- |<

- <

- 1

- >

- >|

-

2025Volume 42 Pages Cover42_1

Published: January 10, 2025

Released on J-STAGE: February 28, 2025

Download PDF (1583K) Full view HTML -

2025Volume 42 Pages EdBrd42_1

Published: January 10, 2025

Released on J-STAGE: February 28, 2025

Download PDF (1113K) Full view HTML

-

2025Volume 42 Pages i-v

Published: January 10, 2025

Released on J-STAGE: February 28, 2025

Download PDF (6905K) Full view HTML

-

2025Volume 42 Pages vi

Published: January 10, 2025

Released on J-STAGE: February 28, 2025

Download PDF (802K) Full view HTML -

2025Volume 42 Pages 1-2

Published: January 10, 2025

Released on J-STAGE: February 28, 2025

Download PDF (997K) Full view HTML

-

2025Volume 42 Pages 3-14

Published: January 10, 2025

Released on J-STAGE: February 28, 2025

Advance online publication: June 29, 2024Download PDF (5764K) Full view HTML -

2025Volume 42 Pages 15-36

Published: January 10, 2025

Released on J-STAGE: February 28, 2025

Advance online publication: March 23, 2024Download PDF (4450K) Full view HTML -

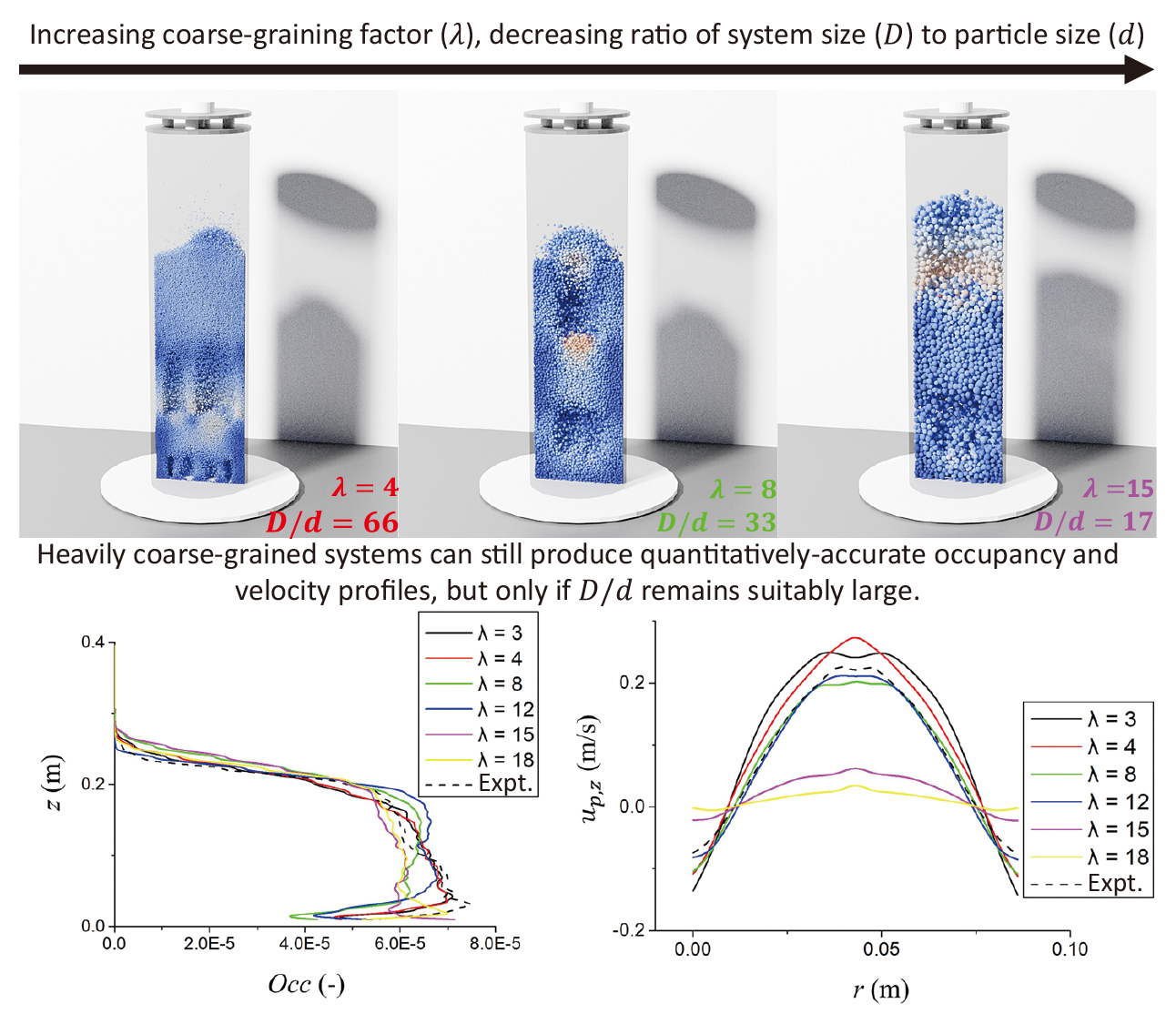

2025Volume 42 Pages 37-56

Published: January 10, 2025

Released on J-STAGE: February 28, 2025

Advance online publication: August 31, 2024Download PDF (18709K) Full view HTML -

2025Volume 42 Pages 57-78

Published: January 10, 2025

Released on J-STAGE: February 28, 2025

Advance online publication: August 10, 2024Download PDF (14617K) Full view HTML -

