- |<

- <

- 1

- >

- >|

-

2022 年 39 巻 p. Cover39_1

発行日: 2022/01/10

公開日: 2022/02/28

PDF形式でダウンロード (1351K) HTML形式で全画面表示 -

2022 年 39 巻 p. EdBrd39_1

発行日: 2022/01/10

公開日: 2022/02/28

PDF形式でダウンロード (3461K) HTML形式で全画面表示

-

2022 年 39 巻 p. i-v

発行日: 2022/01/10

公開日: 2022/02/28

PDF形式でダウンロード (8596K) HTML形式で全画面表示

-

2022 年 39 巻 p. vi

発行日: 2022/01/10

公開日: 2022/02/28

PDF形式でダウンロード (1611K) HTML形式で全画面表示 -

2022 年 39 巻 p. 1-2

発行日: 2022/01/10

公開日: 2022/02/28

PDF形式でダウンロード (1857K) HTML形式で全画面表示

-

2022 年 39 巻 p. 3-28

2022 年 39 巻 p. 3-28

発行日: 2022/01/10

公開日: 2022/02/28

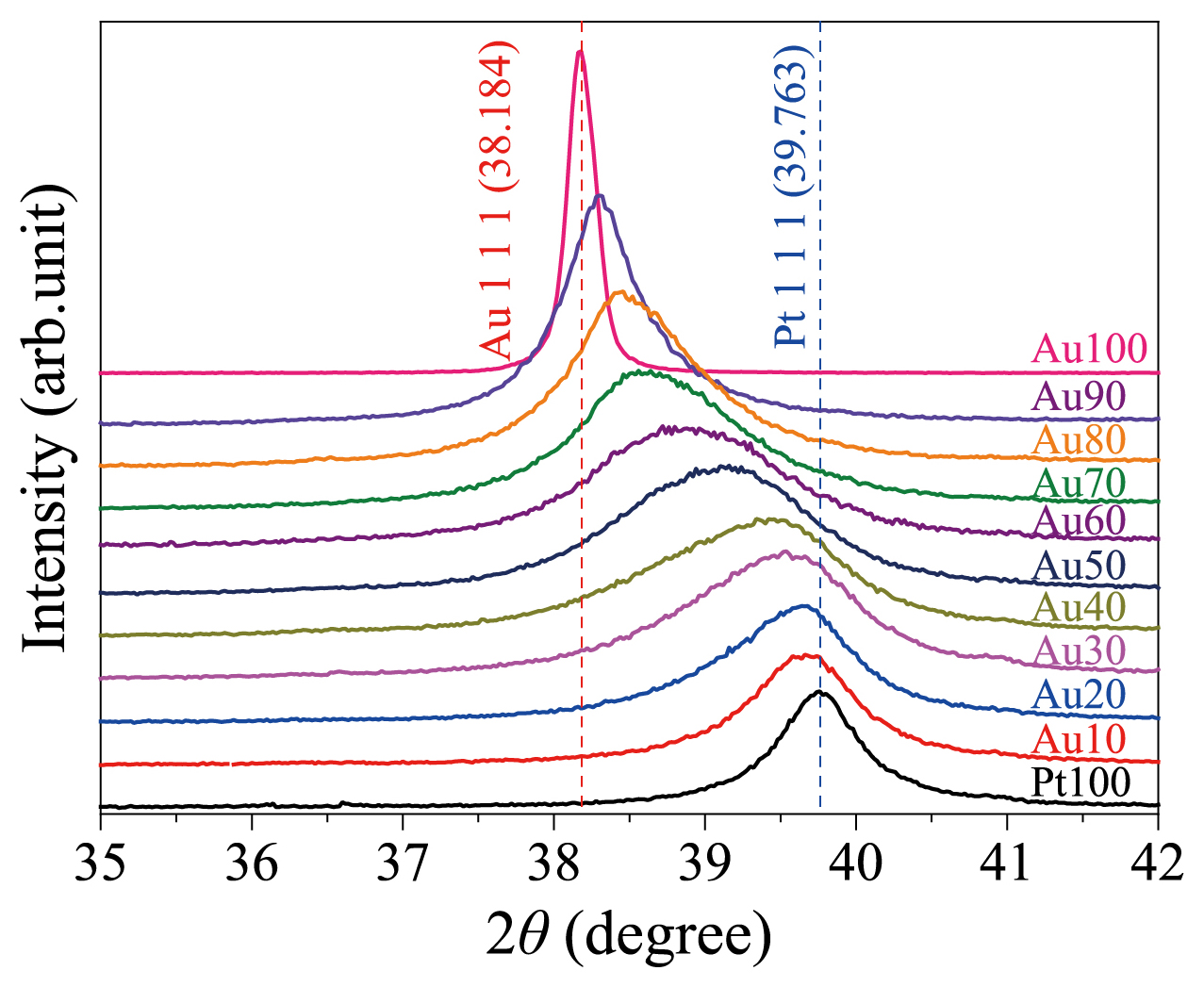

