- |<

- <

- 1

- >

- >|

-

Shin Takeuchi, Yasushi Kamimura, Keiichi EdagawaArticle type: Regular Article

2022 Volume 63 Issue 1 Pages 1-6

Published: January 01, 2022

Released on J-STAGE: December 25, 2021

Advance online publication: November 15, 2021JOURNAL FREE ACCESS FULL-TEXT HTMLIt has been established experimentally from the beginning of 21st century that the yield strengths at room temperature of submicron sized face-centered-cubic and body-centered-cubic metallic single crystals fabricated with the focused ion beam milling process increase dramatically with decreasing specimen diameter. In this paper, the mechanisms of the strengthening have been discussed theoretically on the basis of the single-ended source activation controlled deformation in submicron sized crystals. The experimental results of the power-law dependent yield strength with the decrease of specimen size have been reproduced quantitatively for both types of metallic crystals, where in some body-centered-cubic metals we take into account the effect of the Peierls potential for the screw dislocation motion on the source activation stress.

log(τc/G) vs. log(D/b) plot of critical dislocation bow-out stress component for six BCC metals. The thick line is the average value for each D/b calculated theoretically on the basis of the single-ended source activation controlled deformation in submicron sized crystals. Between the thick and thin dashed lines 95% of the strength distribution is included for each D/b value in the calculated distributions. Fullsize ImageView full abstractDownload PDF (1559K) Full view HTML

log(τc/G) vs. log(D/b) plot of critical dislocation bow-out stress component for six BCC metals. The thick line is the average value for each D/b calculated theoretically on the basis of the single-ended source activation controlled deformation in submicron sized crystals. Between the thick and thin dashed lines 95% of the strength distribution is included for each D/b value in the calculated distributions. Fullsize ImageView full abstractDownload PDF (1559K) Full view HTML -

Akira Takeuchi, Takeshi WadaArticle type: Regular Article

2022 Volume 63 Issue 1 Pages 7-15

Published: January 01, 2022

Released on J-STAGE: December 25, 2021

Advance online publication: November 29, 2021JOURNAL FREE ACCESS FULL-TEXT HTMLOs-free alloys with compositions of Fe12Ir20Re20Rh20Ru28 and Ir25Re25Rh25Ru25 (at%) from an Ir–Re–Rh–Ru system with and without Fe are prepared via conventional arc-melting and subsequent annealing to examine their formation into a single hexagonal close-packed (hcp) structure as high-entropy alloys (HEAs). These alloys are derived by referring to Yunseko et al., who reported the formation of HEAs with a single hcp structure in a near-equiatomic composition (∼Ir20Os20Re20Rh20Ru20) achieved via a chemical reaction. The aim of the present study is to exclude Os from the prototypical HEA (the quinary exact equiatomic Ir20Os20Re20Rh20Ru20 alloy) to prevent hazardous osmium tetroxide (OsO4) from volatilizing in a bulk sample. Fe12Ir20Re20Rh20Ru28 alloy is set as the target alloy by replacing Os with Fe0.6Ru0.4 in the prototypical HEA. The X-ray diffraction (XRD) profile of the Fe12Ir20Re20Rh20Ru28 alloy annealed at 2273 K for 1 h shows an hcp structure, and further scanning electron microscopy (SEM) observations combined with elemental mapping via energy dispersive X-ray spectroscopy (EDX) confirmed a single hcp structure. The XRD profiles of the other samples (the Fe12Ir20Re20Rh20Ru28 alloy in both as-prepared and annealed at 2000 K for 1 h states, and the Ir25Re25Rh25Ru25 alloy in both as-prepared and annealed at 2273 K for 1 h states) exhibit a combination of hcp structures, based on XRD, SEM, and EDX observations. The Fe12Ir20Re20Rh20Ru28 HEA yielded by the conventional solidification method reflects a significant development, as it is an Os-free alloy and the first single-phase hcp-HEA that includes an element from the 3d late transition metal.

