2015 Volume 32 Pages 184-195

2015 Volume 32 Pages 184-195

It is well known that diesel fumes are carcinogenic to humans and may cause inflammation of the respiratory tract, cardiovascular problems, etc. Diesel exhaust particles (DEPs) occurring in diesel fumes are fractal-like aggregates with diameters ranging between 10 and 2000 nm, with various compounds adsorbed on their surface. The fractal-like structure of DEPs and their nanosize leads to the problem of theoretically predicting the DEPs’ filtration efficiency. Thus, experimental studies on effective protection against DEPs as well as theoretical modeling are essential. This study analyzes both experimentally and theoretically the mechanical and electret filters and their potential effectiveness in the filtration of DEPs. The theoretical analysis of the filtration process on fibrous fabrics was performed using classic filtration theory, assuming that the filtration layer can be treated as a system of a single fiber located in the Kuwabara cell. The experimental results show that the fibrous filters, produced using melt-blown technology, provide a high level of protection against DEP aerosols (93 %–99 %). The obtained filtration efficiencies are (in some cases) even higher than requested for particulate respiratory half-mask type 2 (made from a fibrous filter). However, the theoretical results obtained using classic filtration theory indicate lower filtration efficiencies than the experimental ones.

The quality of ambient air in large cities has been monitored for the last decades due to a profound correlation between air pollution levels and human health (Murena, 2004; Kyrkilis et al., 2007). The technological development strongly influences the air quality by increasing the pollution emission. One of the highest sources of particle pollution in the atmosphere is the diesel engine (Weinhold, 2002). In 2010, half of all cars were equipped with diesel engines (ACEA, 2010). The populations of large cities are therefore exposed to diesel exhaust fumes (Groves and Cain, 2000; Kauppinen et al., 2000; Lewne et al., 2007), which are a complex mixture of gas and particulates (diesel exhaust particles—DEPs). DEPs are the result of an incomplete combustion of fuel. Exposure to diesel fumes causes inflammation of the respiratory tract, cardiovascular problems, asthma, allergies (Fujieda et al., 1998; Salvi and Frew, 1998; Norris et al., 1999). The International Agency for Research on Cancer (IARC) has classified diesel fumes as ‘carcinogenic to humans’ (Group 1). In addition, DEPs form fractal-like aggregates with diameters ranging between 10 and 2000 nm, with various inorganic and organic compounds (often mutagenic and cytotoxic) adsorbed on their surface. Thus DEPs are easily inhaled and penetrate the respiratory system (Moskal et al., 2006; Penconek and Moskal, 2013b) and adversely affect human health (Pope et al., 2002). The common solutions for this problem are filtration systems mounted in the car engines or personal protection equipment represented by a half-mask. Particulate half-masks produced using fibrous fabrics are the most widespread form of respiratory protection equipment due to their low price (Huang et al., 2007). Fibrous filters can ensure a high filtration efficiency for a given aerosol characteristic with simultaneously a low pressure drop (Cena et al., 2012; Kim et al., 2009).

Testing and certifying standards for half-masks are different in Europe and the USA (Rengasamy et al., 2009), however, in both cases a certification test is conducted and provided using compact particles (NaCl or DOP—dioctyl phthalate) which are very different in morphology compared to the DEPs. Recently, Penconek et al. (2013a) showed that commercially available half-masks did not satisfy the quality norm (EN149:2004) when operated with DEPs. These results show that complex extensive experimental studies should be carried out, and a theoretical analysis of the filtration of DEPs using fibrous filters was performed to obtain an efficient half-mask for personal respiratory protection. The characteristics of DEPs depend on many factors such as engine type, load, fuel quality, and it has been the subject of scientific works for many years (Lapuerta et al., 2008; Zhang et al., 2009). In this work we focused on the process of DEPs filtration using fibrous structures. The fundamental objective of the present work was to evaluate the filtration efficiency of fibrous fabrics produced using melt-blown technology, applied to real DEP particles created in the diesel engine and compare the efficiency of filtration using electrets and electrically neutral fibers. The point was examined experimentally as well as theoretically.

