-

Volume 41 (2024) Pages 26-41Role of Powder Properties and Flowability in Polymer Selective Laser Sintering—A Review Read moreEditor's pick

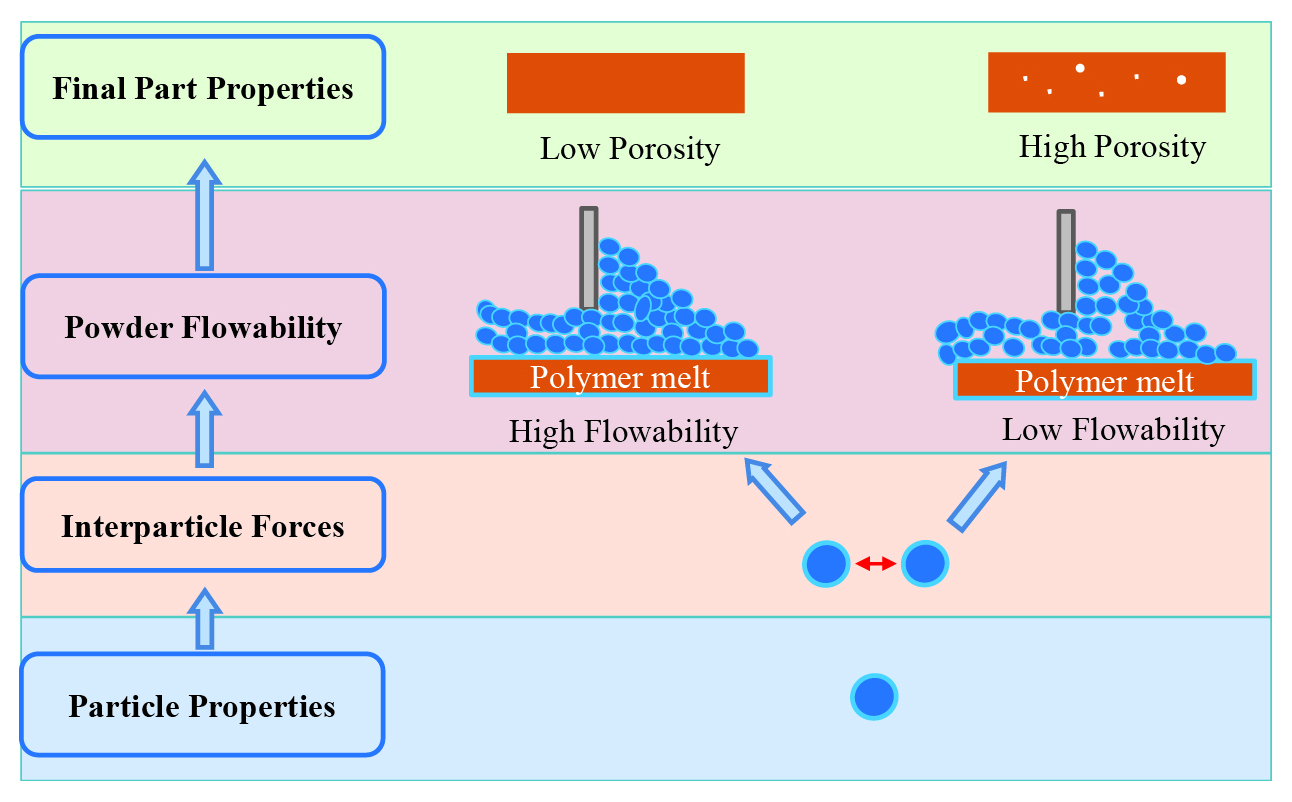

This review highlights the crucial role of powder flowability in polymer selective laser sintering (SLS), a leading additive manufacturing technology for producing highly complex and customized components. It explores key flowability characterization methods suitable for SLS and examines how powder properties influence laser–material interactions and final part quality. Additionally, the paper discusses various strategies from the literature to enhance powder spreading, addressing a critical challenge in expanding the range of polymer materials suitable for SLS. This review serves as a valuable resource for advancing material development and optimizing the SLS printing performance.

-

Volume 41 (2024) Pages 183-196Characteristics of Ultrafine Bubbles (Bulk Nanobubbles) and Their Application to Particle-Related Technology Read moreEditor's pick

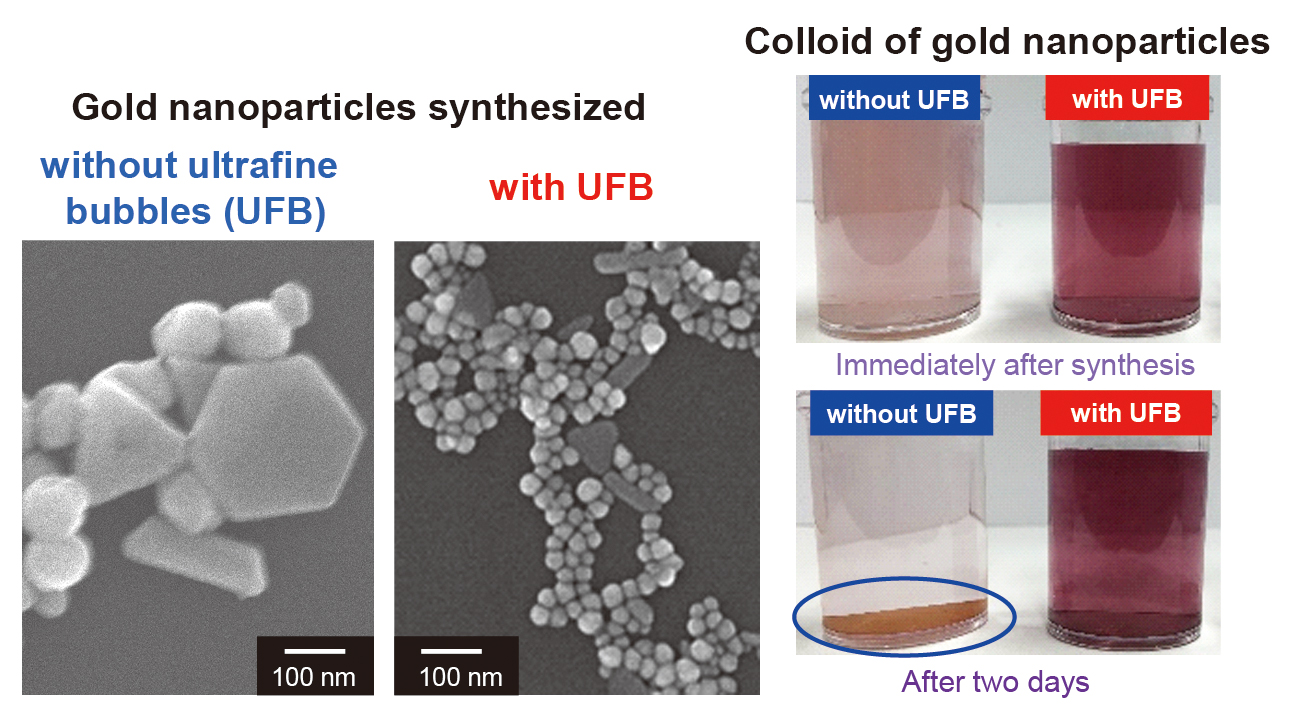

In recent years, ultrafine bubbles have been actively used in the cleaning field. Ultrafine bubbles have numerous advantages, including their chemical-free nature, hydrophobic, pH-dependent surface charge, and extraordinarily long lifetime. By selecting the ultrasonic frequency to be irradiated, the generation and removal of ultrafine bubbles can be controlled. They can produce hollow nanoparticles and enhance ionic adsorption on activated carbon. This review discusses the fundamental and sonochemical characteristics of ultrafine bubbles and their applications in particle-related technologies, encompassing fine particle synthesis, adsorption, desorption, extraction, cleaning, and fouling prevention.

