Volume 60, Issue 7

Displaying 1-31 of 31 articles from this issue

- |<

- <

- 1

- >

- >|

-

Article type: Preface

Subject area: Special Issue on Severe Plastic Deformation for Nanomaterials with Advanced Functionality

2019Volume 60Issue 7 Pages 1103

Published: July 01, 2019

Released on J-STAGE: June 25, 2019

Download PDF (36K) Full view HTML -

Article type: Regular Article

Subject area: Special Issue on Severe Plastic Deformation for Nanomaterials with Advanced Functionality

2019Volume 60Issue 7 Pages 1104-1110

Published: July 01, 2019

Released on J-STAGE: June 25, 2019

Advance online publication: April 05, 2019Download PDF (4531K) Full view HTML -

Article type: Regular Article

Subject area: Special Issue on Severe Plastic Deformation for Nanomaterials with Advanced Functionality

2019Volume 60Issue 7 Pages 1111-1115

Published: July 01, 2019

Released on J-STAGE: June 25, 2019

Advance online publication: May 31, 2019Download PDF (2706K) Full view HTML -

Article type: Overview

Subject area: Special Issue on Severe Plastic Deformation for Nanomaterials with Advanced Functionality

2019Volume 60Issue 7 Pages 1116-1122

Published: July 01, 2019

Released on J-STAGE: June 25, 2019

Advance online publication: June 07, 2019Download PDF (1693K) Full view HTML -

Article type: Overview

Subject area: Special Issue on Severe Plastic Deformation for Nanomaterials with Advanced Functionality

2019Volume 60Issue 7 Pages 1123-1130

Published: July 01, 2019

Released on J-STAGE: June 25, 2019

Advance online publication: May 31, 2019Download PDF (4329K) Full view HTML -

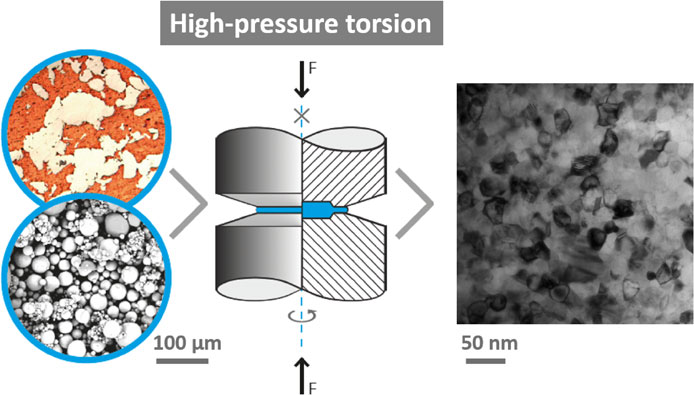

Bulk-State Reactions and Improving the Mechanical Properties of Metals through High-Pressure TorsionArticle type: Overview

Subject area: Special Issue on Severe Plastic Deformation for Nanomaterials with Advanced Functionality

2019Volume 60Issue 7 Pages 1131-1138

Published: July 01, 2019

Released on J-STAGE: June 25, 2019

Advance online publication: May 31, 2019Download PDF (3955K) Full view HTML -

Article type: Overview

Subject area: Special Issue on Severe Plastic Deformation for Nanomaterials with Advanced Functionality

2019Volume 60Issue 7 Pages 1139-1150

Published: July 01, 2019

Released on J-STAGE: June 25, 2019

Advance online publication: June 07, 2019Download PDF (5988K) Full view HTML -

Article type: Review

Subject area: Special Issue on Severe Plastic Deformation for Nanomaterials with Advanced Functionality

2019Volume 60Issue 7 Pages 1151-1158

Published: July 01, 2019

Released on J-STAGE: June 25, 2019

Advance online publication: May 31, 2019Download PDF (4937K) Full view HTML -

Article type: Overview

Subject area: Special Issue on Severe Plastic Deformation for Nanomaterials with Advanced Functionality