1.1 Modeling of DEP penetration through filters layersThe theoretical analysis of the filtration process on fibrous fabrics can be performed using the classic filtration theory (Davies, 1973). It assumes that the filtration layer can be treated as a system of a single fiber located in the Kuwabara cell (Kuwabara, 1959). The particles, depending on their diameter and process conditions, may deposit on the fiber’s surface of the fibrous filters due to various mechanisms, such as diffusion (Brownian motion), interception, inertial impaction, gravitational settling and electrical interactions. The total collection efficiency of the filter layer composed of many fibers, η, is related to the single fiber efficiency, E, as follows:

| (1) |

| (2) |

However, the single fiber filtration efficiency due to diffusional mechanism can also be obtained using the following correlations:

| (3) |

| (4) |

| (5) |

| (6) |

with

and

and

where ρg is the gas density, μ is the gas viscosity.

The single fiber efficiency due to the direct interception mechanism can be described using the formula proposed by Lee and Gieseke (1980):

| (7) |

Kanaoka et al. (1987) proposed the expression for the filtration efficiency due to electrical interaction as follows:

| (8) |

Assuming that Brownian diffusion, interception and electrical interactions are independent mechanisms of deposition, the total single fiber efficiency, E, resulting from them can be calculated as follows (Podgórski et al., 2006):

| (9) |

Introducing Eqn. 9 into the Eqn. 1 allows estimation of the filtration efficiency for a material with a known thickness, average porosity and average fiber diameter.

To calculate the pressure drop across a filter, the theoretical equation reported by Brown’s handbook (Brown, 1993) can be used:

| (10) |

The DEPs form aggregates composed of many fine particles (primary particles) attached together. The number of particles in an aggregate ranges from 2, in the simplest case, to several thousand. The size of primary particles is usually between a few nm and 50 nm (Bałazy et al., 2006). The overall size of such aggregates ranges from nanometers to a few micrometers (Fridlander, 2000). The aggregates emitted by diesel engines (DEPs) contain a soot core with volatile organic and sulfur compounds adsorbed on their surface (Maricq, 2007). The structural parameters of the aggregates influence the dynamic processes such as diffusion, coagulation or sedimentation, especially for nano-size structures; hence, they can also affect filtration of the aggregates with fibrous filters. DEPs have complex structures which depend on the process of their creation and type of fuel used.

To characterize the complex irregular structure of the fractal-like aggregates, the concept of the “equivalent sphere” is used in many practical and theoretical works as well as in this work. The aggregate is treated as a sphere with a characteristic radius, which is a function of the geometrical properties of the cluster. In literature of the subject, various radii may be found. The most common radii are:

| (11) |

| (12) |

| (13) |

The complex structure of the fractal-like aggregates can also be characterized by its porosity or permeability. In this case the aggregate is treated as a porous sphere in which the porosity (and permeability) changes with its radius (Veerapaneni and Wiesner, 1996). The radial variation of the porosity, solids concentration and number of particles within an aggregate of radius Ragg can be related to its fractal dimension as follows (Cohen and Wiesner, 1990; Wiesner, 1992):

| (14) |

| (15) |

| (16) |

In the present work, the mobility diameters measured using a FAPES device (Fast Automotive Particles Emission Spectrometer) were used as the “equivalent diameter” during calculations. The FAPES device is described in the next section (Experimental methods). The DEP density was estimated for aggregates characterized by a high value of fractal dimension using the following formula:

| (17) |

Effective density of diesel exhaust particles obtained from a diesel engine operated at idle-speed conditions. The dashed lines display the best fits to the experimental data.

The effective density of motor vehicle exhaust particulates in Maricq and Xu (2004) studies was obtained from a diesel engine (manufactured in 2003; 4 cylinders; 1,8TDI) running on low-sulfur diesel (< 50 ppm sulfur) under idle-speed conditions.

Using Eqn. 14, the particle number distribution obtained during measurements using the FAPES device can be transformed into the particle mass distribution (Fig. 2).

Particle number distribution vs. mass distribution. A commercial diesel biofuel was used to generate particles.

