Volume 61, Issue 5

Displaying 1-48 of 48 articles from this issue

- |<

- <

- 1

- >

- >|

Publication Data

-

2021 Volume 61 Issue 5 Pages Cover-

Published: May 15, 2021

Released on J-STAGE: May 15, 2021

Download PDF (433K) -

2021 Volume 61 Issue 5 Pages Editorial-

Published: May 15, 2021

Released on J-STAGE: May 15, 2021

Download PDF (400K) -

2021 Volume 61 Issue 5 Pages Contents-

Published: May 15, 2021

Released on J-STAGE: May 15, 2021

Download PDF (167K)

Review Article

Fundamentals of High Temperature Processes

-

Article type: Review

2021 Volume 61 Issue 5 Pages 1337-1347

Published: May 15, 2021

Released on J-STAGE: May 15, 2021

Advance online publication: January 23, 2021Download PDF (924K) Full view HTML

Regular Articles

Fundamentals of High Temperature Processes

-

Article type: Regular Article

2021 Volume 61 Issue 5 Pages 1348-1356

Published: May 15, 2021

Released on J-STAGE: May 15, 2021

Download PDF (1918K) Full view HTML -

Article type: Regular Article

2021 Volume 61 Issue 5 Pages 1357-1362

Published: May 15, 2021

Released on J-STAGE: May 15, 2021

Advance online publication: January 23, 2021Download PDF (760K) Full view HTML -

Article type: Regular Article

2021 Volume 61 Issue 5 Pages 1363-1369

Published: May 15, 2021

Released on J-STAGE: May 15, 2021

Download PDF (928K) Full view HTML -

Article type: Regular Article

2021 Volume 61 Issue 5 Pages 1370-1378

Published: May 15, 2021

Released on J-STAGE: May 15, 2021

Advance online publication: February 28, 2021Download PDF (1832K) Full view HTML -

Article type: Regular Article

2021 Volume 61 Issue 5 Pages 1379-1388

Published: May 15, 2021

Released on J-STAGE: May 15, 2021

Advance online publication: February 25, 2021Download PDF (2186K) Full view HTML -

Effect of Na Ions on Melt Structure and Viscosity of CaO–SiO2–Na2O by Molecular Dynamics SimulationsArticle type: Regular Article

2021 Volume 61 Issue 5 Pages 1389-1395

Published: May 15, 2021

Released on J-STAGE: May 15, 2021

Download PDF (797K) Full view HTML -

Article type: Regular Article

2021 Volume 61 Issue 5 Pages 1396-1403

Published: May 15, 2021

Released on J-STAGE: May 15, 2021

Download PDF (1370K) Full view HTML -

Article type: Regular Article

2021 Volume 61 Issue 5 Pages 1404-1411

Published: May 15, 2021

Released on J-STAGE: May 15, 2021

Download PDF (788K) Full view HTML

Ironmaking

-

Article type: Regular Article

2021 Volume 61 Issue 5 Pages 1412-1422

Published: May 15, 2021

Released on J-STAGE: May 15, 2021

Advance online publication: January 29, 2021Download PDF (1643K) Full view HTML -

Article type: Regular Article

2021 Volume 61 Issue 5 Pages 1423-1430

Published: May 15, 2021

Released on J-STAGE: May 15, 2021

Download PDF (1375K) Full view HTML -

Article type: Regular Article

2021 Volume 61 Issue 5 Pages 1431-1438

Published: May 15, 2021

Released on J-STAGE: May 15, 2021

Download PDF (1594K) Full view HTML -

Article type: Regular Article

2021 Volume 61 Issue 5 Pages 1439-1449

Published: May 15, 2021

Released on J-STAGE: May 15, 2021

Advance online publication: February 21, 2021Download PDF (2354K) Full view HTML -

Article type: Regular Article

2021 Volume 61 Issue 5 Pages 1450-1458

Published: May 15, 2021

Released on J-STAGE: May 15, 2021

Advance online publication: February 19, 2021Download PDF (886K) Full view HTML -

Article type: Regular Article

2021 Volume 61 Issue 5 Pages 1459-1468

Published: May 15, 2021

Released on J-STAGE: May 15, 2021

Download PDF (2068K) Full view HTML -

Article type: Regular Article

2021 Volume 61 Issue 5 Pages 1469-1478

Published: May 15, 2021

Released on J-STAGE: May 15, 2021

Advance online publication: January 28, 2021Download PDF (1059K) Full view HTML -

