- |<

- <

- 1

- >

- >|

-

2024 年41 巻 p. Cover41_1

発行日: 2024/01/10

公開日: 2024/02/29

PDF形式でダウンロード (1454K) HTML形式で全画面表示 -

2024 年41 巻 p. EdBrd41_1

発行日: 2024/01/10

公開日: 2024/02/29

PDF形式でダウンロード (3483K) HTML形式で全画面表示

-

2024 年41 巻 p. i-v

発行日: 2024/01/10

公開日: 2024/02/29

PDF形式でダウンロード (8132K) HTML形式で全画面表示

-

2024 年41 巻 p. vi

発行日: 2024/01/10

公開日: 2024/02/29

PDF形式でダウンロード (1652K) HTML形式で全画面表示 -

2024 年41 巻 p. 1-2

発行日: 2024/01/10

公開日: 2024/02/29

PDF形式でダウンロード (1851K) HTML形式で全画面表示

-

2024 年41 巻 p. 3-25

発行日: 2024/01/10

公開日: 2024/02/29

[早期公開] 公開日: 2023/07/15PDF形式でダウンロード (21634K) HTML形式で全画面表示 -

2024 年41 巻 p. 26-41

2024 年41 巻 p. 26-41

発行日: 2024/01/10

公開日: 2024/02/29

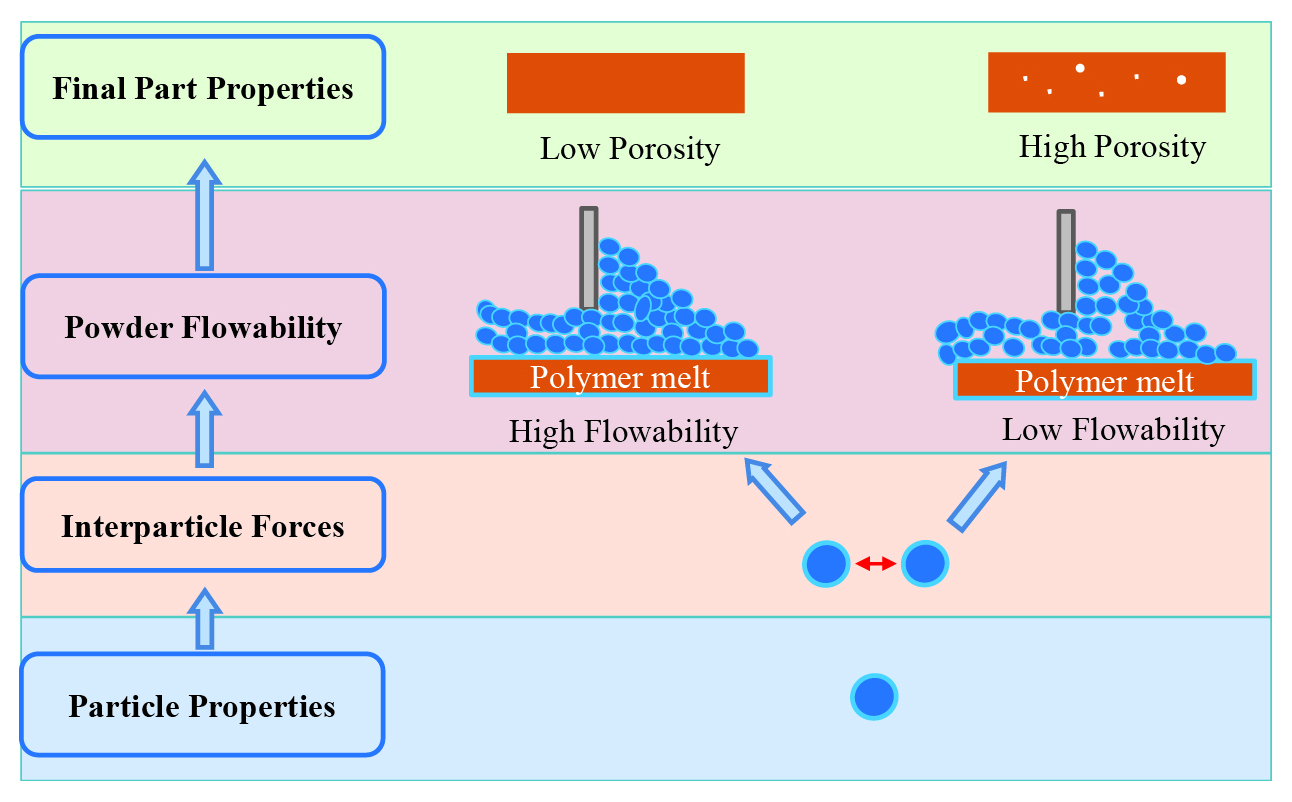

[早期公開] 公開日: 2023/07/29Editor's pickThis review highlights the crucial role of powder flowability in polymer selective laser sintering (SLS), a leading additive manufacturing technology for producing highly complex and customized components. It explores key flowability characterization methods suitable for SLS and examines how powder properties influence laser–material interactions and final part quality. Additionally, the paper discusses various strategies from the literature to enhance powder spreading, addressing a critical challenge in expanding the range of polymer materials suitable for SLS. This review serves as a valuable resource for advancing material development and optimizing the SLS printing performance.