Six fibrous filters made of polypropylene using a modified melt-blown technology were investigated. This entirely controlled method described in detail in a work by Jackiewicz et al. (2013) allows us to produce the desired material with the defined porosity and mean fiber diameter. Three pairs of two filter types were manufactured—a mechanical filter (i.e. electrically neutral) and an electret with charged fibers—with a similar internal structure to check how the additional capture mechanism, which is electrostatic force, besides conventional mechanical ones such as Brownian diffusion or interception affects the penetration of DEPs through the fibrous media. In order to give electrical properties to the polymer fibers, the charging system utilizes a corona discharge in the air between the corona comb electrode and the grounded collecting electrode placed at the outlet of the extruder head. The experiments were carried out at a constant voltage. Its value was determined as 90 % of the voltage at which a jump between the electrodes at a given geometry occurred. The corona comb electrode was composed of thirty-three needles mounted in a row on a metal plate, while the collecting electrode was cylindrical. The fibers’ charging efficiency depends greatly on how long they are in the area of corona discharge—the faster the fiber moves, the less charge will be implemented.

The experiments were carried out at a constant voltage. The structural characteristics of all analyzed materials were determined, see Table 1.

| Filter no. | Filter thickness, L [mm] | Filter porosity, ε [%] | Filter base weight, qs [g m−2] |

|---|---|---|---|

| Filter 1 | 2.13 | 97.5 | 48.1 |

| Filter 2 | 3.39 | 96.3 | 114.4 |

| Filter 3 | 3.63 | 93.9 | 197.9 |

| Electret 1 | 1.76 | 97.3 | 42.6 |

| Electret 2 | 3.69 | 96.2 | 125.4 |

| Electret 3 | 4.22 | 94.9 | 193.8 |

The filter porosity, εF, and the base weight, qs, were determined by a gravimetric method measuring the thickness, L, of the filter sample with the surface, A, and the filter mass, m, according to the following formula:

| (18) |

| (19) |

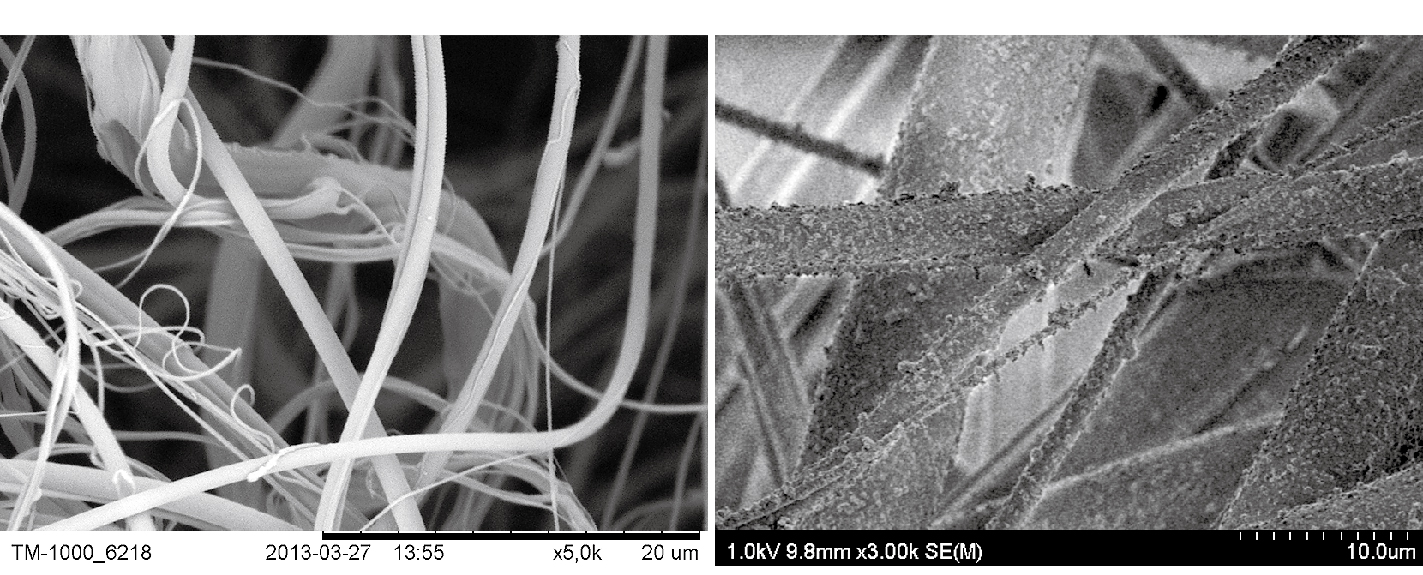

Analysis of the fibrous filter images taken using a scanning electron microscope Hitachi TM-1000 made it possible to obtain fiber size distributions of the tested fabrics. All of them could be precisely fitted by the log-normal distribution with the geometric mean fiber diameter, dFg, and the geometric standard deviation, σgdF, presented in Fig. 3.

Fiber size distributions of the fibrous electret and mechanical filters: (a) Electret 1 and Filter 1, (b) Electret 2 and Filter 2, (c) Electret 3 and Filter 3.

The experimental set-up was based on the previous ones (Penconek et al., 2013abc). The experimental set-up is presented in Fig. 4.

Experimental set-up.

The fibrous filter being tested was placed in a special holder in the chamber (chamber volume is 1 m3) where diesel exhaust fumes from the engine were directed. The diesel engine (manufactured in 1982, 4 cylinders, engine power 53 kW at 4200 rpm; torque 137 Nm at 2400 rpm; engine displacement 2399 cm3) was situated outside the building. Diesel fumes were stabilized in a buffer tank. The air flow was generated by a pump (SC10A 055S Venture Industries, Poland) and controlled by an electronic flowmeter (4040 model nano, TSI Inc., USA). The pressure drop across the sample was measured using a DPCCALC 8710 micromanometer (TSI Inc, USA).

The number distribution of the DEPs was obtained using the Fast Automotive Particles Emission Spectrometer—FAPES (Model 5.601, Grimm GmbH, Germany). The FAPES measurement technique is based on 10 DMAs (Differential Mobility Analyzer) with in-line FCEs (Faraday Cup Electrometers), and the measured particle size was in the range of 5 nm–640 nm with a frequency up to 5 Hz. In this study, a sampling rate of 0.2 Hz was used. The DEP samples were not diluted prior to measuring as a special integrated sample conditioning system with a heated dilution function (temperature up to 500 °C) is a part of FAPES. This dilution rate was 1:32.

Motor emissions were generated continuously throughout the test under idle-speed (800 rpm) conditions. The humidity (40–50 %) and temperature of the air around the diesel engine (20–25 °C) were identical during each test. The experiment started when the diesel engine oil temperature reached 86 °C (the temperature did not change during the test). The filtration efficiency of the DEPs and the pressure drop across fibrous filters were measured at a constant flow rate of 30 dm3·min−1 (air velocity 0.064 m·s−1) during a 20-minute test. The pressure drop across the filter and the DEP number distribution downstream of the filter were measured continuously throughout the test.

The filtration efficiency of the DEPs was determined gravimetrically (by weighing the absolute filter at 5-minute intervals during the test and by weighing the tested fibrous filter at the beginning and at the end of the test) as:

| (20) |

The diesel exhaust particles (DEPs) were generated using a real source, namely a Mercedes-Benz diesel engine. Commercially available diesel fuel was used to generate the DEPs. Table 2 summarizes the physical characteristics of the biofuel provided by manufacturers.

| Parameter. | |

|---|---|

| Number of compounds* | 20 |

| Density at 15 °C, kg·m−3 | 860–900 |

| Sulfur content, mg·kg−1 | 0 |

The average mass and particle number distribution of the DEPs were shown in Fig. 2. The DEPs’ cumulative frequency count of experimental data and their fitting by the log-normal distribution were shown in Fig. 5.

Cumulative frequency count of DEPs vs. particle diameter, and TEM (transmission electron microscopy) photo of DEPs.

