- |<

- <

- 1

- >

- >|

-

2019Volume 36 Pages Cover36_1

Published: January 10, 2019

Released on J-STAGE: February 28, 2019

Download PDF (1337K) Full view HTML -

2019Volume 36 Pages EdBrd36_1

Published: January 10, 2019

Released on J-STAGE: February 28, 2019

Download PDF (575K) Full view HTML

-

2019Volume 36 Pages EdBrd36_2

Published: January 10, 2019

Released on J-STAGE: February 28, 2019

Download PDF (1499K) Full view HTML -

2019Volume 36 Pages 1-2

Published: January 10, 2019

Released on J-STAGE: February 28, 2019

Download PDF (1731K) Full view HTML

-

2019Volume 36 Pages 3-32

Published: January 10, 2019

Released on J-STAGE: February 28, 2019

Advance online publication: August 31, 2018Download PDF (9771K) Full view HTML -

2019Volume 36 Pages 33-49

Published: January 10, 2019

Released on J-STAGE: February 28, 2019

Advance online publication: March 17, 2018Download PDF (5606K) Full view HTML -

2019Volume 36 Pages 50-71

2019Volume 36 Pages 50-71

Published: January 10, 2019

Released on J-STAGE: February 28, 2019

Advance online publication: March 17, 2018Editor's pickDroplet microfluidics is a novel discipline of science dealing with generation, manipulation and creative use of emulsions - fluidic equivalent of granular matter. In this work Authors provide a comprehensive introduction to droplet microfluidics. The review covers fundamentals and presents some of the most important applications of the emulsions - representative to the broad interest in droplet microfluidics ranging from material science, through biomedical experiments and diagnostics, to applications in pharmaceutical, food, and cosmetic industries.

Download PDF (8182K) Full view HTML -

2019Volume 36 Pages 72-87

2019Volume 36 Pages 72-87

Published: January 10, 2019

Released on J-STAGE: February 28, 2019

Advance online publication: March 31, 2018Editor's pickNovel concepts for solar cells to increase the energy conversion efficiency have proven very promising over the last decade or so. However, implementation of such light management designs have not reached commercial products. Bottom up fabrication with nanoparticles, especially from gas aggregation nanoparticle source, are the most likely path to industrial realisation. In this review paper we present a wide range of possibilities to use such nanoparticles to increase the efficiency of solar cells, both as light management and constituent.

