-

Yuanru Yang, Hiromichi Watanabe, Megumi Akoshima, Miyuki Hayashi, Masa ...

Article type: Regular Article

2021 Volume 61 Issue 1 Pages

26-32

Published: January 15, 2021

Released on J-STAGE: January 16, 2021

JOURNAL

OPEN ACCESS

FULL-TEXT HTML

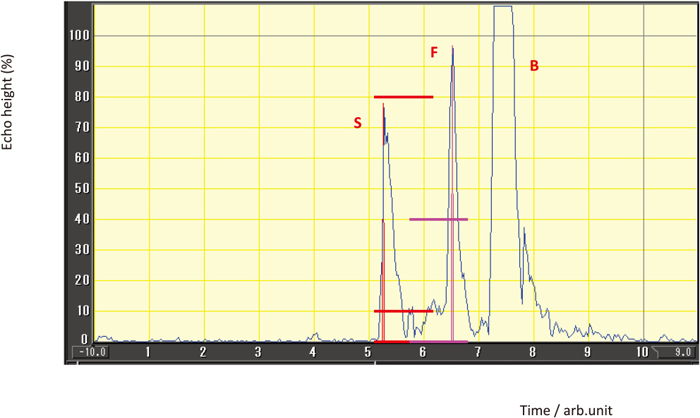

Thermal diffusivity of Fe1−xO scale formed on iron sheets have been measured using an electrical-optical hybrid pulse-heating method, which can avoid decomposition of Fe1−xO scale even at elevated temperatures by executing the experiment rapidly. The samples were 50 µm-thick Fe1−xO scale, which had been obtained by oxidation of a 0.5 mm-thick iron coupon at 1123 K in the air followed by sandblasting to remove the outer oxide layers of Fe3O4 and Fe2O3. In the experiment, the sample was heated by a large current pulse supplied to the iron layer of the coupon, and the Fe1−xO scale was indirectly heated up to experimental temperature from room temperature within 0.2 s. The temperature was maintained at the experimental temperature, and the laser flash method was conducted to measure the effective thermal diffusivity of the coupon. The laser irradiation position was adjusted by two ceramics blocks to make the temperature profile better. The effective thermal diffusivity produced the value for Fe1−xO scale based on a three-layered analysis for the Fe1−x O/iron/Fe1−xO structure. Thermal diffusivities of Fe1−xO scale were around 4.8 × 10−7 m2s−1, and there can be seen no obvious temperature dependence from 600 K to 900 K. X-ray diffraction analysis confirmed that phase transformation did not occur in the Fe1−xO scales during the experiment and x value was calculalted to be 0.09. Non-stoichiometry is supposed to have a significant effect on thermal diffusivity of Fe1−xO scale and its temperature dependence in this research.

View full abstract

-

Takaaki Wajima

Article type: Regular Article

2021 Volume 61 Issue 1 Pages

33-41

Published: January 15, 2021

Released on J-STAGE: January 16, 2021

JOURNAL

OPEN ACCESS

FULL-TEXT HTML

Blast furnace (BF) slag, one of the byproducts of iron- and steel-making plants, was converted to a product, including a hydrogrossular, through the alkali fusion method for HCl gas removal. BF slag was transformed to the alkali-fused slag with reactive phases via alkali fusion, and then, the fused slag was added to distilled water and stirred at room temperature to prepare the precursor for the synthesis of the product including a hydrogrossular by heating. The effects of the mixing ratio of NaOH to slag (NaOH/slag ratio), fusion temperature, ratio of the fused slag mass to distilled water volume (W/V ratio), stirring time, heating time, and heating temperature of the product phase were investigated, and the HCl gas removal ability of the obtained product was determined. The optimal conditions for hydrogrossular synthesis are NaOH/slag ratio of 1.6, fusion temperature of 600°C, W/V ratio of 125 g/L, stirring time of 24 h, heating temperature of 80°C, and heating time of 3–6 h. The product removed more HCl gas than the BF slag and showed higher Cl fixation than lime. These results suggest that a novel scavenger for HCl gas removal at high temperature can be synthesized from the BF slag through alkali fusion.

View full abstract

-

Qi Zhang, Guangye Xu, Kazuhiko Iwai

Article type: Regular Article

2021 Volume 61 Issue 1 Pages

42-48

Published: January 15, 2021

Released on J-STAGE: January 16, 2021

JOURNAL

OPEN ACCESS

FULL-TEXT HTML

A channel type horizontal induction heating tundish compensates for the heat loss of the molten steel due to Joule loss generated by an A.C. magnetic field. It also exhibits another function of inclusions removal because the A.C. magnetic field generates an electromagnetic pinch force. For the inclusions below the center of the horizontal channel, the direction of the electromagnetic pinch force and the buoyancy force acting on them are opposite. Thus, there is a possibility of the existence of the balanced position where the magnitudes of the electromagnetic pinch force and the buoyancy force are same. Around there the net time average force acting on the inclusions is almost zero, and there is a dead zone where the removal time of the inclusions under the imposed A.C. magnetic field is longer than that without it. In this study, non-dimensional models of the force balance and the inclusion trajectory were established and numerically solved to find out the relationship between the dead zone and the A.C. magnetic field parameters because the dead zone range should be reduced for effective removal of the inclusions. Consequently, the dead zone range decreased with the increase in the magnetic field intensity. Furthermore, the shielding parameter of 5–10 is one of the optimum conditions to reduce the dead zone range under the constant magnetic field condition because the dead zone range has the local and/or global minimum at this parameter.