The characteristics of the DEPs are given in Table 3. The fractal dimension of the DEPs was assumed after photo inspections without using any sophisticated algorithms. However, Lapuerta et al. (2006) determined the fractal dimension of compact DEP aggregates as 2.32–2.73. Therefore, based on a comparison of our DEP photos and Lapuerta et al.’s (2006) study, a fractal dimension of ∼2.5 was assumed for our DEPs.

| Geometric particle diameter [nm] | 64.86 |

| Arithmetic particle diameter [nm] | 88.57 |

| Size range of particle diameters [nm] | 10–640 |

| Fractal dimension | ∼ 2.5 |

| Observed shape | Compact |

Six different fibrous filters (three electrets and three mechanical filters) were examined with natural DEP aggregates and were found to have a mass experimental filtration efficiency higher than 93 %. A fibrous filter before and after filtration is shown in Fig. 6.

Fibrous filter before (left side) and after (right side) filtration of diesel exhaust particles.

The theoretical prediction of mass filtration efficiency is in the range of 52–99 %. Table 4 presents the results of the mass filtration efficiencies obtained in experiments and calculated for U = 0.064 m s−1 (Q = 30 l min−1) for the filters with characteristics given in Table 1 for uncharged filters and when the fibers have a charge density of 1.5·10−13 C m−1 (electret filters). The DEPs aggregates deposition is assumed to be driven by diffusion and direct interception for uncharged filters, with additional electrical interaction for electrets. The theoretical filtration efficiencies were calculated using Eqns. 1–9, taking into account the experimental number distribution of DEPs and the function of effective density (Eqn. 17). The filtration efficiency due to the diffusional mechanism was obtained considering the five correlations described earlier, and showed as an average filtration efficiency calculated using those five equations (see Table 5).

| Filter | D + I + E* | D | D + I | Pressure drop | Experiment | SD |

|---|---|---|---|---|---|---|

| Filter 1 | 89.82 | 82.15 | 89.82 | 13.51 | 94.02 | 0.42 |

| Filter 2 | 79.90 | 63.02 | 69.82 | 7.08 | 97.54 | 1.01 |

| Filter 3 | 90.36 | 85.72 | 90.36 | 14.92 | 95.33 | 2.84 |

| Electret 1 | 98.89 | 93.74 | 96.50 | 23.09 | 99.30 | 0.27 |

| Electret 2 | 91.08 | 86.24 | 91.08 | 18.27 | 93.38 | 6.90 |

| Electret 3 | 52.36 | 44.18 | 45.52 | 3.14 | 98.03 | 0.49 |

| Filter | Natanson (a) | Brown | Stechkina & Fuchs | Natanson (b) | Payet |

|---|---|---|---|---|---|

| Filter 1 | 33.84 | 89.66 | 85.21 | 79.82 | 86.46 |

| Filter 2 | 33.45 | 80.45 | 67.62 | 60.39 | 67.48 |

| Filter 3 | 55.43 | 95.38 | 88.84 | 83.88 | 88.70 |

| Electret 1 | 67.66 | 98.77 | 95.56 | 92.47 | 95.81 |

| Electret 2 | 53.87 | 95.71 | 89.37 | 84.51 | 88.98 |

| Electret 3 | 20.67 | 63.45 | 49.38 | 42.55 | 45.20 |

Theoretical analysis showed that the diffusional mechanism is a primary mechanism of DEPs depositing on fibrous filters. However, experimental data showed that the number of aggregates of a diameter smaller than 120 nm is higher after the filtration process than before this process. However, aggregates of a greater diameter are still effectively filtered. This may show that in the case of nanoaggregates, the diffusional mechanism is ineffective. Nevertheless, this phenomenon requires further research.

The differences between experiments and theoretical predictions may be caused by several factors, e.g.: non-homogeneity of the filter structure and shading of one fiber by another one (Bałazy et al, 2006).

