-

Hao Wang, Yan-ping Bao, Jian-guo Zhi, Chen-yi Duan, Shuai Gao, Min Wan ...

Article type: Regular Article

2021 Volume 61 Issue 3 Pages

657-666

Published: March 15, 2021

Released on J-STAGE: March 17, 2021

Advance online publication: December 03, 2020

JOURNAL

OPEN ACCESS

FULL-TEXT HTML

This paper analyzes the control of Al2O3 inclusions in high strength IF steel containing phosphorus. The inclusion statistics and two-dimensional morphology of samples with slab thickness of 1/8, 1/2 and 7/8, and the samples with hot rolling, cold rolling and continuous annealing processes were observed and compared by ASPEX SEM. In addition, the three-dimensional morphology of the inclusions extracted from the electrolysis of slab samples and the original morphology of inclusions from the rolling process samples were observed and compared. The results show that: When rare earth Ce is added to the steel, the combination of Ce with activity O and S in the steel has lower Gibbs free energy, and it is easy to generate CeAlO3, Ce2O2S, Ce2O3, composite rare earth inclusions combined with other inclusions. The concentration and supersaturation of aluminum and oxygen are reduced, and the ability of single particle Al2O3 to aggregate into large-scale cluster inclusions is reduced. The average size of Al2O3 inclusions decreased from 5–7 µm to 2–5 µm in each thickness direction. The morphology of inclusions changed from long strip, sharp angle and cluster to spherical, spindle and round surface. Meanwhile, the number density of Al2O3 inclusions increase, but the area density decreases during continuous casting and rolling process. The size of Al2O3 inclusions in the steel without rare earth addition is mostly large-scale strip shape, and it is crushed during rolling,resulting quality defects on the exposed surface and causing the stamping crack problem. When rare earth is added to the steel, the inclusions in the steel change into small-sized circular inclusions with dispersion distribution. The modulus of elasticity is close to that of the steel matrix, which will not affect the continuity of the strip structure, and is beneficial to the relevant properties of the product.

View full abstract

-

Naoya Saeki, Masanori Suzuki, Masashi Nakamoto, Toshihiro Tanaka, Ken ...

Article type: Regular Article

2021 Volume 61 Issue 3 Pages

667-673

Published: March 15, 2021

Released on J-STAGE: March 17, 2021

JOURNAL

OPEN ACCESS

FULL-TEXT HTML

In order to optimize decarburization in the RH degassing process, it is necessary to develop sensors capable of continuous and direct measurements of an oxygen concentration. However, such measurements are only possible for a few seconds with conventional sensors. Here, the effects that hinder long-time measurements by a single Mo/MoO2–type zirconia oxygen sensor were investigated and an approach to extend sensor lifetime was developed by the direct current (DC) voltage application. Reference electrodes containing molybdenum and molybdenum oxide were constructed in a single-closure tube of zirconia solid electrolyte. The EMF between the reference electrode (negative) and the sample electrode (positive) inserted in molten iron decreased from +300 mV owing to the formation of a metallic molybdenum layer on the inner surface of the zirconia tube. This layer was attributed to reduction of molybdenum oxide gas owing to oxygen diffusion from the inside to the outside of the tube. Because the oxygen diffusion coefficient in molybdenum is much lower than the oxygen ion diffusion coefficient in the zirconia, the layer disrupted oxygen transfer and reduced the EMF. Additionally, a DC voltage of 2.0 V was applied to the reference electrode and EMF recovered over 20 minutes. The molybdenum layer disappeared and the reference electrode was re-exposed to the electrolyte. Thus, the applied DC voltage enabled long-time measurements of oxygen content with a single Mo/MoO2–type zirconia oxygen sensor.

View full abstract

-

Minmin Sun, Jianliang Zhang, Kejiang Li, Ziming Wang, Chunhe Jiang, Ho ...

Article type: Regular Article

2021 Volume 61 Issue 3 Pages

674-683

Published: March 15, 2021

Released on J-STAGE: March 17, 2021

JOURNAL

OPEN ACCESS

FULL-TEXT HTML

Boric acid as a negative catalyst can decrease the coke reactivity, and increase coke strength after reaction which is essentially important for high efficient utilization of coke and stable operation of blast furnace. CO2 gasification was conducted to investigate the gasification characteristics and kinetics of H3BO3 treated metallurgical coke with different loading amount and loading method. After 2.0 wt% H3BO3 sprayed, the thickness of coke pore walls increased from 132.41 µm to 162.34 µm, and the porosity decreased from 46.76% to 42.16%. Gasification reaction was suppressed obviously by introducing 0.5 wt% H3BO3. This effect is slightly increased with further addition of H3BO3. As characterized by reactivity index, reactivity of coke without H3BO3 was 9.72 × 10−3 min−1 at 1473 K, while it decreased to 7.19 × 10−3 min−1 when 2.5 wt% H3BO3 loaded. Unreacted core model was used to establish the corresponding kinetic relationship and analyze the rate-limiting step in gasification process. Internal diffusion resistance reduced as temperature increased, and rose alongside carbon conversion rate. Results from reactivity and strength analysis proved that a certain amount of H3BO3 sprayed onto coke surface can significantly improve the coke strength after reaction and reduce the generations of coke fine.

View full abstract

-

Masayoshi Adachi, Yuji Yamagata, Manabu Watanabe, Sonoko Hamaya, Makot ...

Article type: Regular Article

2021 Volume 61 Issue 3 Pages

684-689

Published: March 15, 2021

Released on J-STAGE: March 17, 2021

Advance online publication: December 19, 2020

JOURNAL

OPEN ACCESS

FULL-TEXT HTML

Ni–Al alloys are good candidates for the fabrication high-efficiency gas turbine blades. The Ni–Al system is also important as a solution for AlN crystal growth. To accurately model the casting process for turbine blade fabrication and design solution growth techniques for AlN, the thermophysical properties of the liquid alloy are required. In this study, the normal spectral emissivity of Ni–Al liquid alloys was measured using the electromagnetic levitation technique under a static magnetic field. Both the melting temperature of Cu and the eutectic temperature of the Ni–C system were used as fixed temperature points for spectrometer calibration to obtain the radiance of liquid Ni–Al alloys. The composition dependence of the normal spectral emissivity of liquid Ni–Al alloys had a maximum at ~40–50 mol%Al-Ni. The Ni–Al binary system had a stable intermetallic compound of NiAl with a melting temperature of 1911 K. The short range chemical ordering could be attributed to strong bonding between Ni and Al atoms, which affected the scattering cross section of the conduction electrons even in the liquid state; hence, the normal spectral emissivity had a maximum at ~40–50 mol%Al-Ni.

