- |<

- <

- 1

- >

- >|

-

2018 Volume 58 Issue 8 Pages Cover-

Published: August 15, 2018

Released on J-STAGE: August 17, 2018

JOURNAL OPEN ACCESSDownload PDF (433K) -

2018 Volume 58 Issue 8 Pages Editorial-

Published: August 15, 2018

Released on J-STAGE: August 17, 2018

JOURNAL OPEN ACCESSDownload PDF (574K) -

2018 Volume 58 Issue 8 Pages Contents-

Published: August 15, 2018

Released on J-STAGE: August 17, 2018

JOURNAL OPEN ACCESSDownload PDF (525K)

-

Youn-Bae Kang, Sung-Hoon JungArticle type: Review

2018 Volume 58 Issue 8 Pages 1371-1382

Published: August 15, 2018

Released on J-STAGE: August 17, 2018

JOURNAL OPEN ACCESS FULL-TEXT HTMLOxide stability diagrams are often used to figure out types of oxide inclusions (i.e., phase) in liquid steels. Such diagram is useful for quick identification of the inclusions by concentrations of deoxidizing components. Obviously, deoxidation of the liquid steel to form the inclusions takes place rapidly. Therefore, thermodynamic principles are applied in the construction of the diagram. To construct it in the correct manner, and to use it in more versatile manner, available methods were reviewed, and possible limits are discussed. It is pointed out that an oxide stability diagram is a projection of several iso-oxygen phase diagram sections, each of which should obey the phase diagram rule and should represent accurate thermodynamic equilibria. In this regard, a CALPHAD method is preferred to conventionally used methods that 1) stable oxide phases are naturally taken into account, 2) activity of oxide component even in solution phase (e.g., liquid oxide) is not assumed to be a constant, and 3) iso-oxygen contours are calculated efficiently as Zero-Phase Fraction (ZPF) line of several oxide phases, which are in equilibrium with the liquid steel. Rule of the phase diagram construction is automatically obeyed in the CALPHAD method. Interpretation and utilization of the oxide stability diagram are discussed. It is proposed that concentration axes be extended to a lower concentration where liquid oxide (rich in Fe oxide) forms. It is also explained how oxide stability diagram can be used to read deoxidation/reoxidation path of liquid steels. Finally, consideration of C in a liquid steel is emphasized.

View full abstractDownload PDF (1089K) Full view HTML

-

Motomichi Koyama, Takahiro Sawaguchi, Kaneaki TsuzakiArticle type: Review

2018 Volume 58 Issue 8 Pages 1383-1395

Published: August 15, 2018

Released on J-STAGE: August 17, 2018

JOURNAL OPEN ACCESS FULL-TEXT HTMLThis paper presents an overview of the recent works on dynamic strain aging (DSA) of Fe–Mn–C austenitic steels including Hadfield and twinning-induced plasticity (TWIP) steels. First, a model of the DSA mechanism and its controlling factors are briefly explained in terms of Mn–C coupling and dislocation separation. Then, we introduce the effects of DSA on mechanical properties such as work hardening capability, uniform elongation, post-uniform elongation, and fatigue strength. Specifically, we note (1) the pinning effect on extended dislocation for the work hardening, (2) the Poretvin–Le Chatelier banding effect on damage evolution for the tensile elongation, and (3) the crack tip hardening/softening effect on crack resistance for the fatigue strength. We believe that this overview will help in designing advanced high-strength steels with superior ductility and fatigue resistance.

View full abstractDownload PDF (2174K) Full view HTML

-

Vinci Mojamdar, Govind Sharan Gupta, Agin PuthukkudiArticle type: Regular Article

2018 Volume 58 Issue 8 Pages 1396-1401

Published: August 15, 2018

Released on J-STAGE: August 17, 2018

JOURNAL OPEN ACCESS FULL-TEXT HTMLRaceway is formed in the blast furnace when high velocity air is blown into a bed of coke particles. The blast furnace is treated as a moving bed as the burden descends to replace the coke particles consumed by the combustion in front of the tuyeres. In this study, an experimental setup is constructed using Perspex sheet to replicate the moving bed and a detailed study of raceway size is carried out with respect to different parameters such as gas velocity, bed height and particles flow rate. Compressed air is used as the gas phase and granules of Linear Low Density Polyethylene (LLDPE) are used as the packing particles. Results confirm the existence of the cavity hysteresis phenomenon in a stationary packed bed. For moving beds, it is found that the cavity hysteresis phenomenon is absent, except at a very low particles flow rate. It is also observed that raceway size in the moving bed is independent of the bed height and solid mass flow rate, except for a very low solid/particles flow rates. Results confirm the previous hypothesis that if there are no frictional forces then there would not be any raceway hysteresis in the system. The study also confirms that the raceway size obtained in a stationary packed bed for decreasing gas velocity condition is similar to that obtained in the moving beds.

