All issues

Successor

Volume 36, Issue 11

Displaying 1-12 of 12 articles from this issue

- |<

- <

- 1

- >

- >|

Preface

-

Hidenori NOGUCHI2015Volume 36Issue 11 Pages 559

Published: November 10, 2015

Released on J-STAGE: December 01, 2015

JOURNAL FREE ACCESSDownload PDF (169K)

Special Issue: Hydrogen Storage, Carriage, and Handling

-

Junji INUKAIArticle type: Introduction

2015Volume 36Issue 11 Pages 560-561

Published: November 10, 2015

Released on J-STAGE: December 01, 2015

JOURNAL FREE ACCESSStorage, transport, and handling of hydrogen are now actively investigated. In this special issue, articles on the present status of hydrogen cylinders, metal and organic hydrides for hydrogen storage, and ammonium as a hydrogen carrier are presented by authors of two universities and three companies.View full abstractDownload PDF (194K) -

Proposal of Design Method Enabling Cr-Mo Steels to be Used in High-Pressure Hydrogen Gas EnvironmentHisao MATSUNAGA, Junichiro YAMABE, Saburo MATSUOKAArticle type: Current Topic

2015Volume 36Issue 11 Pages 562-567

Published: November 10, 2015

Released on J-STAGE: December 01, 2015

JOURNAL FREE ACCESSThis paper presents a design method enabling Cr-Mo steel to be used in high-pressure hydrogen gas. On the basis of a series of experiments, it is suggested that the components can be designed by the conventional design by rule if the following criteria are satisfied under the maximum design pressure of hydrogen gas : firstly, there is no degradation in the tensile strength in slow strain rate tensile (SSRT) test, and secondly, there is no degradation in the fatigue limit. It is also proposed that the components can be designed by the conventional design by analysis, if the following criteria are satisfied under the maximum design pressure of hydrogen gas : firstly, there is an upper bound on the acceleration of fatigue crack growth in hydrogen environment, and secondly, the maximum stress intensity factor of a near-through-wall crack is less than the value of the fracture toughness in air. View full abstractDownload PDF (1845K)

View full abstractDownload PDF (1845K) -

Tatsuya FUURAArticle type: Current Topic

2015Volume 36Issue 11 Pages 568-571

Published: November 10, 2015

Released on J-STAGE: December 01, 2015

JOURNAL FREE ACCESSHydrogen attracts attention as clean energy of the next generation. In order to put a hydrogen energy system to practical use, the technical development of safe and efficient storage/transportation media is on of the most important subjects. Hydrogen storage tank which is under development can be classified into following types; 1) high pressure hydrogen tank, 2) liquid hydrogen tank, 3) metal hydride storage tank and the other. In this paper, I provide the development status of recent “metal hydride storage tank”. View full abstractDownload PDF (897K)

View full abstractDownload PDF (897K) -

Makoto OKUDAArticle type: Current Topic

2015Volume 36Issue 11 Pages 572-576

Published: November 10, 2015

Released on J-STAGE: December 01, 2015

JOURNAL FREE ACCESS‘Liquid organic hydrides’ (such as Methylcyclohexane, generally called Organic hydrides in Japan) are in liquid form under atmospheric temperature and pressure which are able to be hydrogenated and dehydrogenated by a thermochemical process, thus allowing the storage holding high hydrogen content, carriage utilizing present oil related infrastructures (container tanks, storage tanks, filling stations) with little or no modification and production of hydrogen ‘on demand’ for fuel cell vehicles or stationary fuel cells at the point of use. The uniqueness of our mobile hydrogenation equipment is to be able to store fluctuating green hydrogen derived from renewable energy in conjunction with water electrolysis, and available to scale up its size as refinery equipment. Dehydrogenation is endothermic reaction, so our dehydrogenation reactor is designed with consideration of efficient heat transfer utilizing threefold alumite cylinders heated by oxidation reaction with a drop of Toluene (residue of dehydrogenation). View full abstractDownload PDF (1295K)

