- |<

- <

- 1

- >

- >|

-

2015Volume 32 Pages Cover32_1

Published: 2015

Released on J-STAGE: February 28, 2015

Download PDF (5052K) Full view HTML -

2015Volume 32 Pages EdBrd32_1

Published: 2015

Released on J-STAGE: February 28, 2015

Download PDF (197K) Full view HTML

-

2015Volume 32 Pages 1

Published: 2015

Released on J-STAGE: February 28, 2015

Download PDF (649K) Full view HTML

-

2015Volume 32 Pages 2-22

2015Volume 32 Pages 2-22

Published: 2015

Released on J-STAGE: February 28, 2015

Advance online publication: August 30, 2014Editor's pickThe preparation of nano/micromotor systems has been a hot topic in nanotechnology and biotechnology for the last decade. This review explains the underlying physics of the nano/micromotors, which is completely different from that of conventional macroscale motors. Additionally, the authors introduce various types of nano/micromotors, especially chemical reaction propelled motors.

Download PDF (6531K) Full view HTML -

2015Volume 32 Pages 23-40

Published: 2015

Released on J-STAGE: February 28, 2015

Advance online publication: September 12, 2014Download PDF (2584K) Full view HTML -

2015Volume 32 Pages 41-56

Published: 2015

Released on J-STAGE: February 28, 2015

Advance online publication: September 20, 2014Download PDF (1231K) Full view HTML -

2015Volume 32 Pages 57-74

Published: 2015

Released on J-STAGE: February 28, 2015

Advance online publication: October 10, 2014Download PDF (5725K) Full view HTML -

2015Volume 32 Pages 75-84

Published: 2015

Released on J-STAGE: February 28, 2015

Download PDF (3142K) Full view HTML -

2015Volume 32 Pages 85-101

Published: 2015

Released on J-STAGE: February 28, 2015

Download PDF (2013K) Full view HTML -

2015Volume 32 Pages 102-114

Published: 2015

Released on J-STAGE: February 28, 2015

Download PDF (1273K) Full view HTML -

2015Volume 32 Pages 115-130

Published: 2015

Released on J-STAGE: February 28, 2015

Download PDF (1784K) Full view HTML

-

2015Volume 32 Pages 131-142

Published: 2015

Released on J-STAGE: February 28, 2015

Advance online publication: June 25, 2014Download PDF (1332K) Full view HTML -

2015Volume 32 Pages 143-153

Published: 2015

Released on J-STAGE: February 28, 2015

Advance online publication: June 25, 2014Download PDF (3434K) Full view HTML -

2015Volume 32 Pages 154-162

Published: 2015

Released on J-STAGE: February 28, 2015

Advance online publication: June 25, 2014Download PDF (2262K) Full view HTML -

2015Volume 32 Pages 163-175

Published: 2015

Released on J-STAGE: February 28, 2015

Advance online publication: June 30, 2014Download PDF (4238K) Full view HTML -

2015Volume 32 Pages 176-183

Published: 2015

Released on J-STAGE: February 28, 2015

Advance online publication: September 12, 2014Download PDF (961K) Full view HTML -

2015Volume 32 Pages 184-195

Published: 2015

Released on J-STAGE: February 28, 2015

Advance online publication: September 20, 2014Download PDF (2494K) Full view HTML -

2015Volume 32 Pages 196-206

Published: 2015

Released on J-STAGE: February 28, 2015

Advance online publication: September 30, 2014Download PDF (6289K) Full view HTML -

2015Volume 32 Pages 207-216

Published: 2015

Released on J-STAGE: February 28, 2015

Advance online publication: September 30, 2014Download PDF (2839K) Full view HTML -

2015Volume 32 Pages 217-226

Published: 2015

Released on J-STAGE: February 28, 2015

Advance online publication: September 30, 2014Download PDF (1931K) Full view HTML -