-

Volume 41 (2024) Pages 108-122A Review of Analytical Methods for Calculating Static Pressures in Bulk Solids Storage Structures Read moreEditor's pick

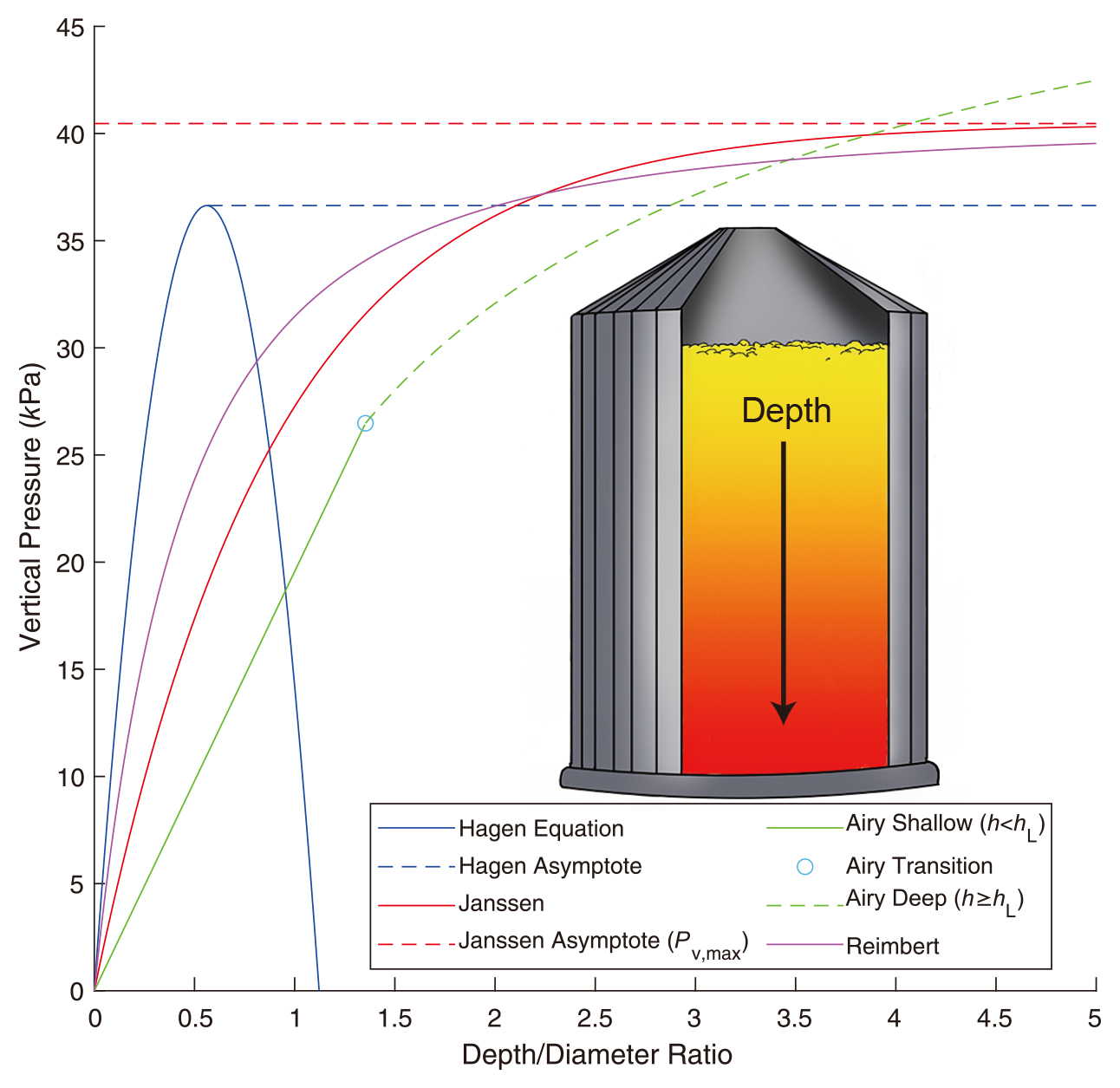

This comprehensive review examines the evolution and applications of the Janssen equation, which is the dominant expression for calculating pressures in bulk storage structures. This paper discusses the history of the model, analyzes the limitations of Janssen’s original formulation and explores various modifications and alternative models developed to better represent shear stress distributions. By examining key parameters like stress ratios (k), friction coefficients (μ, ϕ), and bulk density (ρ), along with modern approaches such as continuum elastic and microscopic theories, this work provides valuable insights for engineers and researchers working with bulk solids storage systems and granular materials.

-

Editor's pick

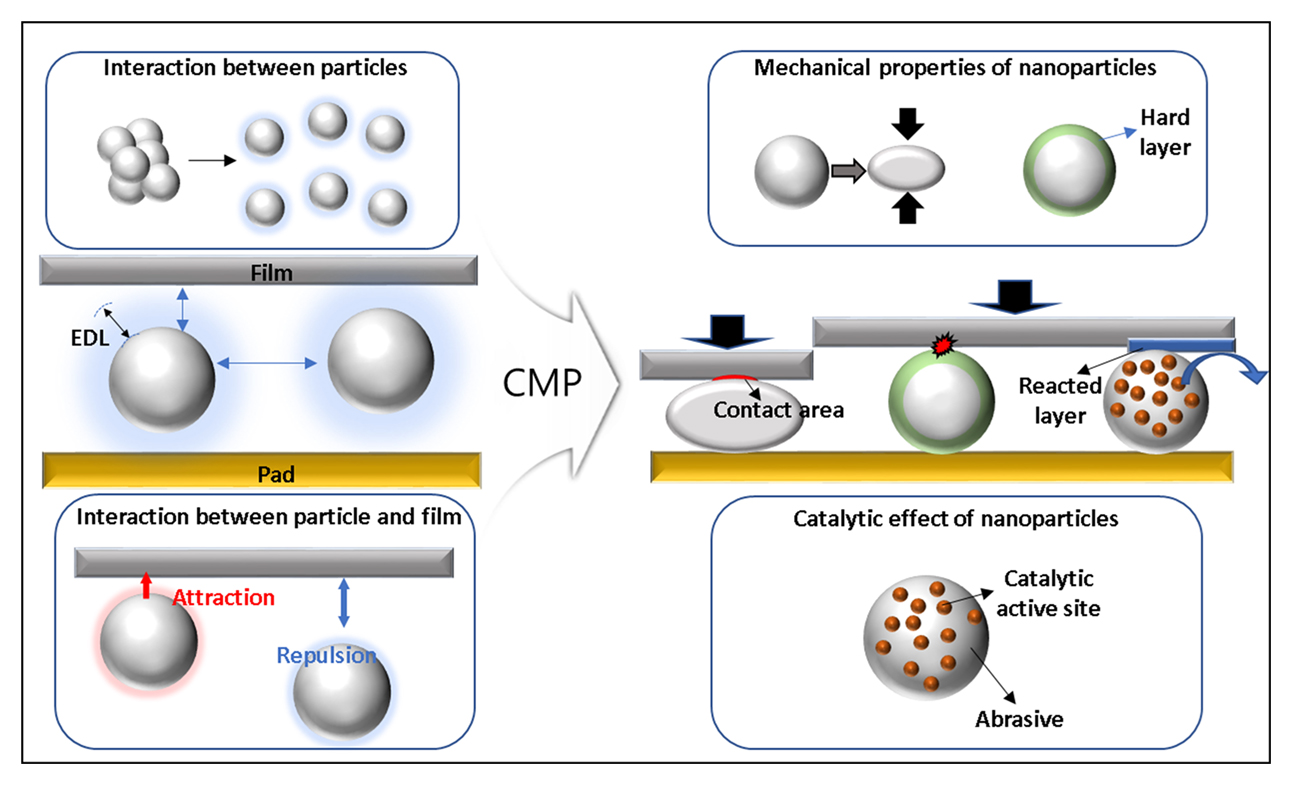

SiO₂ nanoparticles are the most widely used abrasives in chemical mechanical planarization (CMP) slurries, where their structure and surface properties govern dispersion stability, abrasive-abrasive interactions, and abrasive-film interactions. Controlling these factors is essential for achieving desired material removal rates, defect suppression, and polishing uniformity in CMP. This review explores SiO₂ nanoparticle engineering, focusing on synthesis approaches and surface modifications such as functionalization, coating, and doping to regulate dispersion stability, interfacial interactions, and chemical reactivity. It provides insights into how these engineered nanoparticles influence the CMP performance and their role in semiconductor manufacturing.