PDF形式でダウンロード (5856K) HTML形式で全画面表示 -

2024 年41 巻 p. 42-57

発行日: 2024/01/10

公開日: 2024/02/29

[早期公開] 公開日: 2023/06/17PDF形式でダウンロード (6827K) HTML形式で全画面表示 -

2024 年41 巻 p. 58-77

2024 年41 巻 p. 58-77

発行日: 2024/01/10

公開日: 2024/02/29

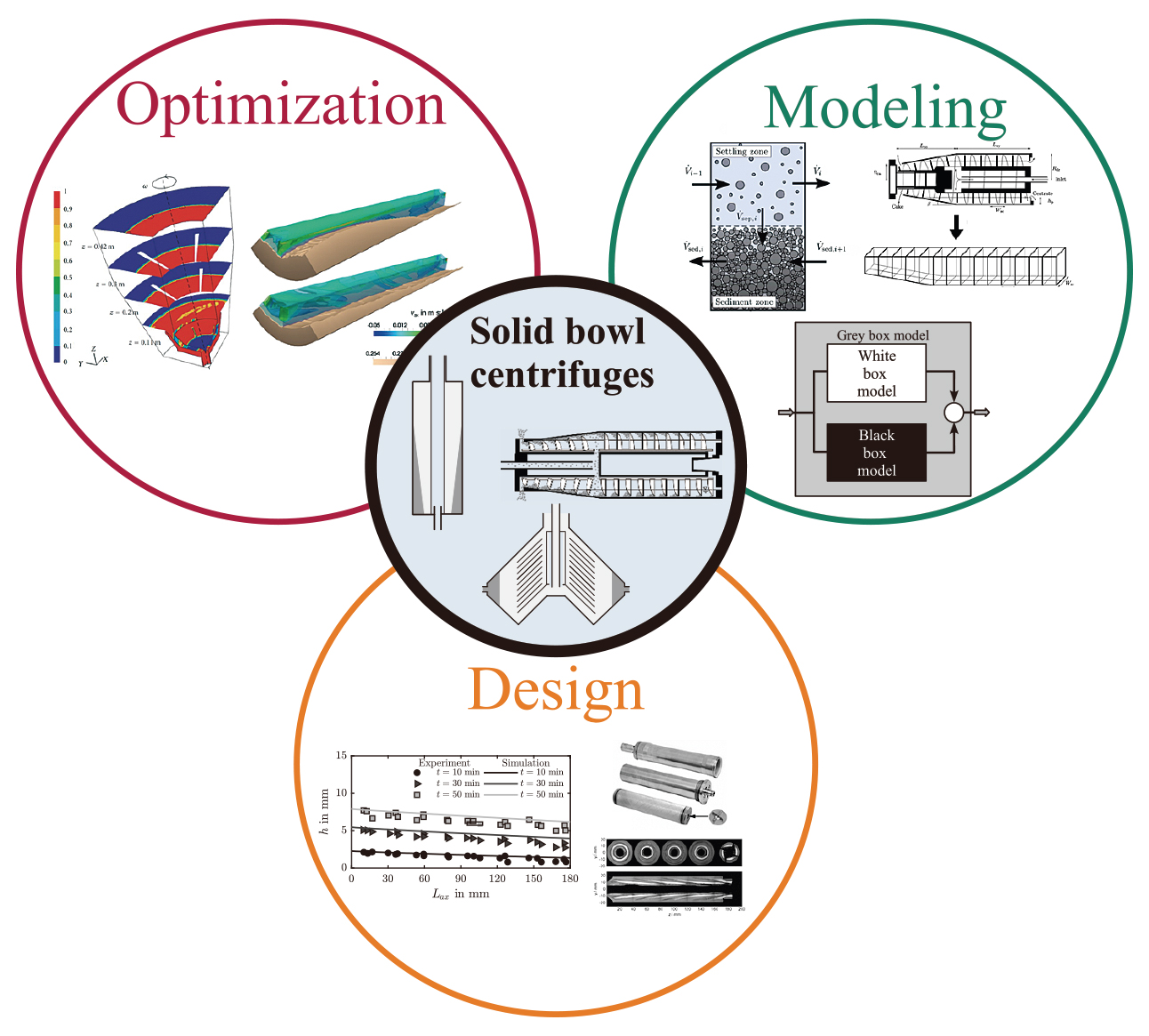

[早期公開] 公開日: 2023/06/30Editor's pickThis review provides an overview of the many applications of solid bowl centrifuges, the different types of machines, and the modeling strategies. Common to all centrifuges is that the material behavior has a significant influence on the process behavior; therefore, the interaction between material and process is of critical importance. Different modeling strategies can be used to better understand and optimize separation processes. Furthermore, the integration of process analytics into the operation of solid bowl centrifuges allows on-line optimization of the process behavior.

