All issues

Successor

Volume 36, Issue 1

Displaying 1-13 of 13 articles from this issue

- |<

- <

- 1

- >

- >|

New Year's Greeting

-

Masaharu OSHIMA2015 Volume 36 Issue 1 Pages 1-2

Published: January 10, 2015

Released on J-STAGE: January 22, 2015

JOURNAL FREE ACCESSDownload PDF (201K)

Preface

-

Takenori NAKAYAMA2015 Volume 36 Issue 1 Pages 3

Published: January 10, 2015

Released on J-STAGE: January 22, 2015

JOURNAL FREE ACCESSDownload PDF (200K)

Special Issue: Surface Science of Corrosion Control —Surface Science for Lifetime Improvement of Infrastructure—

-

Tadashi SHINOHARAArticle type: Review

2015 Volume 36 Issue 1 Pages 4-11

Published: January 10, 2015

Released on J-STAGE: January 22, 2015

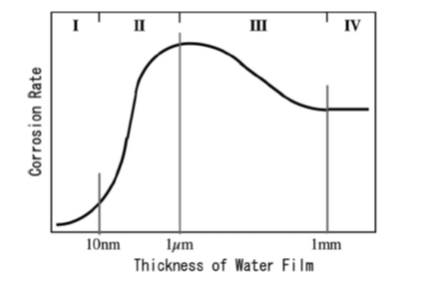

JOURNAL FREE ACCESSMany structural metallic materials are exposed to atmospheric environments. And corrosion in these environments, so called “Atmospheric Corrosion”, commonly initiates and develops under thin water films formed by dew or rain drops. A composition of water film depends on the air pollutant deposition rate, and changes with the humidity and temperature conditions of the atmosphere. Many sensors and the measurement techniques have been developed to evaluated corrosivities in atmospheric environments and corrosion behaviors in those environments. In this paper, the present state of atmospheric corrosion researches are discussed based on the roles of water and deposits and environmental factors which are evaluated by those sensors and measurement techniques. View full abstractDownload PDF (1464K)

View full abstractDownload PDF (1464K) -

Toshiaki OHTSUKAArticle type: Current Topic

2015 Volume 36 Issue 1 Pages 12-17

Published: January 10, 2015

Released on J-STAGE: January 22, 2015

JOURNAL FREE ACCESSThe corrosion of metallic materials is caused by action of aqueous or gaseous environment and the products of the corrosion greatly depend on the environmental condition. It is desired that the identification of the products is done under the in-situ environmental condition. Raman spectroscopy is one the methods to identify them under the condition. The application of Raman spectroscopy to detection of the corrosion products of steel, zinc, and titanium is introduced. View full abstractDownload PDF (1124K)

View full abstractDownload PDF (1124K) -

Aya CHIBA, Izumi MUTO, Yu SUGAWARA, Nobuyoshi HARAArticle type: Current Topic

2015 Volume 36 Issue 1 Pages 18-23

Published: January 10, 2015

Released on J-STAGE: January 22, 2015

JOURNAL FREE ACCESSStainless steels suffer from pitting corrosion in chloride-containing environments. Sulfide inclusions, such as MnS, are known to act as the initiation sites of pitting. The pit initiation mechanism at MnS inclusions in chloride-containing environments is as follows: 1) dissolution of MnS inclusions leads to the deposition of elemental sulfur on and around the inclusions; 2) the coexistence of elemental sulfur and chloride ions results in the dissolution of the steel matrix, forming the trenches at the boundaries between the inclusions and the steel matrix, 3) rapid active dissolution occurs locally at the bottom of the trenches, because of the decrease of pH due to the hydrolysis reaction of Cr3+ and the electrode potential decrease at the bottom of the trench due to the solution resistance. Dissolution behavior of sulfide inclusions is of key importance in pit initiation process. Insoluble sulfide inclusions, such as CrS, TiS, and Ti4C2S2, are unlikely to act as the pit initiation sites. Cr-or Ti-oxide films on the inclusions act as a barrier against inclusion dissolution. An applied stress causes micro-cracks on MnS inclusions, which promotes pit initiation of stainless steels. The micro-crack initiation is closely related to oxide film formation on MnS inclusions. View full abstractDownload PDF (1516K)

View full abstractDownload PDF (1516K) -

Hideki KATAYAMAArticle type: Current Topic

2015 Volume 36 Issue 1 Pages 24-28

Published: January 10, 2015

Released on J-STAGE: January 22, 2015

JOURNAL FREE ACCESSA study on atmospheric corrosion monitoring by electrochemical impedance method has been reviewed. A new type of corrosion sensor, which consists of pin and ring electrodes embedded concentrically in epoxy resin, was successfully applied for the corrosion monitoring. The sensor response showed that the corrosion rate of steel in the sunny day was higher at night than in daytime. The corrosion loss calculated from the monitoring data agreed well with that estimated from the surface roughness by a laser microscope. In addition, the monitoring system has been applied to estimate corrosion resistance at each part of steel model structure exposed to outdoor environment. Low solution resistance and high corrosion rate were measured at all parts in rainfall time. From the corrosion monitoring for about a year, the corrosion loss was larger at horizontal part than at perpendicular part, and the under side of flange gave the largest corrosion loss. View full abstractDownload PDF (832K)