-

Editor's pick

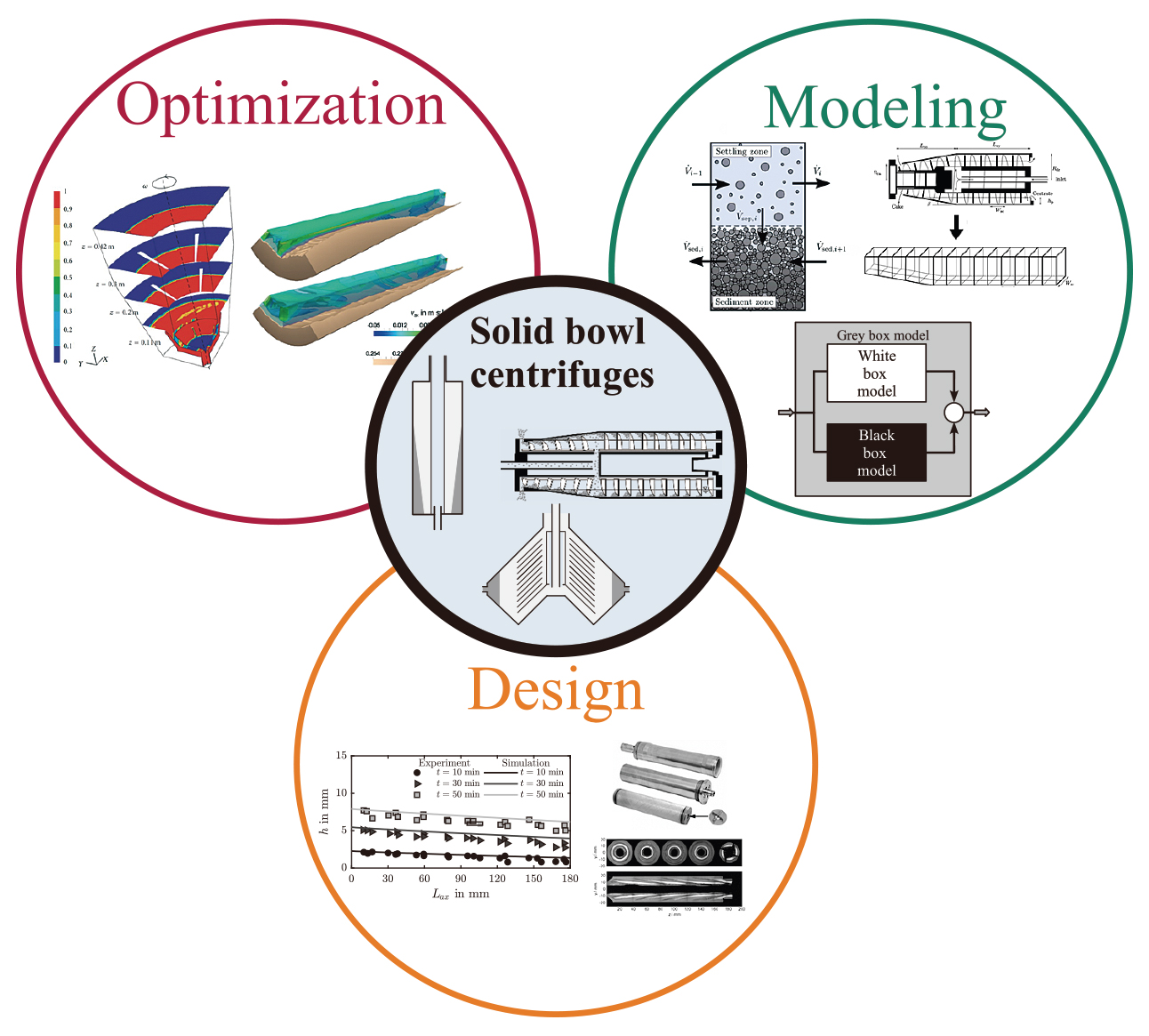

This review provides an overview of the many applications of solid bowl centrifuges, the different types of machines, and the modeling strategies. Common to all centrifuges is that the material behavior has a significant influence on the process behavior; therefore, the interaction between material and process is of critical importance. Different modeling strategies can be used to better understand and optimize separation processes. Furthermore, the integration of process analytics into the operation of solid bowl centrifuges allows on-line optimization of the process behavior.

-

Volume 40 (2023) Pages 50-73Comminution and Classification as Important Process Steps for the Circular Production of Lithium Batteries Read moreEditor's pick

This review describes the importance of comminution and classification processes to produce battery materials and battery electrodes, and to recycle production scrap and end-of-life battery cells. It shows how comminution and classification processes are integrated into the production of various active materials, such as spheronisation of natural graphite, grinding of nano-sized silicon and dispersion of calcined lithium metal oxides, and into the processing of electrode slurries using planetary mixers, extruders or stirred media mills. The use of mills and classifiers in the recycling of battery materials and the mechanochemical synthesis of solid sulphide electrolytes is another important topic.

-

Volume 40 (2023) Pages 94-108Morphology Control of Transition Metal Oxides by Liquid-Phase Process and Their Material Development Read moreEditor's pick

Solution processing is one of the important methods in the synthesis of functional materials. This method can create various compositions and control their crystal structure, particle morphology, and size. It is expected to lead to the development of new functionality of materials. This paper introduces the relationship between powder particle morphology and material functionality, explains the various environmental response functionalities of transition metal oxides synthesized by the environmentally friendly liquid-based method, and indicates that the morphology control associates material science with art. It arouses the reader's interest and implies further potential in developing future functional materials.

-

Volume 40 (2023) Pages 172-185Performance Testing for Dry Powder Inhaler Products: Towards Clinical Relevance Read moreEditor's pick