PDF形式でダウンロード (8844K) HTML形式で全画面表示 -

2024 年41 巻 p. 78-107

発行日: 2024/01/10

公開日: 2024/02/29

[早期公開] 公開日: 2023/09/15PDF形式でダウンロード (17174K) HTML形式で全画面表示 -

2024 年41 巻 p. 108-122

2024 年41 巻 p. 108-122

発行日: 2024/01/10

公開日: 2024/02/29

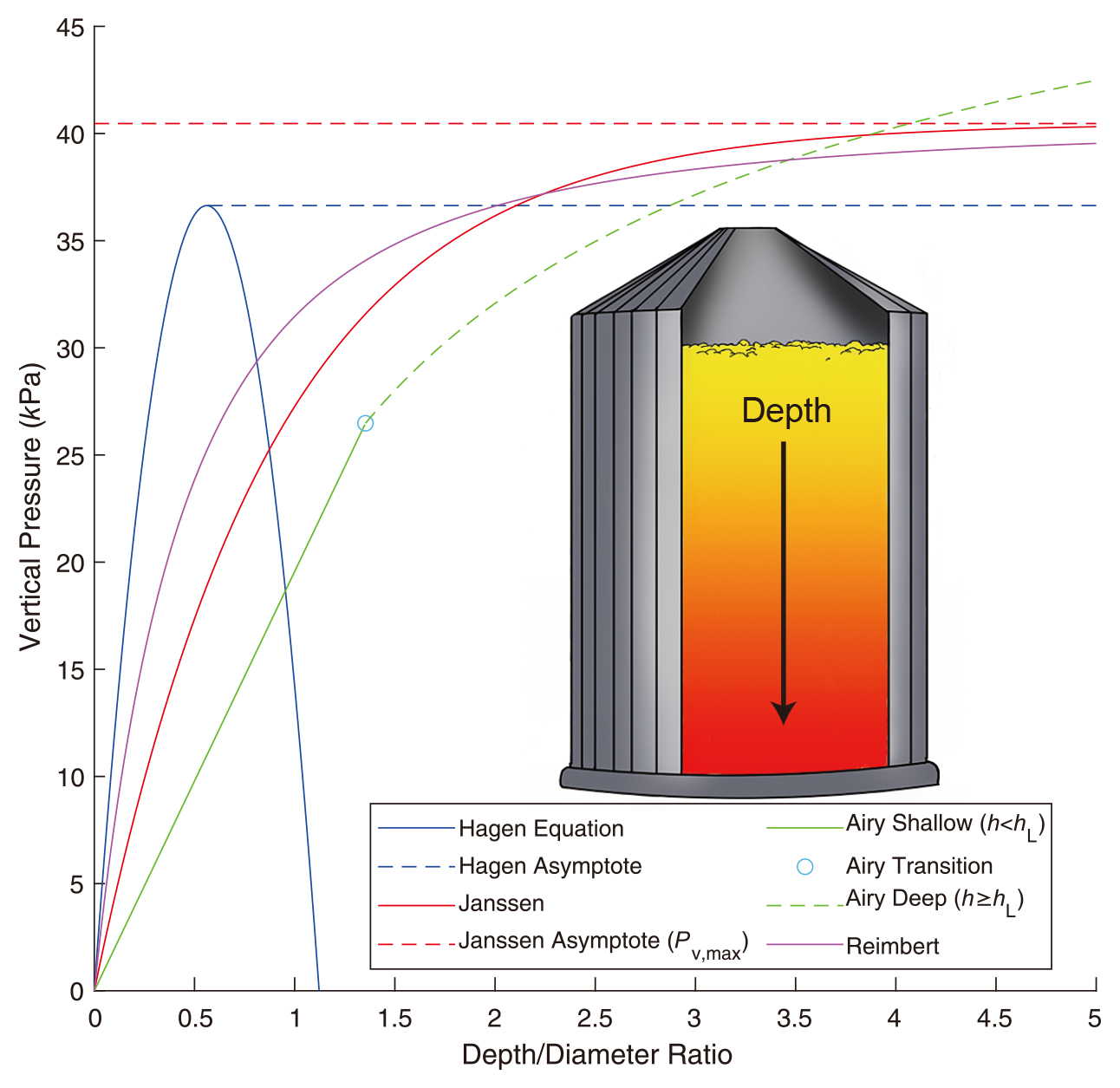

[早期公開] 公開日: 2023/07/29Editor's pickThis comprehensive review examines the evolution and applications of the Janssen equation, which is the dominant expression for calculating pressures in bulk storage structures. This paper discusses the history of the model, analyzes the limitations of Janssen’s original formulation and explores various modifications and alternative models developed to better represent shear stress distributions. By examining key parameters like stress ratios (k), friction coefficients (μ, ϕ), and bulk density (ρ), along with modern approaches such as continuum elastic and microscopic theories, this work provides valuable insights for engineers and researchers working with bulk solids storage systems and granular materials.