View full abstractDownload PDF (832K) -

Shigenobu KAINUMAArticle type: Current Topic

2015 Volume 36 Issue 1 Pages 29-34

Published: January 10, 2015

Released on J-STAGE: January 22, 2015

JOURNAL FREE ACCESSMany severe corrosion damages have been observed in steel structures constructed in a period of high economic growth. To ensure the safety of such structures, it is important to devise a method how corrosion develops in the service. In our research, semi-variogram analyses were carried out on time-dependent corrosion surfaces of unpainted steel plates exposed to atmospheric environment in order to quantitatively clarify the spatial autocorrelation structures and their time-dependence. In addition, by using the spatial statistics and an ordinary kriging technique, numerical simulation for the time-dependent corrosion surfaces in atmospheric environments was proposed and the validity was confirmed by comparing with corrosion surfaces obtained in various exposure fields. View full abstractDownload PDF (1780K)

View full abstractDownload PDF (1780K) -

Wataru OSHIKAWA, Atsushi NAKANOArticle type: Current Topic

2015 Volume 36 Issue 1 Pages 35-40

Published: January 10, 2015

Released on J-STAGE: January 22, 2015

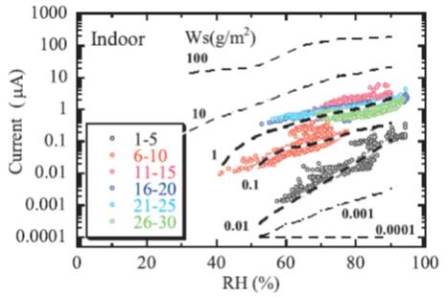

JOURNAL FREE ACCESSAtmospheric corrosion progresses with wetting and drying steps under a very thin film of water. The relative humidity and amount of attached sea salt influence the formation of a thin water film in particular. Thermodynamic calculations of the water film's composition and thickness showed that the thickness of the water film increases rapidly at a relative humidity of 76% RH. The amount of attached sea salt is 1 g/m2 and the water film thickness is approximately 30 μm. In Okinawa, the corrosion environment deteriorates more severely due the increase in sea salt caused by typhoons as well as the high temperatures and humidity. In areas where the amount of rainfall is miniscule, the amount of sea salt tends to be cumulatively enhanced; however, in environments that receive a large amount of rain, this tendency is lessened due to cleaning. An ACM sensor comprised of a Fe-Ag pair is effective for the evaluation of corrosion environments. View full abstractDownload PDF (1408K)

View full abstractDownload PDF (1408K) -

Masatoshi SAKAIRI, Akihiro KAGEYAMA, Shyogo TAKAGIArticle type: Current Topic

2015 Volume 36 Issue 1 Pages 41-46

Published: January 10, 2015

Released on J-STAGE: January 22, 2015

JOURNAL FREE ACCESSA focusing pulse YAG laser beam irradiation (laser machining) technique and micro-electrochemical cell technique were applied to investigate the corrosion behavior of coated steels. These techniques make it possible to investigated the corrosion behavior with control of areas and shapes. In this paper, the application of the techniques for atmospheric corrosion behavior of size controlled model scratches formed on coated steels, detection of atmospheric corrosion generated hydrogen and hydrogen permeation efficiency at scratched areas are described. View full abstractDownload PDF (917K)

View full abstractDownload PDF (917K)

Planning Series

Surface Science for Environmental Issues

-

Kazumi YOSHIKAWA2015 Volume 36 Issue 1 Pages 47-48

Published: January 10, 2015

Released on J-STAGE: January 22, 2015

JOURNAL FREE ACCESS

Science Café

Research Abroad

-

Akira NAMBU2015 Volume 36 Issue 1 Pages 49-50

Published: January 10, 2015

Released on J-STAGE: January 22, 2015

JOURNAL FREE ACCESSDownload PDF (269K)

Qualifying Examination for Surface Science Engineers

-

2015 Volume 36 Issue 1 Pages 51

Published: January 10, 2015

Released on J-STAGE: January 22, 2015

JOURNAL FREE ACCESSDownload PDF (1354K)

News & Trends

-

2014 Volume 36 Issue 1 Pages 52

Published: December 10, 2014

Released on J-STAGE: January 22, 2015

JOURNAL FREE ACCESSDownload PDF (141K)

- |<

- <

- 1

- >

- >|