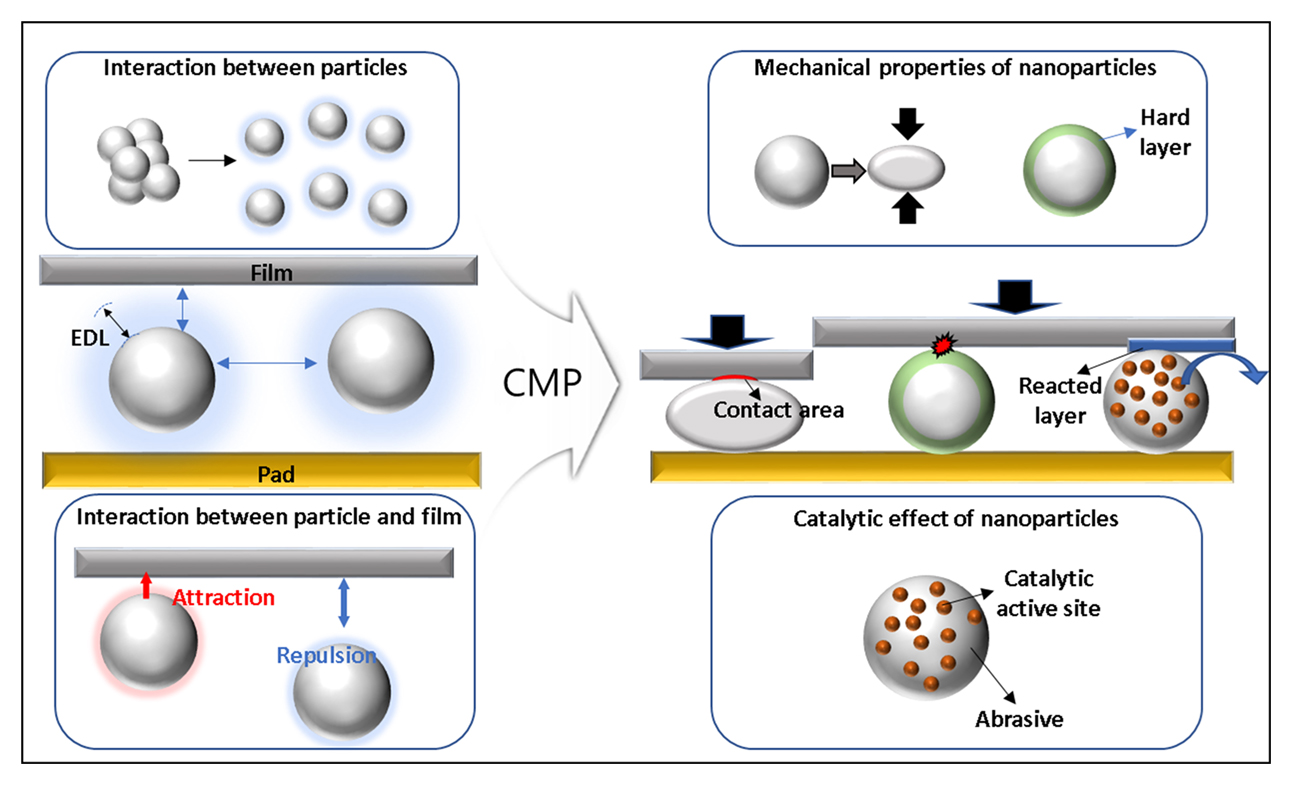

2025Volume 42 Pages 79-99

2025Volume 42 Pages 79-99

Published: January 10, 2025

Released on J-STAGE: February 28, 2025

Advance online publication: December 28, 2023Editor's pickSiO₂ nanoparticles are the most widely used abrasives in chemical mechanical planarization (CMP) slurries, where their structure and surface properties govern dispersion stability, abrasive-abrasive interactions, and abrasive-film interactions. Controlling these factors is essential for achieving desired material removal rates, defect suppression, and polishing uniformity in CMP. This review explores SiO₂ nanoparticle engineering, focusing on synthesis approaches and surface modifications such as functionalization, coating, and doping to regulate dispersion stability, interfacial interactions, and chemical reactivity. It provides insights into how these engineered nanoparticles influence the CMP performance and their role in semiconductor manufacturing.

Download PDF (6303K) Full view HTML -

2025Volume 42 Pages 100-120

Published: January 10, 2025

Released on J-STAGE: February 28, 2025

Advance online publication: March 17, 2024Download PDF (4746K) Full view HTML -

2025Volume 42 Pages 121-133

Published: January 10, 2025

Released on J-STAGE: February 28, 2025