View full abstract

-

Xiang Shen, Min Chen, Xiaorui Zheng

Article type: Regular Article

2021 Volume 61 Issue 1 Pages

49-54

Published: January 15, 2021

Released on J-STAGE: January 16, 2021

JOURNAL

OPEN ACCESS

FULL-TEXT HTML

In order to efficiently recycle valuable element from the molten converter slag and enhance utilization ratio and added value of the slag, a novel aluminothermic smelting reduction process using aluminum dross as reductant was investigated from component migration and reduction kinetics, meanwhile the reduction mechanism of smelting reduction process of molten converter slag using aluminum dross was discussed. The results showed that the reduction of FeO firstly occurred with the Al/(FeO+MnO+P2O5) mass ratio≤0.27, and MnO began to be reduced with the ratio increasing to 0.33. Further increasing the ratio to 0.40, P2O5 could be reduced from the molten slag. Moreover, the contents of FeO, MnO and P2O5 in molten slag decreased sharply within the first 4 min, 6 min, and 6 min respectively and stabilized thereafter, and the Al2O3 content was increased dramatically over the first 6 min and followed by a continuity increase. Recovery of metal was increased to a maximum of 99.32% with the mass ratio increasing, and the crude alloy content containing Fe, Mn, and P was up to 93.31%, 1.98%, and 4.72%, respectively.

View full abstract

-

Xiaogang Ma, Congcong Wen

Article type: Regular Article

2021 Volume 61 Issue 1 Pages

55-61

Published: January 15, 2021

Released on J-STAGE: January 16, 2021

Advance online publication: September 11, 2020

JOURNAL

OPEN ACCESS

FULL-TEXT HTML

Based on the theory of heat transfer, parametric modeling is established for the heat transfer model of copper cooling stave, which appears in recent years, with special-shaped tubes (elliptical, rectangular, double circular, three circular and ortho hexagonal) in a blast furnace (BF) bosh and the optimal tube for the cooling pipe is selected on the basis of the heat transfer characteristics of the stave. The heat transfer model of the hot end of stave embedded bricks which are not covered by slag, is analyzed using thermal-structural coupling method at the initial stage of blow-in under the normal working condition. The mutual influence of various parameters on the mechanical properties of copper stave is obtained using the response surface method. This method is combined with NSGA-II genetic algorithm to optimize the structure parameters and longevity technology of the bosh. The optimized structure of the furnace bosh is improved in heat transfer characteristics and mechanical properties, which proves the model and parameterized calculation program can be used as an optimized design and evaluation of the longevity technology of the bosh structure.

View full abstract

-

Qiuchen Zhang, Liangyu Chen, Xiaogang Ma, Chenchen Zhao

Article type: Regular Article

2021 Volume 61 Issue 1 Pages

62-70

Published: January 15, 2021

Released on J-STAGE: January 16, 2021

Advance online publication: November 13, 2020

JOURNAL

OPEN ACCESS

FULL-TEXT HTML

The high-temperature hot air of hot blast stoves has an important effect on blast furnace ironmaking; it is one of the crucial factors that are used to assess the performance of hot blast stoves. In this study, a three-dimensional fluid flow heat transfer model combining turbulence, heat transfer, combustion, heat radiation, and heat exchange models was developed to assess the combustion and air supply characteristics of a new type of top combustion hot blast stove. The results indicate that nozzles that are alternately arranged in the same layer of the new hot blast stove caused rapid combustion reactions. In addition, it caused the high-temperature flue gas in the pre-combustion chamber to accelerate toward the combustion chamber, thereby eliminating the “eccentric swirl” of the traditional hot blast stove and improving the heat transfer efficiency and heat storage capacity. However, the “attachment effect” of the fluid still occurred in the new stove type, which led to an unreasonable temperature distribution inside the combustion chamber and regenerator. Therefore, an improved design of a top combustion hot blast stove was proposed in this paper. Using the developed numerical model, the performance of the new design was evaluated and compared with the original one.