View full abstract

-

Weijun Huang, Yajing Liu

Article type: Regular Article

2021 Volume 61 Issue 3 Pages

690-696

Published: March 15, 2021

Released on J-STAGE: March 17, 2021

Advance online publication: January 17, 2021

JOURNAL

OPEN ACCESS

FULL-TEXT HTML

To effectively recycle and utilize vanadium and titanium resource from the vanadium slag, the crystallization and separation behaviors of V-spinel phase and Ti-spinel phase in the FeO–SiO2–V2O3–TiO2 system as the main components of vanadium slag were investigated. The results indicated that the suitable temperatures for precipitating V-spinel phase and Ti-spinel phase were chosen as 1723 K and 1623 K, respectively. With introduction supergravity at the parameter of G = 700, T = 1723 K and t = 10 minutes, the solid V-containing phase was intercepted by the filter to form the V-enriched slag, while the residual melt went through the filter into the lower crucible to form the Ti-containing slag. And the mass fraction of V2O3 in the V-enriched slag reached about 32.98 wt% and that of TiO2 in the Ti-containing slag reached about 19.41 wt%; the recovery ratios of V2O3 and TiO2 were about 86.50% and 76.80%, respectively. In addition, the Ti-spinel phase was further separated and concentrated in the Ti-enriched slag from the Ti-containing slag with the gravity coefficient G = 500 at 1623 K for 10 minutes. The mass fraction and the recovery ratio of TiO2 in the Ti-enriched slag could reach 30.83 wt% and 89.80%, respectively. In the whole process, the comprehensive recovery ratio of TiO2 could reach 68.97%.

View full abstract

-

Keijiro Saito, Yusuke Oshima, Masakatsu Hasegawa

Article type: Regular Article

2021 Volume 61 Issue 3 Pages

697-704

Published: March 15, 2021

Released on J-STAGE: March 17, 2021

JOURNAL

OPEN ACCESS

FULL-TEXT HTML

The knowledge of FexO activities in molten slags at lower temperatures is necessary for effective dephosphorization in hot metal pretreatments. However, there have been still differences among the reference data in the FexO–CaO–SiO2 pseudo-ternary system at 1573 K. In the present study, the FexO activities were measured with an electrochemical technique in order to reevaluate the iso-activity curves of FexO. Subsequently, the CaO and SiO2 activities along liquidus lines were calculated by the Gibbs-Duhem equation, and the equilibrium phosphorus contents in molten iron coexisted with dephosphorization slags were estimated by using the present results.

View full abstract

-

Thi Bang Tuyen Nguyen, Subhasish Mitra, Geoffrey Evans, Brian Joseph M ...

Article type: Regular Article

2021 Volume 61 Issue 3 Pages

705-714

Published: March 15, 2021

Released on J-STAGE: March 17, 2021

Advance online publication: January 08, 2021

JOURNAL

OPEN ACCESS

FULL-TEXT HTML

Phosphorus is known to partition to a dicalcium silicate – tricalcium phosphate solid solution (C2S–C3P) during the solidification of basic oxygen steelmaking (BOS) slag. Typically, C2S–C3P solidifies first and has a lower density than the remaining liquid slag, suggesting that gravity separation may be possible. This study simulated the cooling behaviour of BOS slag, and predicted the potential for spherical C2S–C3P particles to float. A lumped parameter heat transfer model based on ordinary differential equations was developed to predict the temporal variations of slag temperature in a 5 mm diameter Pt crucible. Hydrodynamic calculations were also carried out to study the floating behaviour of the spherical particles. The results showed reasonable agreement between predictions and experimental measurements for the slag’s cooling rate. In the separation experiments, coarse C2S–C3P crystals were observed in the upper section of the crucible, while a glassy slag was observed in the lower section. This is consistent with the hydrodynamic calculations that showed the single particles floating up to the interface. Preliminary approximations were also performed for industrial slag pots which showed the higher possibility of separation for a shallow and insulated slag pot. Further studies are required to confirm the nucleation and growth behaviour in the experiments.

View full abstract

-

Akifumi Harada, Akitoshi Matsui, Seiji Nabeshima

Article type: Regular Article

2021 Volume 61 Issue 3 Pages

715-723

Published: March 15, 2021

Released on J-STAGE: March 17, 2021

JOURNAL

OPEN ACCESS

FULL-TEXT HTML

The effect of Al addition at the midpoint of the metal-slag reaction on the formation of MgO·Al2O3 spinel-type inclusions was investigated by laboratory-scale experiments and a kinetic model calculation with the aim of reducing spinel-type inclusions in high-carbon steel. As results of the experiments, the total Mg content in the steel and the average content of MgO in the inclusions were relatively low before Al addition, and formation of spinel-type inclusions was rare. After Al addition, spinel-type inclusions formed when CaO/SiO2 and CaO/Al2O3 in the slag were high, and the total Mg content in the steel and the average MgO content in the inclusions were also high. On the other hand, formation of spinel-type inclusions was suppressed at lower CaO/SiO2 and CaO/Al2O3 in the slag. Therefore, the experimental results indicated that Al addition at the midpoint of the reaction and control of the slag composition are effective for suppression of spinel-type inclusions. However, spinel-type inclusions formed soon after Al addition in slag with higher CaO/SiO2 and higher CaO/Al2O3. To evaluate the effect of midpoint addition of Al in the actual process, a kinetic model calculation was carried out. According to the calculation, the increase in the Mg content in the steel under actual-scale conditions was lower than that in the laboratory, and formation of spinel-type inclusions could be avoided.

