- |<

- <

- 1

- >

- >|

-

2021 Volume 64 Article ID: 2021001

Published: December 15, 2020

Released on J-STAGE: December 15, 2020

Download PDF (1641K)

-

2021 Volume 64 Article ID: 2021002

Published: December 15, 2020

Released on J-STAGE: December 15, 2020

Download PDF (2281K)

-

2021 Volume 64 Article ID: 2021003

Published: December 15, 2020

Released on J-STAGE: December 15, 2020

Download PDF (6776K)

-

2021 Volume 64 Pages 1-2

Published: December 15, 2020

Released on J-STAGE: December 15, 2020

Download PDF (8083K)

-

2021 Volume 64 Pages 3-8

Published: December 15, 2020

Released on J-STAGE: December 15, 2020

Download PDF (4416K) -

2021 Volume 64 Pages 9-17

Published: December 15, 2020

Released on J-STAGE: December 15, 2020

Download PDF (3523K) -

2021 Volume 64 Pages 18-27

Published: December 15, 2020

Released on J-STAGE: December 15, 2020

Download PDF (5513K) -

2021 Volume 64 Pages 28-34

Published: December 15, 2020

Released on J-STAGE: December 15, 2020

Download PDF (3447K) -

2021 Volume 64 Pages 35-41

Published: December 15, 2020

Released on J-STAGE: December 15, 2020

Download PDF (9370K)

-

2021 Volume 64 Pages 42-47

2021 Volume 64 Pages 42-47

Published: December 15, 2020

Released on J-STAGE: December 15, 2020

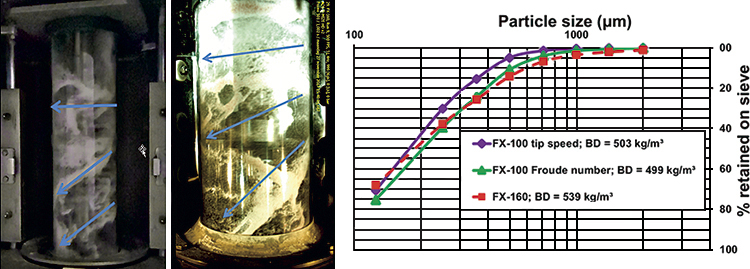

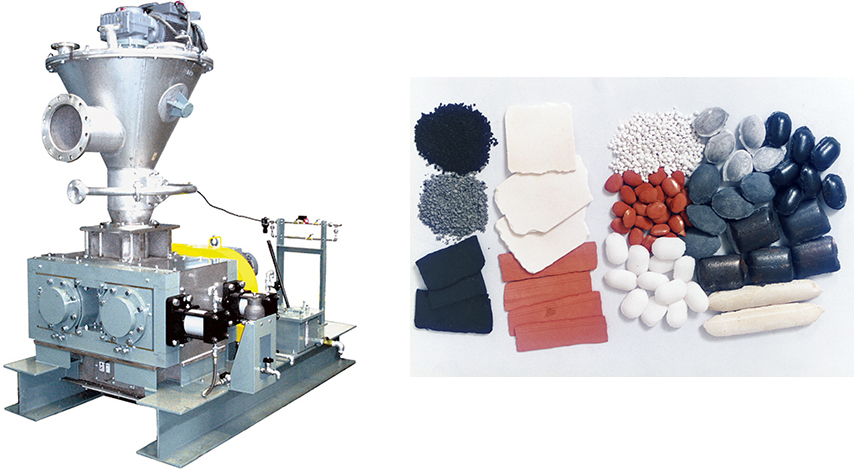

Editor's pickIn order to improve the handling of bulky fine powder materials and reduce the volume, there is increasing interest in dry roll-type compression granulators that compress and mold powder between two rotating rolls. This article introduces the outline, principle, and structure of Hosokawa Micron's roll-type compression granulator for dry granulation, and the development of the enhanced "shear type briquette machine", which increases the shearing force by using different speeds of the rolls, its delivery example, and the track record of scale-up to large machines.