View full abstractDownload PDF (676K) Full view HTML -

Xiaodong Ma, Mao Chen, Jinming Zhu, Haifa Xu, Geoff Wang, Baojun ZhaoArticle type: Regular Article

2018 Volume 58 Issue 8 Pages 1402-1405

Published: August 15, 2018

Released on J-STAGE: August 17, 2018

Advance online publication: June 16, 2018JOURNAL OPEN ACCESS FULL-TEXT HTMLLow slag volume ironmaking blast furnace (BF) operation can reduce the cost of ironmaking by lower flux rate and fuel ratio, meanwhile the operation should be maintained safely in terms of operational temperature, fluidity and desulphurization. One of the approaches for low slag volume BF operation is to decrease MgO content in the slag. In this study, the properties of BF slag have been experimentally investigated in the CaO–SiO2–Al2O3–MgO system from the aspects of phase equilibria, viscosity and sulphide capacity. The liquidus temperature of slag is not sensitive to the MgO concentration. The viscosity of slag increases slightly with decreasing MgO concentration. The sulphide capacity of slag decreases slightly with decreasing MgO concentration. It is suggested that the MgO concentration in the BF slag can be reduced to 5 wt% at the CaO/SiO2 weight ratio of 1.10 to 1.30 and Al2O3 of around 15 wt% under stable BF operation.

View full abstractDownload PDF (616K) Full view HTML -

Nan Yang, Xing-Min Guo, Noritaka Saito, Kunihiko Nakashima, Jie-Ting Z ...Article type: Regular Article

2018 Volume 58 Issue 8 Pages 1406-1412

Published: August 15, 2018

Released on J-STAGE: August 17, 2018

Advance online publication: June 16, 2018JOURNAL OPEN ACCESS FULL-TEXT HTMLMgO is one of essential component in blast furnace slag for improving the fluidity and desulfurization. Generally it is added via sintering process. It has been also proved in practice that the addition of MgO affects the quality of sinter significantly. However, the effect of MgO on formation and crystallization behaviors of calcium ferrite in sintering had been scarcely discussed. In this work, the crystalline products in CaO–Fe2O3 system with different content of MgO were identified by X-ray diffraction (XRD), scanning electron microscopy (SEM) and energy dispersive X-ray spectroscopy (EDS). In order to follow the reactions during heating and cooling, differential scanning calorimetry (DSC) was also conducted. It was found that addition of MgO restrained the formation of CaFe2O4 leading to the decrease in content of original melt during sintering process. The contents of Ca2Fe2O5 and solid solution of magnetite (magnetite s.s) were increased and the crystallization of Ca2Fe2O5 was also promoted with increasing MgO. Compared with forming Ca2Fe2O5, addition of MgO facilitated to form magnetite s.s. Content of initial liquid phase was decreased with increasing MgO, whereas new liquid phase was generated at 1609 K when the content of MgO exceeded 7 mass%, due to the reaction between Ca2Fe2O5 and magnetite.

View full abstractDownload PDF (1222K) Full view HTML -

Moritoshi Mizutani, Tsunehisa Nishimura, Takashi Orimoto, Kenichi Higu ...Article type: Regular Article

2018 Volume 58 Issue 8 Pages 1413-1419

Published: August 15, 2018

Released on J-STAGE: August 17, 2018

JOURNAL OPEN ACCESS FULL-TEXT HTMLIn the field of ironmaking, there are few in situ non-destructive techniques for systematically evaluating the reduction behaviors of blast furnace (BF) burden materials. The standard method for the evaluation of the reduction disintegration index (RDI) includes low temperature reduction with a constant gas composition at a constant temperature followed by a cold strength test after cooling. During the reduction of iron ore burden in the BF, reduction disintegration proceeds in the course of increasing temperature through crack generation and propagation caused by volume expansion due to the reduction from hematite to magnetite. Acoustic emission (AE) method is an in situ non-destructive technique to evaluate the crack generation and propagation phenomena in various fields. In this study, we first attempted to apply AE method for a detailed in situ observation of BF burden materials by a combinational experiment of reduction disintegration. In the case of single-particle reduction, it was possible to detect AEs without friction between the sample and the waveguide giving rise to noise. Although a large number of AEs were measured during cooling of both sinter and pellet, the AE energy of the sinter was larger than that of the pellet. Furthermore, a significant number of AEs were also detected during heating of lump ore containing larger amount of combined water indicating possibility to evaluate the decrepitation behavior of such ores.