View full abstract

-

Tae Sung Kim, Joo Hyun Park

Article type: Regular Article

2021 Volume 61 Issue 3 Pages

724-733

Published: March 15, 2021

Released on J-STAGE: March 17, 2021

JOURNAL

OPEN ACCESS

FULL-TEXT HTML

The effects of iron oxide on the viscosity of the CaO–Al2O3–FetO–SiO2–MgO system Ruhrstahl-Heraeus (RH) refining slags with different CaO/Al2O3 ratios (C/A = 1.0 to 2.0) and various iron oxide contents (T.Fe = 4 to 18 wt%) were investigated. Iron oxide generally decreases the viscosity of the slags. In the relatively low iron oxide content region (i.e., T.Fe < 10 wt%), the increase in the C/A ratio decreases the viscosity of the slags, whereas it has less significant effect on the modification of the aluminate structure in the relatively high iron oxide content region. The addition of iron oxide to the slags with C/A ≤ 1.3 effectively breaks the aluminate networks, while the network structure is less affected by the iron oxide in the slags with C/A ≥ 1.6. From the semi-quantitative analysis of Raman scattering data, the addition of iron oxide into the relatively acidic slags (C/A ≤ 1.3) modifies the aluminate networks, which means that the [FeO4]-tetrahedra substitute for the [AlO4]-tetrahedra. Thus, the degree of polymerization of the melts decreases with increasing content of iron oxides. However, the effect of iron oxides is less significant in the relatively basic compositions (C/A ≥ 1.6). The activation energy for the viscous flow of the slags has a good linear correlation with the fraction of polymerized aluminate species, i.e., ln  . However, the network-modifying role of iron oxide is limited within a critical concentration, which is also dependent on the C/A ratio of the CaO–Al2O3–FetO–SiO2–MgO slags.

. However, the network-modifying role of iron oxide is limited within a critical concentration, which is also dependent on the C/A ratio of the CaO–Al2O3–FetO–SiO2–MgO slags.

View full abstract

-

Phillip Brian Drain, Kezhuan Gu, Neslihan Dogan, Raymond James Longbot ...

Article type: Regular Article

2021 Volume 61 Issue 3 Pages

734-744

Published: March 15, 2021

Released on J-STAGE: March 17, 2021

JOURNAL

OPEN ACCESS

FULL-TEXT HTML

Although the dephosphorization kinetics of bloated metal droplets reacting with oxidizing slag have been studied in detail in the authors’ laboratory, the mechanism of reaction for slags in a basicity range typical of steelmaking, has been sparsely reported. The current study employed a high temperature furnace equipped with X-ray fluoroscopy to observe the bloating behavior of droplets and tracked dephosphorization kinetics by quenching and analyzing droplets after different reaction times. The mechanism of reaction between bloated metal droplets and slag was studied at 1923 K for slags with basicity range C/S=2.56. The rate and extent of dephosphorization was found to be greater in CMS slags compared to CAS slags due to the faster mass transport and a larger thermodynamic driving force. The kinetic analysis showed that the reaction proceeded in two distinct stages, a fast initial stage followed by a slower stage. The km during the first stage of dephosphorization was at least 8 times higher than that during the second stage. This is proposed to be due to a higher internal CO generation rate during the initial stage which increases the rate of surface renewal. The effect of TiO2 on dephosphorization kinetics was also investigated in terms of thermodynamic driving force.

View full abstract

-

Yong Hou, Guo-Hua Zhang, Kuo-Chih Chou

Article type: Regular Article

2021 Volume 61 Issue 3 Pages

745-752

Published: March 15, 2021

Released on J-STAGE: March 17, 2021

JOURNAL

OPEN ACCESS

FULL-TEXT HTML

During the production process of ferrosilicon (FeSi), ferrosilicochrome (FeSiCr) and silicomanganese ferroalloy (SiMn), silicon carbide (SiC) particles are inevitably formed and distribute in the slags. The existence of SiC particles leads to a large difficulty for slag-metal separation and thus a great increase of metal loss. In this paper, the reaction behavior between SiC and CaO–SiO2–Al2O3 slag is investigated in detail. It is of great guiding significance for adjusting the slags for the well separation of slag and metal in the production process of silicon-based ferroalloys. The reaction kinetics between SiC and CaO–SiO2–Al2O3 slag depends significantly on the composition of slag, temperature and the particle size of SiC. Within a certain time, the reaction extent first decreases and then increases with the increase of the CaO/SiO2 binary basicity, but gradually decreases by adding Al2O3 into the slag. Meanwhile, the increase of temperature promotes the solid-liquid reaction between SiC and CaO–SiO2–Al2O3 slag.

View full abstract

-

Yutang Li, Linzhu Wang, Junqi Li, Shufeng Yang, Chaoyi Chen, Changrong ...

Article type: Regular Article

2021 Volume 61 Issue 3 Pages

753-762

Published: March 15, 2021

Released on J-STAGE: March 17, 2021

Advance online publication: December 16, 2020

JOURNAL

OPEN ACCESS

FULL-TEXT HTML

Understanding the mechanism of particle aggregation and dispersion at a liquid surface is important for the design and fabrication of novel materials. The behaviors of particles with various compositions at the interface of high-temperature melts, including the rapid growth of particles, the linear aggregation or curvilinear motion, and the wetting and separation processes, were observed in situ by high-temperature confocal laser scanning microscopy (HT-CLSM). We experimentally investigated the interaction force on particle pairs as a function of the interparticle distance and the size, composition and shape of particles. The experimental results indicate the attractive force between particle pairs decreases with increasing distance, and it increases as the size of the guest particle increases. The acting length of particles increases in the order of the alumina-magnesia particle (30 µm)< calcium aluminate particle with low CaO contents (80 µm)<alumina particle (110 µm). The estimated attractive interaction between particle pairs based on in situ observation increases in the order of Al2O3·35%CaO< Al2O3·19%MgO < Al2O3·38%MgO < Al2O3·15%CaO < Al2O3. The complex selective attraction has been observed in the in situ experiments which is attributed to the polydirectional attractive force and anisotropy in the particle morphology. The relationship between the roundness with acceleration rate of particles indicates that the attraction between spherical particles tends to be less than the attraction between irregular particles with edges.

View full abstract

-

Xiang Li, Ping Tang, Jing Jiang, Qu Fu, Guanghua Wen

Article type: Regular Article

2021 Volume 61 Issue 3 Pages

763-772

Published: March 15, 2021

Released on J-STAGE: March 17, 2021

JOURNAL

OPEN ACCESS

FULL-TEXT HTML

Basic oxygen furnace (BOF) flue gas cleaning system is a crucial flue gas purification device to ensure the cleaner production in steelmaking process. Due to utilization of galvanized steel scrap in steelmaking process, zinc-containing dust collected by the cleaning system forms unremovable high-strength dust agglomerates on the inner wall of evaporative cooler, which can affect the normal operation of cleaning system and seriously hinder the cleaner production in steelmaking process. This issue continuously aggravates as the use of galvanized steel scrap increases, while there are currently no effective control methods. Consequently, how to keep down the zinc-containing dust agglomeration strengthening in the evaporative cooler is a crucial issue for investigation. In this paper, X-ray fluorescence spectrometer, X-ray diffraction, scanning electron microscopy and strength test under high-temperature roasting were carried out to investigate characteristics and strengthening mechanism of dust agglomerates. Based on this, easy implementation of control methods were proposed. The results show that ZnO reacts with Fe2O3 at a high temperature above 600°C to form tightly ZnFe2O4 phase, and chemical adsorption of ZnFe2O4 with BOF dust particles is the primary cause of dust agglomeration strengthening in evaporative coolers. Solid state sintering of low melting point substances containing Na+ and K+ promotes strengthening. Decreasing the temperature in evaporative cooler and controlling the content of low melting point substances in BOF dust are effective measures to reduce dust agglomerates, optimize the environment of cleaning system, and ensure the cleaner production in steelmaking process.