Download PDF (12154K) Full view HTML -

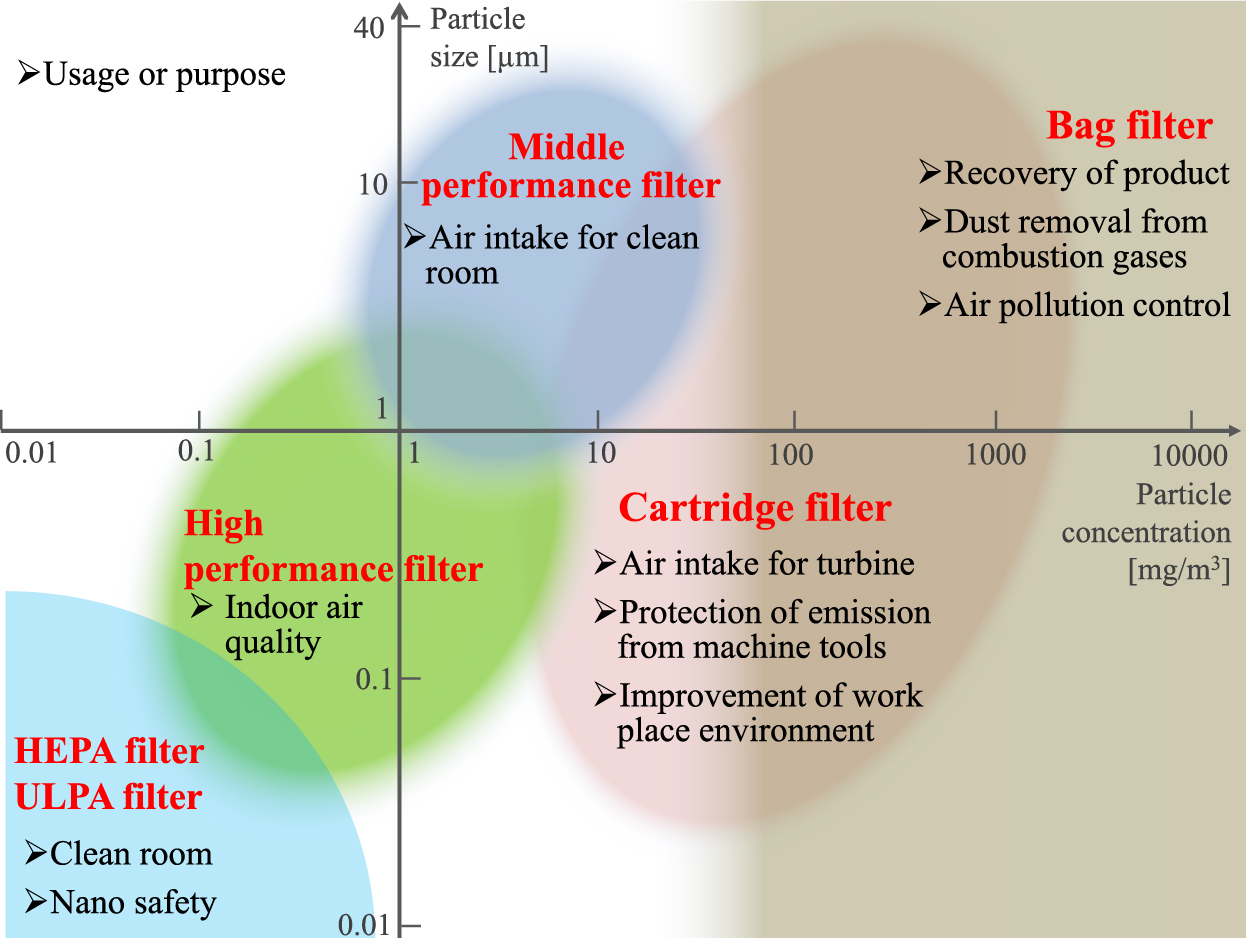

2019Volume 36 Pages 88-113

2019Volume 36 Pages 88-113

Published: January 10, 2019

Released on J-STAGE: February 28, 2019

Advance online publication: March 31, 2018Editor's pickDespite the facts that the applied particle concentration and the field of usages are completely different, air filter and bag filter are regarded as similar because of at the point of using fine fibers as dust collecting body. The article reviewed the collection performance of a single fiber collection efficiency at different mechanisms and time changes of collection performance of both filters is reviewed precisely based on numerous previous studies.