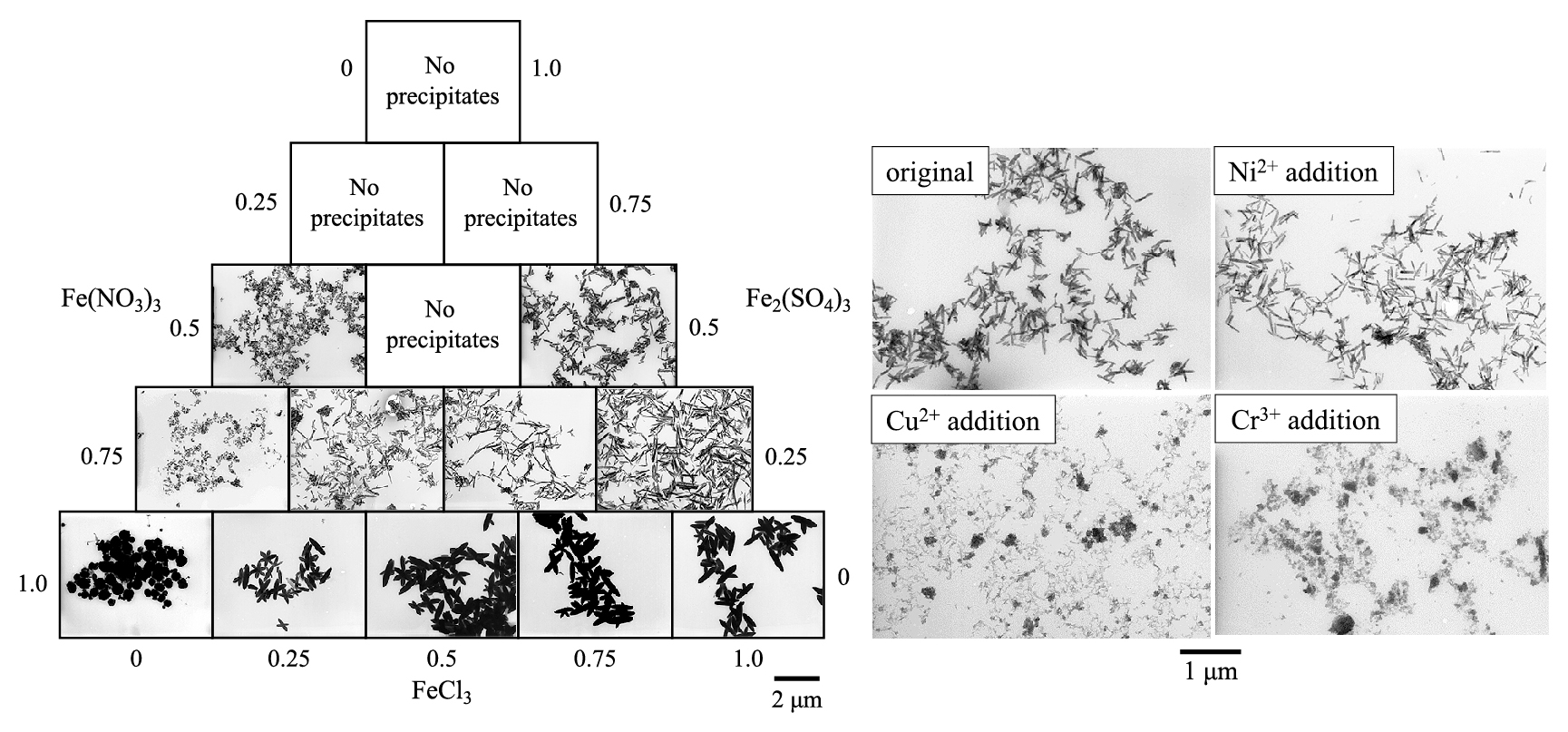

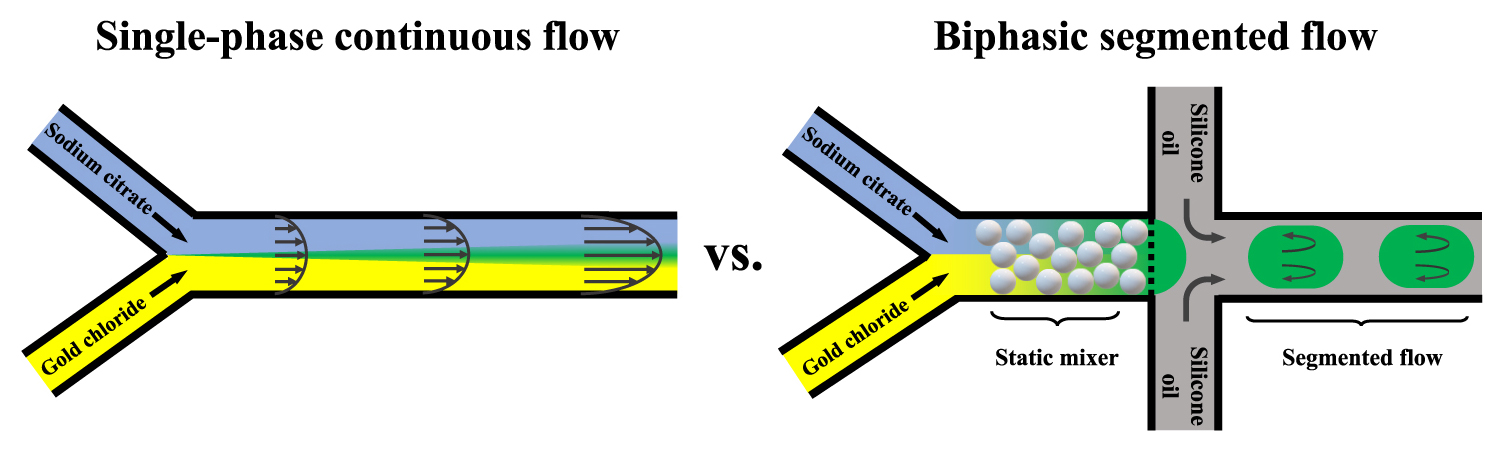

[早期公開] 公開日: 2021/03/06Editor's pickThe current trend in nano- and microparticle technology towards ever increasing complexity requires methods for the multidimensional characterization of the underlying particle property space in terms size, shape, structure, surface and composition. In this review the mathematical description and handling of multidimensional property distributions is outlined. In particular, the authors present and discuss state-of-the-art measurement techniques which are able to extract multidimensional information.