Article type: Regular Article

2021 Volume 61 Issue 5 Pages 1479-1487

Published: May 15, 2021

Released on J-STAGE: May 15, 2021

Download PDF (1298K) Full view HTML -

Article type: Regular Article

2021 Volume 61 Issue 5 Pages 1488-1497

Published: May 15, 2021

Released on J-STAGE: May 15, 2021

Download PDF (2388K) Full view HTML

Steelmaking

-

Article type: Regular Article

2021 Volume 61 Issue 5 Pages 1498-1505

Published: May 15, 2021

Released on J-STAGE: May 15, 2021

Advance online publication: February 24, 2021Download PDF (1057K) Full view HTML -

Article type: Regular Article

2021 Volume 61 Issue 5 Pages 1506-1513

Published: May 15, 2021

Released on J-STAGE: May 15, 2021

Advance online publication: January 23, 2021Download PDF (1508K) Full view HTML -

Article type: Regular Article

2021 Volume 61 Issue 5 Pages 1514-1523

Published: May 15, 2021

Released on J-STAGE: May 15, 2021

Download PDF (1757K) Full view HTML -

Article type: Regular Article

2021 Volume 61 Issue 5 Pages 1524-1531

Published: May 15, 2021

Released on J-STAGE: May 15, 2021

Advance online publication: February 18, 2021Download PDF (1596K) Full view HTML

Casting and Solidification

-

Article type: Regular Article

2021 Volume 61 Issue 5 Pages 1532-1538

Published: May 15, 2021

Released on J-STAGE: May 15, 2021

Download PDF (1159K) Full view HTML -

Article type: Regular Article

2021 Volume 61 Issue 5 Pages 1539-1549

Published: May 15, 2021

Released on J-STAGE: May 15, 2021

Download PDF (616K) Full view HTML -

Article type: Regular Article

2021 Volume 61 Issue 5 Pages 1550-1555

Published: May 15, 2021

Released on J-STAGE: May 15, 2021

Advance online publication: February 21, 2021Download PDF (1155K) Full view HTML -

Article type: Regular Article

2021 Volume 61 Issue 5 Pages 1556-1566

Published: May 15, 2021

Released on J-STAGE: May 15, 2021

Advance online publication: March 14, 2021Download PDF (2776K) Full view HTML -

Article type: Regular Article

2021 Volume 61 Issue 5 Pages 1567-1578

Published: May 15, 2021

Released on J-STAGE: May 15, 2021

Advance online publication: February 17, 2021Download PDF (3127K) Full view HTML

Instrumentation, Control and System Engineering

-

Article type: Regular Article

2021 Volume 61 Issue 5 Pages 1579-1583

Published: May 15, 2021

Released on J-STAGE: May 15, 2021

Download PDF (420K) Full view HTML

Chemical and Physical Analysis

-

Article type: Regular Article

2021 Volume 61 Issue 5 Pages 1584-1593

Published: May 15, 2021

Released on J-STAGE: May 15, 2021

Advance online publication: February 14, 2021Download PDF (1333K) Full view HTML -

Article type: Regular Article

2021 Volume 61 Issue 5 Pages 1594-1602

Published: May 15, 2021

Released on J-STAGE: May 15, 2021

Download PDF (2287K) Full view HTML

Forming Processing and Thermomechanical Treatment

-

Article type: Regular Article

2021 Volume 61 Issue 5 Pages 1603-1613

Published: May 15, 2021

Released on J-STAGE: May 15, 2021

Download PDF (2314K) Full view HTML

Welding and Joining

-

Article type: Regular Article

2021 Volume 61 Issue 5 Pages 1614-1622

Published: May 15, 2021

Released on J-STAGE: May 15, 2021

Download PDF (2679K) Full view HTML

Surface Treatment and Corrosion

-

Article type: Regular Article

2021 Volume 61 Issue 5 Pages 1623-1632

Published: May 15, 2021

Released on J-STAGE: May 15, 2021

Advance online publication: February 25, 2021Download PDF (1607K) Full view HTML -