SEM and EDX images and XRD profiles of samples annealed at 2273 K for 1 h. (top) Fe12Ir20Re20Rh20Ru28 and (bottom) Ir25Re25Rh25Ru25 alloys that formed single and comboned hcp structures, respectively. Fullsize ImageView full abstractDownload PDF (6345K) Full view HTML

SEM and EDX images and XRD profiles of samples annealed at 2273 K for 1 h. (top) Fe12Ir20Re20Rh20Ru28 and (bottom) Ir25Re25Rh25Ru25 alloys that formed single and comboned hcp structures, respectively. Fullsize ImageView full abstractDownload PDF (6345K) Full view HTML -

Phan H. Phuong, Nguyen P. Anh, Trung Dang-Bao, Duong N. Linh, Nguyen V ...Article type: Regular Article

2022 Volume 63 Issue 1 Pages 16-20

Published: January 01, 2022

Released on J-STAGE: December 25, 2021

JOURNAL FREE ACCESS FULL-TEXT HTMLThis study discovered excellent properties for the structures, morphologies and catalytic oxidation of gaseous pollutants as well as antibacterial activity of Mn-doped ceria nanocomposites (MnOx–CeO2). The MnOx–CeO2 samples were synthesized by the impregnation route, based on ceria nanorods pre-formed by the hydrothermal method. The doping of CeO2 nanorods with MnOx led to a decrease in the crystal size of CeO2 and an increase in the reduction capacity of the catalyst at low temperatures. The catalytic activity of as-prepared MnOx–CeO2 was investigated in the deep oxidation of p-xylene and CO at low temperatures (100–300°C). The results exhibited that the catalytic activity of CeO2–MnOx composite oxides was higher than that of the pure CeO2 nanorod. The 7.5MnCe composite was the most efficient for p-xylene oxidation, reaching complete p-xylene conversion at 300°C. Besides, the activity of 7.5MnCe sample in oxidation of single CO or p-xylene or CO + p-xylene mixture was also comparatively investigated. For CO oxidation, the CO conversion in the mixture is lower than that of single CO due to competitive adsorption with p-xylene. In contrast, for the p-xylene oxidation, its conversion in the mixture was higher than that of single p-xylene, caused by the heat promotion from the CO oxidation. The antibacterial effect of the 7.5MnCe sample was evaluated by implementing the minimum inhibitory concentration test (MIC) against P. aeruginosa, Salmonella, E. coli, S. aureus, and B. cereus. The 7.5MnCe sample presented effective antibacterial activity against all bacteria with a lower MIC of 2.5 mg/mL.

Fig. 5 The catalytic activities of 7.5MnCe nanomaterial for p-xylene and/or CO oxidation; the oxidation of single CO or p-xylene (S) and the oxidation of CO + p-xylene mixture (M). Fullsize ImageView full abstractDownload PDF (1622K) Full view HTML

Fig. 5 The catalytic activities of 7.5MnCe nanomaterial for p-xylene and/or CO oxidation; the oxidation of single CO or p-xylene (S) and the oxidation of CO + p-xylene mixture (M). Fullsize ImageView full abstractDownload PDF (1622K) Full view HTML

-

H. Jiang, C. Watanabe, H. Miura, N. MuramatsuArticle type: Regular Article

2022 Volume 63 Issue 1 Pages 21-26

Published: January 01, 2022

Released on J-STAGE: December 25, 2021

Advance online publication: November 15, 2021JOURNAL FREE ACCESS FULL-TEXT HTMLMicrostructures and mechanical properties of Cu–Be–Co alloys having four different Be contents prepared by simply heavy cold rolling (CR) were systematically investigated. The cold-rolled alloys exhibited excellent mechanical properties due to development of heterogeneous nano-structure (HN), which consisted of “eye”-shape deformation twin domains surrounded by shear bands, and they were further embedded in conventional low-angle lamellae. The strength of each alloy increased with increasing Be content. The volume fraction of the twin domains quantitatively evaluated by the texture analyses that increased with increasing Be content rapidly from 0.40 mass% to 1.27 mass% and gradually from 1.27 mass% up to 2.14 mass%. The latter stagnation was attributed to the formation of coarse intermetallic particles, which impeded the formation of the HN structure. It revealed that the strength was correlated closely with the volume fraction of twin domains.

This Paper was Originally Published in Japanese in J. Japan Institute of Copper 60 (2021) 81–86.