View full abstract

-

Tianlu Gao, Kexin Jiao, Jianliang Zhang, Hengbao Ma

Article type: Regular Article

2021 Volume 61 Issue 1 Pages

71-78

Published: January 15, 2021

Released on J-STAGE: January 16, 2021

Advance online publication: September 09, 2020

JOURNAL

OPEN ACCESS

FULL-TEXT HTML

In this paper, the common damage types of tuyere were sampled and analyzed. Specifically, the element content in tuyere was measured by Inductively Coupled Plasma Source Mass Spectrometer, Nitrogen-Hydrogen-Oxygen Analyzer, and Carbon-Sulfur analyzer. Then, Scanning Electron Microscope was used to analyze the microstructure of tuyere damage, and the element distribution of the damaged area was observed by Energy Dispersive Spectrometer. Finally, a metallographical analysis of the damaged location was carried out by an optical microscope. On account of those above analyses, the following results were obtained: firstly, the tuyere damage was mainly caused by erosion. After that, the grains at the hot surface and melting area of the tuyere were large, while those in the middle region were small. The content of the impurity element in tuyere nose increased, and the content of copper decreased. Moreover, there were two interfaces of slag-copper and iron-copper in the damaged area, and the Cu–Fe alloy was formed. At last, the failure mechanism of blast furnace tuyere erosion was explained in the paper.

View full abstract

-

Dharmendra Kumar Rajak, Nidambur Bharath Ballal, Nurni Neelakantan Vis ...

Article type: Regular Article

2021 Volume 61 Issue 1 Pages

79-85

Published: January 15, 2021

Released on J-STAGE: January 16, 2021

JOURNAL

OPEN ACCESS

FULL-TEXT HTML

Properties like shatter index and yield of the top layer of iron ore sinter in a Dwight-Lloyd sintering machine have always been a bottleneck for improvement of overall sinter quality due to the practical limitation of achieving high sintering temperature and dwell time in the top layer. To improve the sinter yield and shatter index of top layer, various technologies like usage of additional coke breeze, gaseous fuel injection and oxygen enrichment have been reported. In this paper, effect of oxygen enrichment of the incoming air on top part of the sinter bed was investigated using pot sinter experiments with varying oxygen percentage of 0 to 12 vol.% in the incoming air for an initial duration of 1/3rd of the total sintering time. It was observed that with increasing oxygen percentage from 0 to 9 vol.% in the incoming air, top layer sinter yield increased from 76.1 to 80.6% and shatter index from 69.0 to 74.8%. The improvement in sintering properties were mainly attributed to the promotion of sintering reaction with improved time-temperature profiles specifically at the top layer which results in increase of phase fraction of Silico ferrites of calcium and aluminum (SFCA-I). However, beyond 9 vol.% oxygen enrichment, change in sinter properties was not significant. It is considered that excessive increase of oxygen enrichment does not contribute much to the increase of top layer peak temperature.

View full abstract

-

Xin Jiang, Jidong Zhao, Lin Wang, Haiwei An, Qiangjian Gao, Haiyan Zhe ...