Advance online publication: April 06, 2024Download PDF (1801K) Full view HTML -

2025Volume 42 Pages 134-155

Published: January 10, 2025

Released on J-STAGE: February 28, 2025

Advance online publication: June 29, 2024Download PDF (18843K) Full view HTML -

2025Volume 42 Pages 156-169

Published: January 10, 2025

Released on J-STAGE: February 28, 2025

Advance online publication: February 24, 2024Download PDF (16823K) Full view HTML -

2025Volume 42 Pages 170-187

Published: January 10, 2025

Released on J-STAGE: February 28, 2025

Advance online publication: February 24, 2024Download PDF (25310K) Full view HTML -

2025Volume 42 Pages 188-199

Published: January 10, 2025

Released on J-STAGE: February 28, 2025

Advance online publication: August 10, 2024Download PDF (8069K) Full view HTML -

2025Volume 42 Pages 200-212

Published: January 10, 2025

Released on J-STAGE: February 28, 2025

Advance online publication: August 24, 2024Download PDF (2194K) Full view HTML -

2025Volume 42 Pages 213-226

Published: January 10, 2025

Released on J-STAGE: February 28, 2025

Advance online publication: March 17, 2024Download PDF (1968K) Full view HTML

-

2025Volume 42 Pages 227-240

Published: January 10, 2025

Released on J-STAGE: February 28, 2025

Advance online publication: January 13, 2024Download PDF (2132K) Full view HTML -