View full abstract

-

Yaoguang Li, Yanhui Sun, Xuesong Bai

Article type: Regular Article

2021 Volume 61 Issue 3 Pages

802-813

Published: March 15, 2021

Released on J-STAGE: March 17, 2021

Advance online publication: November 28, 2020

JOURNAL

OPEN ACCESS

FULL-TEXT HTML

A three-dimensional model, which coupled flow, heat transfer, solidification, solute transport and electromagnetic field, was separately developed for vertical mold and curved mold of billet continuous casting. Therefore, the characteristics and disciplinarians of macroscopic transport behavior for different types of mold were revealed. The influence of mold electromagnetic stirring (M-EMS) and mold curvature on the flow, heat transfer, solidification, solute transport in the mold were investigated in detail. The results indicate that the M-EMS can cause obvious rotating flow in the mold and enhance the superheat dissipation of the molten steel to promote the growth of solidification shell. The mold curvature has a profound effect on the flow field distribution of the mold, and further affects the temperature field and solute distribution in the mold. Therefore, the mold curvature is necessary to consider for predicting the macroscopic transmission phenomenon in the mold. Moreover, the predicted and experimental results for distributions of magnetic flux density and near surface element C content compare agreeably, which indicates the validity of the coupled model in current work.

View full abstract

-

Zhuo Chen, Weitong Du, Min Zhang, Qian Wang, Shengping He

Article type: Regular Article

2021 Volume 61 Issue 3 Pages

814-823

Published: March 15, 2021

Released on J-STAGE: March 17, 2021

Advance online publication: January 23, 2021

JOURNAL

OPEN ACCESS

FULL-TEXT HTML

In order to eliminate the TiN inclusion emerging from the molten steel and maintain the stable performance of mould flux during continuous casting of high Ti-bearing steel, the influence of extra oxidisers, such as Mn2O3, Mn3O4, and Fe2O3 substituting SiO2, on the reaction performance and physical properties of CaO–SiO2 type mould flux was investigated in this study. A detailed study using thermodynamic calculation, X–ray diffraction, and thermogravimetric analysis shows that the oxidisability of oxidisers to TiN, ranging from strong to weak, is Fe2O3, Mn2O3, Mn3O4, and SiO2. The oxidisability of SiO2 in the mould flux is much weaker than that of Mn2O3 and Fe2O3. Results show that the precipitation of solid iron after the reaction between the CaO–SiO2–Al2O3 type or CaO–Al2O3 type mould fluxes with Fe2O3 and TiN worsens the liquidity of the mould flux and further deteriorate its physical properties. Mn2O3 is the best option, with a sustainable change in the physical properties at less than 10 wt.%. Moreover, following the reaction with TiN, the physical properties of the CaO–SiO2–Al2O3 type mould flux with 15 wt.% Mn2O3 show an acceptable change for the application of casting.

View full abstract

-

Jujin Wang, Lifeng Zhang, Yuexin Zhang, Gong Cheng, Yadong Wang, Ying ...

Article type: Regular Article

2021 Volume 61 Issue 3 Pages

824-833

Published: March 15, 2021

Released on J-STAGE: March 17, 2021

JOURNAL

OPEN ACCESS

FULL-TEXT HTML

The transformation of non-metallic inclusions in the first continuous casting bloom of a bearing steel was studied through industrial trials and theoretical calculations. The spatial composition distribution of inclusions in the continuous casting bloom was predicted using a comprehensive model coupling heat transfer, thermodynamics, kinetics and industrial parameters. The effect of cooling rate on the transformation of composition of inclusions was investigated. The total oxygen in the first bloom gradually decreased from 12 ppm at the cast start to 7 ppm at 10 m cast length, and this variety in the total oxygen resulted in the decrease of the Al2O3 content in inclusions from 70% at the casting start to 50% at 10 m cast length. The transformation of inclusions during the continuous casting occurred preferentially at the quarter thickness of the bloom and the reaction zone gradually moved from the subsurface to the center of the bloom. Isothermal transformation diagrams and continuous cooling transformation diagrams of inclusions were established to characterize the transformation kinetics of inclusions. Inclusions at the subsurface of the CC bloom transformed at the mold cooling zone in the actual cooling of the continuous casting bloom, while inclusions at the center transformed at the air-cooling zone. The transformation ratio of inclusions in the CC bloom was determined by the cooling rate and the transformation rate was dominated by the temperature.

View full abstract

-

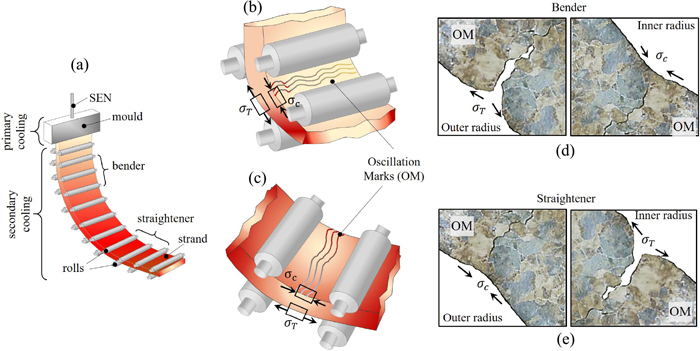

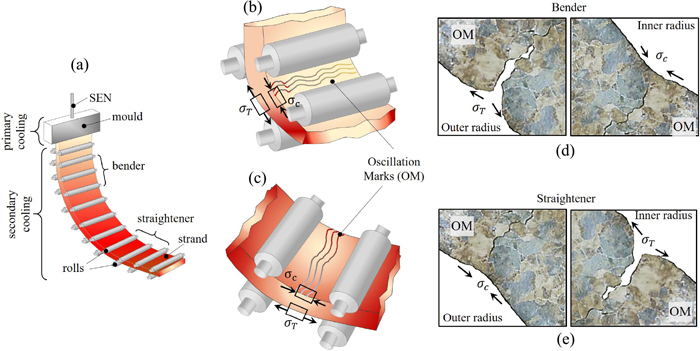

Rosa Maria Pineda Huitron, Pavel Ernesto Ramirez Lopez, Esa Vuorinen, ...