Download PDF (9754K) -

2021 Volume 64 Pages 48-51

2021 Volume 64 Pages 48-51

Published: December 15, 2020

Released on J-STAGE: December 15, 2020

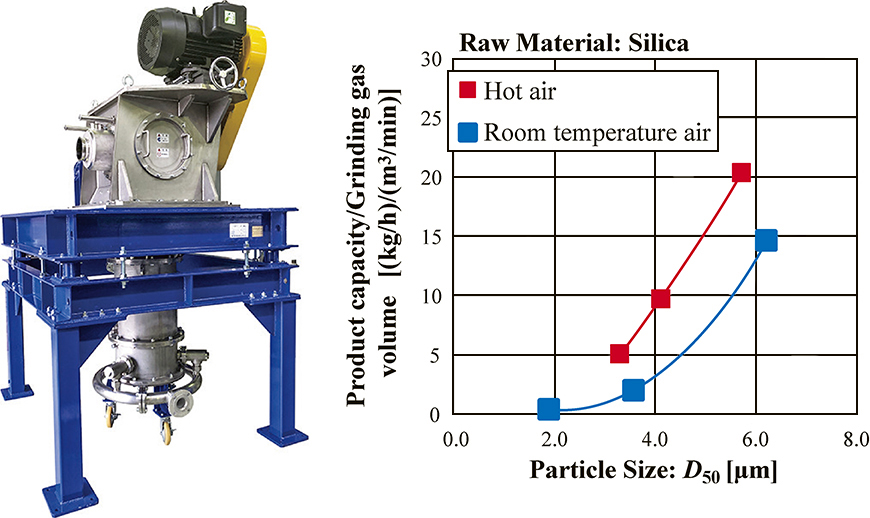

Editor's pickJet mills widely used as dry pulverizers are classified into target type, spiral type, fluidized bed type, etc. Among these, the fluidized bed type counter jet mills have the advantage that the equipment is less worn and impurities are less likely due to the fact that powder raw materials mainly collide with each other, though the jet mills have the disadvantage of low energy efficiency. In this article, the method of using high temperature gas as one of the means to solve this problem is introduced explaining the cause of the improvement of crushing efficiency with the actual experimental data.

Download PDF (3952K) -

2021 Volume 64 Pages 52-55

2021 Volume 64 Pages 52-55

Published: December 15, 2020

Released on J-STAGE: December 15, 2020

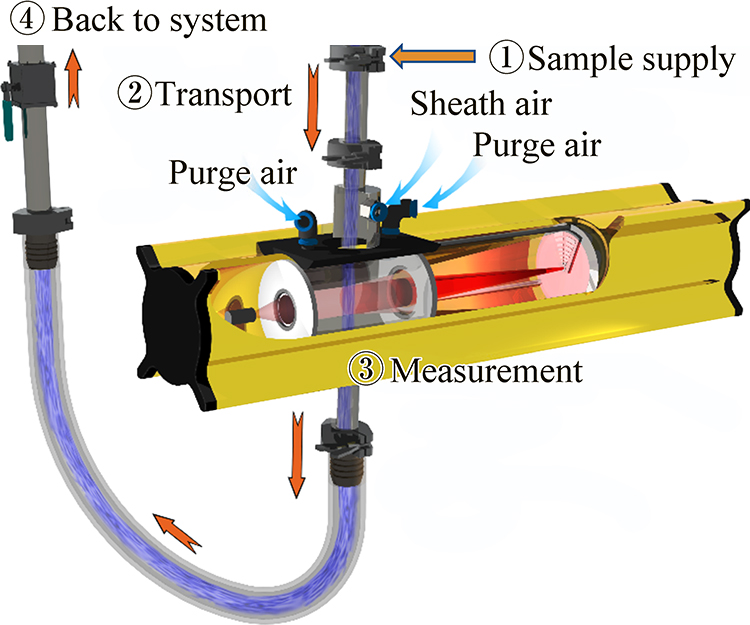

Editor's pickIn recent years, modeling technology using 3D printers has made rapid progress and is becoming more widely used. In the additive manufacturing method using selective laser melting with metal powder, the requirement on the size and shape of the metal particles are becoming more and more stringent. Normally, these metal powders are produced by the gas atomization method, but the particle size distribution has a certain range. Aiming at the sophistication of the laminated molding method, this article introduces an ultra-fine powder classifier, which makes it possible to obtain a product with a fine and sharp distribution by cutting the upper and lower ends of the particle size distribution with one classifier for this metal powder, and the system using this classifier.

Download PDF (4098K) -

2021 Volume 64 Pages 56-61

2021 Volume 64 Pages 56-61

Published: December 15, 2020

Released on J-STAGE: December 15, 2020

Editor's pickIn a powder processing system, it is very important to understand the particle size distribution of powder, but until now, batch measurement by sampling has been performed exclusively. On the other hand, there is an increasing need for online measurement of particle size distribution due to the sophistication, automation, and IoT of production management of powder processing systems in recent years. This article introduces the powder processing system using the online particle size distribution measuring machine Optisizer® series, and explains the points to be noted about online measurement of particle size distribution, feedback control, application to remote monitoring system, etc.