Article type: Regular Article

2021 Volume 61 Issue 1 Pages

86-92

Published: January 15, 2021

Released on J-STAGE: January 16, 2021

Advance online publication: November 03, 2020

JOURNAL

OPEN ACCESS

FULL-TEXT HTML

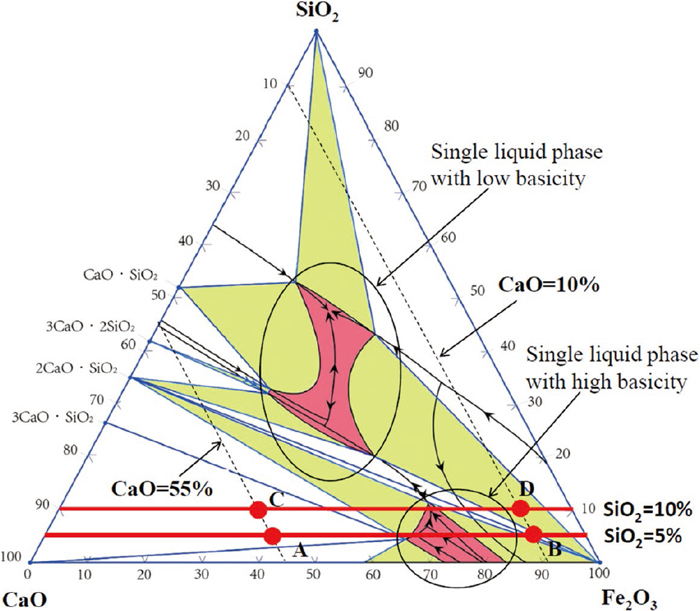

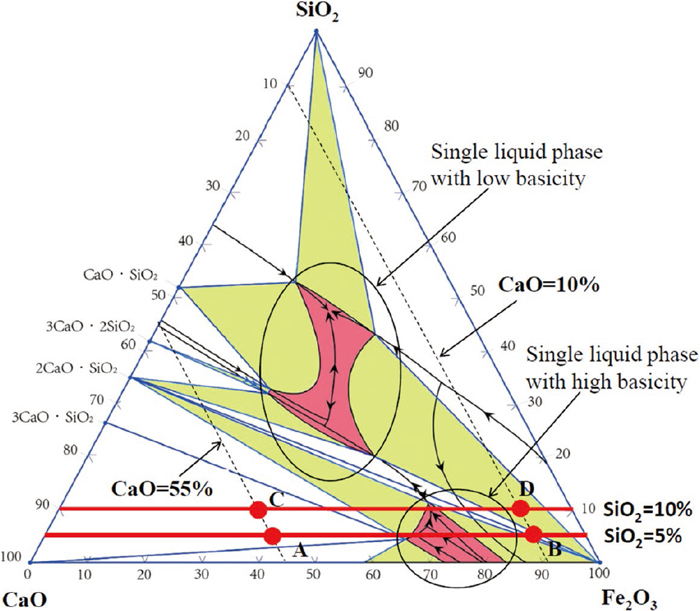

Fluidity is one of the important properties of bonding phase in sintering process, because better fluidity is beneficial for improving the strength of sinter. In this work, the effects of liquidus temperature and liquid amount on the fluidity of bonding phase and the strength of sinter were investigated. The experimental results in SiO2–Fe2O3–CaO system indicated that, for both SiO2=5% and SiO2=10%, with increasing Fe2O3 content (decreasing CaO content), the fluidity indices of samples first increased and then decreased. When the liquidus temperature was lower and the liquid amount was more, the fluidity index of SFC sample was higher, and vice versa. The sinter pot experimental results showed that, (1) for the iron ore with SiO2=4.30%, the major phases in the sinter were hematite and SFCA, and the liquid SFCA phase was evenly distributed in sinter. The tumble strength of sinter was higher than 60% in a wider basicity range of 1.8–2.2. (2) For the iron ore with SiO2=12.42%, the olivine was another major phase, and was unevenly distributed in part of sinter. There was a peak value for tumble strength of sinter when the basicity was 2.0. The basicity was higher or lower, the tumble strength sharply decreased. The reasonable basicity of sinter with high-SiO2 content was difficult to determine, and was not proposed to be used in an actual sintering production. The outcomes of the present work may provide guidelines for better understanding the properties of bonding phase and improving the strength of sinter.

Isothermal section diagram of SiO

2–Fe

2O

3–CaO ternary system at 1300°C.

Fullsize Image

View full abstract

-

Yongqiang Zhao, Tichang Sun, Zhe Wang

Article type: Regular Article

2021 Volume 61 Issue 1 Pages

93-99

Published: January 15, 2021

Released on J-STAGE: January 16, 2021

Advance online publication: September 11, 2020

JOURNAL

OPEN ACCESS

FULL-TEXT HTML

The abundant refractory titanomagnetite (TTM) provides a cheap alternative source of iron, but this ore contains impurities and is difficult to process to make suitable concentrates for the blast furnace. In this study, reduction roasting of a primary TTM concentrate followed by magnetic separation was investigated to understand the effects of reduction time, coal dosage, and CaF2 addition on the reduction behavior of TTM and growth mechanism of iron particles. The phase composition of reduced samples was characterized by X-ray diffraction. The size distribution of iron particles was quantitatively examined using image analysis. Results showed that CaF2 can help improve the reduction degree and particle size of metallic iron. The metallization degree increased from 85.5% to 89.5% when the CaF2 dosage increased from 0% to 4%, while a minor increase was observed when the CaF2 dosage exceeded 4%. Accordingly, the TTM samples were treated by reduction roasting with 4% CaF2 and 25% coal at 1200°C for 60 min followed by magnetic separation. A magnetic concentrate with an iron content of 91.1% and a recovery of 92.9% was achieved. In addition, the relationship between the size distributions of iron particles and grinding fineness was also studied. The size distribution using data from the diameter of iron particles was found to be close to the actual grinding fineness.

View full abstract

-

Ruiqi Zeng, Wei Li, Nan Wang, Guiqin Fu, Mansheng Chu, Miaoyong Zhu

Article type: Regular Article

2021 Volume 61 Issue 1 Pages

100-107

Published: January 15, 2021

Released on J-STAGE: January 16, 2021

Advance online publication: November 11, 2020

JOURNAL

OPEN ACCESS

FULL-TEXT HTML

To develop a novel and clean smelting process for the comprehensive utilization of Hongge vanadium titanomagnetite (HVTM), this work determined the influence of B2O3 on the oxidation and induration process of HVTM pellets (HVTMP). The oxidation degree, compressive strength, porosity, crystalline phase, microstructure, and induration degree of HVTMP were comprehensively investigated, and the relevant mechanisms were discussed. The results indicated that B2O3 decreased the oxidation degree and porosity of HVTMP, while the compressive strength was clearly enhanced. Increasing the amount of B2O3 did not significantly affect the crystalline phase, but it decreased the XRD peak intensity. The induration degree appreciably increased after the addition of B2O3 because it favored the generation of liquid phases and increased the average grain size by creating a dense and continuous bonding structure. Additionally, B-rich phases were mainly uniformly distributed in the liquid phases along the grain boundaries. Based on the experimental results, the induration mechanism of HVTMP with different amounts of B2O3 was proposed. This study provides a theoretical and technical foundation for the effective production of HVTMP.