By the packed bed reduction tests, which could evaluate average properties of iron ore burden, it was found that the AE energy attributed to thermal stress observed during cooling was higher than that to reduction degradation. These results suggest that it will be possible to eliminate the influence of crack generation within the iron ore burdens in the cooling stage by applying the in-situ non-destructive evaluation method developed in this study. It is also expected to apply for the quantitative estimation of the reduction disintegration behavior of burdens in the working BF.

View full abstractDownload PDF (1866K) Full view HTML -

Yui Numazawa, Daisuke Igawa, Shohei Matsuo, Yasuhiro Saito, Yohsuke Ma ...Article type: Regular Article

2018 Volume 58 Issue 8 Pages 1420-1426

Published: August 15, 2018

Released on J-STAGE: August 17, 2018

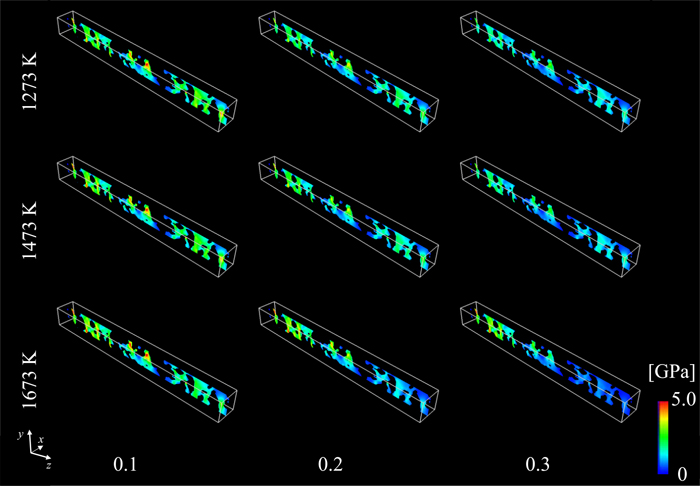

JOURNAL OPEN ACCESS FULL-TEXT HTMLIn order to investigate coke degradation behavior due to CO2 gasification reaction in the blast furnace, mass transfer analyses with the reaction and stress analyses for coke considering its structure after the reaction were performed. Using the finite element method, CO2 gas diffusion in a coke lump and consumption of coke matrices owing to the gasification reaction were considered for the coke model in which the actual coke structure was reproduced. The rate-controlling step was also evaluated calculating the Thiele modulus and the effectiveness factor of catalyst obtained from CO2 concentration distribution in a coke lump. Further, stress analyses assuming a uniaxial tensile test were carried out for the coke model after CO2 gasification reaction, and the effect of the gasification reaction on a stress state in a coke lump was investigated. As a result, the reaction progressed mainly in the vicinity of the external surface with reaction temperature of 1673 K while it did uniformly in the whole coke lump with 1273 and 1473 K. Thus, the rate-controlling step shifted from the reaction-controlling step to the diffusion-controlling step with an increase in a reaction temperature, and the Thiele modulus and the effectiveness factor of catalyst also showed the same trend. From the stress analysis, coke strength decreased uniformly in the whole coke lump in case of the reaction-controlling step whereas it did mainly in the vicinity of the external surface in case of diffusion-controlling step.

Distribution of von Mises stress at x = 0.25 mm. The reaction temperatures were set at (top) 1273 K, (middle) 1373 K, and (bottom) 1473 K. The total conversions are (left) 0.1, (center) 0.2, and (right) 0.3. (Online version in color.) Fullsize ImageView full abstractDownload PDF (904K) Full view HTML

Distribution of von Mises stress at x = 0.25 mm. The reaction temperatures were set at (top) 1273 K, (middle) 1373 K, and (bottom) 1473 K. The total conversions are (left) 0.1, (center) 0.2, and (right) 0.3. (Online version in color.) Fullsize ImageView full abstractDownload PDF (904K) Full view HTML -

Congcong Yang, Deqing Zhu, Jian Pan, Liming LuArticle type: Regular Article

2018 Volume 58 Issue 8 Pages 1427-1436

Published: August 15, 2018

Released on J-STAGE: August 17, 2018

Advance online publication: June 23, 2018JOURNAL OPEN ACCESS FULL-TEXT HTMLThis paper developed a quantitative understanding of the effect of ore properties on granulation effectiveness for different iron ore types based on the mechanistic model proposed by J.D. Litster et al. The granulation effectiveness was measured by the magnitude of x0.5, which was postulated to be a function of the layer binding strength. Water was adopted as the only binder for all granulation tests. A wide range of moisture contents, up to the optimum moisture content that yielded an optimum permeability, was tested for each ore type. The typical structure of granules made from different ores was investigated to reveal the effect of mineralogical properties of ore particles on the growth of granules. The results indicate that the granulation effectiveness x0.5 varies markedly with ore type and moisture content. Feed particle size distribution and moisture for granulation are paramount factors determining the granulation effectiveness x0.5, which has a single relationship with the mass mean size of layering particles independent of ore type. The mass mean size of layering particles is dependent on the inherent size distribution of raw materials and the mass fraction of layering particles, while the latter is linear to available moisture content. The model works well for some ore types except for those with unreasonable size distributions: 1) excessive intermediate particles meanwhile lacking of fine particles; or 2) excessive ultrafine particles. An effective criteria closely related to layer binding strength, (1−ε)S/εd, is proposed to determine the applicability of the model.