2019Volume 60Issue 7 Pages 1159-1167

Published: July 01, 2019

Released on J-STAGE: June 25, 2019

Advance online publication: May 31, 2019Download PDF (3573K) Full view HTML -

Article type: Overview

Subject area: Special Issue on Severe Plastic Deformation for Nanomaterials with Advanced Functionality

2019Volume 60Issue 7 Pages 1168-1176

Published: July 01, 2019

Released on J-STAGE: June 25, 2019

Advance online publication: June 07, 2019Download PDF (6149K) Full view HTML -

Article type: Review

Subject area: Special Issue on Severe Plastic Deformation for Nanomaterials with Advanced Functionality

2019Volume 60Issue 7 Pages 1177-1191

Published: July 01, 2019

Released on J-STAGE: June 25, 2019

Download PDF (19047K) Full view HTML -

Article type: Overview

Subject area: Special Issue on Severe Plastic Deformation for Nanomaterials with Advanced Functionality

2019Volume 60Issue 7 Pages 1192-1202

Published: July 01, 2019

Released on J-STAGE: June 25, 2019

Download PDF (2719K) Full view HTML -

Article type: Review

Subject area: Special Issue on Severe Plastic Deformation for Nanomaterials with Advanced Functionality

2019Volume 60Issue 7 Pages 1203-1208

Published: July 01, 2019

Released on J-STAGE: June 25, 2019

Advance online publication: May 31, 2019Download PDF (3043K) Full view HTML -

Article type: Overview

Subject area: Special Issue on Severe Plastic Deformation for Nanomaterials with Advanced Functionality

2019Volume 60Issue 7 Pages 1209-1220

Published: July 01, 2019

Released on J-STAGE: June 25, 2019

Download PDF (3746K) Full view HTML -

Article type: Overview

Subject area: Special Issue on Severe Plastic Deformation for Nanomaterials with Advanced Functionality

2019Volume 60Issue 7 Pages 1221-1229

Published: July 01, 2019

Released on J-STAGE: June 25, 2019

Advance online publication: May 31, 2019Download PDF (9033K) Full view HTML -

Article type: Overview

Subject area: Special Issue on Severe Plastic Deformation for Nanomaterials with Advanced Functionality

2019Volume 60Issue 7 Pages 1230-1242

Published: July 01, 2019

Released on J-STAGE: June 25, 2019

Advance online publication: June 07, 2019Download PDF (2939K) Full view HTML -

Article type: Overview

Subject area: Special Issue on Severe Plastic Deformation for Nanomaterials with Advanced Functionality

2019Volume 60Issue 7 Pages 1243-1255

Published: July 01, 2019

Released on J-STAGE: June 25, 2019

Advance online publication: June 07, 2019Download PDF (3378K) Full view HTML -

Article type: Overview

Subject area: Special Issue on Severe Plastic Deformation for Nanomaterials with Advanced Functionality

2019Volume 60Issue 7 Pages 1256-1269

Published: July 01, 2019

Released on J-STAGE: June 25, 2019

Download PDF (4852K) Full view HTML -

Article type: Overview

Subject area: Special Issue on Severe Plastic Deformation for Nanomaterials with Advanced Functionality

2019Volume 60Issue 7 Pages 1270-1282

Published: July 01, 2019

Released on J-STAGE: June 25, 2019

Advance online publication: June 07, 2019Download PDF (6055K) Full view HTML -

Article type: Overview

Subject area: Special Issue on Severe Plastic Deformation for Nanomaterials with Advanced Functionality