The experimental mass distribution curves in Fig. 7 depict that filtration efficiencies for nanoaggregates are very low (shape of the curve which describes the experimental mass distribution after filtration is similar to the curve which describes the mass filtration efficiency before filtration). On the other hand, experimental mass filtration efficiencies (given in Table 4) are higher than 93 %. This discrepancy may indicate the presence of substantial quantities of DEPs with diameters higher than 640 nm and with large mass. The filtration efficiency of large aggregates is believed to be almost 100 %, the presented explanation therefore seems to be reasonable.

Distribution of DEPs’ mass ratio vs. particle diameter: (a) Electret 1 and Filter 1, (b) Electret 2 and Filter 2, (c) Electret 3 and Filter 3.

Fig. 8 presents the mass of DEPs that penetrated the tested fibrous filters during experiments. One can observe that the penetrated mass did not increase monotonically. A similar phenomenon was observed in the work of Penconek et al. (2013a) and may be explained by the process of reemission of previously deposited particles in the filter, which is more visible for long exposition of filters on DEPs. This phenomenon needs to be more carefully investigated.

Mass of DEPs that penetrated fibrous filters in the 5th, 10th, 15th and 20th minute of the test. The symbols represent the mean values and error bars represent the standard deviations.

The mass of DEPs was obtained by weighing the absolute filter placed downstream of the tested material (see Fig. 4) in 5-, 10-, 15- and 20-minute intervals during the test. The total mass of DEPs deposited in the absolute filter after 20 min is 1.61 (±0.99) mg for electrets and 2.40 (±0.06) mg for uncharged filters.

The experiment for the electret filter indicates that charging the fibers increases the mass of DEPs that deposit on the filter. The higher the mass of DEPs deposited on the fiber, the higher is the pressure drop across the fibrous filter observed after the test. Such a relationship can be seen if electrets and uncharged filters with similar characteristics are compared. Fig. 9 presents the pressure drop across filters during experiments.

Pressure drop across fibrous filters. Lines represent the mean values and error bars represent the standard deviations

The data presented in Fig. 7 revealed that the maximum DEP penetration through electret filters tested in this study occurred at dp = 180 nm, while for uncharged filters it was dp = 117 nm, 180 nm and 226 nm (filter 1, 2, and 3, respectively), and does not significantly differ from theoretical predictions. There is lack of data in the literature showing the most penetrating DEP aggregate’s size through fibrous filters. However, Bałazy et al. (2006) showed that the most penetrating NaCl particle size through uncharged particulate respirator filters is 300 nm, while for electrets it is 40–50 nm. Martin and Moyer (2000) indicated that the maximum penetration of DOP particles (dioctyl phthalate) through the charged filters occurs at 50–100 nm, but when the electrostatic charge was reduced, the maximum penetration DOP size shifted up to even 400 nm. The maximum fractal-like aggregates (DEPs) penetration through electret filters occurred at higher diameters compared with DOP or NaCl particles, however, slight differences between electrets and mechanical filters, also for DEP aggregates, can be noticed.

This study showed that the fibrous filters produced using melt-blown technology provide a high level of protection against DEP aerosols (93 %–99 %). The obtained filtration efficiencies are (in some cases) even higher than requested for particulate respiratory half-masks type 2 (made from a fibrous filter). In addition, the benefits from an electrostatic filter can be great (higher mass filtration efficiency than uncharged filters). However, mass filtration efficiency even higher than 93 % cannot ensure an adequate level of protection against DEPs, since small aggregates of DEPs (< 120 nm) are still present in the air after the filter.

Although the mass of penetrated nanoaggregates through the tested fibrous filters do not cause health problems, the health effects associated with nanoaggregates are still being investigated and for now, remain largely unknown and do not necessarily relate to the mass.