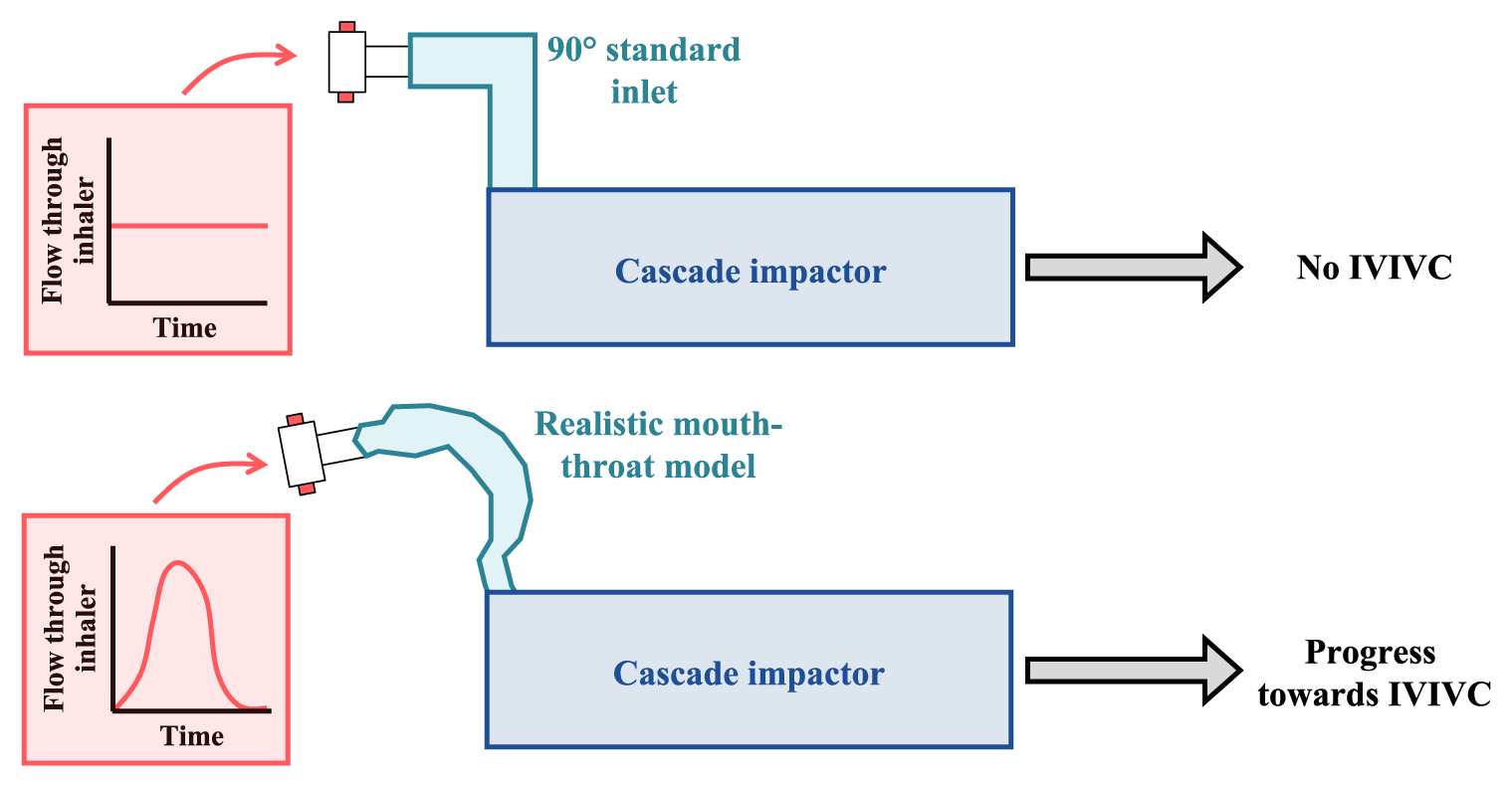

Dry powder inhaler formulations have garnered interest as a way to deliver drugs directly to the lungs in a stable, solid dosage form. Developing generics of brand-name dry powder inhalers is essential to their widespread availability but requires careful consideration in characterizing bioequivalence. This review highlights the standard characterization methods frequently employed as well as physiologically relevant measures that may aid in bioequivalence decisions. The necessity of considering in vivo relevance while performing in vitro testing is highlighted, assisting the field in shifting to physiologically relevant characterization methods.

-

Volume 40 (2023) Pages 74-93Recent Research Trend in Powder Process Technology for High-Performance Rare-Earth Permanent Magnets Read moreEditor's pick

Delve into the forefront of rare earth permanent magnet research with this insightful paper. With electric vehicles driving demand for higher-performance magnets, the quest for advanced structural control in powder metallurgy processes is paramount. Discover how innovative approaches in chemical synthesis have led to the development of submicron-sized Sm-Fe-N powders with remarkable coercivity. Explore the evolution of grain boundary control techniques and the emergence of low-thermal load consolidation methods like spark plasma sintering, crucial for enhancing remanence in next-generation magnets.

-

Editor's pick

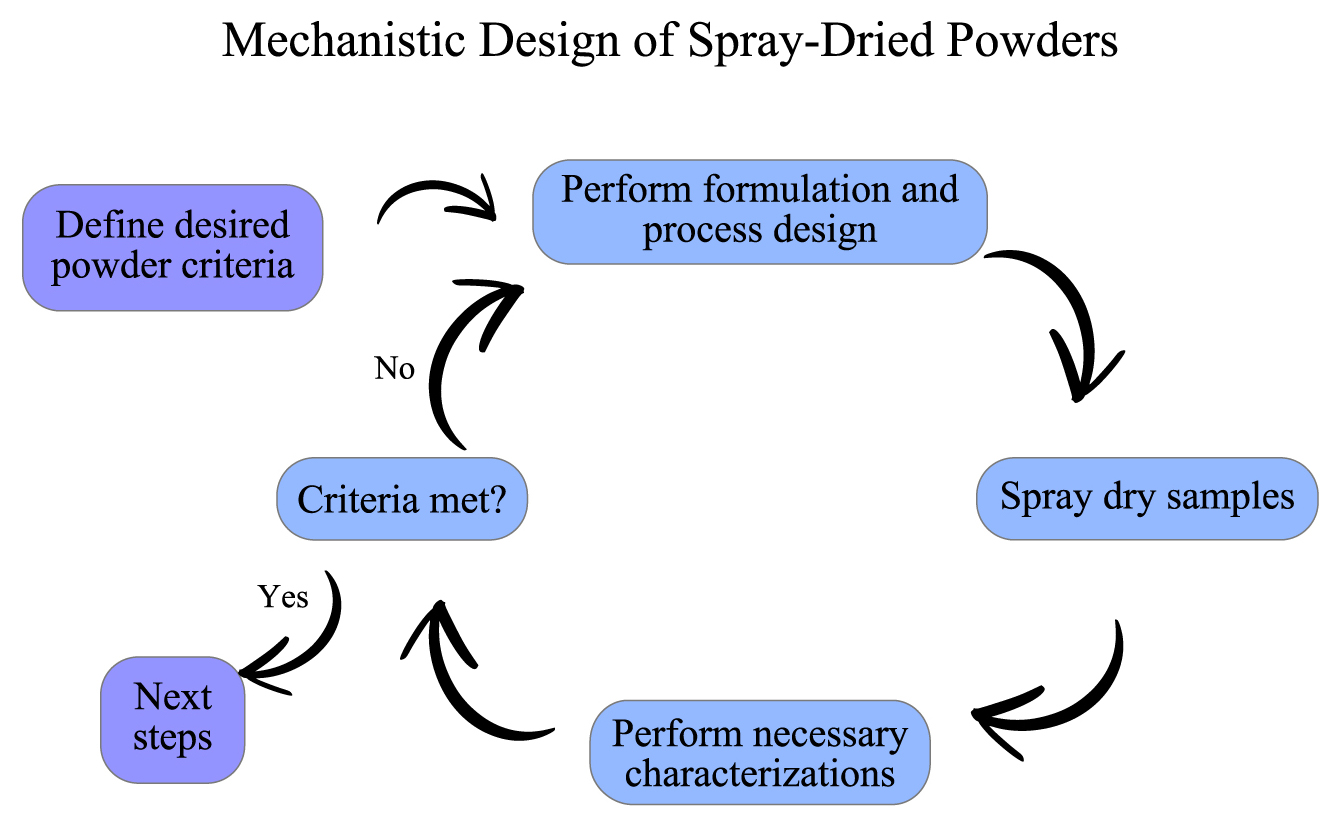

Spray drying emerges as a pivotal method in pharmaceutical manufacturing, offering versatility across various delivery routes. Its capacity to engineer particles enhances drug efficacy and stability, vital for global distribution, notably for vaccines. Despite complexities in formulation design, this review elucidates practical steps and essential background knowledge crucial for successful spray-dried microparticle formulation. It navigates through estimating solute concentration during drying, solidification kinetics, and the role of stabilizers, providing invaluable insights for practitioners striving to optimize particle properties for therapeutic delivery.

