-

Volume 69 (2026) Pages 74-83Development of Functional Cosmetic Materials Based on PLGA Nanoparticle Technology Read moreEditor's pick

The effectiveness of skincare and haircare products is directly influenced by how well ingredients reach and remain at the target site. This study reports on the development and verification of a novel functional raw material utilizing proprietary PLGA nanoparticle technology. Designed for efficient delivery and sustained release, the technology maximizes the efficacy of functional ingredients. The findings provide compelling insight into how this approach can address the growing demands of today’s beauty consumers.

-

Editor's pick

This paper presents advanced dry processing technologies for particle structure control, offering significant advantages in energy efficiency and environmental sustainability. Integration of high-performance classifiers with grinding equipment enables continuous production of sub-micron particles, while dry composite processing demonstrates effectiveness in battery material modification and pharmaceutical dissolution control. The binder-free nature eliminates drying processes and wastewater treatment, making it economically viable for industrial-scale production. With growing demands for automotive battery materials and increasing numbers of poorly soluble drugs, these dry processing technologies are expected to find expanded applications in advanced material fields, contributing to sustainable manufacturing practices.

-

Volume 69 (2026) Pages 68-73Powder-Based Approaches to Sustainable Development: Plant Material (Lignin) Valorization Strategies Read moreEditor's pick

This article examines lignin, a by-product generated in pulp and bioethanol production, and presents a systematic overview of powder processing technologies that enable its high-value utilization. Particular emphasis is placed on fine grinding and dry granulation, including their fundamental principles, equipment selection, and energy characteristics. The discussion addresses key challenges associated with lignin powders, such as particle size control, handling safety, and explosion risk, from an engineering perspective. By illustrating how appropriate powder processes improve process stability and material functionality, the article clarifies the critical role of powder technology in reducing environmental impact and supporting the development of carbon-neutral materials.

-

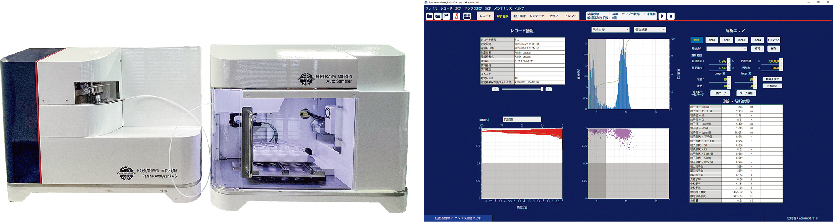

Volume 69 (2026) Pages 63-67E-SPART Analyzer® for Simultaneous Particle Size and Charge Measurement Read moreEditor's pick

Particle charging characteristics significantly impact product quality, but conventional Faraday cage methods only measure average charge of bulk samples, failing to capture individual particle charge distribution or correlation with particle size. This paper introduces the E-SPART Analyzer®, the world's only device capable of simultaneously measuring particle size and charge at the individual particle level. With over 30 years of proven performance, a next-generation model featuring miniaturization and digitalization is currently under development, promising advanced powder evaluation technology for precise particle characterization.

-

Editor's pick

This article explains the principles of drying and classifies dryers into direct/indirect heating types and continuous/batch systems with clear explanations. It also discusses equipment suitability based on material properties. Four representative Hosokawa Micron dryers with different drying methods are summarized: "Drymeister," "Nauta Mixer," "TorusDisc," and "Solidaire," detailing their features and suitable material properties for each system.

-

Editor's pick

This study investigates the novel application of PLGA nanoparticles for periodontal disease prevention. IPMP-loaded PLGA nanoparticles exhibited significant biofilm inhibition and deep-layer penetration of active ingredients. Clinical trials demonstrated reductions in bacterial counts, subgingival bleeding, and halitosis, making them a promising candidate for advanced oral health solutions. The safety and low irritancy of IPMP further support its integration into daily dental care products. These findings provide a basis for developing novel periodontal care standards, with further studies needed to elucidate mechanisms and enable product commercialization.

-

Editor's pick

As powder technology becomes more sophisticated, more precise particle characterization is required. This paper introduces Hosokawa Micron's Parshe Analyzer®, a dynamic image analyzer, and E-SPART Analyzer®, a particle size and charge measurement system. These instruments enable detailed analysis of particle shape and charge characteristics, and are expected to be a new evaluation tool to support the development of advanced powder technology.

-

Volume 68 (2025) Pages 51-56Verification for Constructing Digital Twin of Powder Tester: Part 2 Read moreEditor's pick

In recent years, the development of machines for powder operations such as grinding, classification, mixing, drying, granulation, and measurement has reached a mature stage, making it increasingly difficult to create new products. Amid this challenge, new product development efforts are being advanced by combining traditional development methods with IoT and AI technologies, particularly through the use of digital twin technology. This report introduces the "Powder Tester™" as an example of such efforts.

-

Editor's pick

The "Solidaire" dryer, indirect heating dryer, a flagship product of our company, has been instrumental in drying a wide range of raw materials for many years. However, rather than resting on these achievements, our research and development team has been diligently working toward the development of next-generation indirect dryers. Through rigorous hypothesis modeling and practical testing, their dedication and passion for innovation are evident.