This scientific work was partly financed from the budget for sciences in the years 2010–2013 as Research Project No. NN209023739, and was also supported by Cummins Filtration Ltd. This work has been partially supported by the European Union in the framework of European Social Fund through the Warsaw University of Technology Development Programme.

radius of primary particle, (μm)

Asurface of filter sample, (mm2)

CCCunningham slip correction factor, (−)

Cd, Cd’parameters, (−)

dfaverage fiber diameter, (μm)

dpparticle diameter, (μm)

Dcoefficient of Brownian diffusion for particles, (m2 s−1)

DEPdiesel exhaust particles

Dffractal dimension, (−)

Esingle fiber efficiency, (−)

EDsingle fiber filtration efficiency due to diffusion mechanism, (−)

EEsingle fiber efficiency due to electrical interaction mechanism, (−)

EFmass filtration efficiency, (%)

ERsingle fiber efficiency due to direct interception mechanism, (−)

kcoefficient in Eqn. 14, (−)

Lfilter layer thickness, (mm)

mfilter mass, (kg)

Maf, Mfmass of DEPs deposited on the reference absolute filter and on the tested fibrous filter after 20 min, (kg)

Nnumber of identical particles, (−)

NRinterception parameter, (−)

Ppressure, (Pa)

qcharge density of electret fiber, (C m−1)

qeparticle effective density, (g cm−3)

qsfilter base weight, (g m−2)

ri, rGposition of the ith primary particle center and center of gravity of the cluster, (−)

Raggradius of aggregate, (μm)

Rdyndynamic radius, called mobility radius, (μm)

Rgradius of gyration, (μm)

Rmmass-equivalent radius, (μm)

Rmaxradius of circumscribed sphere, sometimes called outer maximum radius of aggregate, (μm)

Ugas face velocity, (m s−1),

αfilter average packing density, (−)

ηtotal collection efficiency of the filter layer composed of many fibers, (−)

λgas mean free path, (m)

μgas viscosity, (Pa s)

ρsolid concentration in the cluster, (−)

ρggas density, (kg m−3)

ρppdensity of the polypropylene, (kg m−3)

εaggregate porosity, (−)

εFfilter porosity, (−)

εpdielectric constant of particle, (−)

ε0permittivity of the vacuum, (F m−1)

Agata Penconek

PhD, assistant professor at the Faculty of Chemical and Process Engineering Warsaw University of Technology, Poland.

2008: MSc in biotechnology, 2009: BCH in biology; 2014 PhD in chemical engineering; Scientific interests: anthropogenic aerosols (e.g. diesel exhaust particles), their filtration, deposition in human respiratory system, and interaction with eukaryotic/prokaryotic cells, aerosol particle transfer through mucus layer, aerosol particle mechanics.

Author and co-author of 8 scientific papers and chapter in one book.

Anna Jackiewicz

PhD, assistant professor at the Faculty of Chemical and Process Engineering Warsaw University of Technology, Poland

2004 MSc in chemical Engineering; 2010 PhD in chemical Engineering; 2006 course at the Technische Universitat Berlin (Berlin), 2008 - Institute for Experimental Physics, University of Vienna (Austria).

Scientific interests: processes of separating solid and liquid particles from fluids, filtering media design, modeling of filtration in fibrous filters, techniques for aerosol generation and detection, materials science.

Author and co-author of over 47 papers published in periodicals and conference proceedings.

Recipient of awards and scholarships: Award of the Ignacy Łukasiewicz Grant Fund of PGNiG S.A., Fiat grant, two scholarships for distinguished Ph.D. in the field of science and research; an individual Award of the Rector of the Warsaw University of Technology for scientific achievements, the presentation of achievements at the exhibition entitled “Maria Skłodowska-Curie in the Service of Science Yesterday and Today” at the European Parliament in Brussels, winner of the prestigious program for young scientists “LEADER” from the National Centre for Research and Development, under which she received funding for the creation of her own research team.

Arkadiusz Moskal

PhD, DSc, professor at the Faculty of Chemical and Process Engineering Warsaw University of Technology, Poland.

1997: MSc in chemical engineering; 2002: PhD in chemical engineering; 2011: DSc in chemical engineering; 2002 – 2003 postdoc at The Institute of Chemical Engineering Sciences (ICE-HT), Patras, Greece.

Scientific interests: aerosol particle mechanics, aerosol filtration, and deposition of aerosol particles in human respiratory system, drug delivery, mathematical modeling, and aerosol aggregate dynamics, diesel exhaust particle filtration and interaction with human cells.

Author and co-author of over 150 scientific papers, 2 patents, 1 book.