- |<

- <

- 1

- >

- >|

-

2022 Volume 65 Article ID: 2022001

Published: December 15, 2021

Released on J-STAGE: December 15, 2021

Download PDF (1250K)

-

2022 Volume 65 Article ID: 2022002

Published: December 15, 2021

Released on J-STAGE: December 15, 2021

Download PDF (2259K)

-

2022 Volume 65 Article ID: 2022003

Published: December 15, 2021

Released on J-STAGE: December 15, 2021

Download PDF (11764K)

-

2022 Volume 65 Pages 1-2

Published: December 15, 2021

Released on J-STAGE: December 15, 2021

Download PDF (3021K)

-

2022 Volume 65 Pages 3-10

Published: December 15, 2021

Released on J-STAGE: December 15, 2021

Download PDF (4444K) -

2022 Volume 65 Pages 11-17

Published: December 15, 2021

Released on J-STAGE: December 15, 2021

Download PDF (9828K) -

2022 Volume 65 Pages 18-27

Published: December 15, 2021

Released on J-STAGE: December 15, 2021

Download PDF (4366K) -

2022 Volume 65 Pages 28-37

Published: December 15, 2021

Released on J-STAGE: December 15, 2021

Download PDF (2674K) -

2022 Volume 65 Pages 38-44

Published: December 15, 2021

Released on J-STAGE: December 15, 2021

Download PDF (4475K) -

2022 Volume 65 Pages 45-52

Published: December 15, 2021

Released on J-STAGE: December 15, 2021

Download PDF (4536K)

-

2022 Volume 65 Pages 53-57

2022 Volume 65 Pages 53-57

Published: December 15, 2021

Released on J-STAGE: December 15, 2021

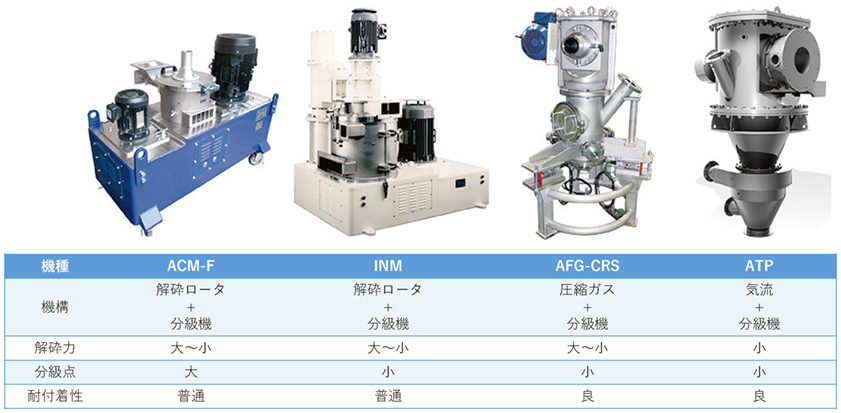

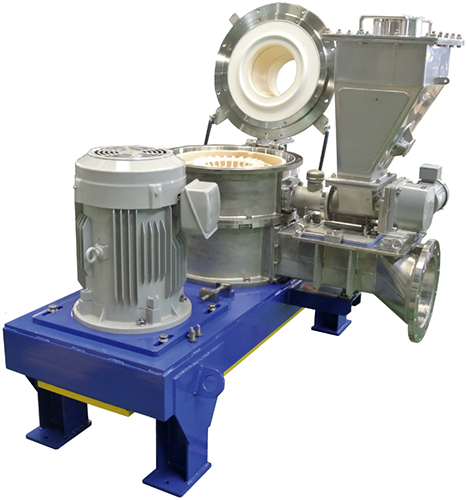

Editor's pickWhen different types of raw material powders are mixed and fired for a solid-phase reaction, it is often necessary to crush the calcined particle agglomerates to near the primary particles. In this article, the features of various powder processing devices of Hosokawa Micron used for the purpose of such crushing are explained together with introduction of some applications of latest crushing technology for crushing ceramic aggregates including powders for capacitors and ceramic powders for secondary battery positive electrode materials.

Download PDF (2642K) -

2022 Volume 65 Pages 58-62

2022 Volume 65 Pages 58-62

Published: December 15, 2021

Released on J-STAGE: December 15, 2021

Editor's pickAgainst the backdrop of an increasing number of new drug development products and the aging of the population in recent years, efforts are being made to expand production facilities in the pharmaceutical industry. As the handling of highly pharmacologically active drugs increases, it is necessary to have a containment technology to prevent hazard substances from scattering in order to deal with problems such as cross-contamination, health problems, and environmental pollution. This article summarizes the management categories of hazard substances, applicable equipment, and types of containment equipment, and introduces containment technology in the pharmaceutical market.