View full abstractDownload PDF (1295K) -

—SPERA Hydrogen® System—Yoshimi OKADA, Makoto YASUIArticle type: Current Topic

2015Volume 36Issue 11 Pages 577-582

Published: November 10, 2015

Released on J-STAGE: December 01, 2015

JOURNAL FREE ACCESSChiyoda Corporation has been completed a technical development of “SPERA H2” system for the massive H2 storage and transportation technology through a pilot plant demonstration. The system employs the Organic Chemical Hydride method (OCH method). In the method, hydrogen is fixed to toluene and converted to methylcyclohexane (MCH) as a Liquid Organic Hydrogen Carrier (LOHC). Toluene and MCH are gasoline components and in the liquid phase under the ambient temperature and pressure. In the method, the potential risk for the massive hydrogen storage and transportation can be reduced to the conventional one for the gasoline storage and transportation, since hydrogen is stored as MCH in the liquid phase under the ambient condition as same as gasoline. It is considered that the conventional storage tanks and the chemical tankers which are conventional infrastructure can be used to this system is also the merit. View full abstractDownload PDF (1686K)

View full abstractDownload PDF (1686K) -

Yoshitsugu KOJIMAArticle type: Current Topic

2015Volume 36Issue 11 Pages 583-588

Published: November 10, 2015

Released on J-STAGE: December 01, 2015

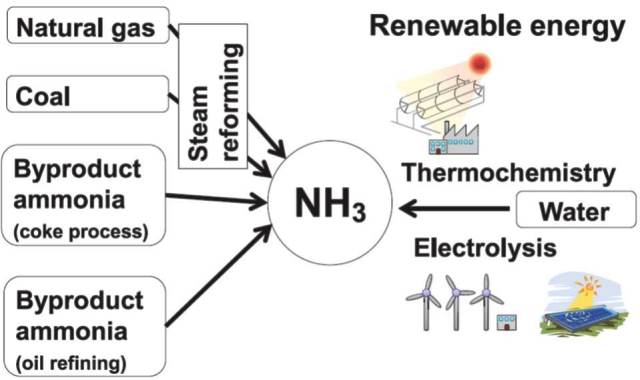

JOURNAL FREE ACCESSHydrogen can be stored in many different forms as compressed or liquefied hydrogen in tanks, as a hydrogen-absorbing alloy, as metal hydrides with light elements, as organic hydrides or by adsorption on carbon materials. Ammonia has been expected as a hydrogen energy carrier because it has a high H2 storage capacity with 17.8 wt% and 10.7-12.1 kgH2/100 L. The volumetric hydrogen density is 1.5-2.5 times of liquid hydrogen, and it is easily liquefied under about 1 MPa at room temperature. Ammonia has advantages in cost and convenience as a hydrogen carrier for fuel cell vehicles, energy carrier for solid oxide fuel cell (SOFC), gas turbine of electric power plants. Current PEM fuel cells are poisoned by trace levels (> 0.1 ppm) of ammonia. After hydrogen generation by ammonia cracking, ammonia absorption materials will be useful to produce the high purity hydrogen gas. View full abstractDownload PDF (1400K)

View full abstractDownload PDF (1400K)

Planning Series

Surface Science for Environmental Issues

-

Mitsutsugu HAMAMOTO2015Volume 36Issue 11 Pages 589-591

Published: November 10, 2015

Released on J-STAGE: December 01, 2015

JOURNAL FREE ACCESS

Science Café

Research Abroad

-

Donald A. TRYK2015Volume 36Issue 11 Pages 592-593

Published: November 10, 2015

Released on J-STAGE: December 01, 2015

JOURNAL FREE ACCESSDownload PDF (232K)

Conference Report

-

Muneo YORINAGA2015Volume 36Issue 11 Pages 594

Published: November 10, 2015

Released on J-STAGE: December 01, 2015

JOURNAL FREE ACCESSDownload PDF (302K)

Qualifying Examination for Surface Science Engineers

-

2015Volume 36Issue 11 Pages 595

Published: November 10, 2015

Released on J-STAGE: December 01, 2015

JOURNAL FREE ACCESSDownload PDF (1248K)

News & Trends

-

2015Volume 36Issue 11 Pages 596

Published: November 10, 2015

Released on J-STAGE: December 01, 2015

JOURNAL FREE ACCESSDownload PDF (156K)

- |<

- <

- 1

- >

- >|