View full abstract

-

Hongyang Li, Xiangping Bu, Xiaojie Liu, Xin Li, Hongwei Li, Fulong Liu ...

Article type: Regular Article

2021 Volume 61 Issue 1 Pages

108-118

Published: January 15, 2021

Released on J-STAGE: January 16, 2021

Advance online publication: September 05, 2020

JOURNAL

OPEN ACCESS

FULL-TEXT HTML

The applications of big data in the steel industry are widely developed. Ironmaking is a multi-sectoral joint-operation production process that generates massive data constantly. It is required to build the big data platform to efficiently organize and fully utilize the production data of the ironmaking. In this work, we build a comprehensive status evaluation and prediction system for the blast furnace (BF) to achieve the goal of high production, low consumption, high quality and long life of the BF. The evaluation system is based on the big data platform and equipped with the factor analysis method, which can define and extract the hidden common factors in the production index of the BF by considering 19 state parameters and can calculate the comprehensive BF status index as well. The prediction system employs the AdaBoost model which can accurately predict the BF status index 3 hours in advance. Evaluation results show that the proposed BF status index is highly consistent with the actual status of the BF in the selected time period. The coincidence degree between BF status index in different time periods and the actual situation is also verified by factor analysis. Although the evaluation and prediction system demonstrates high accuracy in current production environment, it may still need calibrate and update regularly due to the changing of the BF production in the long run. The online comprehensive evaluation and prediction system for BF can effectively assist operators to optimize the BF operation and maintain the stabilization of BF.

View full abstract

-

Yuya Sumitani, Yuya Ono, Yasuhiro Saito, Yohsuke Matsushita, Hideyuki ...

Article type: Regular Article

2021 Volume 61 Issue 1 Pages

119-128

Published: January 15, 2021

Released on J-STAGE: January 16, 2021

JOURNAL

OPEN ACCESS

FULL-TEXT HTML

In this study, we evaluated the effect of the CO2 or H2O gasification reaction on the mechanical property of the coke matrix by measuring the elastic modulus of the coke matrix before and after the gasification reaction. We also investigated the effect of the distribution of the elastic modulus in the coke matrix on the strength of the lump coke by conducting the fracture analysis for the coke model with porosity of 0–0.4 in which the distribution of the elastic modulus obtained by the experiment was reflected. The nanoindentation measurements of the elastic modulus of the coke matrix before and after the gasification reaction implied that the distribution of the elastic modulus in the coke matrix differs depending on the gasification agent. In the case of the CO2 gasification reaction, both the coke matrices with high and low elastic moduli were consumed by the gasification. On the other hand, in the case of the H2O gasification reaction, only the coke with an elastic modulus of over 30 GPa before the reaction was consumed by the gasification reaction. Also, the numerical results showed that the distribution of the elastic modulus in the coke matrix affects the strength of the coke model with low porosity whereas the one did not affect that with high porosity.

View full abstract

-

Xin Jiang, Fang Long, Lin Wang, Yulu Zhou, Haiyan Zheng, Qiangjian Gao ...

Article type: Regular Article

2021 Volume 61 Issue 1 Pages

129-137

Published: January 15, 2021

Released on J-STAGE: January 16, 2021

Advance online publication: November 04, 2020

JOURNAL

OPEN ACCESS

FULL-TEXT HTML

Reduction shaft furnace is an effective process to produce Direct Reduced Iron (DRI), in which natural gas is used as reducing agent and heat source. Recently, in some countries lacking natural gas resources, Coke Oven Gas (COG) was proposed to be used in shaft furnace process instead of natural gas. In the present work, the effect of COG consumption on the yield of metallic Fe in shaft furnace was thermodynamically calculated. Both the chemical equilibrium and heat balance were considered. The main findings include, in shaft furnace process, the COG consumption as heat source is more than that as reducing agent. In the case of directly supplying reformed COG, the yield of metallic Fe decreases with increasing formation temperature of metallic Fe. For a coke oven with capacity of 600000 tons, as the formation temperature are 850°C and 900°C, the corresponding annual yields of shaft furnace are 253.58 × 103 tons/year and 249.48 × 103 tons/year. In the case of ZR technology followed by supplying extra COG, the yield of metallic Fe first increases and then decreases, and there is a peak value. For a coke oven with capacity of 600000 tons, as the formation temperature are 845°C and 900°C, the corresponding annual yields of shaft furnace are 283.44 × 103 tons/year (maximum value) and 278.38 × 103 tons/year. The findings from this work may provide guidelines for choosing optimal parameters for an actual shaft furnace process.