Normalized dependence of granulation effectiveness x0.5 on mass mean size of layering particles Fullsize ImageView full abstractDownload PDF (1567K) Full view HTML

Normalized dependence of granulation effectiveness x0.5 on mass mean size of layering particles Fullsize ImageView full abstractDownload PDF (1567K) Full view HTML

-

Kyung-Hyo Do, Jung-Mock Jang, Hae-Sol Son, Min-Kyu Paek, Jong-Jin PakArticle type: Regular Article

2018 Volume 58 Issue 8 Pages 1437-1442

Published: August 15, 2018

Released on J-STAGE: August 17, 2018

JOURNAL OPEN ACCESS FULL-TEXT HTMLThe effect of silicon on TiN formation in liquid iron was studied by measuring the nitrogen solubility and TiN solubility product in liquid Fe–Ti alloys with silicon additions under various nitrogen partial pressures in the temperature range of 1823–1923 K. The first- and second order interaction parameters of silicon on titanium,

and

and  were determined as −0.038 and 0, respectively, and the second-order cross-product parameter of titanium and silicon on nitrogen in liquid iron,

were determined as −0.038 and 0, respectively, and the second-order cross-product parameter of titanium and silicon on nitrogen in liquid iron,  was determined as 0. Temperature dependence of these parameters were negligible.View full abstractDownload PDF (759K) Full view HTML

was determined as 0. Temperature dependence of these parameters were negligible.View full abstractDownload PDF (759K) Full view HTML -

Seong-Mook Cho, Brian G. Thomas, Seon-Hyo KimArticle type: Regular Article

2018 Volume 58 Issue 8 Pages 1443-1452

Published: August 15, 2018

Released on J-STAGE: August 17, 2018

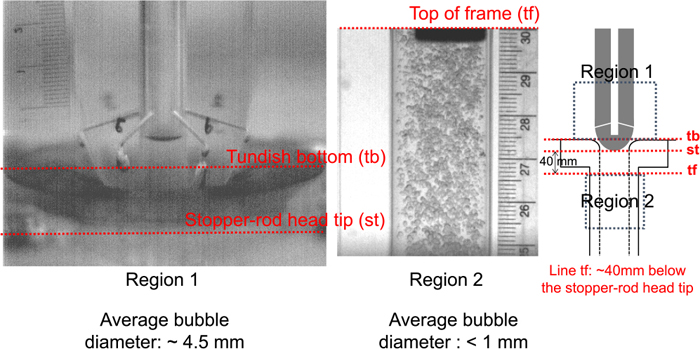

JOURNAL OPEN ACCESS FULL-TEXT HTMLArgon-gas injection parameters including flow rate and bubble size distribution are important to prevent nozzle clogging, control the mold flow, and reduce bubble-related defects in steel continuous casting. This work employs water-air model experiments and analytical modeling to quantify the behavior and size distributions of gas bubbles in the nozzle and mold during nominally steady-state slab-casting, focusing on gas injection through a stopper-rod with multiple side-channels. Bubble formation, breakup, coalescence, and accumulation are investigated with experiments using a one-third scale water model with the aid of high-speed video recording and analytical models to predict gas pressure, initial bubble size, bubble descending velocity, bubble residence time, and bubble size distribution considering accumulation. In addition, size distributions of the bubbles in the nozzle and mold are quantified by analyzing snapshots of bubble images. Bubbles initiate at the gas channel exit in the stopper-rod after overcoming the pressure threshold, and then expand and elongate until detaching from the stopper-rod surface. After that, turbulent flow breaks up the bubbles inside the gap between the stopper-rod and the nozzle inlet. The bubbles sometimes coalesce with others, and get bigger while flowing down through the nozzle. The bigger bubbles have longer residence time, and accumulate in the nozzle, due to higher buoyancy on them. With higher gas flow-rate, bubble size distribution in the nozzle and mold shows larger average-size and broader size-range. Finally, the validated initial bubble-size model with the water-air model measurements is extrapolated to estimate argon-bubble sizes in molten steel with real caster conditions.