Fig. 8 Relationship between ultimate tensile strength and the volume fraction of deformation twin domains developed in 90% cold-rolled Cu–Be–Co alloys with different Be concentrations. The values of ultimate tensile strength were obtained from tensile tests performed with the stress axis parallel to RD or TD. Fullsize ImageView full abstractDownload PDF (4087K) Full view HTML

Fig. 8 Relationship between ultimate tensile strength and the volume fraction of deformation twin domains developed in 90% cold-rolled Cu–Be–Co alloys with different Be concentrations. The values of ultimate tensile strength were obtained from tensile tests performed with the stress axis parallel to RD or TD. Fullsize ImageView full abstractDownload PDF (4087K) Full view HTML

-

Guojun Lu, Kensuke Miyazaki, Hiromoto Kitahara, Shinji AndoArticle type: Regular Article

2022 Volume 63 Issue 1 Pages 27-32

Published: January 01, 2022

Released on J-STAGE: December 25, 2021

JOURNAL FREE ACCESS FULL-TEXT HTMLFatigue tests of single crystalline Mg–0.026 at%Ce were carried out to investigate the effects of cerium on crystal orientation dependence of fatigue lives. Three crystal orientations were investigated: B specimen with [1100](0001)], D specimen with [1120](1100)] and E specimen with [0001](1120)]. Fatigue lives increased by the cerium addition in D and E crystal orientations, but decreased in B crystal orientation. The cerium additions decreased critical resolved shear stress (CRSS) for second order pyramidal slip, resulting in ridge and stripe (RS) patterns which were observed on fracture surfaces in B specimen. A fatigue crack propagation mechanism was proposed to account for the RS patterns.

Fig. 9 SEM images of (a) fatigue fracture surface of B specimen of Mg–Ce single crystals at a stress amplitude of 120 MPa, (b) ridge and stripe (RS) patterns and (c) coarse grooves in the center of B specimen. Fullsize ImageView full abstractDownload PDF (5042K) Full view HTML

Fig. 9 SEM images of (a) fatigue fracture surface of B specimen of Mg–Ce single crystals at a stress amplitude of 120 MPa, (b) ridge and stripe (RS) patterns and (c) coarse grooves in the center of B specimen. Fullsize ImageView full abstractDownload PDF (5042K) Full view HTML -

Luxin Chi, Shifa Liang, Xinxin Wang, Yang Ran, Yingying WangArticle type: Regular Article

2022 Volume 63 Issue 1 Pages 33-42

Published: January 01, 2022

Released on J-STAGE: December 25, 2021

Advance online publication: November 19, 2021JOURNAL FREE ACCESS FULL-TEXT HTMLWith the advantages of free the heating and cooling, electromagnetic pulse welding is suitable for joining copper to steel. The microstructure morphology of the wavy interface was represented by the particles trajectory of the smoothed particle hydrodynamics (SPH) model, owing to the rapid welding process. In this study, experimental tests and numerical simulations of smooth particle dynamics were performed to reveal the forming process of a wavy interface and vortex. A salient jet and a re-entrant jet were postulated based on the behavior of metallic jets to similar low-viscosity liquids. These jets were then used to analyze the relationship between the moving behavior of the metal particles and the interface formation. The simulation results showed that some copper particles accelerated and then decelerated to stay at the interface. Some copper particles flowed out of the interface at 20 times the initial velocity to form a high-energy ejection, in the welding direction. The velocity of the copper particles decelerated, accelerating that of the steel particles and generating the front wave, and subsequently, the back wave. The re-entrant jet met the steel stream to form a front vortex, mainly composed of Fe elements, and the steel particles were pressed into the wave trough under the salient jet action to create a back vortex with Cu and Fe elements. Finally, microstructural analyses showed that particles moving in the same direction had a streamline organization. Particles in opposite directions had no significant effect on the organization, but caused a high-density plastic deformation and increased hardness. The experimental data were in good agreement with the simulation results.

Fig. 10 SEM micrograph of wavy interface at: (a) front-wave (b) wave trough (c) back-wave (d) wave crest. Fullsize ImageView full abstractDownload PDF (13475K) Full view HTML

Fig. 10 SEM micrograph of wavy interface at: (a) front-wave (b) wave trough (c) back-wave (d) wave crest. Fullsize ImageView full abstractDownload PDF (13475K) Full view HTML

