- |<

- <

- 1

- >

- >|

-

Keiko OHTSUKA2018Volume 54Issue 8 Pages 310-316

Published: August 01, 2018

Released on J-STAGE: November 20, 2018

JOURNAL FREE ACCESS4,4’-Diphenylmethane bismaleimide(BMI) resin possesses high heat resistance, favorable mechanicaland dielectric properties, and excellent chemical resistance. High heat resistance is due to its aromaticheterocyclicstructure and the high cross-link density of cured resin. Therefore, these polymers havebeen widely used as a matrix for advanced composites in aerospace, electronics, and other related hightechindustries. While the excellent properties of these materials are favorable for real-world applications,the cured resin is brittle due to the high cross-link density of cured network. This drawback has becomemore crucial due to the recent requirements for the improvement in the toughness of BMI resin used inindustries such as aerospace and electronics. In this paper, the material design for improving the toughness ofbismaleimide resin was summarized.

View full abstractDownload PDF (4605K)

-

Masahiro FURUTANI, Koji ARIMITSU2018Volume 54Issue 8 Pages 302-309

Published: August 01, 2018

Released on J-STAGE: November 20, 2018

JOURNAL FREE ACCESSIn this article, we review on dismantlable adhesives using cleavage reactions of chemical bonds. We featuredisulfide bonds, and describe their reactions and applications. We also show the results and discuss on ourthermally dismantlable photoadhesive having disulfide bonds.

View full abstractDownload PDF (6476K)

-

Eijiro OKINO, Satoshi SAKAGUCHI, Toshio OGAWA, Matashige OYABU2018Volume 54Issue 8 Pages 294-301

Published: August 01, 2018

Released on J-STAGE: November 20, 2018

JOURNAL FREE ACCESSIn the manufacturing processes for lacquer wares, a color conflict between a raw lacquer solution mixed withpigments and resulting oriental lacquer coatings often becomes a problem. This can be attributed to stronglydark brawn color of the original lacquer solution. In this paper, effects of curing conditions, UV irradiation andconventional enzymatic laccase oxidation at room temperature, of the lacquer coatings on their color aftercuring are investigated. As a result, curing by UV provided clearer colors of a lacquer film as compared to theconventional curing. Furthermore, an addition effect of acid or base into the lacquer solution is also examinedwith the conventional curing process. When a lacquer coating was cured by an ordinary enzyme together withacid or base additives under certain humidity, the coating with acid condition showed stronger colors thanthe ones with base. This demonstrates that acidic reagents should be added in the coating solution in order toobtain the desired color of lacquer wares rather than basic reagents. Finally, the component which leads thesecolor changes were estimated by GC/MS analysis and they indicated that condensed catechol compounds areconsidered to be actual color changing agents.

View full abstractDownload PDF (2515K)

-

Shun OKADA, Ryota TSUTSUMI, Toshimitsu MAEDA, Syuji FUJII, Yoshinob ...2018Volume 54Issue 8 Pages 287-293

Published: August 01, 2018

Released on J-STAGE: December 07, 2018

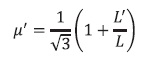

JOURNAL FREE ACCESSJ. Dow-type rolling ball tack test for crosslinked poly(n-butyl acrylate-acrylic acid) pressure-sensitiveadhesive( PSA) was done as a function of crosslinking agent content. To compare the result of ball tack testquantitatively, the following coefficient of friction, μ ׳ was proposed by solving the equation of motion for therolling ball on a slope of PSA tape:

where L is the length of approach run of a ball( = 100 mm) and L is the distance until the stop point of ballon the slope of PSA tape. The ball has the kinetic and potential energies at the start point of contact withthe PSA tape. The μ ׳ means the criterion of absorption of these energies by the PSA tape. A specific contentof crosslinking agent showed the peak of μ ׳. On the other hand, the tack measured by the probe tack testdecreased gradually with an increase in the crosslinking agent content. Adhesion strength is influenced by twofactors: the interfacial adhesion and the cohesive strength of PSA. The tack measured by the probe tack test isinfluenced by only the interfacial adhesion. Whereas, the tack measured by the ball tack test is influenced byboth factors when the ball is stopped.

View full abstractDownload PDF (2832K)

- |<

- <

- 1

- >

- >|