2015Volume 32 Pages 227-235

Published: 2015

Released on J-STAGE: February 28, 2015

Download PDF (1081K) Full view HTML -

2015Volume 32 Pages 236-252

2015Volume 32 Pages 236-252

Published: 2015

Released on J-STAGE: February 28, 2015

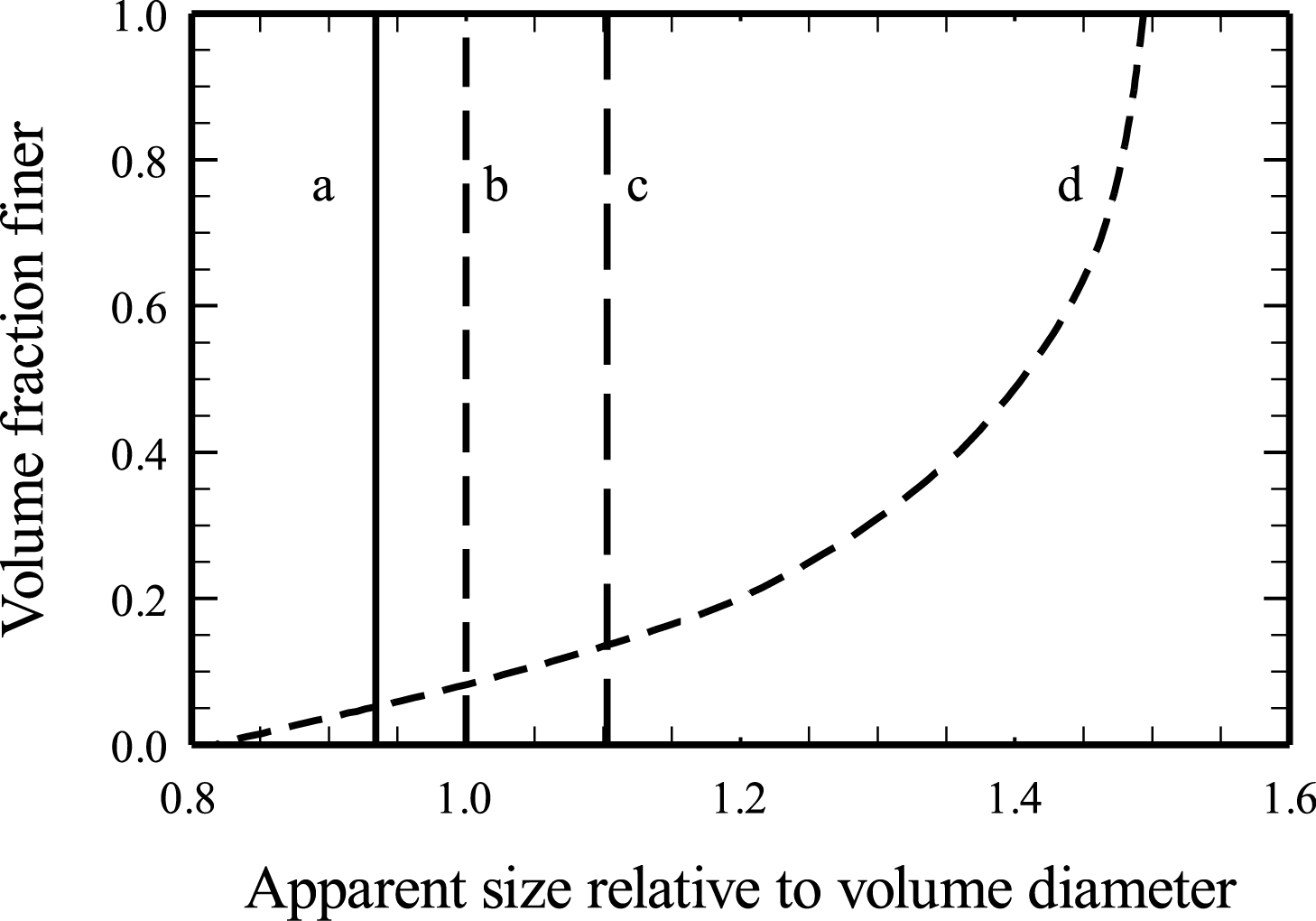

Editor's pickAs Discrete Element Modelling (DEM) increases its utilization as tool for the simulation of particulate materials in a variety of processing unit operations, there is a continuous focus on develop robust methodologies for model calibration to guarantee reliable predictive results. This paper focus on providing insights on advantages and limitations on typical approaches for calibration and validation. The calibration process using a series of small scale tests was then validated experimentally and numerically utilizing independent application tests.

Download PDF (6059K) Full view HTML -

2015Volume 32 Pages 253-263

Published: 2015

Released on J-STAGE: February 28, 2015

Download PDF (4625K) Full view HTML -

2015Volume 32 Pages 264-269

Published: 2015

Released on J-STAGE: February 28, 2015

Download PDF (4183K) Full view HTML -

2015Volume 32 Pages 270-278

Published: 2015

Released on J-STAGE: February 28, 2015

Download PDF (2307K) Full view HTML

-

2015Volume 32 Pages 279-281

Published: 2015

Released on J-STAGE: February 28, 2015

Download PDF (2785K) Full view HTML -

2015Volume 32 Pages 282

Published: 2015

Released on J-STAGE: February 28, 2015

Download PDF (693K) Full view HTML -

2015Volume 32 Pages 283

Published: 2015

Released on J-STAGE: February 28, 2015

Download PDF (240K) Full view HTML

- |<

- <

- 1

- >

- >|