Article type: Regular Article

2021 Volume 61 Issue 5 Pages 1633-1640

Published: May 15, 2021

Released on J-STAGE: May 15, 2021

Download PDF (1490K) Full view HTML

Transformations and Microstructures

-

Article type: Regular Article

2021 Volume 61 Issue 5 Pages 1641-1649

Published: May 15, 2021

Released on J-STAGE: May 15, 2021

Download PDF (1975K) Full view HTML -

Article type: Regular Article

2021 Volume 61 Issue 5 Pages 1650-1659

Published: May 15, 2021

Released on J-STAGE: May 15, 2021

Download PDF (2087K) Full view HTML -

Article type: Regular Article

2021 Volume 61 Issue 5 Pages 1660-1668

Published: May 15, 2021

Released on J-STAGE: May 15, 2021

Download PDF (1465K) Full view HTML -

Article type: Regular Article

2021 Volume 61 Issue 5 Pages 1669-1678

Published: May 15, 2021

Released on J-STAGE: May 15, 2021

Download PDF (2095K) Full view HTML

Mechanical Properties

-

Article type: Regular Article

2021 Volume 61 Issue 5 Pages 1679-1687

Published: May 15, 2021

Released on J-STAGE: May 15, 2021

Advance online publication: February 28, 2021Download PDF (1797K) Full view HTML -

Article type: Regular Article

2021 Volume 61 Issue 5 Pages 1688-1697

Published: May 15, 2021

Released on J-STAGE: May 15, 2021

Advance online publication: February 24, 2021Download PDF (2657K) Full view HTML

Physical Properties

-

Article type: Regular Article

2021 Volume 61 Issue 5 Pages 1698-1707

Published: May 15, 2021

Released on J-STAGE: May 15, 2021

Download PDF (1131K) Full view HTML -

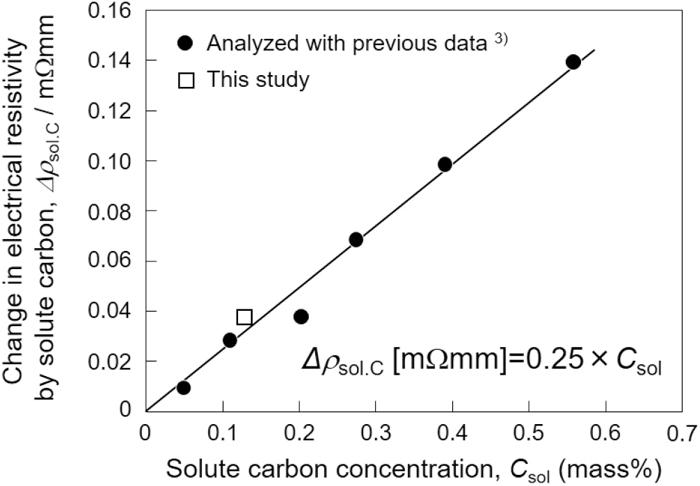

Estimation of Solute Carbon Concentration by Electrical Resistivity Measurement in Martensitic SteelArticle type: Regular Article

2021 Volume 61 Issue 5 Pages 1708-1715

Published: May 15, 2021

Released on J-STAGE: May 15, 2021

Download PDF (1099K) Full view HTML

Social and Environmental Engineering

-

Article type: Regular Article

2021 Volume 61 Issue 5 Pages 1716-1724

Published: May 15, 2021

Released on J-STAGE: May 15, 2021

Advance online publication: February 27, 2021Download PDF (3017K) Full view HTML -

Article type: Regular Article

2021 Volume 61 Issue 5 Pages 1725-1735

Published: May 15, 2021

Released on J-STAGE: May 15, 2021

Advance online publication: February 21, 2021Download PDF (1619K) Full view HTML

Note

Mechanical Properties

-

Article type: Note

2021 Volume 61 Issue 5 Pages 1736-1738

Published: May 15, 2021

Released on J-STAGE: May 15, 2021

Advance online publication: January 21, 2021Download PDF (515K) Full view HTML

- |<

- <

- 1

- >

- >|

,

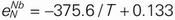

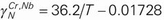

,  . In the liquid Fe–Cr–Nb and Fe–Ni–Nb systems, the second-order cross-interaction parameters of chromium or nickel with niobium on nitrogen were determined as follows:

. In the liquid Fe–Cr–Nb and Fe–Ni–Nb systems, the second-order cross-interaction parameters of chromium or nickel with niobium on nitrogen were determined as follows:  ,

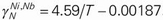

,  . Furthermore, a more accurate nitrogen solubility prediction model for the liquid Fe–Cr–Ni–Nb system was established based on the existing thermodynamic parameters and the interaction parameters obtained in this study.

. Furthermore, a more accurate nitrogen solubility prediction model for the liquid Fe–Cr–Ni–Nb system was established based on the existing thermodynamic parameters and the interaction parameters obtained in this study.