Bubble breakup in the nozzle inlet region near the stopper-rod tip: 35.0 LPM (water) and 1.6 LPM (air). (Online version in color.) Fullsize ImageView full abstractDownload PDF (2785K) Full view HTML

Bubble breakup in the nozzle inlet region near the stopper-rod tip: 35.0 LPM (water) and 1.6 LPM (air). (Online version in color.) Fullsize ImageView full abstractDownload PDF (2785K) Full view HTML

-

Jiu Zhang, Guohui Mei, Zhi Xie, Shumao ZhaoArticle type: Regular Article

2018 Volume 58 Issue 8 Pages 1453-1458

Published: August 15, 2018

Released on J-STAGE: August 17, 2018

JOURNAL OPEN ACCESS FULL-TEXT HTMLResponse lag is an outstanding problem of the traditional blackbody cavity sensor for continuously measuring the molten steel temperature, which is due to the thick-walled structure of the sensor, caused by the limitation of the sensor’s Al2O3–C material in harsh environment. Thus, a fast response sensor with a thin-walled temperature measuring unit of blackbody cavity has been developed. A new sensor material of Mo–W–ZrO2 cermet that had a small corrosion rate of about 0.05 mm/h was developed for making the thin-walled sensor with a thickness of 3 mm, while the thickness of the traditional sensor was 20–30 mm. The temperature measuring unit of the cermet tube was supported by an Al2O3–C unit. In addition, the structure of the fast sensor was designed to form an online blackbody cavity approximately for a high accuracy (measurement error ≤ 3°C) as the sensor was dipped into molten steel, the length/radius ratio of the temperature measuring unit of the cermet tube should reach 12. Industrial test showed that the fast sensor improved the response speed significantly from 5–6 min to about 55 s. It was helpful to solve the problem for continuously measuring the molten steel temperature of these fields that needed a fast response.

View full abstractDownload PDF (1142K) Full view HTML

-

Minoru Ochi, Kousei Sato, Ryo Teranishi, Yukio Sato, Jun-ichi Hamada, ...Article type: Regular Article

2018 Volume 58 Issue 8 Pages 1459-1466

Published: August 15, 2018

Released on J-STAGE: August 17, 2018

JOURNAL OPEN ACCESS FULL-TEXT HTMLMore than one thousand intragranular and intergranular precipitates of nitrogen-added austenitic stainless steel, SUSXM15J1, were characterized by FIB-SEM serial-sectioning tomography, by conventional transmission electron microscopy (TEM) and by scanning transmission electron microscopy (STEM). All of intragranular precipitates were found nitrided to form dichromium nitride, Cr2N, two types of intergranular precipitates were found Cr2N and Cr3Ni2Si(N), and some of them were grown and jointed due to the additional heat treatment during the tensile test at 1173 K, which probably contributed to its high-temperature strength.

More than 1000s of precipitates were characterized three dimensionally by FIB-SEM serial sectioning tomography. Fullsize ImageView full abstractDownload PDF (2457K) Full view HTML

More than 1000s of precipitates were characterized three dimensionally by FIB-SEM serial sectioning tomography. Fullsize ImageView full abstractDownload PDF (2457K) Full view HTML -

Xiaoling Zhou, Zhiqiang Xu, Yinzhong Shen, Tiantian Shi, Xi HuangArticle type: Regular Article

2018 Volume 58 Issue 8 Pages 1467-1473

Published: August 15, 2018

Released on J-STAGE: August 17, 2018

JOURNAL OPEN ACCESS FULL-TEXT HTMLTo further increase steam temperature in ultra-supercritical power plants, 9–12%Cr ferritic/martensitic (FM) steels with target operating temperatures up to 650°C and higher are being developed. An 11% Cr F/M steel was prepared by reference to the nominal chemical composition of SAVE12 steel with an expected maximum use temperature of 650ºC. Precipitate phases in the 11%Cr FM steel after a short-term creep at 600°C/180 MPa for 1100 h were investigated by transmission electron microscopy with energy dispersive X-ray spectrometers. Precipitate phases in the crept steel were identified to be Fe-W-Cr-rich M6C carbide, Cr-rich M23C6 and M7C3 carbides, Fe-rich Laves phase, Nb-Ta-rich/Ta-Nb-rich/V-rich MX phases, as well as Fe-Cr-rich sigma phase. The identified M6C carbides with a f.c.c. crystal structure have a metallic element composition of about 41Fe, 31W, 20Cr, and 4Ta (in at.%) and an irregular block-like morphology with sizes ranging from 70 to 310 nm in diameter. The M6C and Cr-rich M7C3 carbides, as well as Fe-W-rich Laves phase are considered to be formed during the creep. The present investigation reveals that the M6C carbide is a dominant phase in the steel after the creep. The formation of the M6C carbide in the crept steel is also discussed.

