Volume 60, Issue 8

Displaying 1-37 of 37 articles from this issue

- |<

- <

- 1

- >

- >|

Publication Data

-

2020 Volume 60 Issue 8 Pages Cover-

Published: August 15, 2020

Released on J-STAGE: August 18, 2020

Download PDF (432K) -

2020 Volume 60 Issue 8 Pages Editorial-

Published: August 15, 2020

Released on J-STAGE: August 18, 2020

Download PDF (1107K) -

2020 Volume 60 Issue 8 Pages Contents-

Published: August 15, 2020

Released on J-STAGE: August 18, 2020

Download PDF (142K)

Review Article

New Materials and Processes

-

Article type: Review

2020 Volume 60 Issue 8 Pages 1571-1576

Published: August 15, 2020

Released on J-STAGE: August 18, 2020

Advance online publication: February 28, 2020Download PDF (1627K) Full view HTML

Regular Articles

Fundamentals of High Temperature Processes

-

Article type: Regular Article

2020 Volume 60 Issue 8 Pages 1577-1585

Published: August 15, 2020

Released on J-STAGE: August 18, 2020

Advance online publication: March 06, 2020Download PDF (1736K) Full view HTML -

Article type: Regular Article

2020 Volume 60 Issue 8 Pages 1586-1595

Published: August 15, 2020

Released on J-STAGE: August 18, 2020

Download PDF (2460K) Full view HTML -

Article type: Regular Article

2020 Volume 60 Issue 8 Pages 1596-1601

Published: August 15, 2020

Released on J-STAGE: August 18, 2020

Advance online publication: February 19, 2020Download PDF (1279K) Full view HTML -

Article type: Regular Article

2020 Volume 60 Issue 8 Pages 1602-1609

Published: August 15, 2020

Released on J-STAGE: August 18, 2020

Download PDF (1350K) Full view HTML -

Article type: Regular Article

2020 Volume 60 Issue 8 Pages 1610-1616

Published: August 15, 2020

Released on J-STAGE: August 18, 2020

Download PDF (611K) Full view HTML -

Article type: Regular Article

2020 Volume 60 Issue 8 Pages 1617-1623

Published: August 15, 2020

Released on J-STAGE: August 18, 2020

Advance online publication: February 18, 2020Download PDF (1762K) Full view HTML

Ironmaking

-

Article type: Regular Article

2020 Volume 60 Issue 8 Pages 1624-1632

Published: August 15, 2020

Released on J-STAGE: August 18, 2020

Download PDF (1337K) Full view HTML -

Article type: Regular Article

2020 Volume 60 Issue 8 Pages 1633-1640

Published: August 15, 2020

Released on J-STAGE: August 18, 2020

Download PDF (489K) Full view HTML -

Article type: Regular Article

2020 Volume 60 Issue 8 Pages 1641-1648

Published: August 15, 2020

Released on J-STAGE: August 18, 2020

Download PDF (2056K) Full view HTML -

Article type: Regular Article

2020 Volume 60 Issue 8 Pages 1649-1654

Published: August 15, 2020

Released on J-STAGE: August 18, 2020

Download PDF (980K) Full view HTML -

Article type: Regular Article

2020 Volume 60 Issue 8 Pages 1655-1661

Published: August 15, 2020

Released on J-STAGE: August 18, 2020

Advance online publication: February 19, 2020Download PDF (1587K) Full view HTML -

Article type: Regular Article

2020 Volume 60 Issue 8 Pages 1662-1668

Published: August 15, 2020

Released on J-STAGE: August 18, 2020

Download PDF (1004K) Full view HTML -

Article type: Regular Article

2020 Volume 60 Issue 8 Pages 1669-1674

Published: August 15, 2020

Released on J-STAGE: August 18, 2020

Advance online publication: February 15, 2020Download PDF (1130K) Full view HTML

Steelmaking

-

Article type: Regular Article

2020 Volume 60 Issue 8 Pages 1675-1683

Published: August 15, 2020

Released on J-STAGE: August 18, 2020

Download PDF (1063K) Full view HTML

Casting and Solidification

-

Article type: Regular Article

2020 Volume 60 Issue 8 Pages 1684-1692

Published: August 15, 2020

Released on J-STAGE: August 18, 2020

Advance online publication: February 28, 2020Download PDF (1378K) Full view HTML -