PDF形式でダウンロード (17908K) HTML形式で全画面表示 -

2022 年 39 巻 p. 29-44

発行日: 2022/01/10

公開日: 2022/02/28

[早期公開] 公開日: 2021/06/26PDF形式でダウンロード (7642K) HTML形式で全画面表示 -

2022 年 39 巻 p. 45-61

発行日: 2022/01/10

公開日: 2022/02/28

[早期公開] 公開日: 2021/10/09PDF形式でダウンロード (2538K) HTML形式で全画面表示 -

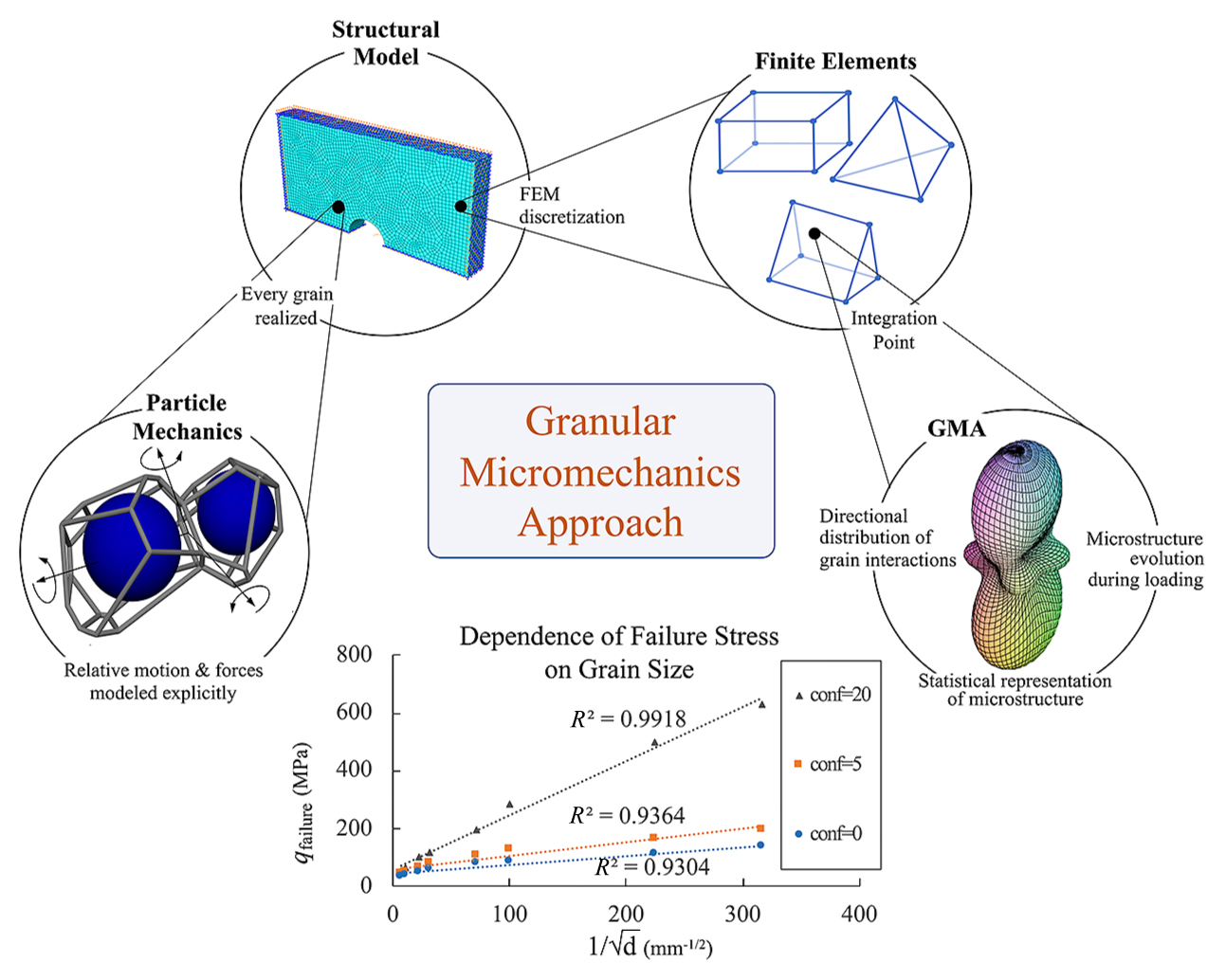

2022 年 39 巻 p. 62-83

2022 年 39 巻 p. 62-83

発行日: 2022/01/10

公開日: 2022/02/28

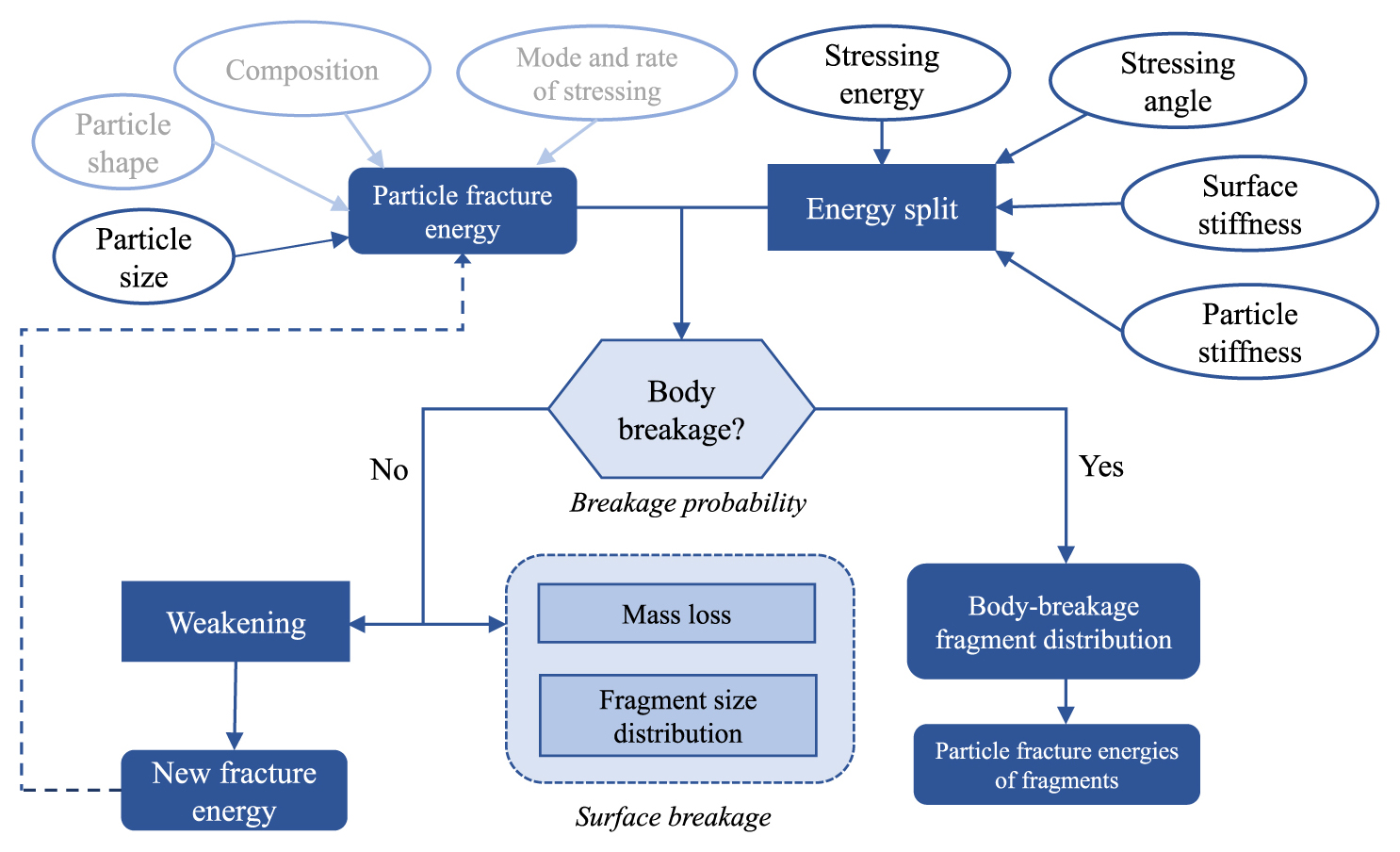

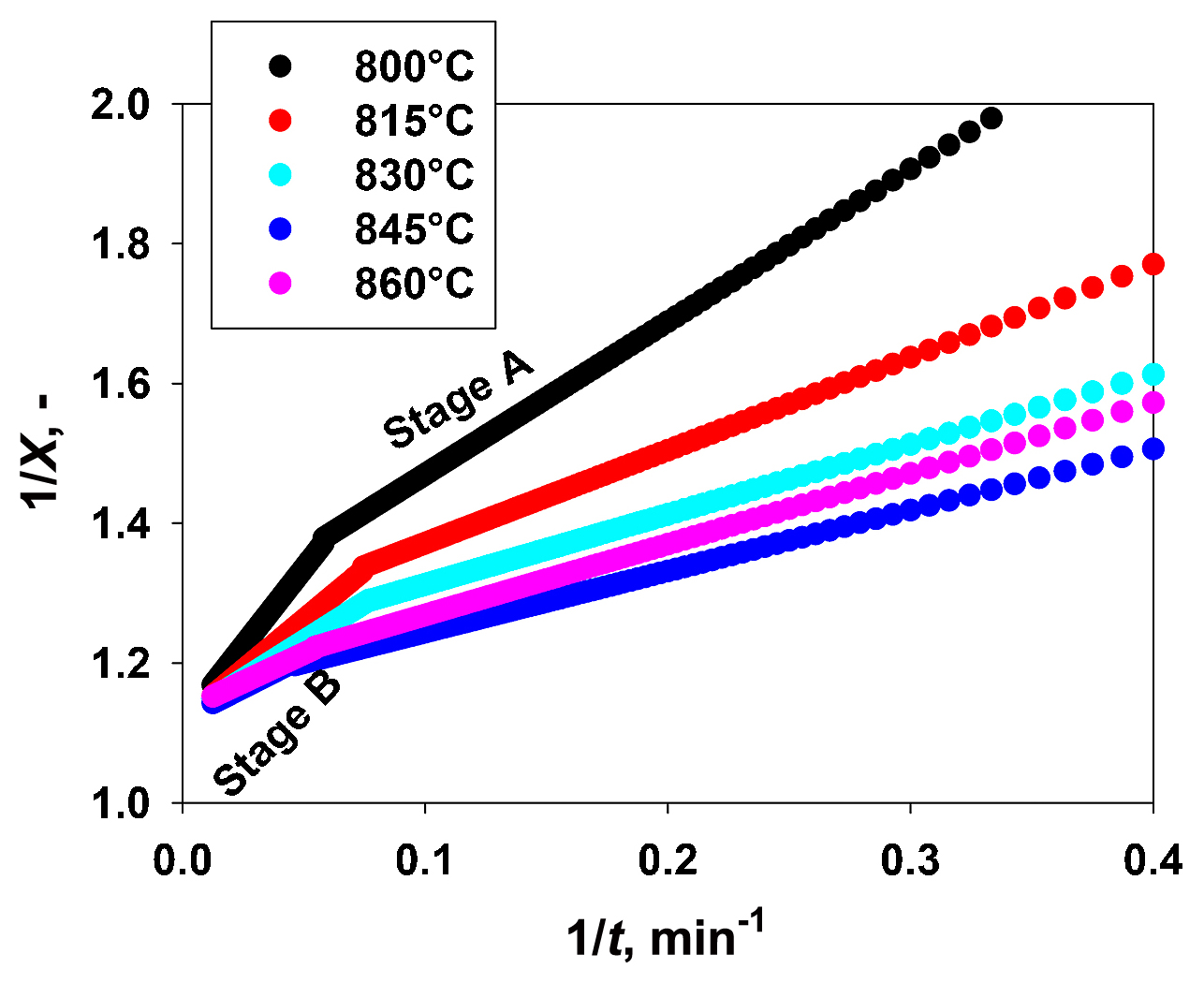

[早期公開] 公開日: 2021/08/07Editor's pickSingle-particle breakage studies were, in the not-so-distant past, only of academic interest, since no tools were available to transfer the microscale information they provide to deal with problems in industry. Fortunately, the discrete element method (DEM), along with properly-formulated population balance models, not make it possible to carry information from single particles to predict the performance of crushers, mills and handling systems that may cause their mechanical degradation. The work critically analyzes one model that has been found quite powerful in this task.