Flow chart of reduction shaft furnace process (O

2 pyrolysis).

Fullsize Image

View full abstract

-

Cui Wang, Kexin Jiao, Jianliang Zhang, Senran Wu

Article type: Regular Article

2021 Volume 61 Issue 1 Pages

138-145

Published: January 15, 2021

Released on J-STAGE: January 16, 2021

Advance online publication: November 03, 2020

JOURNAL

OPEN ACCESS

FULL-TEXT HTML

Ti(C,N) in BF hearth plays an important role in protecting the BF lining and prolonging the life of BF. The characterization and the crystallization process of the Ti(C,N) obtained from one dead BF were clarified in the paper. It is found that the precipitated Ti(C,N) exhibits annual-ring shape features and different colors. The annual-ring shape topography is caused by the change of the C/N ratio. The precipitated Ti(C,N) is composed of one or more large grains. Ti(C,N) presents as a superstructure or mesocrystal and evolves from Ti(C,N) nanoparticles, which are self-assembled nanomaterials with highly ordered structures. Ti(C,N) deposit forms continuously with layer-by-layer grain growth because the mesocrystal has a large specific surface area. The phase interface of Ti(C,N)-Fe presents as a shape of jagged step, and the phase interface is inlaid by many random mesocrystal structures. The Ti(C,N) deposit derived from hot metal is accompanied by layer-by-layer mesocrystal structures. The results of phase transition and morphology of Ti(C,N) provide guidance for the regulation of Ti(C,N) behavior in BF hearth.

View full abstract

-

Wei Zhao, Mansheng Chu, Hongwei Guo, Zhenggen Liu, Bingji Yan, Peng Li

Article type: Regular Article

2021 Volume 61 Issue 1 Pages

146-157

Published: January 15, 2021

Released on J-STAGE: January 16, 2021

Advance online publication: November 22, 2020

JOURNAL

OPEN ACCESS

FULL-TEXT HTML

As an innovative and promising BF iron-bearing burden, the vanadium-titanium magnetite carbon composite briquette (VTM-CCB) charging significantly affects the softening-melting-dripping characteristics and cohesive zone of the mixed burden. In this study, the interface behaviors between VTM-CCB and sinter were investigated by conducting interrupted softening-melting experiments to elucidate intrinsic structure evolution and interaction mechanisms. During softening, when the FC/O ratio of VTM-CCB ranges from 0.8 to 1.0, the molten slag-metal coexisting structure formed at the interface, thereby promoting the shrinking and decreasing T4 and T40. However, with increasing FC/O ratio higher than 1.0, the interface slagging and bonding would be suppressed due to the unconsumed carbon particles. During melting, the increasing of FC/O ratio would lower the FeO content and decrease the molten slag, and the interface layer transformed from molten slag-iron coexisting structure to dense metallic iron shell, suppressing the collapse of molten mixtures and increasing Ts. In the dripping process, increasing the FC/O ratio appropriately could promote the interface iron carburization and the aggregation of molten iron, thereby decreasing TD and improving the dripping performance. Besides, the VTM-CCB, acting as skeleton in the molten mixtures, could provide more gas channels to improve the permeability of packed bed. However, as the FC/O ratio exceeds 1.2, the Ti(C,N) would precipitate at the slag-metal interface and deteriorate the fluidity of molten mixtures, thereby deteriorating the gas permeability and increasing TD notably. Fully considering the softening-melting-dripping characteristics and the gas permeability, the appropriate FC/O ratio of VTM-CCB should not be higher than 1.2.

View full abstract

-

Chen-chen Lan, Shu-hui Zhang, Xiao-jie Liu, Ran Liu, Qing Lyu

Article type: Regular Article

2021 Volume 61 Issue 1 Pages

158-166

Published: January 15, 2021

Released on J-STAGE: January 16, 2021

JOURNAL

OPEN ACCESS

FULL-TEXT HTML

The gasification behaviors of coke in a blast furnace with and without H2 were studied by thermodynamic calculations and high-temperature simulation experiments, and the change in the coke porosity was also studied. The results show that with the decrease in φ(CO)/φ(H2), the temperature range of C gasification decreases and moves to the low-temperature zone. In the absence of H2, the increase in φ(CO) increases the Ri, RC. In the presence of H2, φ(CO) and Ri increase, whereas the RC, decreases. With the increase in φ(CO) and φ(H2), the reduction of iron oxide tends to be carried out in the low-temperature zone, and the φ(CO2) and φ(H2O) produced in the high-temperature zone decrease, which is conducive to reducing the consumption of coke. The presence of H2 intensifies the gasification of coke. The presence of H2 aggravates the increase of coke porosity in the low temperature region, but it reduces the internal porosity in the high temperature region.

