- |<

- <

- 1

- >

- >|

-

[in Japanese]2024Volume 24Issue 5 Pages 190

Published: 2024

Released on J-STAGE: May 02, 2024

JOURNAL FREE ACCESSDownload PDF (455K)

-

Noriko KANAI, Izuru KAWAMURA2024Volume 24Issue 5 Pages 191-195

Published: 2024

Released on J-STAGE: May 02, 2024

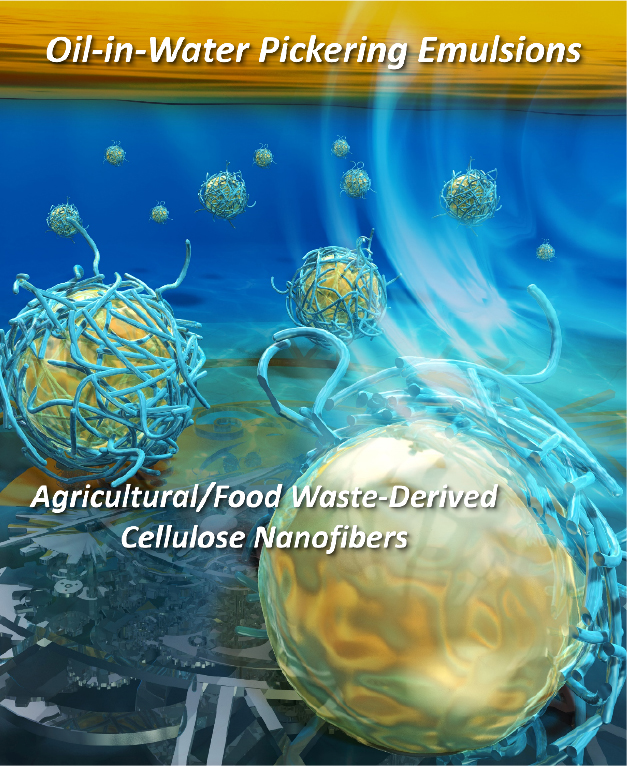

JOURNAL FREE ACCESSPickering emulsions stabilized with nanoparticles attract attention as environmentally friendly emulsification technology. Cellulose nanofibers (CNFs), downsized from highly crystalline cellulose in plant cell walls to the nanometer scale, can be used as natural stabilizers for oil-in-water Pickering emulsions. While wood pulp is commonly used as a CNF source, CNFs derived from agricultural/food waste offer the compatible quality as wood-derived CNFs, enabling upcycling waste materials. This paper evaluates the long-term stability of Pickering emulsions stabilized with agricultural/food waste-derived CNFs and elucidates instability mechanisms through relaxation and diffusion measurements using magnetic resonance imaging. The development of sustainable Pickering emulsions using CNFs from agricultural/food waste contributes to establishing a circular economy.

graphical abstract Fullsize ImageView full abstractDownload PDF (3217K)

graphical abstract Fullsize ImageView full abstractDownload PDF (3217K) -

Katsuhide FUJITA2024Volume 24Issue 5 Pages 197-203

Published: 2024

Released on J-STAGE: May 02, 2024

JOURNAL FREE ACCESSCellulose nanofibrils (CNFs), a lightweight and extremely strong material derived from biomass, has shown great promise in various industrial fields as a potential alternative to petroleum-based materials. However, the increased usage of CNF has raised concerns about its potential toxicity, primarily due to physicochemical properties such as its ultrafine fibrous shape. Managing the inhalation exposure of workers, particularly during the manufacturing stage, is crucial. However, there are few test reports on inhalation toxicity of CNFs, leaving the actual situation unclear, and challenges persist in test methodologies. This paper aims to bridge these gaps by offering a comprehensive overview of potential implications linked to CNF exposure. Special emphasis is given to insights obtained from our ongoing inhalation toxicity assessments, with the primary objective of offering valuable guidance for the development of CNF products.

graphical abstract Fullsize ImageView full abstractDownload PDF (8816K)

graphical abstract Fullsize ImageView full abstractDownload PDF (8816K) -

Kenji AOKI2024Volume 24Issue 5 Pages 205-210

Published: 2024

Released on J-STAGE: May 02, 2024

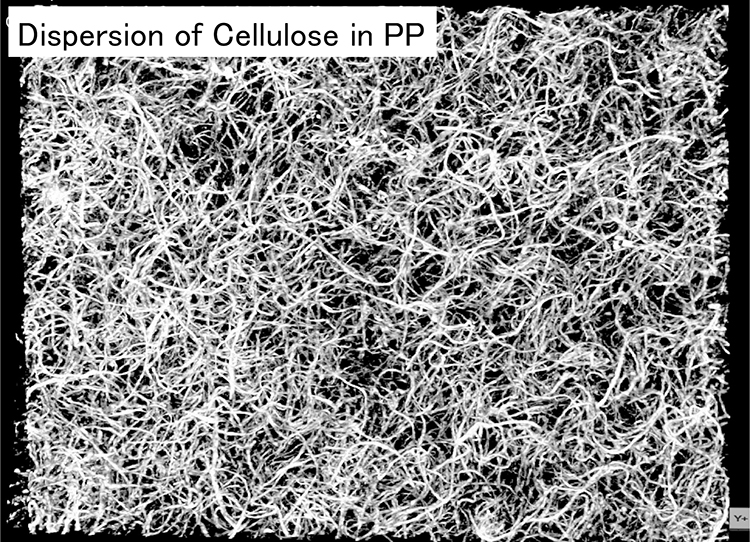

JOURNAL FREE ACCESSIn recent years, research and development of Cellulose Nano Fiber(CNF)/polypropylene (PP) composites as a material for automobiles and home appliances has been actively carried out. Hydrophilic CNF and non-polar resin such as PP do not mix. In other words, it is the relationship between water and oil. However, the function of CNF is obtained by uniformly dispersing CNF in PP. Therefore, it is necessary to add a Maleic Anhydride-modified polypropylene(MAPP) in order to improve the dispersibility of CNF. MAPP has a structure in which maleic anhydride is grafted on a PP chain, and is an essential additive for PP composites such as Glass fiber reinforced PP(GFRPP) and Wood plastic composites(WPC). The characteristic of MAPP(graft amount, molecular weight) affects not only the dispersibility of CNF but also the mechanical properties of CNF/PP composites.

This paper introduces the functions and roles of MAPP in the development of CNF/PP composites, the examples of observing the distributed state of CNF by various methods and the examples of application using CNF/PP composites. graphical abstract Fullsize ImageView full abstractDownload PDF (1996K)

graphical abstract Fullsize ImageView full abstractDownload PDF (1996K)

-

Yoshimune Nonomura2024Volume 24Issue 5 Pages 211-213

Published: 2024

Released on J-STAGE: May 02, 2024

JOURNAL FREE ACCESSDownload PDF (330K)

-

2024Volume 24Issue 5 Pages 17_623E

Published: 2024

Released on J-STAGE: April 09, 2024

JOURNAL FREE ACCESSDownload PDF (160K)

- |<

- <

- 1

- >

- >|