Article type: Regular Article

2021 Volume 61 Issue 3 Pages

834-843

Published: March 15, 2021

Released on J-STAGE: March 17, 2021

Advance online publication: November 21, 2020

JOURNAL

OPEN ACCESS

FULL-TEXT HTML

A holistic approach to diagnose the occurrence of cracking on HSLA steel slabs and propose countermeasures to prevent them is presented. The approach consisted on plant monitoring, including direct temperature measurements in the strand with pyrometers. Extensive characterization was performed via thermo-mechanical tests and microscopy techniques which revealed combination of Widmanstätten ferrite, acicular ferrite and secondary phases that promote embrittlement during casting with a minimum ductility between 700°C–800°C (± 50°C) which is responsible for cracking in this steel. Finally, 1D and 3D numerical models were developed to test possible cooling strategies which proved that reductions in water flowrate can have a positive effect in slab quality by avoiding the low ductility zone. Corrective actions included decreasing cooling to increase the overall temperature of the strand before the straightener to increase the overall temperature. Yet, some slabs still observed the presence of cracks which points at secondary factors such as high tundish temperatures >1530°C producing cracking. Other secondary factors include strong temperature variations up to ± 250°C during measurements which would send the strand corners into the low ductility range producing cracking despite having a hot slab centre. Although these optimization strategies are particular to each caster and steel grade, a similar approach could be applied to address secondary cooling issues during continuous casting. The models presented are an ideal toolkit to analyse the influence of product size and operation parameters in combination with plant monitoring and extensive microstructure characterization to improve the quality and productivity of the process.

View full abstract

-

Dongwei Guo, Zibing Hou, Zhiqiang Peng, Qian Liu, Yi Chang, Jianghai C ...

Article type: Regular Article

2021 Volume 61 Issue 3 Pages

844-852

Published: March 15, 2021

Released on J-STAGE: March 17, 2021

JOURNAL

OPEN ACCESS

FULL-TEXT HTML

The statistics of extreme values (SEV) and the generalized Pareto distribution (GPD) are introduced to obtain the predicted maximum carbon content and represent the macrosegregation degree along the casting direction in continuous casting billets (represented by 82B cord steel). Subsequently, the influence mechanism of the superheat on macrosegregation has been investigated. It’s found that the SEV and the GPD methods can correctly obtain the predicted maximum carbon content and the results obtained by the SEV method increase linearly with the return period, while the GPD method can calculate the upper limit value of carbon content. The stochastic mathematical methods can get rid of the limitations of the sampling length and analysis area. During the exploration of the superheat influence mechanism based on the results obtained by these two methods, lower superheat can increase the secondary dendritic arm spacing (SDAS) and make the enriched carbon element easier concentrating on the centerline, resulting in centerline segregation and the increase of the corresponding result in the centerline. Under higher superheat condition, the segregation will be mainly represented as V-shaped segregation due to the decrease of the SDAS, leading to the increase of corresponding result in the off-center position.

View full abstract

-

Yanbin Yin, Jiongming Zhang

Article type: Regular Article

2021 Volume 61 Issue 3 Pages

853-864

Published: March 15, 2021

Released on J-STAGE: March 17, 2021

Advance online publication: December 18, 2020

JOURNAL

OPEN ACCESS

FULL-TEXT HTML

To investigate the transient multiphase flow, slag entrainment and exposed slag eye in the mold with EMBr and argon injection, a transient multiphase LES model was constructed. In the model, the multiphase (steel-slag-air) flow was simulated through VOF method, argon bubbles were tracked using DPM method. The model was validated by previous experimental measurements through the particle image velocimetry. The results indicated that argon injection weakened the upper recirculation flow, and reduced the molten steel jet downward angle. Moreover, the turbulent flow in the mold was suppressed by EMBr. The slag entrainment mechanisms are different under different conditions. In the case without argon injection and EMBr, three slag entrainment mechanisms were found: shear flow, Von Kármán vortex, and level fluctuation. Nevertheless, when argon was injected, in addition to the above mechanisms, one extra mechanism was predicted that was bubble interaction. Additionally, bubble interaction was the unique slag entrainment mechanism in the case with argon injection and EMBr. The impact of argon bubbles on the steel-slag interface resulted in exposed slag eye. In the case without EMBr, the exposed slag eye phenomenon was intermittent. However, the phenomenon was persistent when EMBr was applied.

View full abstract

-

Chuanjun Li, Qiong Zhang, Longqiang Zhu, Weidong Xuan, Jiang Wang, Qua ...

Article type: Regular Article

2021 Volume 61 Issue 3 Pages

865-870

Published: March 15, 2021

Released on J-STAGE: March 17, 2021

JOURNAL

OPEN ACCESS

FULL-TEXT HTML

The heat absorption method (HAM) was proposed to improve the quality of a large steel ingot. The CaO–CaF2 inorganic material rods was used to reduce 5 K superheat of the 6-ton GCr15 molten steel. The quality of the steel ingots with and without the HAM was compared. In comparison with conventional casting, the HAM not only significantly alleviated the A- and V-segregation and the segregation levels of carbon and sulfur, but also reduced the number of inclusions and the shrinkage porosity zone in the 6-ton steel ingot. The simulation results demonstrated that the molten steel could quickly be cooled from within by the inorganic material rods, which is the main reason for the reduction of macrosegregation. Additionally, the majority of inclusions could be absorbed and removed when the liquid inorganic material floated up in the molten steel.

View full abstract

-

Keisuke Fukuda, Yuki Kashiwa, Satoshi Oue, Tomio Takasu, Hiroaki Nakan ...