View full abstract

-

Chen-chen Lan, Shu-hui Zhang, Xiao-jie Liu, Ran Liu, Qing Lyu

Article type: Regular Article

2021 Volume 61 Issue 1 Pages

167-173

Published: January 15, 2021

Released on J-STAGE: January 16, 2021

JOURNAL

OPEN ACCESS

FULL-TEXT HTML

In the temperature range of 1173–1573 K, the constant temperature weight-loss experiment of coke reaction with CO2 and H2O was carried out by thermogravimetry. The gasification kinetic behaviors of coke reaction with CO2 and H2O were compared and analyzed, and the mechanism of the difference of the kinetic behaviors was discussed. The results show that the internal diffusion condition and interfacial reaction condition of coke gasification in H2O are better than those in CO2, and the difference of diffusion property is greater than that of interface reaction property. The activation energies of internal diffusion and interface reaction of coke gasification in H2O are 80.36 kJ/mol and 36.97 kJ/mol lower than that in CO2, respectively. In H2O, the controlling region of interfacial reaction is larger than that in CO2, and the effect of temperature on controlling region of the interfacial reaction is also greater than that in CO2. The energy required for the chemical adsorption of H2O on the coke surface to form a stable intermediate configuration is 40.22 kJ/mol less than that of CO2, and the energy barrier that needs to cross during the coke gasification in H2O is 29.11 kJ/mol less than that in CO2. The chemisorption capacity of CO2 on coke surface is weaker than that of H2O.

View full abstract

-

Heng Zhou, Xu Tian, Shun Yao, Mingyin Kou, Shengli Wu, Yansong Shen

Article type: Regular Article

2021 Volume 61 Issue 1 Pages

174-181

Published: January 15, 2021

Released on J-STAGE: January 16, 2021

JOURNAL

OPEN ACCESS

FULL-TEXT HTML

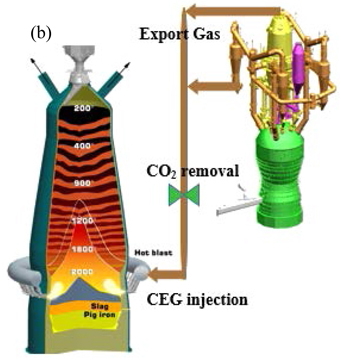

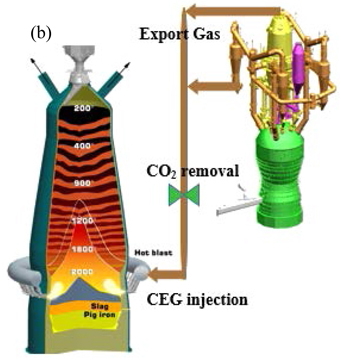

Blast furnace (BF) injection of COREX export gas after removal of CO2 (CEG) displays many ecological and environmental advantages. A static model of BF operation of CEG was developed according to mass and heat balance. The effect of CEG injection on the raceway adiabatic flame temperature (RAFT), the amount and composition of bosh gas, and the shape of raceway were studied. The acceptable injection volume of CEG under different thermal compensation measures was investigated. The results show that under no thermal compensation, with the increase of CEG injection, the RAFT decreases but the volume of bosh gas increases. The content of CO and H2 increases with the increase of CEG injection. Based on the standard of maintaining the RAFT and volume of bosh gas, addition of oxygen, reducing blast humidity and increasing blast temperature are effective measures of thermal compensation to increase the quantity of CEG injection. The characteristics of high temperature zone of BF under different suitable CEG injection volumes were also studied. The findings of this work can be used as a theoretical basis to guide plant operations for CEG injection in BF.

View full abstract

-

Tiago Ramos Ribeiro, João Batista Ferreira Neto, João Guilherme Rocha ...

Article type: Regular Article

2021 Volume 61 Issue 1 Pages

182-189

Published: January 15, 2021

Released on J-STAGE: January 16, 2021

Advance online publication: October 31, 2020

JOURNAL

OPEN ACCESS

FULL-TEXT HTML

Direct Reduction processes use gases (CO and H2) for iron reduction and production of sponge iron or direct reduced iron (DRI). The generation of this gas occurs through methane reforming, which can be done in a reformer or inside the reduction shaft with the sponge iron as a catalyst. The latter occurs in the auto-reforming processes. The kinetics of steam reforming of methane catalyzed by sponge iron was studied at temperatures between 875°C and 1050°C. Results showed that sponge iron acts as a catalyst and methane conversion is increased in higher temperatures and with higher H2/H2O ratio in the inlet gas. The inlet gas composition like one of the industrial auto-reforming processes led to intense carburization and hindered the catalytic reforming reaction.