PDF形式でダウンロード (3198K) HTML形式で全画面表示 -

2022 年 39 巻 p. 84-99

発行日: 2022/01/10

公開日: 2022/02/28

[早期公開] 公開日: 2021/06/26PDF形式でダウンロード (6974K) HTML形式で全画面表示 -

2022 年 39 巻 p. 100-109

発行日: 2022/01/10

公開日: 2022/02/28

[早期公開] 公開日: 2021/09/11PDF形式でダウンロード (1614K) HTML形式で全画面表示 -

2022 年 39 巻 p. 110-118

発行日: 2022/01/10

公開日: 2022/02/28

[早期公開] 公開日: 2020/10/17PDF形式でダウンロード (8785K) HTML形式で全画面表示 -

2022 年 39 巻 p. 119-129

発行日: 2022/01/10

公開日: 2022/02/28

[早期公開] 公開日: 2020/11/28PDF形式でダウンロード (4911K) HTML形式で全画面表示 -

2022 年 39 巻 p. 130-149

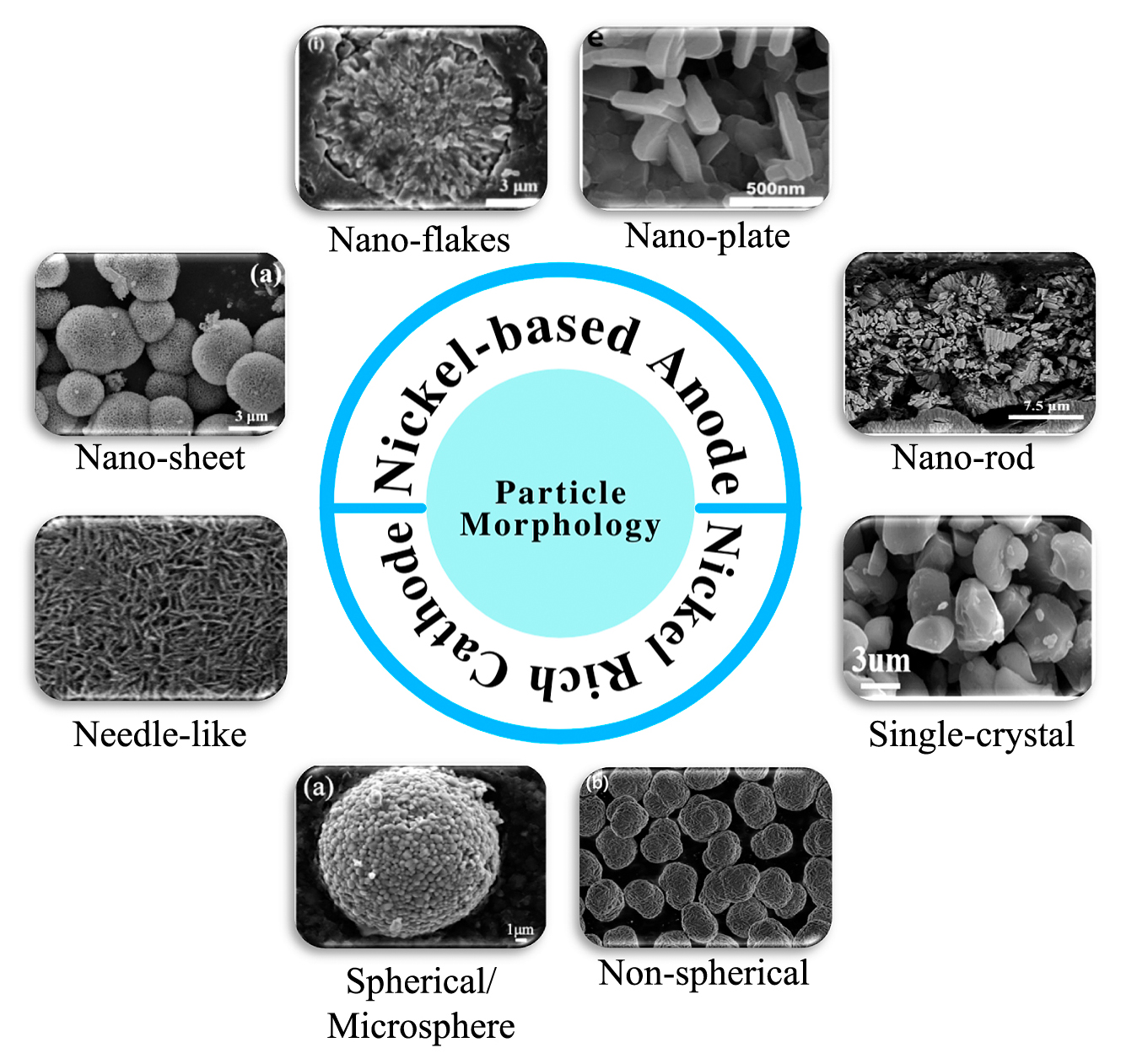

2022 年 39 巻 p. 130-149

発行日: 2022/01/10

公開日: 2022/02/28

[早期公開] 公開日: 2021/09/18Editor's pickNickel is set to play a pivotal role in the next chapter of energy storage. Over the next decade, nickel-based Li-ion batteries are expected to dominate the battery market for both energy storage systems (ESS) and electric vehicles. One of the key features of nickel-based active materials is their morphology; the shape and size of the particles can affect the electrochemical performance of the active materials. Both nickel-containing anode and cathode materials with excellent morphology have been reported to have high capacity, excellent cycle stability, and rate-ability. These key performance metrics demonstrate the promising future for the development of a clean and sustainable energy industry.