-

Volume 39 (2022) Pages 130-149High Performance Nickel Based Electrodes in State-of-the-Art Lithium-Ion Batteries: Morphological Perspectives Read moreEditor's pick

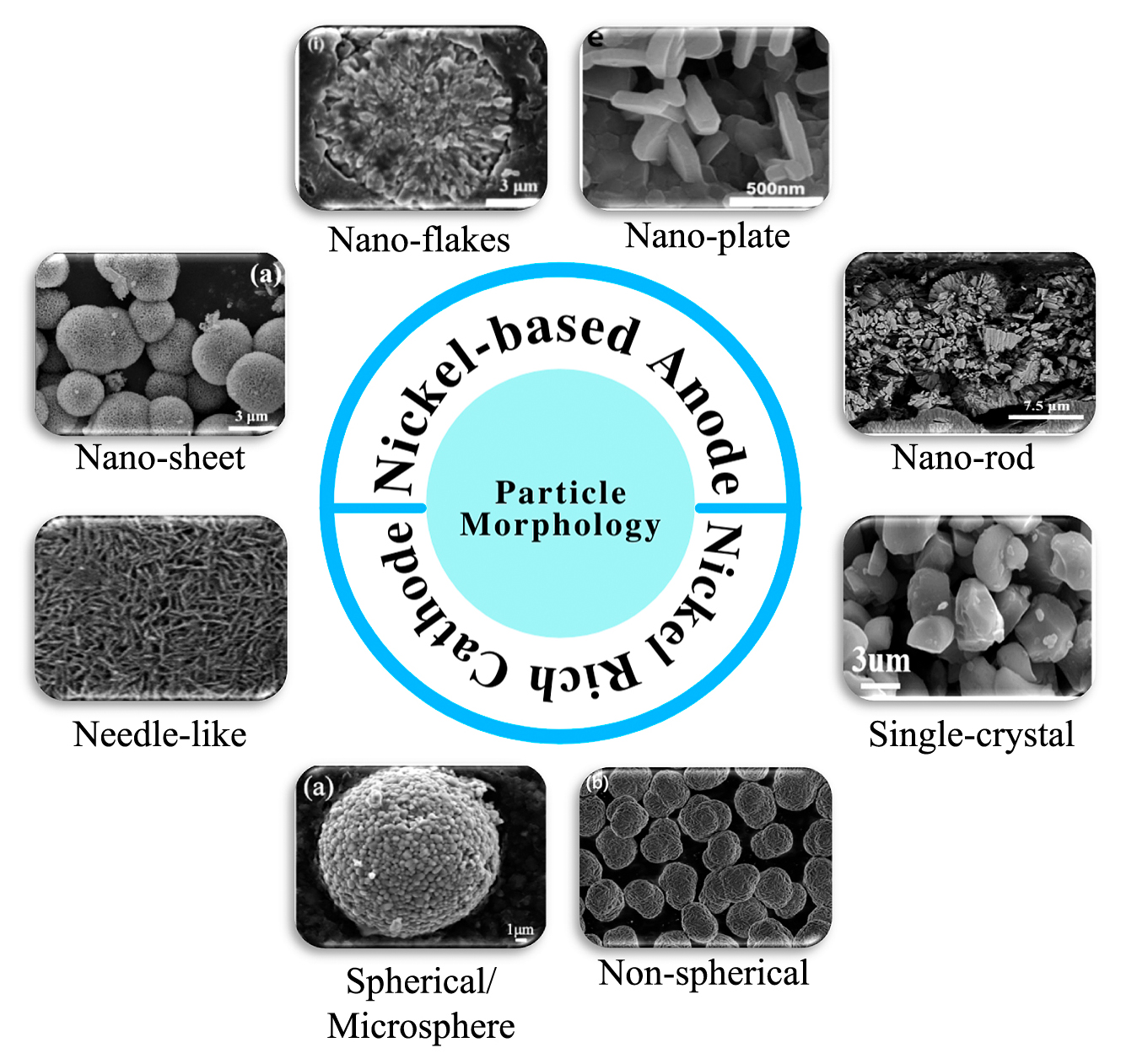

Nickel is set to play a pivotal role in the next chapter of energy storage. Over the next decade, nickel-based Li-ion batteries are expected to dominate the battery market for both energy storage systems (ESS) and electric vehicles. One of the key features of nickel-based active materials is their morphology; the shape and size of the particles can affect the electrochemical performance of the active materials. Both nickel-containing anode and cathode materials with excellent morphology have been reported to have high capacity, excellent cycle stability, and rate-ability. These key performance metrics demonstrate the promising future for the development of a clean and sustainable energy industry.

-

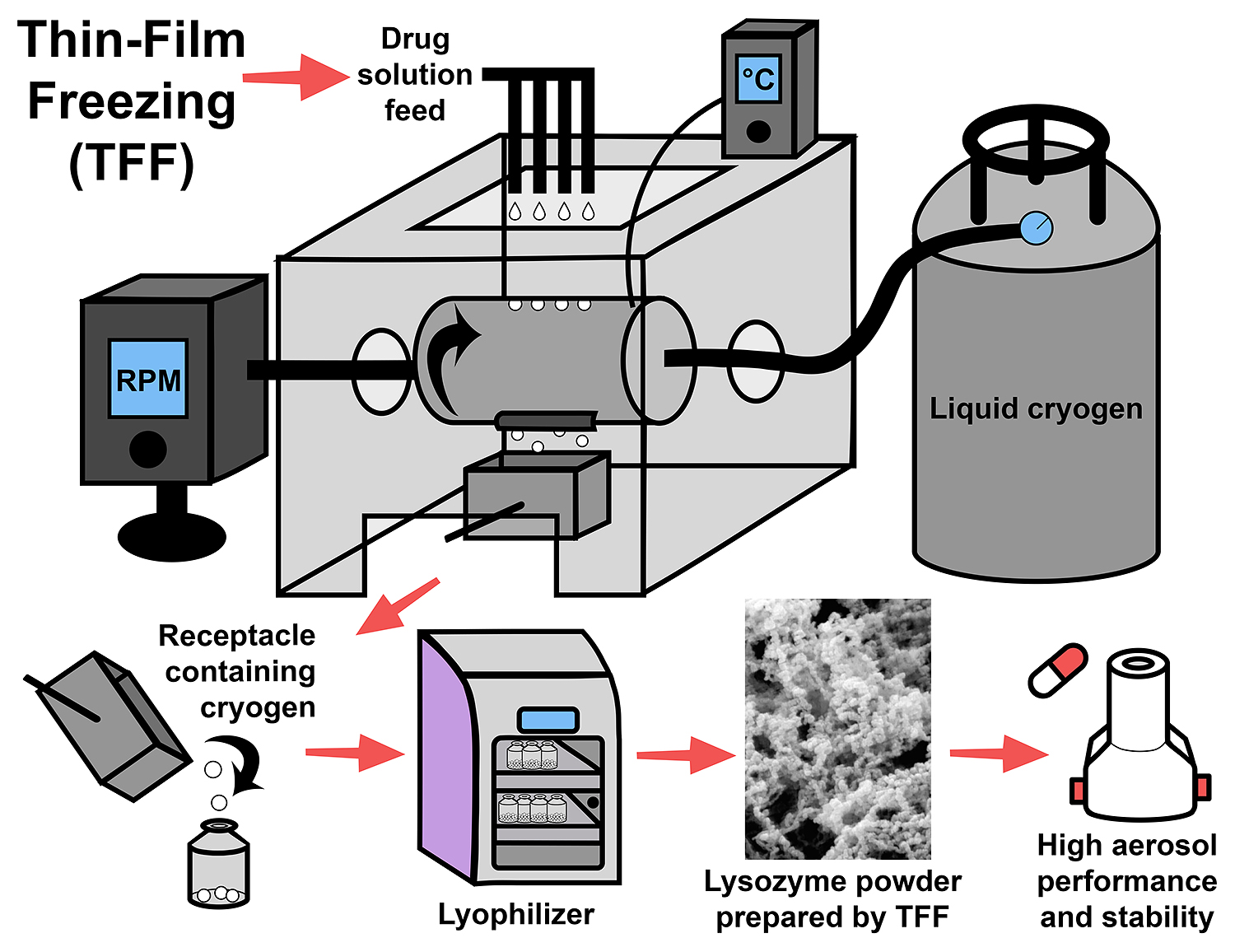

Volume 39 (2022) Pages 176-192The Development of Thin-Film Freezing and Its Application to Improve Delivery of Biologics as Dry Powder Aerosols Read moreEditor's pick

Pharmaceutical dry powders with desired aerosol properties are required for efficient pulmonary drug delivery. Thin-film freezing (TFF) followed by lyophilization is a particle engineering technology that produces highly porous, brittle, powder matrices with excellent aerosol properties and high drug loading. In this review article, the authors describe the TFF technology and discuss the physical and aerosol properties of TFF powders as well as factors affecting those properties. Finally, the authors provide a comprehensive review of published literature for applying the TFF technology to prepare aerosolizable dry powders of protein-based pharmaceuticals for pulmonary delivery.