View full abstractDownload PDF (909K) Full view HTML -

Nobuo Uehara, Masatoshi TakitaArticle type: Regular Article

2018 Volume 58 Issue 8 Pages 1474-1479

Published: August 15, 2018

Released on J-STAGE: August 17, 2018

JOURNAL OPEN ACCESS FULL-TEXT HTMLThe optimum composition of mixtures of iodine, ethanol, and ethylene glycol as selective extraction media for free magnesia in steelmaking slags was explored. Hydration of free magnesia in steelmaking slags increases its volume to expand the slags, resulting in deteriorate pavement of roads when the steelmaking slags were used as a road-constructing material. Therefore, accurate analytical methods to determine free magnesia in the steelmaking slags have been sought in steel industries. Ethanolic solutions of iodine without ethylene glycol afforded higher selectivity for the extraction of magnesia than ternary mixtures of iodine, ethanol, and ethylene glycol. Although the addition of up to 5 wt% of ethylene glycol to the ethanolic iodine solution increased the amount of magnesia extracted, it also increased the extraction of other magnesium species present in the steelmaking slags, resulting in decreased selectivity toward magnesia. The dissolution of magnesia in ethanolic iodine solution was promoted by the alkalinity of the magnesia. Meanwhile, the dissolution of magnesia promoted the redox reaction between ethanol and iodine in the extraction medium.

View full abstractDownload PDF (545K) Full view HTML

View full abstractDownload PDF (545K) Full view HTML

-

Ya-xing Liu, Cheng Qian, Xi-ying Cui, Ya-ya Cui, Zhen-hua BaiArticle type: Regular Article

2018 Volume 58 Issue 8 Pages 1480-1489

Published: August 15, 2018

Released on J-STAGE: August 17, 2018

Advance online publication: June 21, 2018JOURNAL OPEN ACCESS FULL-TEXT HTMLIn the strip trimming process, defects such as buckle edge, burr, and imbalance of cutoff ratio often occur. This study investigated the mechanism of these defects and analyzed the influence of disc shears process parameters, including overlap, clearance, fron and back tension on the quality of strip edge. On this basis, a comprehensive evaluation function of strip trimming quality is proposed. Furthermore, the process parameter optimization technology of the disc shears is developed. Subsequently, an on-line grinding device for strip edge is designed to fundamentally control burr defect. Via field application of this technology and this device, the comprehensive treatment of buckle edge, burr, and imbalance of cutoff ratio is realized. Therefore, improving the quality of finished strip is helpful and has the value of further popularization and application.

View full abstractDownload PDF (1533K) Full view HTML -

Mari Maeda, Junji Shimamura, Shinsuke SuzukiArticle type: Regular Article

2018 Volume 58 Issue 8 Pages 1490-1499

Published: August 15, 2018

Released on J-STAGE: August 17, 2018

JOURNAL OPEN ACCESS FULL-TEXT HTMLThe effect of cementite dispersion on ductile fracture was investigated by comparing void formations in different spheroidize-annealed steels. Two types of steels with different grain sizes and interparticle distances were used. Tensile tests of plate specimens were performed in longitudinal direction along the rolling direction. After the tensile tests, the fractured specimens were cut in the middle along the width. The cross sections near the fractured surface were observed using a scanning electron microscope. Voids in the microstructure were observed in five thickness reduction areas corresponding to different strain levels. As a result, the number density of voids increased as the strain increased in both steels. The number density of voids in steel containing large cementite grains was higher for all strain values, and the fraction of long voids in this steel was higher with greater applied high strain. Two types of voids were mainly observed in this study: One was decohesion of the interface between bainitic ferrite and cementite, while the other was cracking of the cementite itself. Void formation was evaluated using electron back scatter diffraction analysis with kernel average misorientation (KAM) as parameter. The obtained KAM values (representing misorientation in crystal grains) increased with increasing strain, and the areas with high KAM values were concentrated locally along cementite in the long spacing cementite steel. Therefore, it was revealed that void formation in steels with large cementite grains and long cementite spacings occurred more easily by the stress applied to cementite.

View full abstractDownload PDF (2472K) Full view HTML -

Hirokazu Kobayashi, Kazuhisa Kabeya, Yukio Takashima, Hideyuki Takahas ...Article type: Regular Article

2018 Volume 58 Issue 8 Pages 1500-1509

Published: August 15, 2018

Released on J-STAGE: August 17, 2018

JOURNAL OPEN ACCESS FULL-TEXT HTMLGas jet cooling is widely used because the device is simple, it is possible to prevent oxidation and a uniform cooling ability can be obtained with thin steel sheets.

