of the indica rice grains (long and slender) had a negative effect on amorphization by SHMM. However, even in the case of AFP, the indica rice showed slightly higher crystallinity than that of japonica. We also expect that the original crystallinity of the untreated samples affected the resultant crystallinity of the SHMM-processed amorphous rice flour.

| Samples | Crystallinity (%) | |

|---|---|---|

| Indica rice | Japonica rice | |

| Untreated rice | 26 | 23 |

| AFP | 13 | 12 |

| AFG | 5.2 | 1.9 |

Figure 4 shows that both rice flours showed the lowest crystallinity at 100 °C, i.e., the optimal milling temperature of amorphization by SHMM for the present study. The optimal milling temperature was the same for both indica and japonica rice varieties. This optimization occurred as a result of the interaction between milling temperature and moisture content of the samples. In SHMM, the moisture contained in rice samples is required for amorphization, i.e., a lack of water impedes the motion of starch molecules. Further, for the motion of starch molecules, activation at a high temperature is needed. However, high temperatures induce water evaporation, lowering the moisture content. Thus, there is a trade-off between the two factors (heating at a high milling temperature and the water content of samples) required for the motion of starch molecules. Amorphization was incomplete at a temperature of 140 °C because of the lack of water in the samples. On the other hand, the rice flours milled at 80 °C required a higher temperature to obtain molecular motion for amorphization, even though they showed the highest moisture content. For both the indica and japonica rices, at 100 °C, the samples were heated well while maintaining sufficient water content for amorphization by SHMM.

Particle size analysis of SHMM-processed indica and japonica rice flours Figure 5 shows the results of particle size distribution measurement of the rice flours milled at various temperatures. A bimodal particle size distribution was observed. The primary peak showed a size of about 100 µm, except for in japonica rice flour milled at 120 °C (Figure 5 (b)), which showed a size of about 200 µm. The size of the secondary peak was about 10 µm for all conditions. Since the gap between SHMM mortars was 10 µm, we suggest that the primary distribution peak was caused by agglomeration. Particles that were not agglomerated comprised the secondary peak of around 10 µm. Specifically, in the SEM image of the rice flour milled at 120 °C (Figure 6), it was observed that small particles were stuck together into a larger agglomeration.

Particle size distribution of amorphous rice flours milled from rice grain (AFG) milled at (a) 80 °C, (b) 100 °C, (c) 120 °C, and (d) 140 °C. Closed circles and open squares are indica and japonica rice, respectively.

SEM images of indica and japonica amorphous rice flours milled from rice grain (AFG) milled at 120 °C. (a) indica rice, (b) japonica rice, (c) magnification of (a), and (d) magnification of (b).

The size of agglomerates depended on the milling temperature. Figure 7 shows the median diameter of rice flour samples in relation to the milling temperature. The rice flour milled at 100 °C exhibited the largest particle size due to aggregation. Further, in a comparison of indica and japonica rice flour samples (Figure 7), the indica sample had a smaller particle size. It was suggested that indica rice flour is less likely to agglomerate than japonica rice flour. The slightly lower moisture content of raw indica rice may have led to smaller particle size of indica rice flour than japonica rice one.

Median diameter of amorphous rice flour samples milled from rice grain (AFG) in relation to the milling temperature.

We expect that rice flour agglomeration is stabilized by the moisture that binds particles. We suggest that the smaller size agglomeration at 140 °C compared to that at 100 °C is attributable to moisture evaporation at the higher temperature. A lack of moisture reduces the stickiness of flour, leading to smaller sized agglomerates. However, at a milling temperature of 80 °C, obvious aggregation did not occur. Since 80 °C is lower than the boiling temperature of water, water was not egress from the rice flour particles to bind the flour.

The present study examined the application of SHMM, which is used to produce amorphous rice flour, to indica and japonica rice varieties. Khao Hom Mali and Haenuki were used as the representative indica and japonica rice samples, respectively, and the effects of sample shape and milling temperature on amorphous rice properties was determined. This study provided the following new findings:

Acknowledgements We are grateful to our laboratory members, Ms. Apakorn Thongmeepech and Ms. Marin Abiko, for the valuable discussion. This work was partially supported by Heiwa Nakajima Foundation as a project led by Prof. Dr. Akihiro Nishioka. This work was supported by JSPS KAKENHI Grant Number JP19H02904.