-

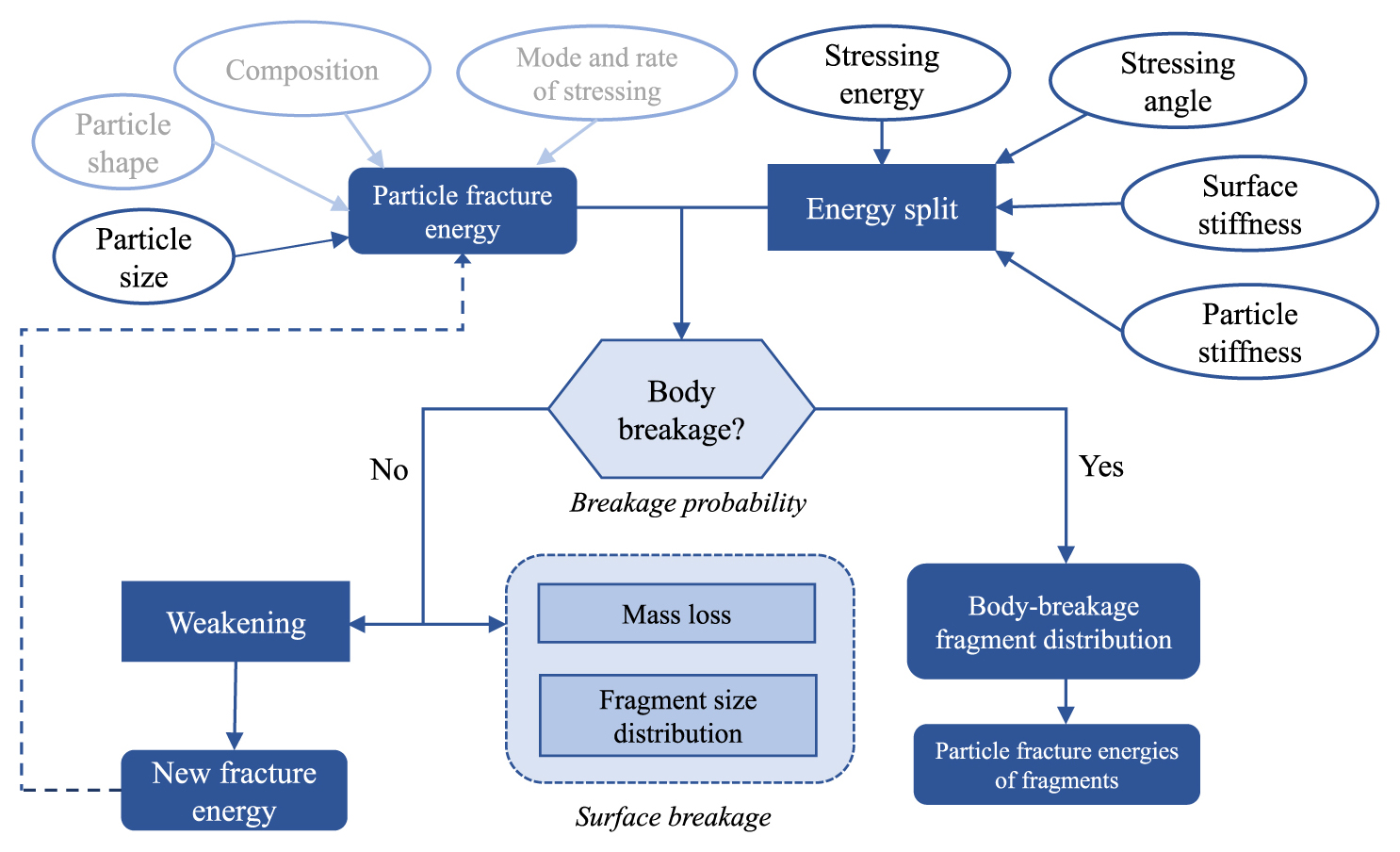

Volume 39 (2022) Pages 62-83Review and Further Validation of a Practical Single-Particle Breakage Model Read moreEditor's pick

Single-particle breakage studies were, in the not-so-distant past, only of academic interest, since no tools were available to transfer the microscale information they provide to deal with problems in industry. Fortunately, the discrete element method (DEM), along with properly-formulated population balance models, not make it possible to carry information from single particles to predict the performance of crushers, mills and handling systems that may cause their mechanical degradation. The work critically analyzes one model that has been found quite powerful in this task.

-

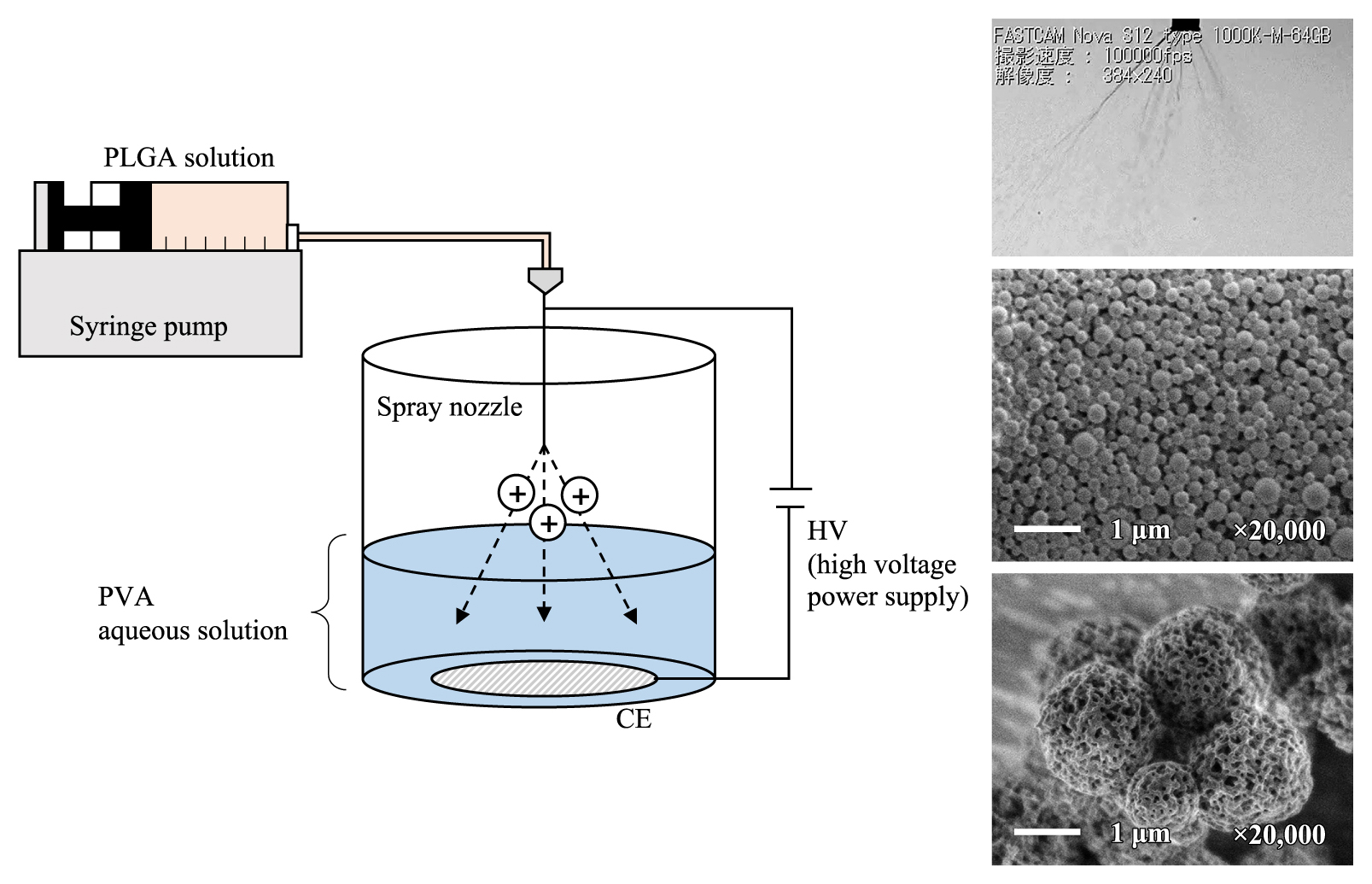

Volume 39 (2022) Pages 251-261Biodegradable PLGA Microsphere Formation Mechanisms in Electrosprayed Liquid Droplets Read moreEditor's pick