2019Volume 60Issue 7 Pages 1283-1293

Published: July 01, 2019

Released on J-STAGE: June 25, 2019

Download PDF (5701K) Full view HTML -

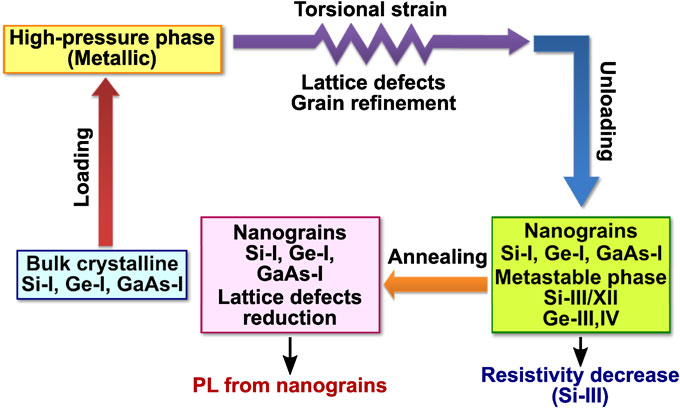

High-Pressure Phase Transformations under Severe Plastic Deformation by Torsion in Rotational AnvilsArticle type: Review

Subject area: Special Issue on Severe Plastic Deformation for Nanomaterials with Advanced Functionality

2019Volume 60Issue 7 Pages 1294-1301

Published: July 01, 2019

Released on J-STAGE: June 25, 2019

Advance online publication: June 07, 2019Download PDF (2131K) Full view HTML -

Article type: Overview

Subject area: Special Issue on Severe Plastic Deformation for Nanomaterials with Advanced Functionality

2019Volume 60Issue 7 Pages 1302-1315

Published: July 01, 2019

Released on J-STAGE: June 25, 2019

Download PDF (9079K) Full view HTML -

Article type: Overview

Subject area: Special Issue on Severe Plastic Deformation for Nanomaterials with Advanced Functionality

2019Volume 60Issue 7 Pages 1316-1330

Published: July 01, 2019

Released on J-STAGE: June 25, 2019

Download PDF (4301K) Full view HTML -

Article type: Overview

Subject area: Special Issue on Severe Plastic Deformation for Nanomaterials with Advanced Functionality

2019Volume 60Issue 7 Pages 1331-1343

Published: July 01, 2019

Released on J-STAGE: June 25, 2019

Download PDF (6226K) Full view HTML -

Article type: Overview

Subject area: Special Issue on Severe Plastic Deformation for Nanomaterials with Advanced Functionality

2019Volume 60Issue 7 Pages 1344-1355

Published: July 01, 2019

Released on J-STAGE: June 25, 2019

Download PDF (4663K) Full view HTML -

Article type: Overview

Subject area: Special Issue on Severe Plastic Deformation for Nanomaterials with Advanced Functionality

2019Volume 60Issue 7 Pages 1356-1366

Published: July 01, 2019

Released on J-STAGE: June 25, 2019

Download PDF (3727K) Full view HTML -

Article type: Overview

Subject area: Special Issue on Severe Plastic Deformation for Nanomaterials with Advanced Functionality

2019Volume 60Issue 7 Pages 1367-1376

Published: July 01, 2019

Released on J-STAGE: June 25, 2019

Download PDF (2109K) Full view HTML -

Article type: Regular Article

2019Volume 60Issue 7 Pages 1377-1383

Published: July 01, 2019

Released on J-STAGE: June 25, 2019

Download PDF (2028K) Full view HTML -

Article type: Regular Article

2019Volume 60Issue 7 Pages 1384-1389

Published: July 01, 2019

Released on J-STAGE: June 25, 2019

Download PDF (2824K) Full view HTML -

Article type: Technical Article

2019Volume 60Issue 7 Pages 1390-1397

Published: July 01, 2019

Released on J-STAGE: June 25, 2019

Download PDF (2806K) Full view HTML -

Article type: Rapid Publication

2019Volume 60Issue 7 Pages 1398-1401

Published: July 01, 2019

Released on J-STAGE: June 25, 2019

Advance online publication: May 31, 2019Download PDF (2297K) Full view HTML

- |<

- <

- 1

- >

- >|