Download PDF (4040K) -

2021 Volume 64 Pages 62-68

2021 Volume 64 Pages 62-68

Published: December 15, 2020

Released on J-STAGE: December 15, 2020

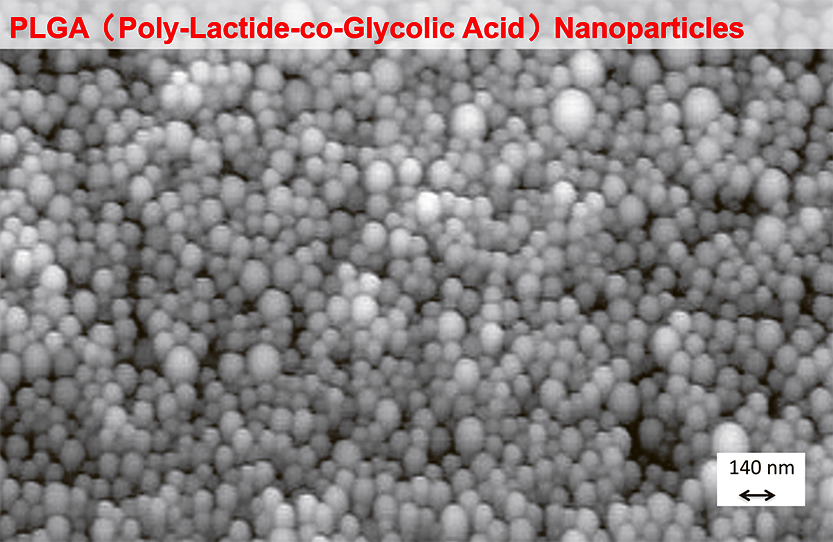

Editor's pickHair follicle stem cells at the base of hair produce special 3D collagen (type 17 collagen: COL17), which is used as an adhesive for the stem cells to stay on the inner wall of the hair follicle, where it produces hair matrix cells that grow hair. In general, as the amount of COL17 produced decreases with age and the adhesion of stem cells to the inner wall of hair follicles weakens, the stem cells detach from the hair follicles and the supply of hair matrix cells is stopped, resulting in thinning hair progresses. Therefore, it is necessary to give hair follicle stem cells the ingredients to produce COL17 by themselves. In this article, it is reported that the effect of promoting the production of COL17 and the effect of improving the activity of hair follicle stem cells were obtained by utilizing the excellent scalp-pore permeability and the intracellular targeting of PLGA nanoparticles as a carrier that can efficiently supply chlorogenic acid, which is known to promote the production of COL17, from the scalp-pore to the hair follicle stem cells.

Download PDF (5341K)

-

2021 Volume 64 Pages 69-70

Published: December 15, 2020

Released on J-STAGE: December 15, 2020

Download PDF (2081K) -

2021 Volume 64 Pages 71-72

Published: December 15, 2020

Released on J-STAGE: December 15, 2020

Download PDF (5530K)

-

2021 Volume 64 Pages 73-75

Published: December 15, 2020

Released on J-STAGE: December 15, 2020

Download PDF (6981K) -

2021 Volume 64 Pages 76-77

Published: December 15, 2020

Released on J-STAGE: December 15, 2020

Download PDF (1585K) -

2021 Volume 64 Pages 78-80

Published: December 15, 2020

Released on J-STAGE: December 15, 2020

Download PDF (11655K) -

2021 Volume 64 Pages 81-83

Published: December 15, 2020

Released on J-STAGE: December 15, 2020

Download PDF (3727K) -

2021 Volume 64 Pages 84-86

Published: December 15, 2020

Released on J-STAGE: December 15, 2020

Download PDF (7354K) -

2021 Volume 64 Pages 87-89

Published: December 15, 2020

Released on J-STAGE: December 15, 2020

Download PDF (10711K) -

2021 Volume 64 Pages 90-91

Published: December 15, 2020

Released on J-STAGE: December 15, 2020

Download PDF (7327K)

-

2021 Volume 64 Pages 92-94

Published: December 15, 2020

Released on J-STAGE: December 15, 2020

Download PDF (8980K) -

2021 Volume 64 Pages 95-97

Published: December 15, 2020

Released on J-STAGE: December 15, 2020

Download PDF (9475K) -

2021 Volume 64 Pages 98-103

Published: December 15, 2020

Released on J-STAGE: December 15, 2020

Download PDF (2415K) -

2021 Volume 64 Pages 104-106

Published: December 15, 2020

Released on J-STAGE: December 15, 2020

Download PDF (10308K) -

2021 Volume 64 Pages 107

Published: December 15, 2020

Released on J-STAGE: December 15, 2020

Download PDF (609K)

- |<

- <

- 1

- >

- >|