Because the gas jet cooling ability is affected by the gas properties and nozzle geometry, quantitative evaluation of the influences of these factors is very important.

Several non-dimensional empirical equations have been proposed for prediction of the gas jet cooling ability of geometrically arranged nozzles. In this research, the accuracy of Martin’s non-dimensional empirical equations was investigated by gas jet cooling experiments and fluid analyses with different nozzle geometries and distances from the cooled surface.

Two nozzle geometries were examined, namely, a slit-like (linear) arrangement of round nozzles and a staggered arrangement of round nozzles.

The difference between the experimental results and the results of predictions by Martin’s equations increased as the distance between the nozzle tips and the cooled surface decreased. It was suggested that the characteristic difference of the jet flow between the flow development region (potential core region) and the fully developed flow region influenced the cooling ability.

The trend of divergence between the experimental and predicted cooling ability was clearly presented in this research. The results of this study make it possible to improve the accuracy of predictions when the distance between the nozzle tips and the cooled surface is set within the potential core region of the jet.

View full abstractDownload PDF (1620K) Full view HTML

-

Shih-Hsien Chang, Chang-Kai Peng, Kuo-Tsung Huang, Chung-Ming LiuArticle type: Regular Article

2018 Volume 58 Issue 8 Pages 1510-1518

Published: August 15, 2018

Released on J-STAGE: August 17, 2018

JOURNAL OPEN ACCESS FULL-TEXT HTMLIn the present research, DLC films are produced by asymmetric bipolar pulsed plasma enhanced CVD after preparing oxynitride-treated PM30 steel. The experimental parameters include various CH4 gas flows (3, 7, 11, 15 and 19 sccm) with asymmetric bipolar pulsed voltages (−15+10%) and a deposition time of 90 min, respectively. In order to evaluate the properties of the DLC films for oxynitride-treated PM30 steel, Raman spectroscopy analysis, adhesion tests, nano-indentation, wear tests, and corrosion resistance inspections were performed. The experimental results reveal that the DLC/oxynitride duplex coating layers have better properties when the DLC films are treated with an appropriate CH4 gas flow (15 sccm). Meanwhile, the coatings possess the highest hardness and elastic modulus (5.91 and 89.87 GPa, respectively), the lowest wear loss volume (for axial loads of 2 and 5 N of 3.82 × 10−3 and 5.49 × 10−3 mm3, respectively), the lowest corrosion current (1.43 × 10−4 A·cm−2), and the highest polarization resistance (5.32 × 102 Ω·cm2) after a 3.5 mass% NaCl corrosion test. This study also confirms that the wear and corrosion resistance of DLC/oxynitride duplex-treated PM30 steel can be effectively improved via asymmetric bipolar pulsed plasma enhanced CVD.

View full abstractDownload PDF (2481K) Full view HTML -

Nik Rozlin Nik Masdek, Ain Athirah Rozali, Mardziah Che Murad, Zuraida ...Article type: Regular Article

2018 Volume 58 Issue 8 Pages 1519-1523

Published: August 15, 2018

Released on J-STAGE: August 17, 2018

JOURNAL OPEN ACCESS FULL-TEXT HTMLTitanium and stainless steel have become attractive materials especially in medical applications due to their improvement of implant performance and longevity. The corrosion behaviour for stainless steel 316L (316L SS) and Ti-6Al-4V under simulated biological conditions with the presence of proteins were investigated using electrochemical methods. The electrochemical tests were performed with the addition of bovine serum albumin (BSA) with concentrations of 2%, 4%, 6%, 8% and 10% at 37°C. The electrochemical methods used in this study were open circuit potential (OCP), potentiodynamics polarization and electrochemical impedance spectroscopy (EIS). The results showed that stable corrosion resistance of the two alloys can be obtained under protein-containing solutions. The protein adsorption to the metal surface at high impedance results indicated that at all protein concentrations showed great performance and the most stable film formed on the 316L SS and Ti-6Al-4V are in the solution that contain 8% of BSA.