2025Volume 42 Pages 241-250

Published: January 10, 2025

Released on J-STAGE: February 28, 2025

Advance online publication: April 13, 2024Download PDF (2306K) Full view HTML -

2025Volume 42 Pages 251-260

Published: January 10, 2025

Released on J-STAGE: February 28, 2025

Advance online publication: June 29, 2024Download PDF (3228K) Full view HTML -

2025Volume 42 Pages 261-267

Published: January 10, 2025

Released on J-STAGE: February 28, 2025

Advance online publication: August 10, 2024Download PDF (1744K) Full view HTML -

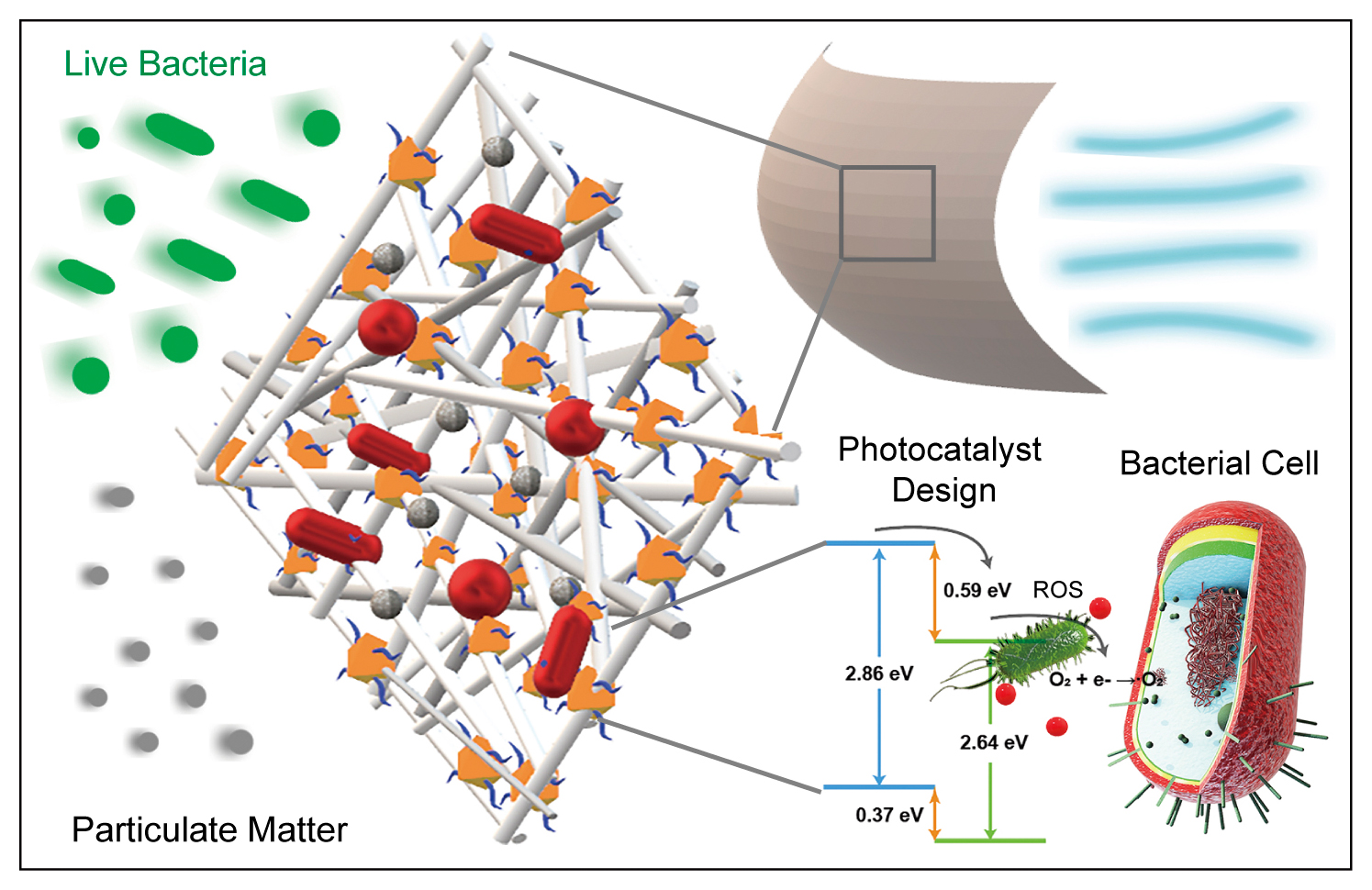

2025Volume 42 Pages 268-284

Published: January 10, 2025

Released on J-STAGE: February 28, 2025

Advance online publication: October 19, 2024Download PDF (15086K) Full view HTML

-

2025Volume 42 Pages 285-287

Published: January 10, 2025

Released on J-STAGE: February 28, 2025

Download PDF (6975K) Full view HTML -

2025Volume 42 Pages 288

Published: January 10, 2025

Released on J-STAGE: February 28, 2025

Download PDF (1170K) Full view HTML -

2025Volume 42 Pages 289

Published: January 10, 2025

Released on J-STAGE: February 28, 2025

Download PDF (679K) Full view HTML

- |<

- <

- 1

- >

- >|