Article type: Regular Article

2020 Volume 60 Issue 8 Pages 1693-1702

Published: August 15, 2020

Released on J-STAGE: August 18, 2020

Advance online publication: March 21, 2020Download PDF (2547K) Full view HTML

Instrumentation, Control and System Engineering

-

Article type: Regular Article

2020 Volume 60 Issue 8 Pages 1703-1713

Published: August 15, 2020

Released on J-STAGE: August 18, 2020

Download PDF (1406K) Full view HTML -

Article type: Regular Article

2020 Volume 60 Issue 8 Pages 1714-1723

Published: August 15, 2020

Released on J-STAGE: August 18, 2020

Advance online publication: February 22, 2020Download PDF (2134K) Full view HTML

Chemical and Physical Analysis

-

Article type: Regular Article

2020 Volume 60 Issue 8 Pages 1724-1731

Published: August 15, 2020

Released on J-STAGE: August 18, 2020

Advance online publication: February 28, 2020Download PDF (1035K) Full view HTML

Forming Processing and Thermomechanical Treatment

-

Article type: Regular Article

2020 Volume 60 Issue 8 Pages 1732-1736

Published: August 15, 2020

Released on J-STAGE: August 18, 2020

Download PDF (1354K) Full view HTML -

Article type: Regular Article

2020 Volume 60 Issue 8 Pages 1737-1742

Published: August 15, 2020

Released on J-STAGE: August 18, 2020

Download PDF (1110K) Full view HTML -

Article type: Regular Article

2020 Volume 60 Issue 8 Pages 1743-1751

Published: August 15, 2020

Released on J-STAGE: August 18, 2020

Download PDF (1328K) Full view HTML

Welding and Joining

-

Article type: Regular Article

2020 Volume 60 Issue 8 Pages 1752-1757

Published: August 15, 2020

Released on J-STAGE: August 18, 2020

Download PDF (999K) Full view HTML -

Article type: Regular Article

2020 Volume 60 Issue 8 Pages 1758-1764

Published: August 15, 2020

Released on J-STAGE: August 18, 2020

Advance online publication: March 11, 2020Download PDF (2512K) Full view HTML

Surface Treatment and Corrosion

-

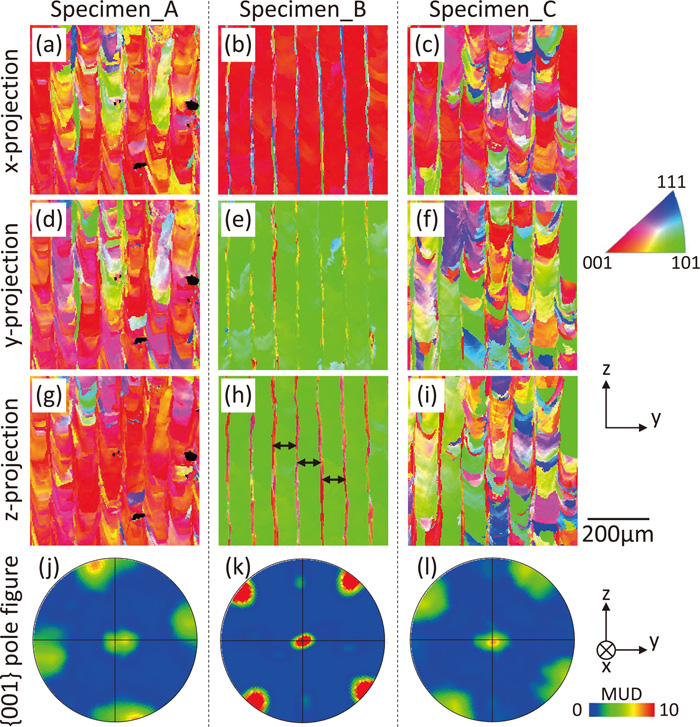

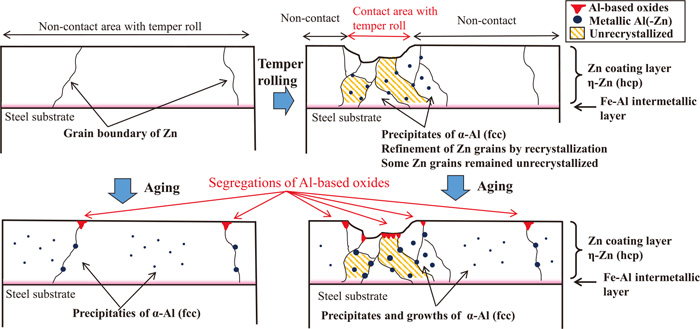