-

Editor's pick

This article explains the basic mixing mechanisms and design principles of the Nauta Mixer®, a representative batch-type mixer, providing an opportunity to better understand its principles and performance. Additionally, a low-floor model of the Nauta Mixer® is introduced, which addresses the challenges of installation in buildings with height limitations that previously made installation difficult

-

Volume 67 (2024) Pages 61-69Development and Practical Use of Integrating Regenerative Medicine and Nanotechnology Read moreEditor's pick

Recently, the fusion of regenerative medicine and nanotechnology has been garneringgarnered attention in the field of cosmetics. The combination of Human Stem Cell Culture Supernatant and PLGA nanotechnology, pursued by the authors, offers an innovative approach to skin regeneration and rejuvenation, and is also being applied in the development of cosmetics. This paper focuses on the cosmetic effects of this combined technology and its potential for future medical applications.

-

Volume 67 (2024) Pages 99-105New Evidence of Hair Growth with PLGA Nano-Sphere Technology Read moreEditor's pick

At the Hosokawa Micron Pharmaceutical and Beauty Science Research Center, extensive efforts have been dedicated to developing a hair growth agent that utilizes PLGA nanospheres for targeted delivery deep into the pores (intracellular). This paper validates, through assessments involving hair papilla cells, the enhancement of cellular functionality by the intracellular introduction of PLGA nanospheres, demonstrating the promotion of hair cycle gene expression and suppression of hair loss gene expression. These findings represent intriguing outcomes in the pursuit of enhancing the efficacy of hair growth ingredients.

-

Volume 67 (2024) Pages 70-76On Development of New High-Speed Airflow Direct Heating Dryer Read moreEditor's pick

DRYMEISTER® (DMR), a direct heating type dryer using high-speed airflow, is a multifunctional powder processing equipment that can simultaneously dry, grind, and classify wet powder materials. Various improvements have been made since it was developed in 2000, but this time, while the basic concept remains the same, the main body of the machine has been significantly shortened and made more compact, reducing the amount of material that adheres inside the machine. Experimental results have shown that the dryer has a higher grinding performance than conventional machines, and is expected to be used as a new useful dryer.

-

Editor's pick

Evaluation of powder particle shape and detection of small amounts of coarse particles are important for various powder materials, such as electrophotographic developer materials, and we use dynamic image analysis methods that can measure and evaluate them in a short time. Actual measurement results have shown that the Parshe Analyzer is a measurement device with excellent detection sensitivity and operability because of its automatic focus adjustment and automatic lens magnification switching. In addition, more stable measurement results have been obtained using an automatic pretreatment device, Auto Sampler (PAS-AS) equipped with a stirrer and an ultrasonic dispersion mechanism.

-

Editor's pick

In a near future society facing the problem of global warming, sustainability has become a very important keyword for the survival and development of companies. As a company-wide initiative, the Hosokawa Micron Group has formed project teams with the cooperation of external consultants to advance efforts toward achieving the Sustainable Development Goals (SDGs). These allowed us to estimate greenhouse gas (GHG) emissions, develop a materiality plan to reduce them, and disclose proposals to the Task Force on Climate-related Disclosure (TCFD) in line with the Corporate Governance Code.

-

Editor's pick

In recent years, eyelash serums have become widely used by women of all ages. In this article, nanotechnology (PLGA nanocapsules) x biotechnology (human stem cell culture supernatant derived from regenerative medicine technology) will continuously activate the cells involved in eyelashes to maximize the hair growth effect of eyelashes. A new technology has been developed and its effectiveness has been verified for the hair growth.

-

Editor's pick

The performance of a hair restorer is determined by the combination of ingredients and the ingenuity of the formulation. Aiming to increase the action and effect of the ingredients, Hosokawa Micron provides characteristic hair restorer products making use of nanoparticle DDS technology, which enables to deliver them to the back of the pores (cells) and maximize the retaining and action time there. This article is an interesting report that allows you to read a part of the back side of the company's latest hair restorer development.

-

Volume 66 (2023) Pages 37-42Hosokawa Micron’s Equipment and Technology Development Considering SDGs Read moreEditor's pick

As a powder processing machine and system manufacturer, efforts are being made to improve energy efficiency from the perspective of SDGs. It is aimed to further improve the efficiency by using hot air for the jet mill, which is generally considered to have low energy efficiency, and by improving the impact type pulverizer with a built-in classifier. In addition, remote monitoring of plant operations and data collection systems using online digital technology are expected to be further developed in the future from the viewpoint of labor cost reduction.

-

Editor's pick

With the progress of IoT(Internet of Things), we are now in a "connected world" in various fields using online. Demands and expected technologies related to powder processes are being examined from the viewpoint of both product quality and energy consumption for the production. The on-line and in-line measuring devices and technologies for powders required to realize these are introduced along with remote monitoring systems that utilize big data. They seem to become more and more useful in the future for the process optimization.

-

Editor's pick

As a part of measures against global warming, in the drying system, which consumes a large amount of heat energy in addition to mechanical energy in the powder process, a high-performance pulverization and classification mechanism is used, and the hot air that was previously discarded from the system is returned to the furnace for effective utilization of thermal energy. At that time, the water content of the circulating hot air increases and condensation tends to easily occur, so attention is paid to dew point control and dew condensation countermeasures within the system. In this way, energy saving and CO2 reduction are achieved for the entire system.