Article type: Regular Article

2021 Volume 61 Issue 3 Pages

919-928

Published: March 15, 2021

Released on J-STAGE: March 17, 2021

JOURNAL

OPEN ACCESS

FULL-TEXT HTML

The electrodeposition of Invar Fe–Ni alloy with low thermal expansion was performed at 100–5000 A·m−2 and 105 C·m−2 in agitated Watt’s solutions containing NiSO4, NiCl2, FeSO4, malonic acid (C3H4O4), saccharin sodium (C7H4NNaO3S), and H3BO3 at 50°C. With increasing concentration of malonic acid, the Ni content in deposits formed at current densities greater than 2000 A·m−2 decreased, whereas the Ni content increased in deposits formed at current densities less than 1000 A·m−2. The current efficiency for alloy deposition decreased with increasing concentration of malonic acid. The deposits were composed of granular crystals whose size decreased with increasing concentration of malonic acid. With the addition of saccharin, the Ni content in the deposits decreased substantially, and the current efficiency for alloy deposition increased. With the addition of boric acid, the Ni content in the deposits somewhat decreased, and the current efficiency for alloy deposition increased. The surface morphology of deposits changed as the current density was varied and with the addition of saccharin, whereas it rarely changed with the addition of boric acid. The morphology was found to depend on the Ni content in the deposits. The deposits with a Ni content of 29–38 mass% were composed of granular crystals approximately 300 nm in size, whereas the deposits with a Ni content of 41–52 mass% exhibited a smooth surface that consisted of fine crystals. The effects of additives on the Ni content in deposits and current efficiency can be explained by the changes in the partial polarization curves for Fe and Ni depositions and H2 evolution during Fe–Ni alloy deposition.

View full abstract

-

Takeshi Konishi, Hideaki Sawada, Takashi Doi, Kohsaku Ushioda

Article type: Regular Article

2021 Volume 61 Issue 3 Pages

929-936

Published: March 15, 2021

Released on J-STAGE: March 17, 2021

Advance online publication: November 29, 2020

JOURNAL

OPEN ACCESS

FULL-TEXT HTML

In a molten zinc bath in a continuous galvanizing line, the top dross particles crystallize as a Zn-containing intermetallic Fe2Al5 compound, which generates surface defects in the final product by easily adhering to the steel sheets. The present study focused on analysis of the crystal structure of a top dross by first principles calculation and synchrotron X-ray diffraction of the top dross prepared in a laboratory. The following results were obtained: first principles calculation on the top dross suggested that two Al atoms at four of the partially occupied Al sites in the Fe2Al5 structure proposed by Mihalkovič et al., were replaced by two Zn atoms. In addition, the Al atoms at both the types of partially occupied Al sites in Fe2Al5 proposed by Burkhardt et al., were equally replaced by Zn atoms. The proposed crystal structure of the top dross was verified by conducting X-ray diffraction profile analysis using RIETAN-FP simulations as well as the experimentally determined lattice constant of the Zn-containing top dross.

Calculated X-ray diffraction profiles by RIETAN-FP.

21) (a) Fe

2Al

5, (b) crystal structure when all the Fe atoms of Fe

2Al

5 are replaced by Zn atoms, (c) crystal structure when all the Al atoms at the Al

I sites of Fe

2Al

5 are replaced by Zn atoms, (d) crystal structure when all the Al atoms at the Al

II sites of Fe

2Al

5 are replaced by Zn toms, and (e) crystal structure when all Al atoms in Al

III sites of Fe

2Al

5 are replaced by Zn atoms. (f) Experimentally measured X-ray diffraction profile of sample 1 of the top dross.

Fullsize Image

View full abstract

-

Takeshi Konishi, Mina Shibata, Junpei Miki, Yuu Nemoto, Kohsaku Ushiod ...

Article type: Regular Article

2021 Volume 61 Issue 3 Pages

937-944

Published: March 15, 2021

Released on J-STAGE: March 17, 2021

Advance online publication: November 20, 2020

JOURNAL

OPEN ACCESS

FULL-TEXT HTML

In a molten zinc bath in a continuous galvanizing line (CGL), top dross particles crystallize as Fe–Al–Zn intermetallic compounds. These particles easily adhere to the steel sheets causing surface defects. Therefore, controlling the top dross particles is a key issue. Our study focused on the structural and mechanical characterizations of the top dross particles using an electron probe micro analyzer, X-ray diffraction, electron back scattering diffraction, Vickers hardness measurements, and nano-indentation measurements. The following results were obtained: (1) The crystal structure of the top dross particles Fe2Al5Znx having 37–38 wt% Fe, 44–45 wt% Al, and 18–19 wt% Zn belongs to the orthorhombic system with lattice constants of a = 7.61 Å, b = 6.48 Å, and c = 4.23 Å. The a-axis of Fe2Al5Znx becomes shorter, while its b- and c-axes become longer compared to those of the binary Fe2Al5. (2) The coarsening of the top dross particles with the faceted interface was postulated to occur as a result of the driving force provided by the anisotropic interface energy between the top dross particles and molten Zn, rather than via the aggregation mechanism. (3) The hardness and the elastic modulus of the top dross particles are the lowest in the [001] orientation, similar to Fe2Al5, and are lower than those of Fe2Al5. (4) The fracture toughness of the top dross particles is approximately 1.1 MPa·m1/2, which is slightly lower than that of Fe2Al5.

(a) EPMA compositional image of Fe

2Al

5Zn

x phase dross particles showing the concentration of (b) Al, (c) Fe and (d) Zn (mass%).

Fullsize Image

View full abstract

-

Kano Nakajima, Takayuki Yamada, Michihisa Fukumoto

Article type: Regular Article

2021 Volume 61 Issue 3 Pages

945-952

Published: March 15, 2021

Released on J-STAGE: March 17, 2021

JOURNAL

OPEN ACCESS

FULL-TEXT HTML

A porous surface layer was formed by Al electrodepositing and Al dissolving on the surface of stainless steel using molten salt. Furthermore, the relationship between the morphology of the alloy layer produced by Al electrodeposition and the porous layer was clarified. As a result, Fe aluminide with high Al concentration was formed on the surface by lowering the Al electrodeposition potential. Then, in order to investigate the dissolution behavior of Al, the anodic polarization curves of the Al electrodeposited sample and the untreated sample were measured. An increase in the anode current was observed from around −1.2 V in the Al electrodeposited sample. On the other hand, an increase in the anode current was observed from around −0.8 V for the untreated sample. Therefore, the dissolution experiment was performed at −0.9 V, where Al dissolution occurs and SUS304 dissolution does not occur. The lower the potential during Al electrodeposition, the thicker the porous layer with higher porosity formed. As a result of point analysis of the composition of the porous layer, it was recognized to be an austenite phase having a lower Cr concentration than untreated SUS304. It is considered that Fe remains in the porous layer as Al is dissolved and that Fe diffuses at high temperature to form a porous layer. Thus, the sliding characteristics of the stainless steel with the porous layer and the untreated stainless steel were evaluated. The porous sample showed better characteristics than the untreated sample.