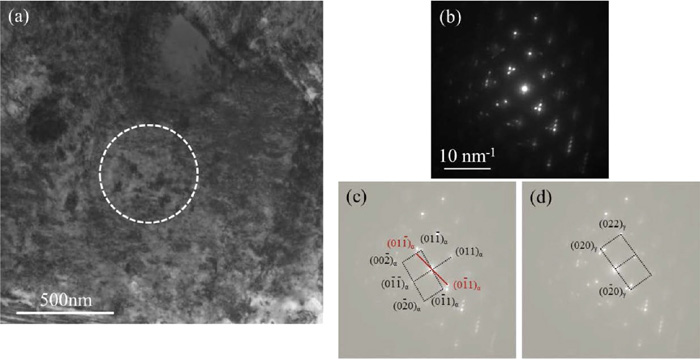

Segregation Mechanism of Al-based Oxides on Surface of Zn-0.2mass%Al Hot-dip Galvanized Steel SheetsArticle type: Regular Article

2020 Volume 60 Issue 8 Pages 1765-1773

Published: August 15, 2020

Released on J-STAGE: August 18, 2020

Advance online publication: February 06, 2020Download PDF (4090K) Full view HTML

Transformations and Microstructures

-

Article type: Regular Article

2020 Volume 60 Issue 8 Pages 1774-1783

Published: August 15, 2020

Released on J-STAGE: August 18, 2020

Download PDF (1623K) Full view HTML -

Article type: Regular Article

2020 Volume 60 Issue 8 Pages 1784-1795

Published: August 15, 2020

Released on J-STAGE: August 18, 2020

Advance online publication: March 11, 2020Download PDF (7079K) Full view HTML -

Article type: Regular Article

2020 Volume 60 Issue 8 Pages 1796-1802

Published: August 15, 2020

Released on J-STAGE: August 18, 2020

Download PDF (1423K) Full view HTML

Mechanical Properties

-

Article type: Regular Article

2020 Volume 60 Issue 8 Pages 1803-1809

Published: August 15, 2020

Released on J-STAGE: August 18, 2020

Download PDF (1311K) Full view HTML -

Article type: Regular Article

2020 Volume 60 Issue 8 Pages 1810-1818

Published: August 15, 2020

Released on J-STAGE: August 18, 2020

Download PDF (1572K) Full view HTML -

Article type: Regular Article

2020 Volume 60 Issue 8 Pages 1819-1828

Published: August 15, 2020

Released on J-STAGE: August 18, 2020

Advance online publication: February 21, 2020Download PDF (1441K) Full view HTML

Notes

Casting and Solidification

-

Article type: Note

2020 Volume 60 Issue 8 Pages 1829-1831

Published: August 15, 2020

Released on J-STAGE: August 18, 2020

Download PDF (581K) Full view HTML

Transformations and Microstructures

-

Article type: Note

2020 Volume 60 Issue 8 Pages 1832-1834

Published: August 15, 2020

Released on J-STAGE: August 18, 2020

Download PDF (346K) Full view HTML

- |<

- <

- 1

- >

- >|