PDF形式でダウンロード (10346K) HTML形式で全画面表示 -

2022 年 39 巻 p. 150-175

発行日: 2022/01/10

公開日: 2022/02/28

[早期公開] 公開日: 2021/10/02PDF形式でダウンロード (7953K) HTML形式で全画面表示 -

2022 年 39 巻 p. 176-192

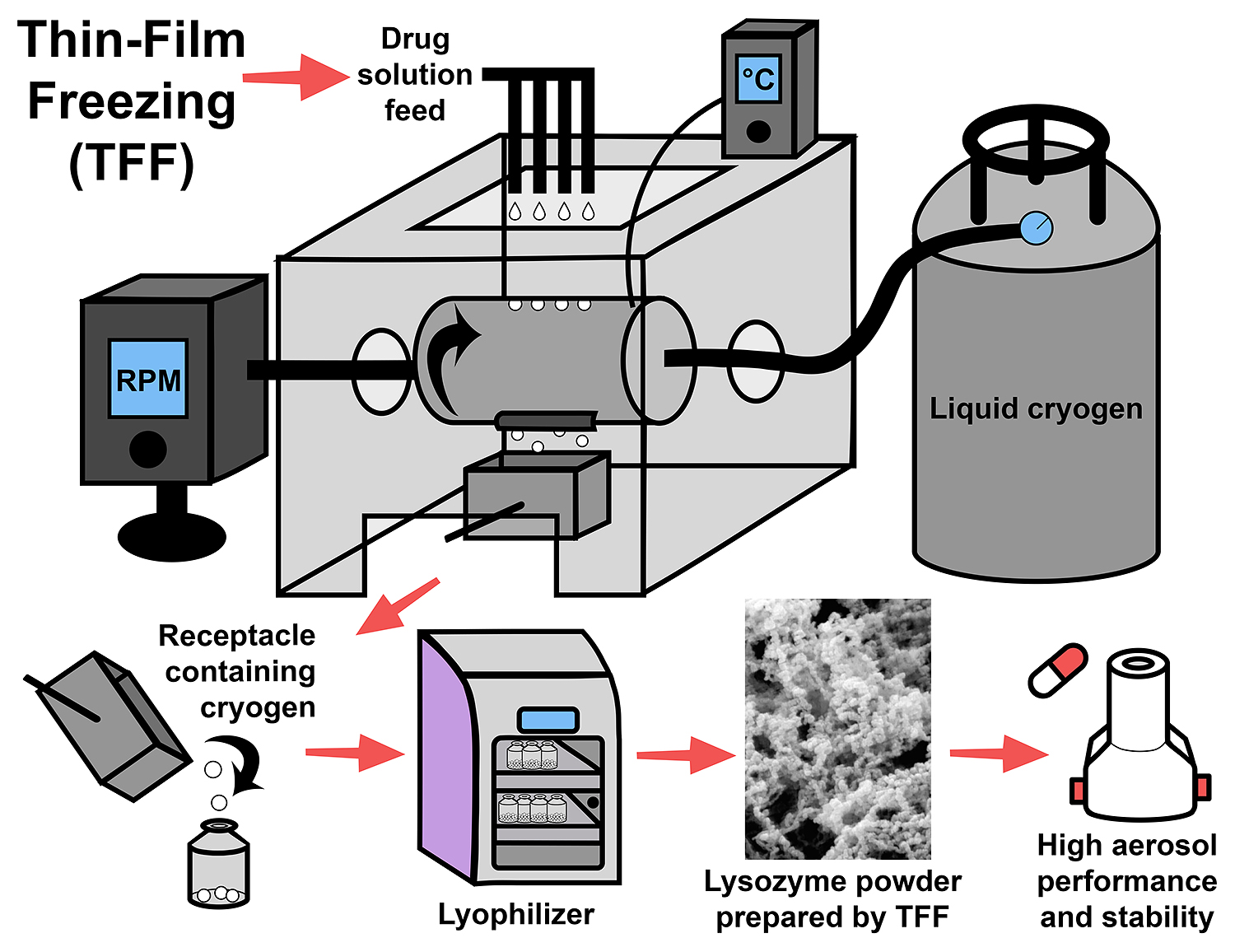

2022 年 39 巻 p. 176-192

発行日: 2022/01/10

公開日: 2022/02/28

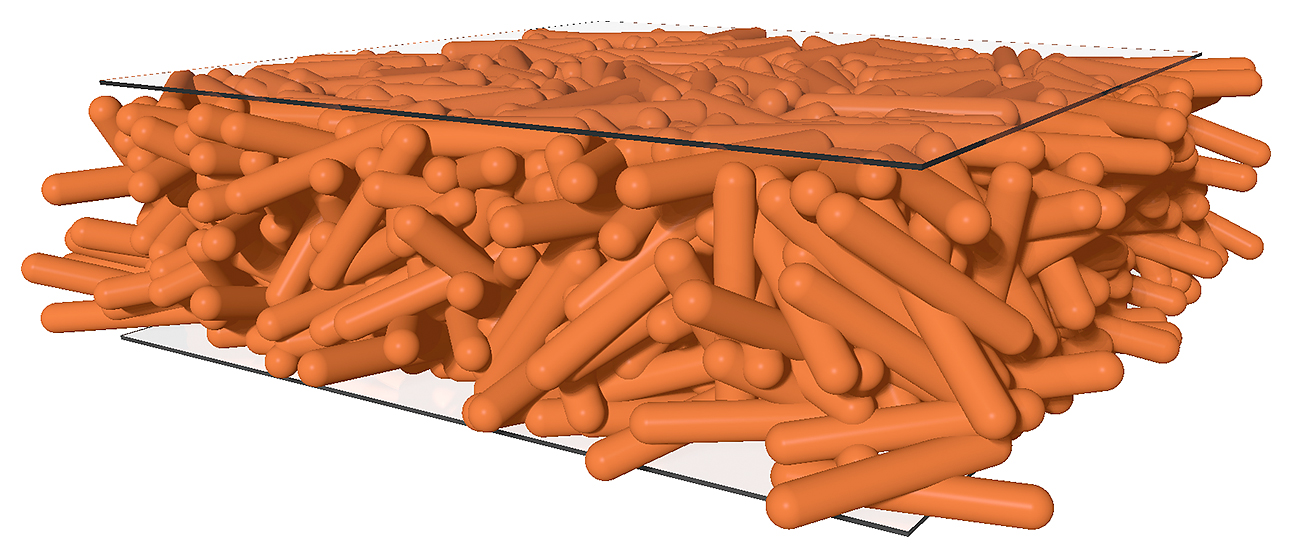

[早期公開] 公開日: 2021/06/26Editor's pickPharmaceutical dry powders with desired aerosol properties are required for efficient pulmonary drug delivery. Thin-film freezing (TFF) followed by lyophilization is a particle engineering technology that produces highly porous, brittle, powder matrices with excellent aerosol properties and high drug loading. In this review article, the authors describe the TFF technology and discuss the physical and aerosol properties of TFF powders as well as factors affecting those properties. Finally, the authors provide a comprehensive review of published literature for applying the TFF technology to prepare aerosolizable dry powders of protein-based pharmaceuticals for pulmonary delivery.

