- |<

- <

- 1

- >

- >|

-

2023 Volume 40 Pages Cover40_1

Published: January 10, 2023

Released on J-STAGE: February 28, 2023

Download PDF (1313K) Full view HTML -

2023 Volume 40 Pages EdBrd40_1

Published: January 10, 2023

Released on J-STAGE: February 28, 2023

Download PDF (3486K) Full view HTML

-

2023 Volume 40 Pages i-v

Published: January 10, 2023

Released on J-STAGE: February 28, 2023

Download PDF (13115K) Full view HTML

-

2023 Volume 40 Pages 1-2

Published: January 10, 2023

Released on J-STAGE: February 28, 2023

Download PDF (1675K) Full view HTML

-

2023 Volume 40 Pages 3-13

Published: January 10, 2023

Released on J-STAGE: February 28, 2023

Advance online publication: June 18, 2022Download PDF (14621K) Full view HTML -

2023 Volume 40 Pages 14-28

Published: January 10, 2023

Released on J-STAGE: February 28, 2023

Advance online publication: November 13, 2021Download PDF (9260K) Full view HTML -

2023 Volume 40 Pages 29-49

Published: January 10, 2023

Released on J-STAGE: February 28, 2023

Advance online publication: January 29, 2022Download PDF (25107K) Full view HTML -

2023 Volume 40 Pages 50-73

2023 Volume 40 Pages 50-73

Published: January 10, 2023

Released on J-STAGE: February 28, 2023

Advance online publication: April 23, 2022Editor's pickThis review describes the importance of comminution and classification processes to produce battery materials and battery electrodes, and to recycle production scrap and end-of-life battery cells. It shows how comminution and classification processes are integrated into the production of various active materials, such as spheronisation of natural graphite, grinding of nano-sized silicon and dispersion of calcined lithium metal oxides, and into the processing of electrode slurries using planetary mixers, extruders or stirred media mills. The use of mills and classifiers in the recycling of battery materials and the mechanochemical synthesis of solid sulphide electrolytes is another important topic.

Download PDF (8731K) Full view HTML -

Recent Research Trend in Powder Process Technology for High-Performance Rare-Earth Permanent Magnets2023 Volume 40 Pages 74-93

Recent Research Trend in Powder Process Technology for High-Performance Rare-Earth Permanent Magnets2023 Volume 40 Pages 74-93

Published: January 10, 2023

Released on J-STAGE: February 28, 2023

Advance online publication: May 21, 2022Editor's pickDelve into the forefront of rare earth permanent magnet research with this insightful paper. With electric vehicles driving demand for higher-performance magnets, the quest for advanced structural control in powder metallurgy processes is paramount. Discover how innovative approaches in chemical synthesis have led to the development of submicron-sized Sm-Fe-N powders with remarkable coercivity. Explore the evolution of grain boundary control techniques and the emergence of low-thermal load consolidation methods like spark plasma sintering, crucial for enhancing remanence in next-generation magnets.

Download PDF (15802K) Full view HTML -

Morphology Control of Transition Metal Oxides by Liquid-Phase Process and Their Material Development2023 Volume 40 Pages 94-108

Morphology Control of Transition Metal Oxides by Liquid-Phase Process and Their Material Development2023 Volume 40 Pages 94-108

Published: January 10, 2023

Released on J-STAGE: February 28, 2023

Advance online publication: September 10, 2022Editor's pickSolution processing is one of the important methods in the synthesis of functional materials. This method can create various compositions and control their crystal structure, particle morphology, and size. It is expected to lead to the development of new functionality of materials. This paper introduces the relationship between powder particle morphology and material functionality, explains the various environmental response functionalities of transition metal oxides synthesized by the environmentally friendly liquid-based method, and indicates that the morphology control associates material science with art. It arouses the reader's interest and implies further potential in developing future functional materials.

Download PDF (15149K) Full view HTML -

2023 Volume 40 Pages 109-123

Published: January 10, 2023

Released on J-STAGE: February 28, 2023

Advance online publication: February 16, 2022Download PDF (6966K) Full view HTML -