-

Masataka Yamamoto, Masamitsu HayashidaArticle type: Regular Article

2022 Volume 63 Issue 1 Pages 43-50

Published: January 01, 2022

Released on J-STAGE: December 25, 2021

Advance online publication: November 15, 2021JOURNAL FREE ACCESS FULL-TEXT HTMLMg-alloy-based composites, a type of metal matrix composites (MMC), wherein SiC continuous fibers are uniaxially oriented are fabricated using a low-pressure infiltration method. Al particles are dispersed between the SiC fibers in the preform to orient the SiC fibers with equal spacing. The optimum particle size and additive amount of Al particles are determined by evaluating the uniformity of the SiC fiber spacing and the bending strength. In addition, the optimum infiltration pressure is determined by evaluating the ratio of the infiltration failure (the part where the molten alloy does not completely fill the space between the SiC fibers) and the bending strength. The results show that there is a threshold value for the infiltration pressure (0.30 MPa at a SiC fiber volume fraction of 20%). When the infiltration pressure exceeds the threshold value, the ratio of the infiltration failure increases and the bending strength decreases because the areas with slightly wide fiber spacing are preferentially infiltrated, and the areas with narrow fiber spacing are not infiltrated. The maximum strength of the Mg-alloy-based MMC obtained herein was 415 MPa at a SiC fiber volume fraction of 20%.

View full abstractDownload PDF (5149K) Full view HTML

View full abstractDownload PDF (5149K) Full view HTML -

Yasushi Iwata, Kazuma Hibi, Hiroshi Kawahara, Takuma Minoura, Jun Yaok ...Article type: Regular Article

2022 Volume 63 Issue 1 Pages 51-56

Published: January 01, 2022

Released on J-STAGE: December 25, 2021

Advance online publication: November 15, 2021JOURNAL FREE ACCESS FULL-TEXT HTMLThe size of defects in castings affects mechanical properties such as fatigue strength. These properties are the most important properties used for designing aluminum alloy casting components, and usually increase with decreasing size of internal defects. Large internal defects mainly form due to the volumetric shrinkage of melt at the last solidified position. In this study, we therefore examined the possibility of generating microbubbles in aluminum alloy melts for dispersing internal defects in castings.

Ultrasonic treatment was used for generating nitrogen or argon microbubbles in the melt and was found to be suitable for forming fine gas porosities dispersed in castings. The fine gas remained in the melt for 3600 s, and the generated argon gas was detected from the porosities in the castings. The ultrasonic treatment could also remove inclusions and hydrogen in the melt. Moreover, the fine gas porosities in castings did not decreases the tensile strength of the castings.

This Paper was Originally Published in Japanese in J. JFS 93 (2021) 394–399.

View full abstractDownload PDF (5151K) Full view HTML -

Takahiro OhtaArticle type: Regular Article

2022 Volume 63 Issue 1 Pages 57-62

Published: January 01, 2022

Released on J-STAGE: December 25, 2021

JOURNAL FREE ACCESS FULL-TEXT HTMLShot peening is applied to shafts and pipes to improve fatigue strength. In this study, the peening intensity and residual stress distributions on the cylindrical surface were investigated for shot peening. When fixing the cylinder, the peening intensity varied depending on the position of the cylinder, because the collision angle γ between the cylindrical surface and the shot was greatly affected by the position. The function approximation method for estimating the peening intensity distribution was studied. The peening intensity was proportional to sin γ, and the modified Gaussian distribution approximated the peening intensity on the cylindrical surface. The residual stress distribution on the surface was different from the peening intensity distribution, and the compressive residual stress was highest when the central angle α was around 45°. The maximum compressive stress was on the surface when α was 45° and inside the cylinder when α was 0°. The rotation angle with uniform intensity was determined by the approximation method. When the cylinder was rotated at that angle, the compressive residual stress distribution on the cylinder surface became uniform. However, it was noted that the cylindrical surface had a history of peening at different collision angles γ.

This Paper was Originally Published in Japanese in J. JSTP 61 (2020) 239–243. Figures 2, 6, 7, 8, 9, 10, and 12 were slightly modified.

View full abstractDownload PDF (1755K) Full view HTML -

Hubiao Wang, Guixiong Gao, Yunhai Ma, Hongwei Zhao, Bharat Bhushan, Ji ...Article type: Regular Article

2022 Volume 63 Issue 1 Pages 63-68

Published: January 01, 2022

Released on J-STAGE: December 25, 2021

JOURNAL FREE ACCESS FULL-TEXT HTMLRecent developments in wear-resistant coating technology offer new opportunities to enhance the service life of cutting tools. The wear properties of self-fluxing Ni–Cr–Mo–Si–B (Ni60A) and Ni60A–AlMgB14 composite coating fabricated by Plasma Spraying were investigated by a ball-on-disc wear tester. The results showed that the average friction coefficient of 5 mass% and 10 mass% AlMgB14 coating were 0.296 and 0.279, respectively. Compared to that of Ni60A coating, these two values decreased approximately 31.5% and 35.4%. The coatings were examined after the tests using SEM and EDS for evidence of wear mechanism and tribo-chemical reactions. The worn surface topographies of coatings indicated that the dominant wear mechanisms were abrasive wear. The low-friction behavior of the Ni60A–AlMgB14 composite coatings was due to the formation of lubricious boric acid.