View full abstract

-

Junji Miyamoto, Ryo Tsuboi, Kazushige Tokuno

Article type: Regular Article

2021 Volume 61 Issue 3 Pages

953-959

Published: March 15, 2021

Released on J-STAGE: March 17, 2021

JOURNAL

OPEN ACCESS

FULL-TEXT HTML

Atmospheric-pressure plasma nitriding of AISI H13 tool steel is performed using a dielectric barrier discharge method. As the surface of the sample nitrided by atmospheric-pressure plasma is oxidized, the surface characteristics are considered to be different from those of conventional plasma nitriding in a vacuum. In this study, the surface properties of the nitrided layer such as tribological properties generated by atmospheric-pressure plasma nitriding are investigated. The results show that the surface and cross-sectional hardness of the nitrided sample increase as the amount of nitrogen gas increases. By contrast, the surface and cross-sectional hardness of the nitrided sample increase as the amount of hydrogen gas decreases. Moreover, the surface luster of the nitrided samples changes unlike the untreated samples; however, the surface roughness of all the nitrided samples is similar to that of the untreated samples. When compared with an untreated sample, the friction coefficient and wear resistance of the nitrided sample are improved. For this reason, we consider that the nitriding in this research also causes oxidation by oxygen, similar to oxynitriding. Samples with oxidation film formed by atmospheric-pressure plasma nitriding have excellent wear resistance and friction coefficient, demonstrating the superiority of atmospheric-pressure plasma nitriding for treating small components.

View full abstract

-

Takashi Kataoka, Haruhiko Atsumi, Masato Yasuda, Nobusato Morishige, K ...

Article type: Regular Article

2021 Volume 61 Issue 3 Pages

960-966

Published: March 15, 2021

Released on J-STAGE: March 17, 2021

Advance online publication: October 30, 2020

JOURNAL

OPEN ACCESS

FULL-TEXT HTML

To understand the factors that determine the secondary recrystallization textures of Fe–Si alloy, the change in the secondary recrystallization textures of Fe–Si sheets was investigated by increasing the cold-rolled reduction rate (CR) from 70 up to 95%.

The secondary recrystallization textures in the CRs=90–95% samples accumulated in specific orientations; the main components of the secondary recrystallization were {110}<001> in the CRs=90 and 93% samples, and {110}<001> with {110}<112> in the CR=95% sample. The experimental results were reproduced by calculations based on the idea that the secondary recrystallization texture is mainly determined by the frequency of the specific-orientation-grain-boundaries, for example, coincidence-site-lattice grain boundaries. In contrast, in the CR=70% sample, the secondary recrystallization texture was not accumulated but dispersed from {110}<001> to {110}<225> and was inaccurately reproduced by the above calculations.

The study concludes that the secondary recrystallization textures in the CRs=90–95% samples are mainly determined by the grain boundary effect. It is also concluded that the secondary recrystallization textures of the CR=70% sample are determined by both grain boundary effect and nucleus effect. The difference in the mechanisms originates from the changes in the frequency of the specific-orientation-grain-boundaries in the matrix and of the nuclei at the surface in the primary recrystallization textures of various CRs.

View full abstract

-

Haijian Xu, Wanqing Hu, Chao Kang, Weijuan Li, Xiaochun Sha

Article type: Regular Article

2021 Volume 61 Issue 3 Pages

967-974

Published: March 15, 2021

Released on J-STAGE: March 17, 2021

JOURNAL

OPEN ACCESS

FULL-TEXT HTML

In this study, hot deformation behavior of lean duplex stainless steel 2101 (LDX2101) is investigated via isothermal compressive tests in the temperature ranges of 900–1150°C and the strain rate ranges of 0.01–10 s−1. The effect of temperature and strain rate on the hot workability, strain partitioning and flow behaviour of LDX2101 is systematically investigated. It is found that the peak stress decreased with an increase in deformation temperature and a decrease in strain rate. The softening mechanism of the ferrite and austenite is dynamic recovery (DRV) and dynamic recrystallization (DRX), respectively. Further increasing the strain rate promote the DRX. The hot processing map was constructed in the sample. There are two flow instability regions at lower strain rate and lower temperature due to the lack of sufficient extra stress for the discrepancy of deformation coordination between the ferrite/austenite phases. Moreover, brittle Cr2N precipitates are observed along the ferrite/austenite phase boundaries, which can act micro-cracks initiation position. Considering the hot processing map and microstructural evolution in LDX2101, the optimum hot processing parameters for LDX2101 are found to be in a strain rate range of 0.01–10 s−1 with the temperature range of above 1050°C and strain rate of 0.8–10 s−1.

View full abstract

-

Suresh Kodukula, Pentti Karjalainen, David Porter

Article type: Regular Article

2021 Volume 61 Issue 3 Pages

975-984

Published: March 15, 2021

Released on J-STAGE: March 17, 2021

Advance online publication: January 23, 2021

JOURNAL

OPEN ACCESS

FULL-TEXT HTML

Ridging means the appearance of surface profile undulations, i.e. peaks and valleys, as a result of plastic strain. The reasons for the different ridging behaviour of industrially produced, stabilized ferritic stainless steel sheets (EN 1.4509) have been investigated after straining in the rolling and transverse directions with low and high resistance towards ridging. The evolution of macro-texture has been measured by X-ray diffraction (XRD) both before and after ridging tests in the rolling and transverse directions. The macro texture results showed that straining along the rolling direction strengthened the α fibre whereas the γ fibre was strengthened by grain rotations after straining along transverse direction. Electron backscatter diffraction (EBSD) imaging was used to establish the micro-textural variations over the thickness of the sheets among the high and low ridging materials. Mean orientations of individual grains determined from the EBSD data were utilized to calculate plastic strain ratio r-values by considering all slip systems weighted according to their Schmid factors. The calculated r-values were used to predict the ridging surface profile after straining along the rolling and transverse directions. The results demonstrated the influence of local variations in micro-texture on the severity of ridging.

View full abstract

-

Qi Wang, Xiangtao Deng, Long Huang, Tianliang Fu, Ye Jia, Chengru Li, ...