PDF形式でダウンロード (4352K) HTML形式で全画面表示 -

2024 年41 巻 p. 123-139

発行日: 2024/01/10

公開日: 2024/02/29

[早期公開] 公開日: 2023/03/25PDF形式でダウンロード (5172K) HTML形式で全画面表示 -

2024 年41 巻 p. 140-150

発行日: 2024/01/10

公開日: 2024/02/29

[早期公開] 公開日: 2023/06/30PDF形式でダウンロード (13521K) HTML形式で全画面表示 -

2024 年41 巻 p. 151-171

発行日: 2024/01/10

公開日: 2024/02/29

[早期公開] 公開日: 2023/08/31PDF形式でダウンロード (27294K) HTML形式で全画面表示 -

2024 年41 巻 p. 172-182

発行日: 2024/01/10

公開日: 2024/02/29

[早期公開] 公開日: 2022/12/29PDF形式でダウンロード (11420K) HTML形式で全画面表示 -

2024 年41 巻 p. 183-196

2024 年41 巻 p. 183-196

発行日: 2024/01/10

公開日: 2024/02/29

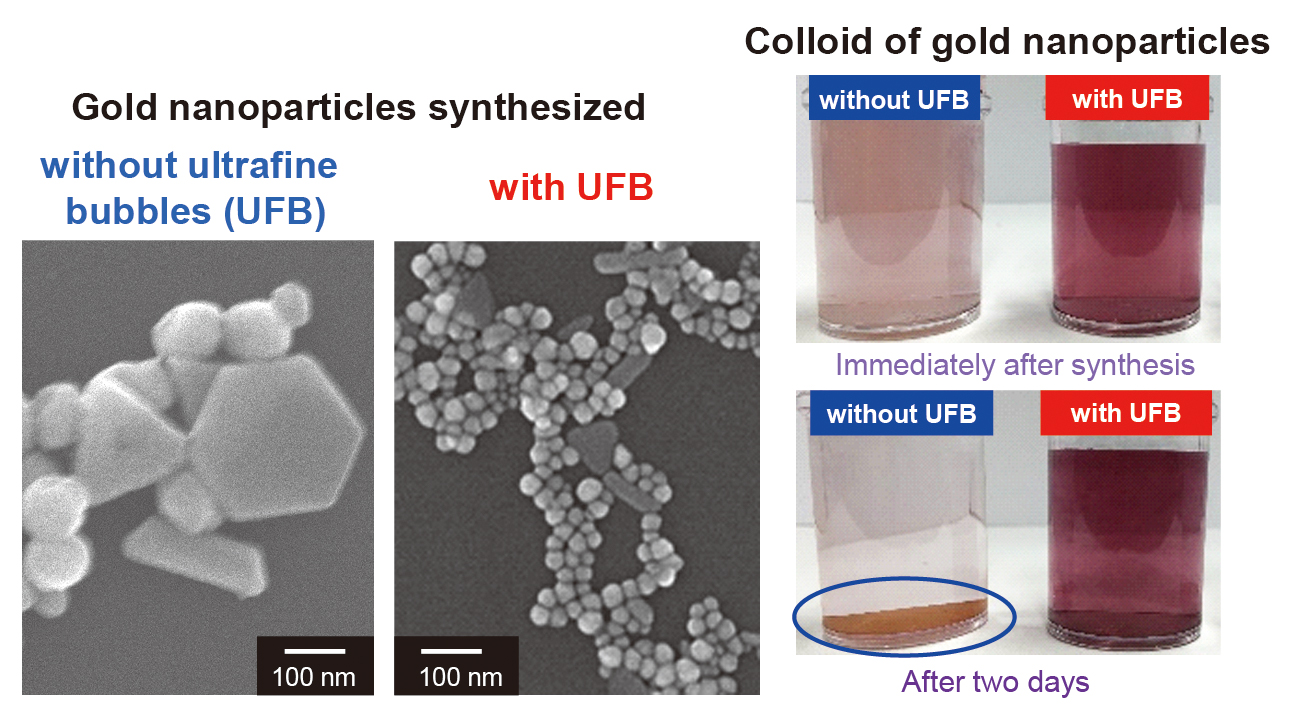

[早期公開] 公開日: 2023/03/25Editor's pickIn recent years, ultrafine bubbles have been actively used in the cleaning field. Ultrafine bubbles have numerous advantages, including their chemical-free nature, hydrophobic, pH-dependent surface charge, and extraordinarily long lifetime. By selecting the ultrasonic frequency to be irradiated, the generation and removal of ultrafine bubbles can be controlled. They can produce hollow nanoparticles and enhance ionic adsorption on activated carbon. This review discusses the fundamental and sonochemical characteristics of ultrafine bubbles and their applications in particle-related technologies, encompassing fine particle synthesis, adsorption, desorption, extraction, cleaning, and fouling prevention.