Delivery systems using nanoparticles and microparticles composed of biodegradable polymers such as polylactic glycolic acid have attracted much attention in the pharmaceutical and cosmetic fields to the delivery of active ingredients into the body. This paper describes a novel microparticle preparation method using fine-charged droplets as reaction fields generated by electrospray. This method is unique and impactful because tailored PLGA microspheres with various sizes and different structures such as porous and solid structures can be prepared by controlling the process conditions. The formation mechanism of particles with different sizes and structures within the droplets is also explained.

-

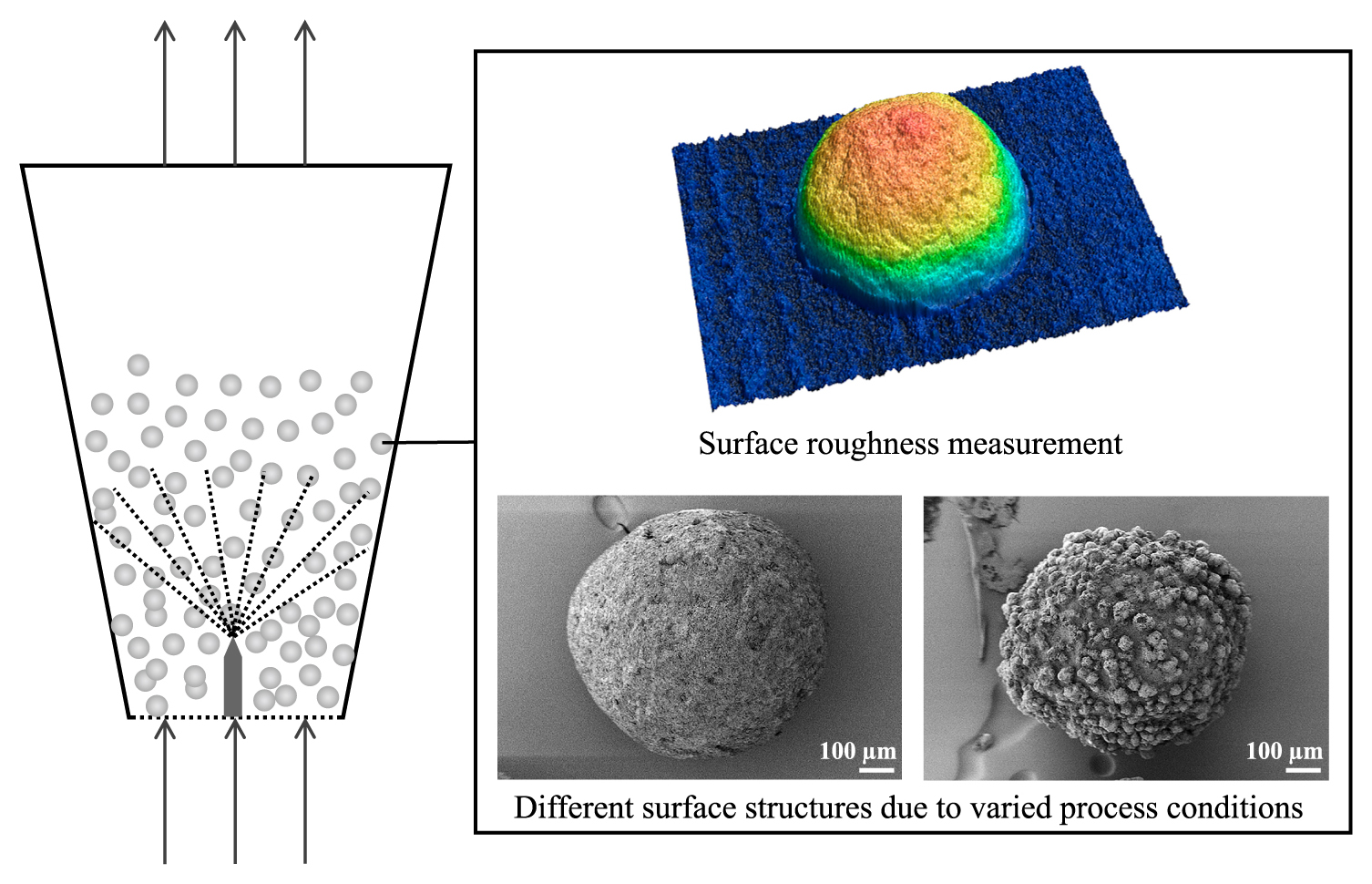

Volume 39 (2022) Pages 230-239Correlating Granule Surface Structure Morphology and Process Conditions in Fluidized Bed Layering Spray Granulation Read moreEditor's pick

Due to their easy handling, transport, and storage compared to liquids and gases, solid products in particulate form are of great interest in both, daily life and industrial applications. Along with the high demand for those products comes the need for a thorough understanding of particle production and modification processes, like fluidized bed spray granulation, to achieve the desired product properties. To contribute to that process understanding and to, in the long term, enable the production of tailor-made particles, this study aims to correlate process parameters and particle surface structure in fluidized bed spray granulation.