Article type: Regular Article

2021 Volume 61 Issue 3 Pages

985-992

Published: March 15, 2021

Released on J-STAGE: March 17, 2021

JOURNAL

OPEN ACCESS

FULL-TEXT HTML

TiC is a widely used reinforcement in wear-resistant materials. In recent years, many researchers have studied the effect of TiC on wear resistance, and the size of TiC particles is often perceived to influence the wear resistance. However, when the size of TiC particles changes, the composition or hardness of the experimental steel also changes. In this study, (Ti, Mo)xC-reinforced steels with the same composition were prepared though melt solidification processing using stepped molds of variable thicknesses to exclude the influence of the composition and hardness of the steel on the abrasion resistance. The solidification rate was varied by the thickness of billets, which directly affected the nucleation and growth rates of the (Ti, Mo)xC particles. The size of the (Ti, Mo)xC particles in the (Ti, Mo)xC-reinforced steels varied between 1.88 and 3.20 µm. The three-body abrasive wear behavior of the (Ti, Mo)xC-reinforced steels was determined using a wet sand/rubber wheel testing machine and the wear morphology was observed using scanning electron microscopy. The results indicated that the three-body abrasive wear mechanism of the (Ti, Mo)xC-reinforced steels was mainly pits and micro-cuttings. As the size of the (Ti, Mo)xC increased, the wear resistance of the (Ti, Mo)xC-reinforced steels decreased. Larger stress occurred owing to different thermal expansion coefficients between the coarse particle and the surrounding matrix, which was more conducive to crack initiation and propagation. The optimum abrasion resistance of the (Ti, Mo)xC-reinforced steel was 1.76 times that of traditional low alloy wear-resistant steel with similar hardness.

View full abstract

-

Tomotaka Hatakeyama, Kota Sawada, Kaoru Sekido, Toru Hara, Kazuhiro Ki ...

Article type: Regular Article

2021 Volume 61 Issue 3 Pages

993-1001

Published: March 15, 2021

Released on J-STAGE: March 17, 2021

Advance online publication: December 17, 2020

JOURNAL

OPEN ACCESS

FULL-TEXT HTML

Graphitization in carbon steels must be prevented because it reduces the amount of carbon in the matrix, which degrades the material performance due to loss in strength. In addition, when graphite particles are aligned, they can cause fracture by their linkage. The safety management standards for carbon steels in high-temperature applications state that graphitization should be considered at 698 K and above. The number of reported cases on graphitization in steels below 698 K is limited, and the mechanism has not yet been well investigated. This paper reports the finding of unprecedented graphitization at 673 K in creep-ruptured carbon steel and an elongated form of graphite that appears after a much shorter time at 673–773 K than other previously reported times. Furthermore, the formation mechanism of this elongated graphite is discussed. Dislocations and inclusions in the vicinity of grain boundaries may facilitate graphitization kinetics at these temperatures.

View full abstract

-

Hiroyuki Kawata, Osamu Umezawa

Article type: Regular Article

2021 Volume 61 Issue 3 Pages

1002-1010

Published: March 15, 2021

Released on J-STAGE: March 17, 2021

JOURNAL

OPEN ACCESS

FULL-TEXT HTML

The influence of martensite-austenite constituents on the two-step ductile to brittle transition (DBT) behavior of low carbon steel sheets was evaluated using Charpy impact tests with sub-size specimens. Four kinds of steel sheets containing 0–38% volume fraction of MA and polygonal ferrite in the matrix were chosen. Small volumes of MA (i.e., 2 and 14%) revealed a slightly higher transition temperature between the middle shelf (MS) and lower shelf, TML, compared to sheets with 0% MA. Furthermore, the transition temperature between the upper shelf and MS was not affected. The steel sheet containing 38% MA constituents exhibited a normal one-step DBT curve without MS, and a significantly higher transition temperature than the steel sheets containing 0, 2, and 14% MA. The increase in the austenite volume fraction in MA from 0.6 to 10.2% was not responsible for the DBT behavior, which may depend on the volume fraction of martensite in MA. A model of two-step DBT for multi-phase steel sheets, in which the small volume of MA lowered the fracture stress of the hard structure and elevated TML, was proposed. The TML depended on the intersection between the fracture stress of the hard structure and the yield stress of the soft structure. In the two-step DBT, the cleavage crack propagation was arrested at ferrite grain boundaries through the MS. A large volume of MA (e.g., all the ferrite grains fully covered) may promote one-step DBT in multi-phase steel sheets, owing to cleavage crack propagation.

View full abstract

-

Hiroaki Matsumoto

Article type: Regular Article

2021 Volume 61 Issue 3 Pages

1011-1021

Published: March 15, 2021

Released on J-STAGE: March 17, 2021

JOURNAL

OPEN ACCESS

FULL-TEXT HTML

The Ti–6Al–2Sn–4Zr–6Mo (Ti-6246) alloy is an α + β titanium alloy with good combination of strength, toughness, high temperature creep property and crack growth resistance. This work examined the dynamic microstructural conversion behavior (specifically focusing on dynamic globularization of α phase) occurred under hot forging process (at temperatures ranging from 750°C to 1050°C) of the Ti-6246 alloy with various kinds of starting microstructure. Plastic flow behavior of the microstructure having the α-lamellae exhibited a peak stress followed by continuous flow softening due to frequent occurrence of lamellae kinking and globularization of the α phase. For the microstructural conversion of β phase, continuous dynamic recrystallization (CDRX) was dominantly occurred. And the enhanced CDRX is observed for the lamellar starting microstructure as compared to the bimodal and the equiaxed starting microstructures. On the globularization kinetics according to a phenomenological Avrami approach and a machine learning approach, when the processing conditions were categorized into 3 groups from a hierarchical clustering, the estimated globularization fraction from Avrami approach corresponded reasonably well with the experimental data only in a specific process condition group in which corresponded with a higher temperature and a higher dynamic globularization fraction. Thus, this work points out the possibility of a reliable prediction of dynamic globularization according to an optimal combination of the Avrami approach and the machine learning approach.

View full abstract

. However, the network-modifying role of iron oxide is limited within a critical concentration, which is also dependent on the C/A ratio of the CaO–Al2O3–FetO–SiO2–MgO slags.

. However, the network-modifying role of iron oxide is limited within a critical concentration, which is also dependent on the C/A ratio of the CaO–Al2O3–FetO–SiO2–MgO slags.