PDF形式でダウンロード (7772K) HTML形式で全画面表示

-

2022 年 39 巻 p. 193-207

発行日: 2022/01/10

公開日: 2022/02/28

[早期公開] 公開日: 2020/10/03PDF形式でダウンロード (4744K) HTML形式で全画面表示 -

2022 年 39 巻 p. 208-218

発行日: 2022/01/10

公開日: 2022/02/28

[早期公開] 公開日: 2021/08/07PDF形式でダウンロード (20201K) HTML形式で全画面表示 -

2022 年 39 巻 p. 219-229

発行日: 2022/01/10

公開日: 2022/02/28

[早期公開] 公開日: 2021/02/20PDF形式でダウンロード (10306K) HTML形式で全画面表示 -

2022 年 39 巻 p. 230-239

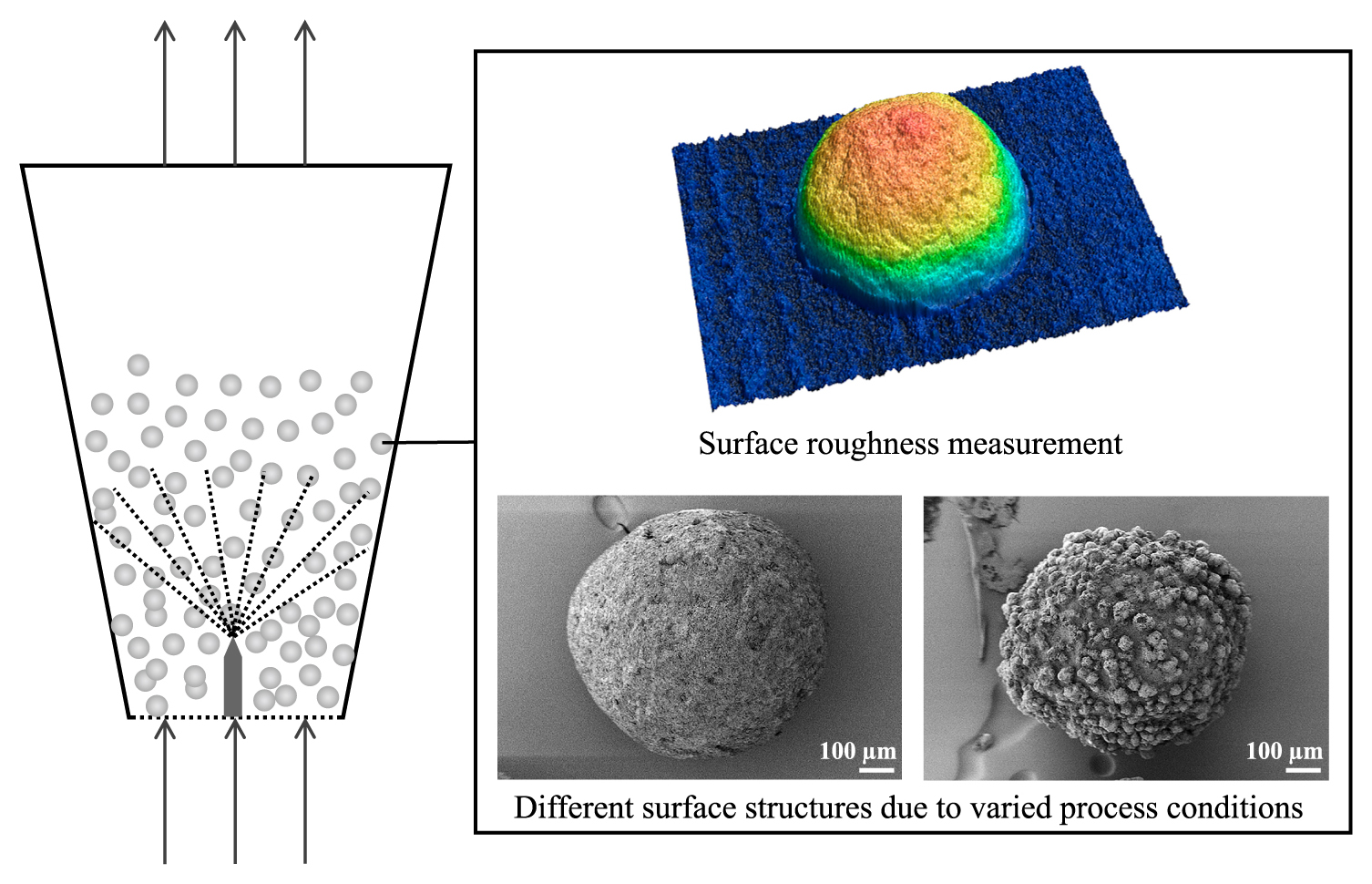

2022 年 39 巻 p. 230-239

発行日: 2022/01/10

公開日: 2022/02/28

[早期公開] 公開日: 2021/09/25Editor's pickDue to their easy handling, transport, and storage compared to liquids and gases, solid products in particulate form are of great interest in both, daily life and industrial applications. Along with the high demand for those products comes the need for a thorough understanding of particle production and modification processes, like fluidized bed spray granulation, to achieve the desired product properties. To contribute to that process understanding and to, in the long term, enable the production of tailor-made particles, this study aims to correlate process parameters and particle surface structure in fluidized bed spray granulation.