View full abstractDownload PDF (754K) Full view HTML

-

Taisuke Hayashi, Shigekazu Morito, Takuya OhbaArticle type: Regular Article

2018 Volume 58 Issue 8 Pages 1524-1531

Published: August 15, 2018

Released on J-STAGE: August 17, 2018

JOURNAL OPEN ACCESS FULL-TEXT HTMLLow-alloy medium carbon steel martensite that is obtained by quenching from austenite is composed of lath and butterfly types of martensite. Lath martensite is the major microstructure in most martensite microstructures of low-alloy medium carbon steels. However, the fraction of butterfly martensite is not negligible. Furthermore, butterfly martensite may affect the evolution of martensite microstructures during quenching, because some of the butterfly martensite in medium carbon steels seems to be formed before the lath martensite. Here we quantitatively evaluated the composite martensite microstructure of a medium carbon steel, and briefly discussed the mechanism of the composite microstructure formation. Sizes of martensite blocks were measured via an automated procedure based on orientation maps obtained by electron backscatter diffraction. The block thickness and area of the butterfly martensite were larger than those of the lath martensite. The coarse-grained appearance of the butterfly martensite was originated from relatively large single variant blocks. This result is also supported by transmission electron microscopy observations. A simple habit plane trace analysis shows that the block shape of the butterfly martensite was distorted by austenite grain boundary. In addition, the butterfly block shape suggests that the growth of the butterfly martensite was earlier than that of the lath martensite.

View full abstractDownload PDF (1589K) Full view HTML

-

Jian-Ping Lai, Qing-Lin Pan, Yuan-Wei Sun, Chang-An XiaoArticle type: Regular Article

2018 Volume 58 Issue 8 Pages 1532-1537

Published: August 15, 2018

Released on J-STAGE: August 17, 2018

Advance online publication: June 30, 2018JOURNAL OPEN ACCESS FULL-TEXT HTMLEffect of Si content on the wear resistance of high chromium cast iron was investigated. The result showed that the eutectic carbides were greatly refined and increased with the increase of Si addition from 0.5 to 1.5 wt.%. Meanwhile, the transformation of austenitic matrix to pearlite was observed. After destabilized treatment at 950°C for 3 h, denser secondary carbides precipitated from the matrix are observed in the alloy containing 1.5wt.%Si. Such microstructure changes leaded to the increase of hardness and improvement of abrasive wear resistance. An increase in load from 20 N to 100 N, the extent of carbide fragmentation was much greater and extended to a deeper distance. Severer fracture of carbides was observed in the alloy containing 0.5wt.%Si. The higher resistance with addition of Si was attributed to the denser secondary carbides, which strengthened the matrix between the eutectic carbides and in turn increased the mechanical support to the carbides against cracking.

View full abstractDownload PDF (2062K) Full view HTML -

Dongwei Fan, Pallava Kaushik, Howard PieletArticle type: Regular Article

2018 Volume 58 Issue 8 Pages 1538-1544

Published: August 15, 2018

Released on J-STAGE: August 17, 2018

Advance online publication: June 16, 2018JOURNAL OPEN ACCESS FULL-TEXT HTMLLocal formability is one of the most critical properties of Advanced High Strength Steels for successful implementation in automotive applications. However, attaining satisfactory local formability is a challenge for many Advanced High Strength Steels. In the present study, a hot dip galvannealed dual-phase steel with 980 MPa minimum tensile strength was selected as the AHSS and its local formability was evaluated by conducting 90-degree V-bend tests. The bend samples, particularly those that experienced failure during testing, were subjected to intense characterization using Scanning Electron Microscope, Cathodoluminescence Microscope and Thermal Desorption Analyzer. Fractography study indicated that the bend failure is associated with the interaction between inclusions near the steel surface and the diffusible hydrogen in the steel. The same underlying failure mode was also observed in two additional zinc coated AHSS grades. Improved steel cleanliness resulted in reduction of inclusions and diffusible hydrogen amounts, and facilitated enhanced steel bendability. Diffusible hydrogen content in the steel could be reduced by removing the surface zinc coating or by heat treatment; such treatments also led to a significant improvement in bendability.

View full abstractDownload PDF (1285K) Full view HTML

-

Dipak Mazumdar, Prince Kumar Singh, Rohit Kumar TiwariArticle type: Note

2018 Volume 58 Issue 8 Pages 1545-1547

Published: August 15, 2018

Released on J-STAGE: August 17, 2018

JOURNAL OPEN ACCESS FULL-TEXT HTMLIn many earlier studies, argon-steel flows in ladle shrouds have been mathematically modeled via the discrete phase modelling (DPM) approach assuming a bubbly liquid flow. Similarly, in several physicals model investigations, oversimplified shroud–collector plate nozzle geometry, having little or no similarity with the actual, has been considered. To assess these critically, industrial teeming practices, from ladle to tundish, have been reviewed and experimental results derived from two, full scale, PERSPEX models of ladle shroud presented. It is shown that bubbly flow in shroud is encountered only at very low gas-liquid loading ratio (i.e., Qg/Ql–0.02 or so), much smaller than those typically practiced in the industry. Simplification of shroud geometry and consideration of direct injection of gas onto a falling liquid are undesirable as these distort results from physical model investigations.

View full abstractDownload PDF (382K) Full view HTML

- |<

- <

- 1

- >

- >|