2023 Volume 40 Pages 124-148

Published: January 10, 2023

Released on J-STAGE: February 28, 2023

Advance online publication: April 02, 2022Download PDF (19994K) Full view HTML -

2023 Volume 40 Pages 149-171

2023 Volume 40 Pages 149-171

Published: January 10, 2023

Released on J-STAGE: February 28, 2023

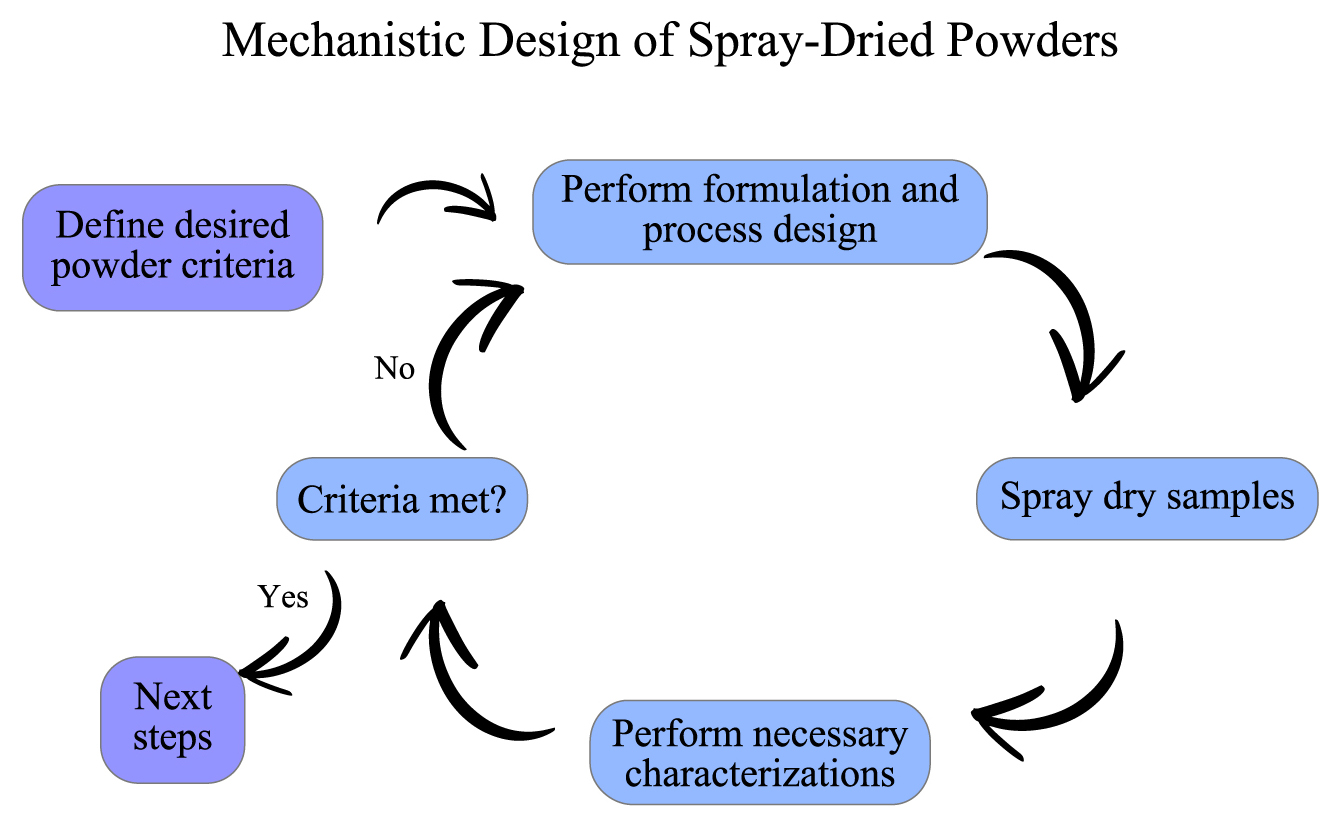

Advance online publication: July 09, 2022Editor's pickSpray drying emerges as a pivotal method in pharmaceutical manufacturing, offering versatility across various delivery routes. Its capacity to engineer particles enhances drug efficacy and stability, vital for global distribution, notably for vaccines. Despite complexities in formulation design, this review elucidates practical steps and essential background knowledge crucial for successful spray-dried microparticle formulation. It navigates through estimating solute concentration during drying, solidification kinetics, and the role of stabilizers, providing invaluable insights for practitioners striving to optimize particle properties for therapeutic delivery.