Download PDF (8343K) -

2022 Volume 65 Pages 63-68

2022 Volume 65 Pages 63-68

Published: December 15, 2021

Released on J-STAGE: December 15, 2021

Editor's pickThe sieving operation is a highly reliable operation for quality assurance in principle, and by performing this in a wet manner, more detailed and efficient analysis becomes possible. The wet sieving device VIBLETTE® (VBL-F) has been exclusively used for analysis using water, but the newly developed VBL-FS type is now available, which is compatible with organic solvents, and enables to evaluate powders that cannot be sufficiently sifted with water due to their water solubility and water repellency, and powders that are dispersed in organic solvents for use.

Download PDF (6397K) -

2022 Volume 65 Pages 69-72

2022 Volume 65 Pages 69-72

Published: December 15, 2021

Released on J-STAGE: December 15, 2021

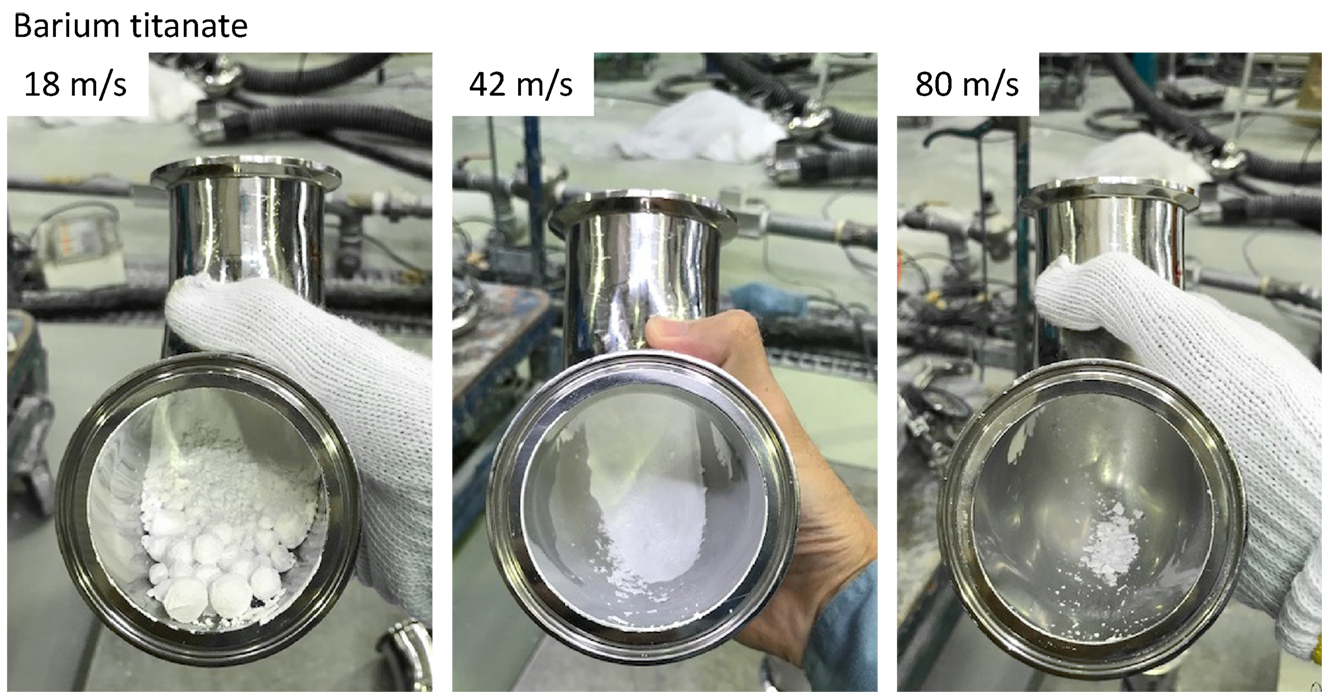

Editor's pickIn recent years, there has been an urgent need to respond to global environmental problems, and investment in battery manufacturing equipment has been expanding toward the shift to EVs for automobiles in order to achieve the carbon dioxide reduction target. At the same time, however, further cost reduction of the manufacturing equipment is required. Hosokawa Micron manufactures equipment used for the production of positive and negative electrode materials related to lithium-ion batteries used in EVs. This paper introduces efforts for Hosokawa Micron's crushing equipment used for positive electrode materials.