Download PDF (4392K) Full view HTML -

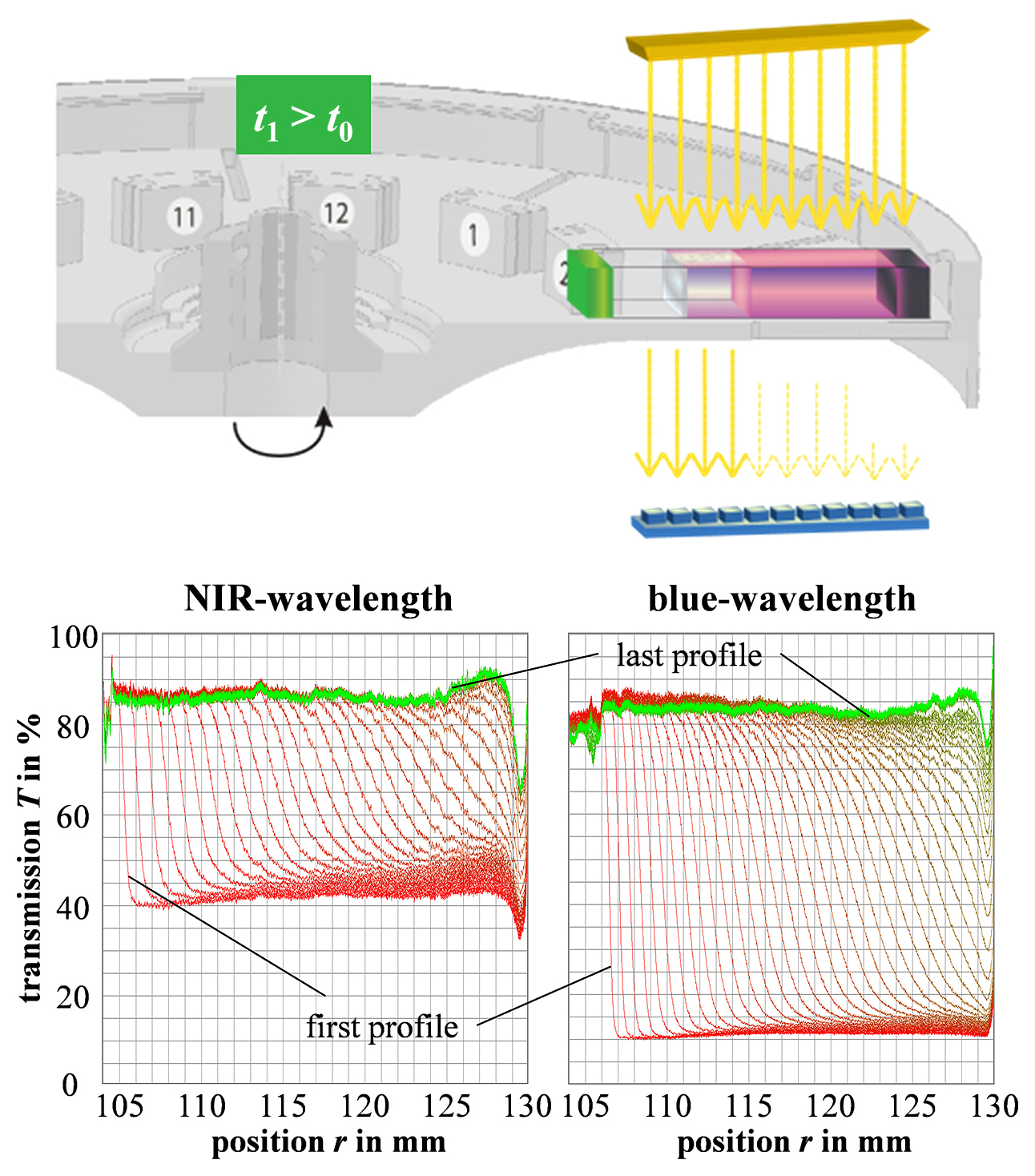

2019Volume 36 Pages 114-128

Published: January 10, 2019

Released on J-STAGE: February 28, 2019

Advance online publication: March 31, 2018Download PDF (15067K) Full view HTML -

Challenges Associated with the Pulmonary Delivery of Therapeutic Dry Powders for Preclinical Testing2019Volume 36 Pages 129-144

Challenges Associated with the Pulmonary Delivery of Therapeutic Dry Powders for Preclinical Testing2019Volume 36 Pages 129-144

Published: January 10, 2019

Released on J-STAGE: February 28, 2019

Advance online publication: March 31, 2018Editor's pickInhaled dry powder therapeutics occupy a growing sector in the pharmaceutical market and meet demands unmet by alternative formulation counterparts. The dry powder inhaler offers the benefits of short delivery times, ease of administration, increased bioavailability, and excellent shelf-life. However, dry powder therapeutics have not transitioned to the market at the same rate as alternative pulmonary delivery platforms. This article addresses some of the barriers to the success of dry powder therapeutics from the preclinical stage to the market. The article concludes with a discussion on improvements needed to address current research model failures and identifies barriers to dry powder formulation and development.

Download PDF (5116K) Full view HTML -

2019Volume 36 Pages 145-155

Published: January 10, 2019

Released on J-STAGE: February 28, 2019

Advance online publication: June 30, 2018Download PDF (2084K) Full view HTML -

2019Volume 36 Pages 156-186

Published: January 10, 2019

Released on J-STAGE: February 28, 2019

Advance online publication: July 31, 2018Download PDF (16507K) Full view HTML -

2019Volume 36 Pages 187-200

Published: January 10, 2019

Released on J-STAGE: February 28, 2019

Advance online publication: July 31, 2018Download PDF (5133K) Full view HTML -

2019Volume 36 Pages 201-214

Published: January 10, 2019

Released on J-STAGE: February 28, 2019

Advance online publication: August 31, 2018Download PDF (9061K) Full view HTML -

2019Volume 36 Pages 215-223

Published: January 10, 2019

Released on J-STAGE: February 28, 2019

Advance online publication: September 15, 2018Download PDF (8809K) Full view HTML