PDF形式でダウンロード (7316K) HTML形式で全画面表示 -

2024 年41 巻 p. 197-220

発行日: 2024/01/10

公開日: 2024/02/29

[早期公開] 公開日: 2023/08/31PDF形式でダウンロード (20970K) HTML形式で全画面表示

-

2024 年41 巻 p. 221-228

発行日: 2024/01/10

公開日: 2024/02/29

[早期公開] 公開日: 2023/01/28PDF形式でダウンロード (9743K) HTML形式で全画面表示 -

2024 年41 巻 p. 229-241

発行日: 2024/01/10

公開日: 2024/02/29

[早期公開] 公開日: 2023/08/31PDF形式でダウンロード (16935K) HTML形式で全画面表示 -

2024 年41 巻 p. 242-253

発行日: 2024/01/10

公開日: 2024/02/29

[早期公開] 公開日: 2023/06/03PDF形式でダウンロード (9336K) HTML形式で全画面表示 -

2024 年41 巻 p. 254-264

発行日: 2024/01/10

公開日: 2024/02/29

[早期公開] 公開日: 2023/06/17PDF形式でダウンロード (26048K) HTML形式で全画面表示 -

2024 年41 巻 p. 265-279

発行日: 2024/01/10

公開日: 2024/02/29

[早期公開] 公開日: 2023/03/25PDF形式でダウンロード (13631K) HTML形式で全画面表示

-

2024 年41 巻 p. 280-281

発行日: 2024/01/10

公開日: 2024/02/29

PDF形式でダウンロード (9961K) HTML形式で全画面表示 -

2024 年41 巻 p. 282-283

発行日: 2024/01/10

公開日: 2024/02/29

PDF形式でダウンロード (9354K) HTML形式で全画面表示 -

2024 年41 巻 p. 284-285

発行日: 2024/01/10

公開日: 2024/02/29

PDF形式でダウンロード (5196K) HTML形式で全画面表示 -

2024 年41 巻 p. 286

発行日: 2024/01/10

公開日: 2024/02/29

PDF形式でダウンロード (702K) HTML形式で全画面表示

- |<

- <

- 1

- >

- >|