Download PDF (3675K) -

2022 Volume 65 Pages 73-79

Published: December 15, 2021

Released on J-STAGE: December 15, 2021

Download PDF (4351K) -

2022 Volume 65 Pages 80-85

2022 Volume 65 Pages 80-85

Published: December 15, 2021

Released on J-STAGE: December 15, 2021

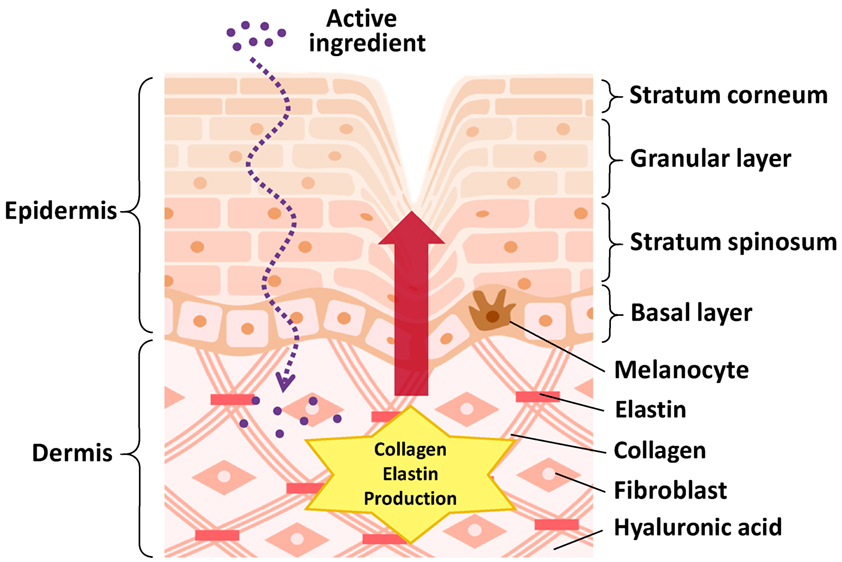

Editor's pickRecently, skin care technology derived from regenerative medicine has attracted attention for the purpose of "fundamental treatment" of skin symptoms such as wrinkles and spots, and eggshell membranes and human stem cell culture medium are used as cosmetic raw materials. Due to their complex composition and large molecular size, these raw materials are difficult to penetrate through the skin. In this paper, it is explained that PLGA nanoparticles encapsulating hydrolyzed eggshell membrane, which is a macromolecular component, are useful for improving dermal wrinkle.

Download PDF (4677K)

-

2022 Volume 65 Pages 86-87

Published: December 15, 2021

Released on J-STAGE: December 15, 2021

Download PDF (2845K) -

2022 Volume 65 Pages 88-89

Published: December 15, 2021

Released on J-STAGE: December 15, 2021

Download PDF (4107K)

-

2022 Volume 65 Pages 90-91

Published: December 15, 2021

Released on J-STAGE: December 15, 2021

Download PDF (7968K) -

2022 Volume 65 Pages 92-93

Published: December 15, 2021

Released on J-STAGE: December 15, 2021

Download PDF (3663K) -

2022 Volume 65 Pages 94-95

Published: December 15, 2021

Released on J-STAGE: December 15, 2021

Download PDF (10463K) -

2022 Volume 65 Pages 96-97

Published: December 15, 2021

Released on J-STAGE: December 15, 2021

Download PDF (2392K) -

2022 Volume 65 Pages 98-99

Published: December 15, 2021

Released on J-STAGE: December 15, 2021

Download PDF (10768K) -

2022 Volume 65 Pages 100-101

Published: December 15, 2021

Released on J-STAGE: December 15, 2021

Download PDF (9429K) -

2022 Volume 65 Pages 102-103

Published: December 15, 2021

Released on J-STAGE: December 15, 2021

Download PDF (8696K)

-

2022 Volume 65 Pages 104-106

Published: December 15, 2021

Released on J-STAGE: December 15, 2021

Download PDF (10642K) -

2022 Volume 65 Pages 107-113

Published: December 15, 2021

Released on J-STAGE: December 15, 2021

Download PDF (24488K) -

2022 Volume 65 Pages 114

Published: December 15, 2021

Released on J-STAGE: December 15, 2021

Download PDF (4163K) -

2022 Volume 65 Pages 115-118

Published: December 15, 2021

Released on J-STAGE: December 15, 2021

Download PDF (11215K) -

2022 Volume 65 Pages 119

Published: December 15, 2021

Released on J-STAGE: December 15, 2021

Download PDF (264K)

- |<

- <

- 1

- >

- >|