-

2019Volume 36 Pages 224-231

Published: January 10, 2019

Released on J-STAGE: February 28, 2019

Advance online publication: March 17, 2018Download PDF (9723K) Full view HTML -

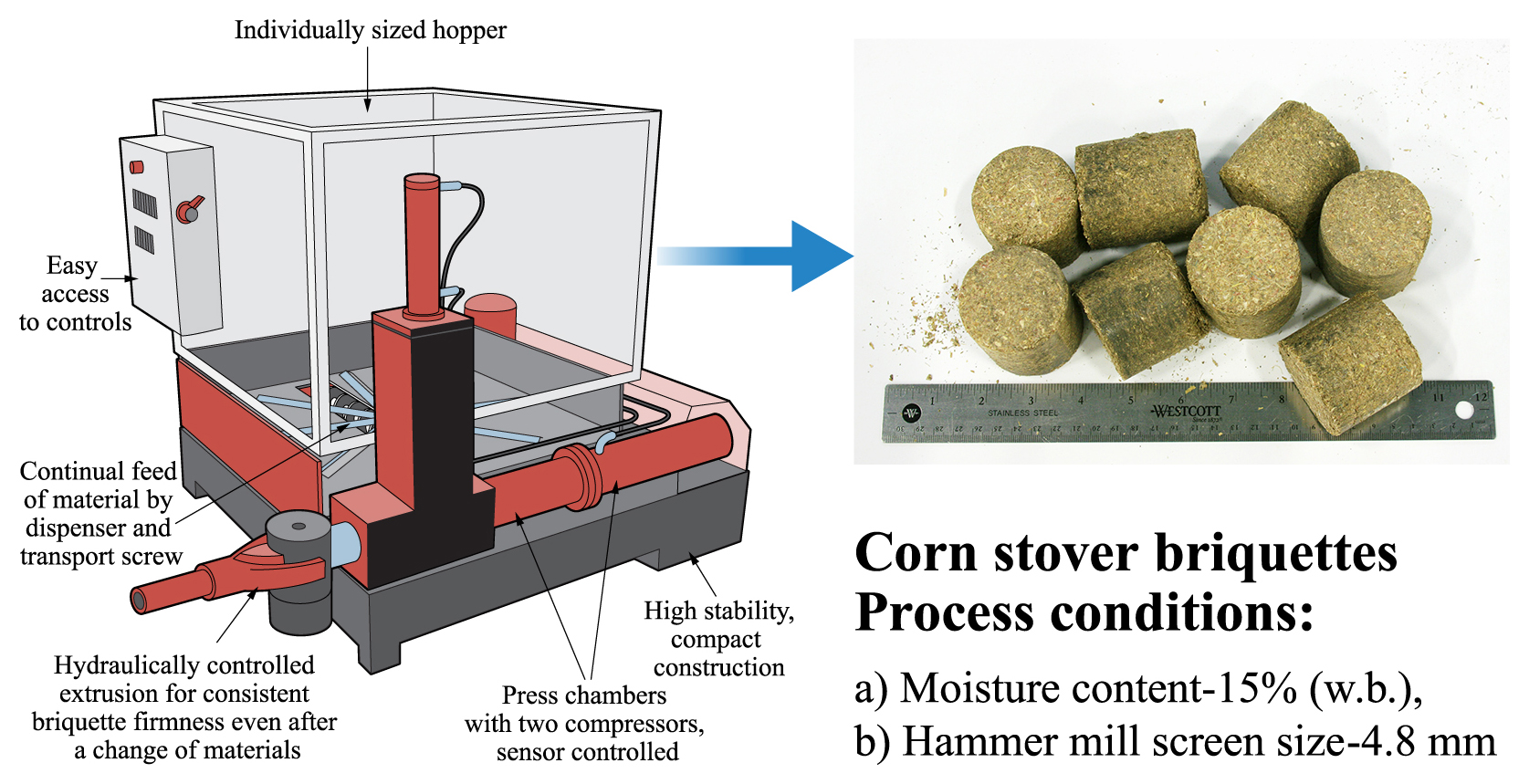

2019Volume 36 Pages 232-240

2019Volume 36 Pages 232-240

Published: January 10, 2019

Released on J-STAGE: February 28, 2019

Advance online publication: March 17, 2018Editor's pickThe present study address the challenges with modeling the fluidization of ground biological materials which are typically non-spherical in shape, and have widely varying sizes. The Ergun equation that is commonly used to model particle fluidization was modified to incorporate non-uniformity sizes, shape factor, and the high void ratio that are typically present in ground biological materials. The results of the study will address the challenges in using models to scale up, size, and design equipment reactors for fluidizing biomass and other biological materials.

Download PDF (6861K) Full view HTML -

2019Volume 36 Pages 241-251

Published: January 10, 2019

Released on J-STAGE: February 28, 2019

Advance online publication: June 30, 2018Download PDF (7117K) Full view HTML -

2019Volume 36 Pages 252-263

Published: January 10, 2019

Released on J-STAGE: February 28, 2019

Advance online publication: June 30, 2018Download PDF (8083K) Full view HTML -

2019Volume 36 Pages 264-270

Published: January 10, 2019

Released on J-STAGE: February 28, 2019

Advance online publication: August 31, 2018Download PDF (12114K) Full view HTML -

2019Volume 36 Pages 271-293

Published: January 10, 2019

Released on J-STAGE: February 28, 2019

Advance online publication: September 15, 2018Download PDF (5336K) Full view HTML

-

2019Volume 36 Pages 294-295

Published: January 10, 2019

Released on J-STAGE: February 28, 2019

Download PDF (9116K) Full view HTML -

2019Volume 36 Pages 296

Published: January 10, 2019

Released on J-STAGE: February 28, 2019

Download PDF (3221K) Full view HTML -

2019Volume 36 Pages 297

Published: January 10, 2019

Released on J-STAGE: February 28, 2019

Download PDF (554K) Full view HTML

- |<

- <

- 1

- >

- >|