Download PDF (7118K) Full view HTML -

2023 Volume 40 Pages 172-185

2023 Volume 40 Pages 172-185

Published: January 10, 2023

Released on J-STAGE: February 28, 2023

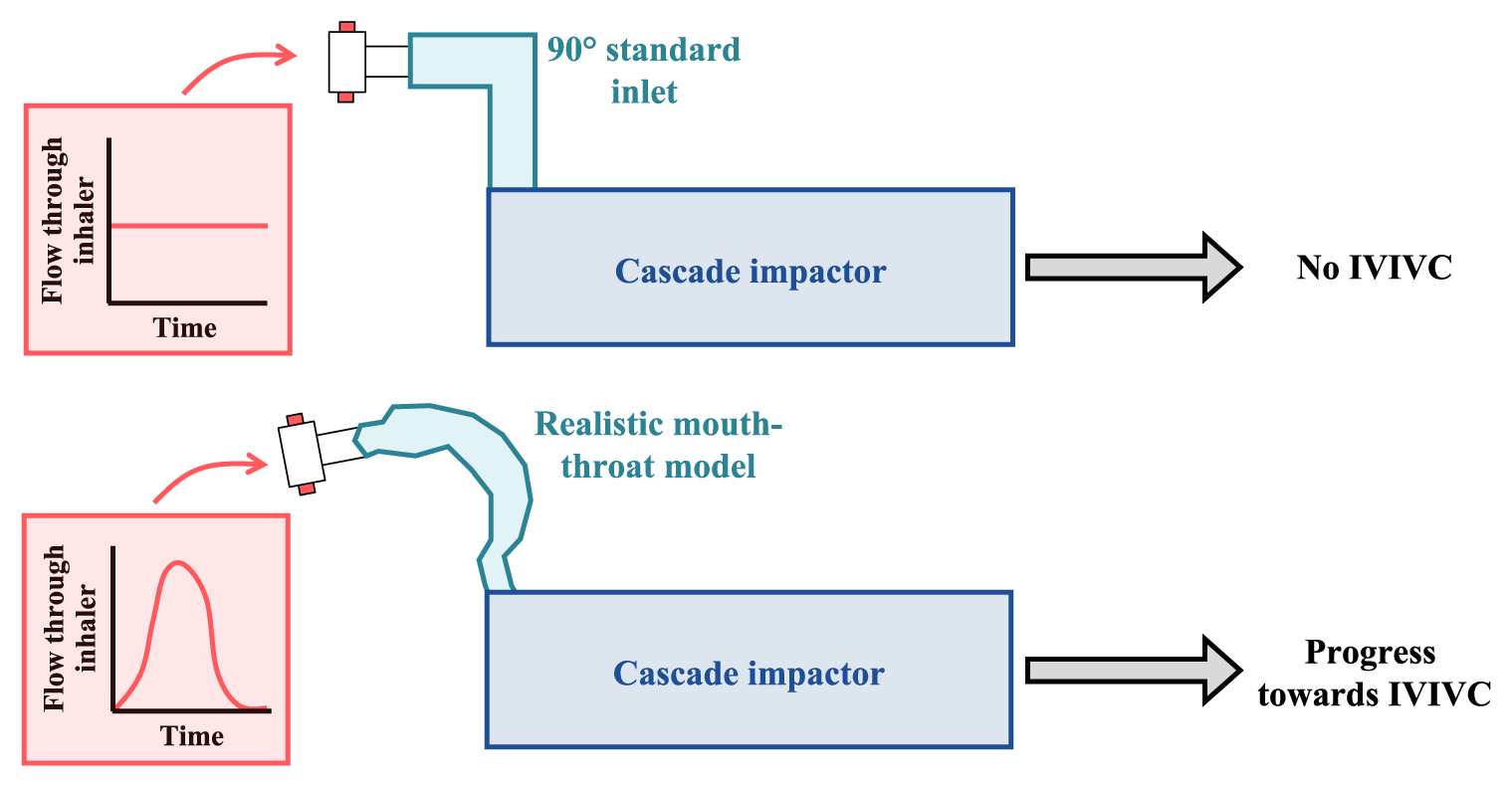

Advance online publication: September 03, 2022Editor's pickDry powder inhaler formulations have garnered interest as a way to deliver drugs directly to the lungs in a stable, solid dosage form. Developing generics of brand-name dry powder inhalers is essential to their widespread availability but requires careful consideration in characterizing bioequivalence. This review highlights the standard characterization methods frequently employed as well as physiologically relevant measures that may aid in bioequivalence decisions. The necessity of considering in vivo relevance while performing in vitro testing is highlighted, assisting the field in shifting to physiologically relevant characterization methods.

Download PDF (5494K) Full view HTML -

2023 Volume 40 Pages 186-196

Published: January 10, 2023

Released on J-STAGE: February 28, 2023

Advance online publication: September 03, 2022Download PDF (10056K) Full view HTML -

2023 Volume 40 Pages 197-218

Published: January 10, 2023

Released on J-STAGE: February 28, 2023

Advance online publication: September 23, 2022Download PDF (12187K) Full view HTML

-

2023 Volume 40 Pages 219-235

Published: January 10, 2023

Released on J-STAGE: February 28, 2023

Advance online publication: June 04, 2022Download PDF (5598K) Full view HTML -

2023 Volume 40 Pages 236-249

Published: January 10, 2023

Released on J-STAGE: February 28, 2023

Advance online publication: June 25, 2022Download PDF (4575K) Full view HTML -

2023 Volume 40 Pages 250-261

Published: January 10, 2023

Released on J-STAGE: February 28, 2023

Advance online publication: April 23, 2022Download PDF (1734K) Full view HTML -

2023 Volume 40 Pages 262-276

Published: January 10, 2023

Released on J-STAGE: February 28, 2023

Advance online publication: July 02, 2022Download PDF (10379K) Full view HTML

-

2023 Volume 40 Pages 277-278

Published: January 10, 2023

Released on J-STAGE: February 28, 2023

Download PDF (10020K) Full view HTML -

2023 Volume 40 Pages 279-280

Published: January 10, 2023

Released on J-STAGE: February 28, 2023

Download PDF (6490K) Full view HTML -

2023 Volume 40 Pages 281

Published: January 10, 2023

Released on J-STAGE: February 28, 2023

Download PDF (639K) Full view HTML

- |<

- <

- 1

- >

- >|