View full abstractDownload PDF (4413K) Full view HTML

View full abstractDownload PDF (4413K) Full view HTML

-

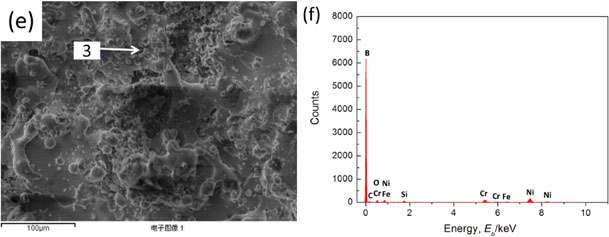

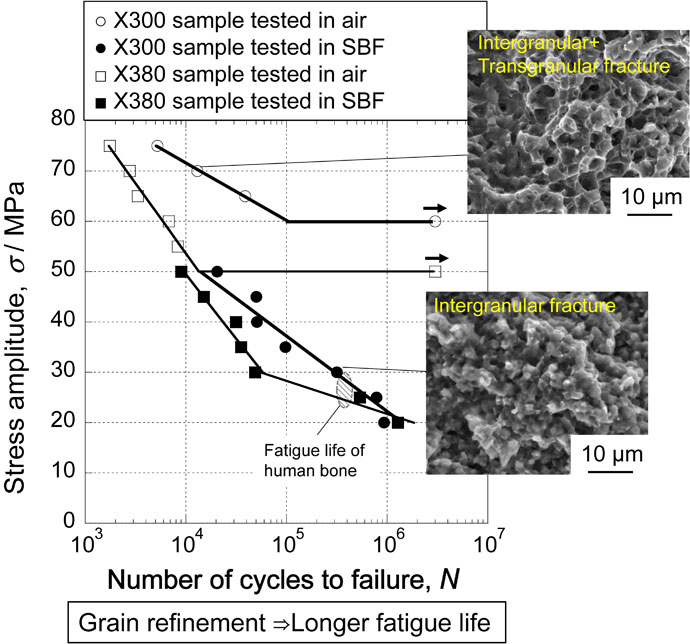

Naoko Ikeo, Naoya Kawamura, Toshiji MukaiArticle type: Regular Article

2022 Volume 63 Issue 1 Pages 69-72

Published: January 01, 2022

Released on J-STAGE: December 25, 2021

Advance online publication: November 15, 2021JOURNAL FREE ACCESS FULL-TEXT HTMLWe investigated the effect of grain refinement on the fatigue properties of biodegradable Mg–0.3 at%Ca alloy, which is expected to be applied in bone fixation devices. Mg–0.3 at%Ca alloy had poorer fatigue properties in simulated body fluid than in air, even after grain refinement. However, the alloy maintained mechanical properties similar to those of human cortical bone. Based on the fatigue fracture surface, the fracture modes of the Mg–0.3 at%Ca alloy differ markedly in air and simulated body fluid. In air, both transgranular and intragranular fractures occurred frequently, whereas in the simulated body fluid, intergranular fracture was the dominant mode. Although the effect of grain refinement on fatigue life was less pronounced in simulated body fluid than in air, the Mg–0.3 at%Ca alloy with grain refinement is considered a promising material for orthopedic devices.

View full abstractDownload PDF (2152K) Full view HTML

View full abstractDownload PDF (2152K) Full view HTML -

Issei Suzuki, Sakiko Kawanishi, Naoki Ohashi, Aiga Gomi, Junya Kano, H ...Article type: Regular Article

2022 Volume 63 Issue 1 Pages 73-81

Published: January 01, 2022

Released on J-STAGE: December 25, 2021

Advance online publication: November 29, 2021JOURNAL FREE ACCESS FULL-TEXT HTMLThe stability and electronic structure of enargite-type Cu3AsO4 were investigated through first principles calculations. Although its synthesis has not been reported to date, the calculations indicate the possibility of synthesis of enargite-type Cu3AsO4. Enargite-type Cu3AsO4 is expected to possess a 1–1.2-eV band gap and a large optical absorption coefficient comparable to those of absorber materials for thin-film solar cells such as CdTe and GaAs. Enargite-type Cu3AsO4 is also expected to exhibit both p-type and n-type conduction by appropriate impurity doping. This property will enable use of this material in a p–n homojunction. In contrast, enargite-type Cu3AsS4 exhibits p-type conduction whereas n-type conduction is not expected. The results of this study indicate that enargite-type Cu3AsO4 is very promising as an absorber material for thin-film solar cells.