PDF形式でダウンロード (6009K) HTML形式で全画面表示 -

2022 年 39 巻 p. 240-250

発行日: 2022/01/10

公開日: 2022/02/28

[早期公開] 公開日: 2021/06/26PDF形式でダウンロード (3409K) HTML形式で全画面表示 -

2022 年 39 巻 p. 251-261

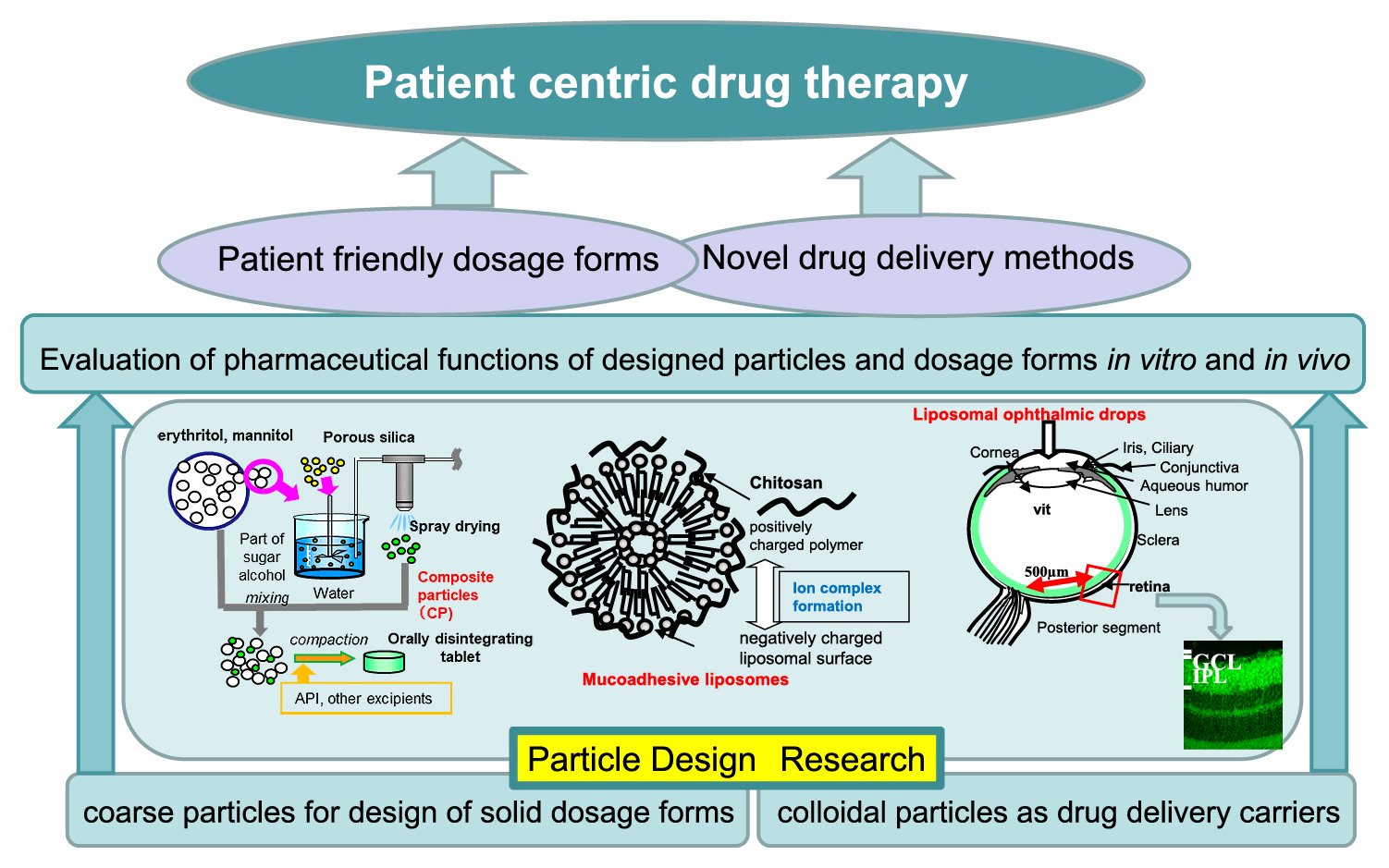

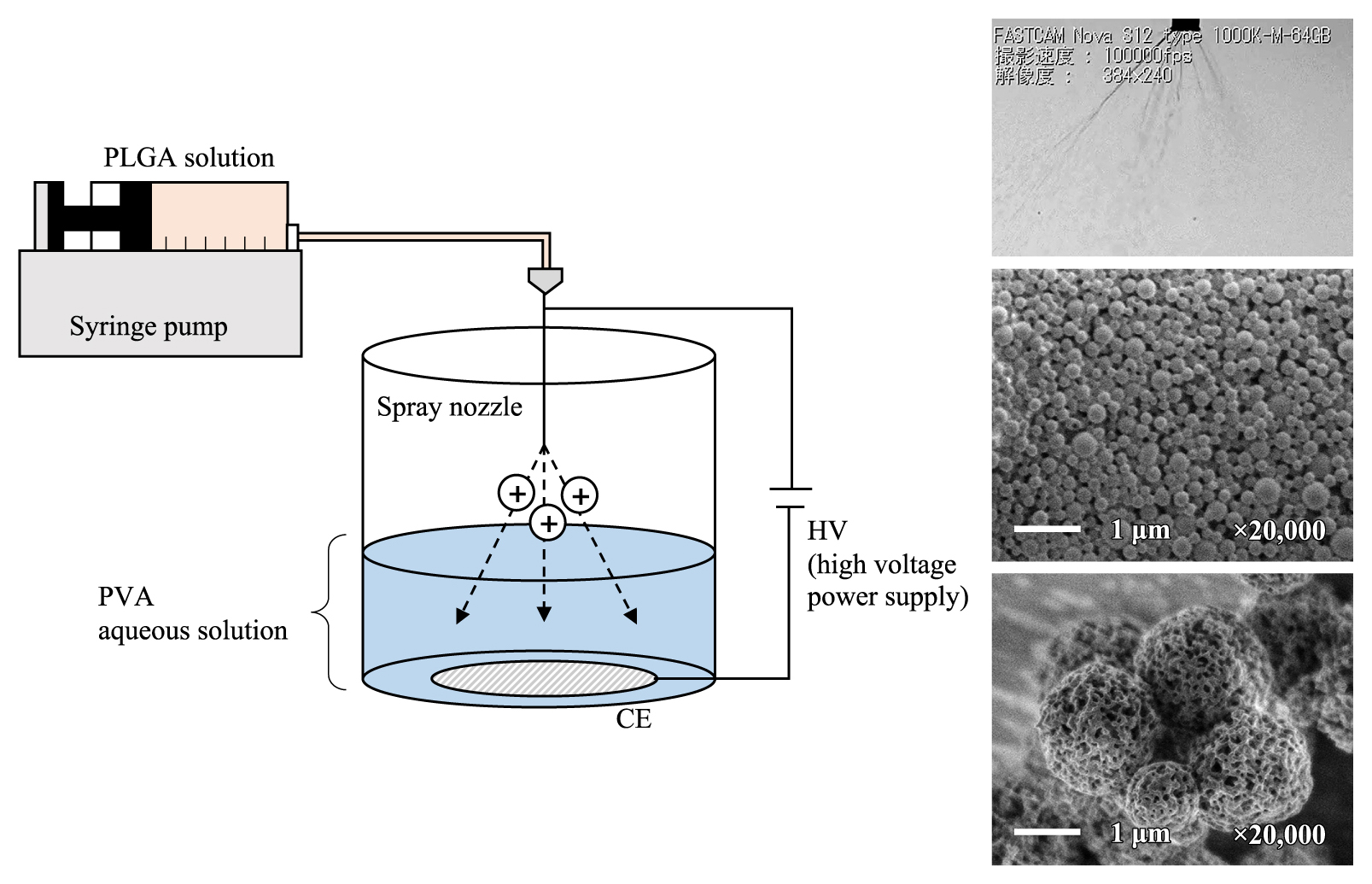

2022 年 39 巻 p. 251-261

発行日: 2022/01/10

公開日: 2022/02/28

[早期公開] 公開日: 2021/10/09Editor's pickDelivery systems using nanoparticles and microparticles composed of biodegradable polymers such as polylactic glycolic acid have attracted much attention in the pharmaceutical and cosmetic fields to the delivery of active ingredients into the body. This paper describes a novel microparticle preparation method using fine-charged droplets as reaction fields generated by electrospray. This method is unique and impactful because tailored PLGA microspheres with various sizes and different structures such as porous and solid structures can be prepared by controlling the process conditions. The formation mechanism of particles with different sizes and structures within the droplets is also explained.

PDF形式でダウンロード (12263K) HTML形式で全画面表示 -

2022 年 39 巻 p. 262-269

発行日: 2022/01/10

公開日: 2022/02/28

[早期公開] 公開日: 2021/07/22PDF形式でダウンロード (10920K) HTML形式で全画面表示

-

2022 年 39 巻 p. 270

発行日: 2022/01/10

公開日: 2022/02/28

[早期公開] 公開日: 2021/03/20PDF形式でダウンロード (696K) HTML形式で全画面表示

-

2022 年 39 巻 p. 271-274

発行日: 2022/01/10

公開日: 2022/02/28

PDF形式でダウンロード (2789K) HTML形式で全画面表示 -

2022 年 39 巻 p. 275

発行日: 2022/01/10

公開日: 2022/02/28

PDF形式でダウンロード (6510K) HTML形式で全画面表示 -

2022 年 39 巻 p. 276

発行日: 2022/01/10

公開日: 2022/02/28

PDF形式でダウンロード (3016K) HTML形式で全画面表示 -

2022 年 39 巻 p. 277

発行日: 2022/01/10

公開日: 2022/02/28

PDF形式でダウンロード (625K) HTML形式で全画面表示

- |<

- <

- 1

- >

- >|