-

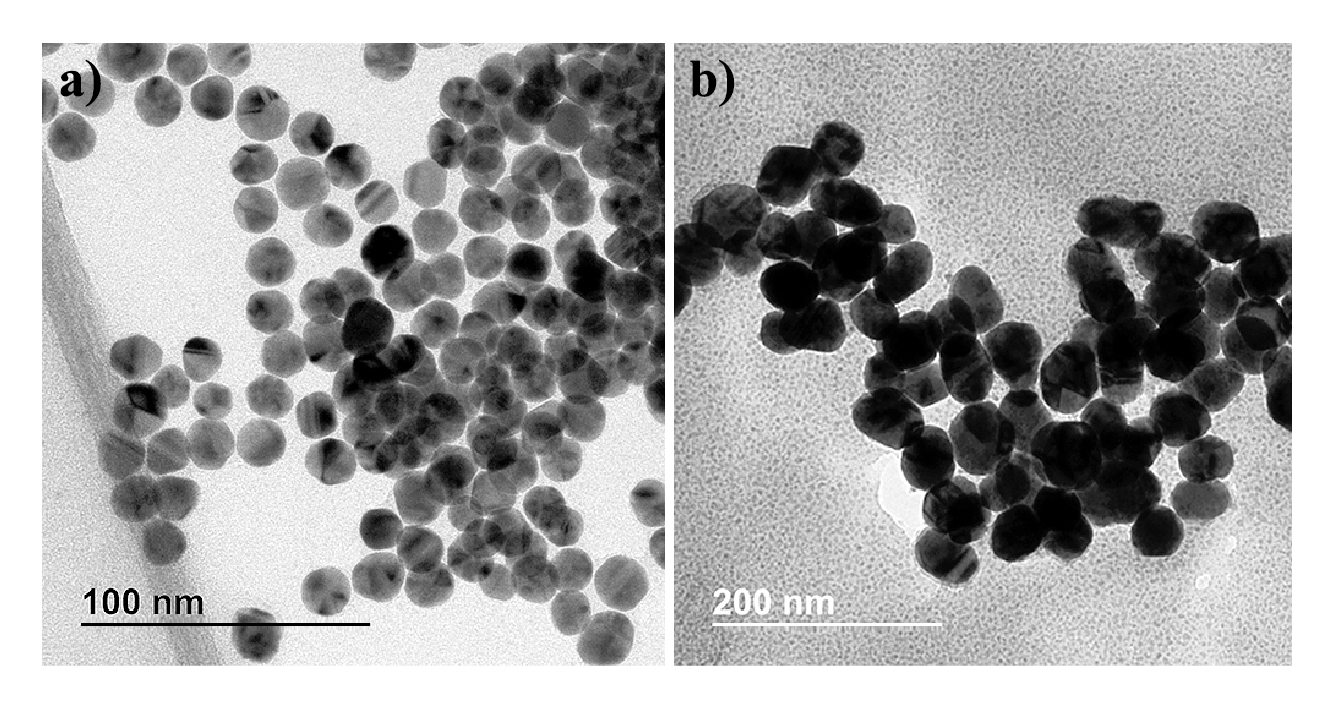

Volume 37 (2020) Pages 224-232Synthesis of Precision Gold Nanoparticles Using Turkevich Method Read moreEditor's pick

High-precision AuNPs can provide more focused optical absorption, better-targeted drug delivery, higher yield and efficiency in chemical reactions, and more reliable performance. However, the precision control of the nanoparticles has presented a major challenge. This work investigated and discussed the major process parameters of AuNPs synthesis using the Turkevich method. The authors provided detailed characterization and explanations to the correlations between the processing parameters and the nanoparticle properties. The additional knowledge would facilitate larger-scale synthesis of precision gold nanoparticles, encourage broader applications and provide insight into the synthesis and study of other engineered nanomaterials.

-

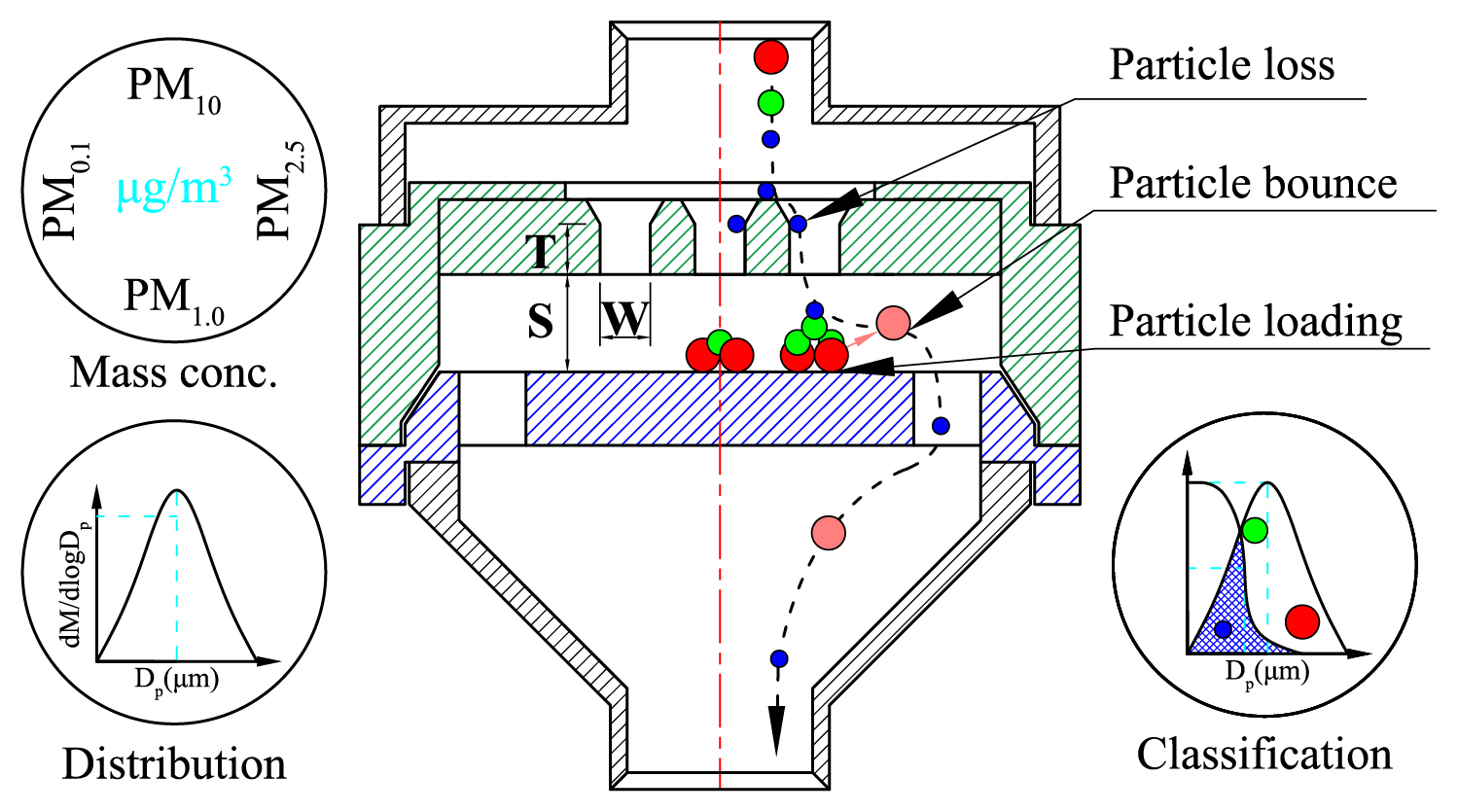

Volume 38 (2021) Pages 42-63Inertial Impaction Technique for the Classification of Particulate Matters and Nanoparticles: A Review Read moreEditor's pick

The inertial impaction technique is applied extensively for particulate matter classification and understanding the characteristics of inertial impactors is important for designing a good classifier. This article reviewed and synthesized the knowledge of the design and improvement of inertial impactors for long-term use without frequent maintenance needs. The applications of the inertial impactors for personal exposure measurement, particulate matter control and potential power classification at very high concentrations with the cutoff diameter down to submicron even nanometer sizes were addressed.

-

Volume 38 (2021) Pages 189-208Scaling-up the Calcium-Looping Process for CO2 Capture and Energy Storage Read moreEditor's pick

Increasing renewable energy storage and boosting CO2 capture systems are considered two key routes within the near-future energy scenario. The calcium looping (CaL) process, based on limestone as (cheap) raw material, is a flexible technology that can operate under both routes simply by modifying its operation conditions, namely, reactor gas composition, temperature, pressure, and particle size. As a post-combustion CO2 capture system, the CaL process (TRL7) could capture CO2 on a large scale with an energy consumption lower than 3MJ/kg CO2. As a thermochemical energy storage system (TRL 5), thermal-to-electric efficiencies above 45% could be reached in fully dispatchable renewable plants.

-

Editor's pick

The current trend in nano- and microparticle technology towards ever increasing complexity requires methods for the multidimensional characterization of the underlying particle property space in terms size, shape, structure, surface and composition. In this review the mathematical description and handling of multidimensional property distributions is outlined. In particular, the authors present and discuss state-of-the-art measurement techniques which are able to extract multidimensional information.

-

Volume 37 (2020) Pages 132-144Recent Progress on Mesh-free Particle Methods for Simulations of Multi-phase Flows: A Review Read moreEditor's pick

The role of modeling and simulation becomes more important in the era of digital transformation. As designated in Industry 4.0 and Society 5.0, a smart factory will appear, where cyber and physical spaces will be highly integrated. A physics simulation-based digital twin is one of the promising technologies. This paper presents the latest numerical models for powder systems, which will contribute to the realization of the digital twin in the future.