View full abstractDownload PDF (2781K) Full view HTML

View full abstractDownload PDF (2781K) Full view HTML -

Yasuharu Tanaka, Takashi Miyagi, Misao Ogawa, Junki Natori, Minoru Sug ...Article type: Regular Article

2022 Volume 63 Issue 1 Pages 82-87

Published: January 01, 2022

Released on J-STAGE: December 25, 2021

Advance online publication: November 19, 2021JOURNAL FREE ACCESS FULL-TEXT HTMLIn the draw forming of ultrahigh-strength steel sheets into the L or T shape seen at the end of automobile parts, the top face easily wrinkles and the vertical wall easily breaks. For satisfactory forming, good elongation characteristics of the material are necessary. For this reason, it is difficult to form small-elongation ultrahigh-strength steel sheets into the L or T shape by draw forming. In this study, fundamental research has been carried out on the forming of an ultrahigh-strength steel sheet into the T model shape by finite element method (FEM) analyses and press experiments. The draw forming and the new bending method utilizing high-load pads “free bend sheet forming” were compared and the states and mechanisms of forming failure generation were analyzed. In free bend sheet forming, it was confirmed that an ultrahigh-strength steel sheet with a tensile strength of up to 1470 MPa can be formed into the T model shape by suppressing the generation of cracks and wrinkles.

This Paper was Originally Published in Japanese in J. JSTP 60 (2019) 283–288.

View full abstractDownload PDF (3722K) Full view HTML

View full abstractDownload PDF (3722K) Full view HTML

-

Taein Kong, Motomichi Koyama, Misaho Yamamura, Eiji AkiyamaArticle type: Express Rapid Publication

2022 Volume 63 Issue 1 Pages 88-91

Published: January 01, 2022

Released on J-STAGE: December 25, 2021

Advance online publication: November 29, 2021JOURNAL FREE ACCESS FULL-TEXT HTMLNi–20Cr alloy is a representative model alloy that shows planar dislocation motion. The planar dislocation motion causes plasticity-induced stress concentration at grain boundaries, which can be a reason for intergranular cracking. In this study, the micro-deformation behavior in Ni–20Cr alloy and its interaction with grain boundaries were investigated. To clarify the micro-plasticity near grain boundaries in Ni–20Cr alloy, we present an applicability of the in situ electron channeling contrast imaging (ECCI) method coupled with in situ micro-deformation analysis, digital image correlation (DIC), and post-mortem electron backscatter diffraction (EBSD). The in situ multi-probe microscopy showed planar dislocation pile-up and local dislocation accumulation, which caused local stress concentration at the grain boundaries. The degree of plasticity-enhanced stress concentration appeared most distinctly near grain boundary triple junction. This result is consistent with previous studies that reported brittle-like cracking can preferentially occur at the grain boundary triple junction. That is, the plasticity-enhanced stress concentration can play a role in brittle-like intergranular cracking that occurs after significant plastic deformation under some special conditions such as hydrogen environment.

Fig. 1 (a) In situ tensile test curve, and ECC images at the strains of (b) 0%, (c) 0.08%, (d) 0.15%, (e) 0.37%, and (f) 0.43%. The planar dislocation arrays are marked with yellow dashed lines. The small arrows in (c) indicate a newly formed dislocation planar array. The inset in (c)–(f) indicates the magnification of the highlighted region for each step that show the pile-up of dislocations. The video file is also uploaded as the supplemental material. Fullsize ImageView full abstractDownload PDF (2642K) Full view HTML

Fig. 1 (a) In situ tensile test curve, and ECC images at the strains of (b) 0%, (c) 0.08%, (d) 0.15%, (e) 0.37%, and (f) 0.43%. The planar dislocation arrays are marked with yellow dashed lines. The small arrows in (c) indicate a newly formed dislocation planar array. The inset in (c)–(f) indicates the magnification of the highlighted region for each step that show the pile-up of dislocations. The video file is also uploaded as the supplemental material. Fullsize ImageView full abstractDownload PDF (2642K) Full view HTML

- |<

- <

- 1

- >

- >|