View full abstract

-

Xiaojun Xi, Sai Chen, Shufeng Yang, Maolin Ye, Jingshe Li

Article type: Regular Article

2021 Volume 61 Issue 1 Pages

190-199

Published: January 15, 2021

Released on J-STAGE: January 16, 2021

Advance online publication: September 19, 2020

JOURNAL

OPEN ACCESS

FULL-TEXT HTML

Based on the analysis of single-bar melting experiments in a previous article,1) the effect of spacing between the steel bars on the agglomeration of steel shells around the steel bars and the melting rate of steel scrap samples was studied in this article. In addition, a calculation model of melting time of steel scrap in the electric arc furnace under different bulk densities and random stacking conditions was also established. The two-bar melting experimental results show that the thermal simulation results are basically consistent with the numerical simulation results. And an increase in the spacing between the steel bars up to 6 mm and the preheating temperature of the steel scrap samples up to 1073 K, can greatly reduce or eliminate the adverse effect of the agglomeration of steel shells around the steel bars on the melting process, thus greatly reducing the melting time. The multibar melting experimental results show that an increase in the porosity is beneficial to the melting of steel scrap samples, and when the porosity reached 0.84 and above, the melting time of multibar samples is close to that of an individual steel bar. In addition, the calculation model can accurately predict the melting time of the steel scrap in the electric arc furnace.

View full abstract

-

Fuhang Chen, Ping Tang, Guanghua Wen, Liang Yu, Shaopeng Gu

Article type: Regular Article

2021 Volume 61 Issue 1 Pages

200-208

Published: January 15, 2021

Released on J-STAGE: January 16, 2021

JOURNAL

OPEN ACCESS

FULL-TEXT HTML

In view of the deficiencies of traditional methods to study the dissolution kinetics of solid oxides in molten slag, a novel method based on single hot thermocouple technique (SHTT) is proposed in this paper. The feasibility of this method is verified and the controlling means of experiment reproducibility is explored. And the effect of slag basicity and Li2O content on the dissolution behavior of Al2O3 in mold flux is investigated via SHTT. The results show that: 1) Under the condition that the density of the Al2O3 particle is slightly higher than that of slag and the mass ratio of Al2O3 particle to liquid slag is less than 2%, the relative standard error of Al2O3 dissolution rate is within 10%. 2) The effect rule of slag basicity on the Al2O3 dissolution rate studied via SHTT is same as that of rotating cylinder method. The dissolution rate of Al2O3 increases with the increase of slag basicity. When the basicity increases from 1.0 to 1.2, the dissolution rate increases significantly, which is due to the formation of xCaO∙yAl2O3 or xCaO∙yAl2O3∙zSiO2 intermediate compounds with low melting point at the Al2O3 boundary layer. 3) With the increase of the Li2O content in mold flux, the dissolution rate of Al2O3 first increases and then decreases. The decrease in dissolution rate is caused by the formation of high-melting MgAl2O4 at the boundary of Al2O3 particle.

View full abstract

-

Yong Wang, Andrey Karasev, Joo Hyun Park, Pär Göran Jönsson

Article type: Regular Article

2021 Volume 61 Issue 1 Pages

209-218

Published: January 15, 2021

Released on J-STAGE: January 16, 2021

Advance online publication: October 31, 2020

JOURNAL

OPEN ACCESS

FULL-TEXT HTML

Nb is an important microalloying element in steelmaking. Its interaction with liquid Fe during an early stage of the alloying process has a considerable influence on the Nb recovery. In the present work, the inclusions in FeNb alloys were characterized using the electrolytic extraction method combined with SEM-EDS. The interfacial reactions between FeNb alloy and liquid Fe, as well as inclusion formations, were studied during an early stage of an alloy addition using a liquid-metal-suction method. The results revealed that a diffusion zone consisting of different regions of Fe–Nb phases was formed and that the thickness of the zone increased with time. Based on the experimental findings, the mechanism of the early dissolution process of FeNb alloys in liquid Fe was discussed. Moreover, the Nb rich regions formed after the alloy contacted with liquid Fe could modify the existing inclusions in the alloy, also their evolution mechanisms were studied. The addition of FeNb alloys can introduce inclusions, such as Al–O and Al–Ti–Nb–O inclusions to the liquid steel. Overall, this study has contributed to the understanding the behaviour of impurities from the FeNb source at the early dissolution process during the microalloying process of steels containing Nb.

View full abstract

-

Congpeng Kang, Fubin Liu, Xin Geng, Zhouhua Jiang, Kui Chen, Junzhe Ga ...

Article type: Regular Article

2021 Volume 61 Issue 1 Pages

219-228

Published: January 15, 2021

Released on J-STAGE: January 16, 2021

Advance online publication: October 28, 2020

JOURNAL

OPEN ACCESS

FULL-TEXT HTML

Experimental investigation and kinetics model ware carried out to study the effect of the atmosphere on the desulfurization of low-sulfur plastic die steel during the electroslag remelting process. 55Cr17Mo1VN plastic die steel was applied as the electrode and remelted with two different kinds of atmospheres using a laboratory-scale ESR furnace. It was found that the sulfur content of 50 ppm in the electrode decreased to 8–12 ppm in the air atmosphere, while reduced to 9–14 ppm in a protective atmosphere. The desulfurization rates were 82% and 78%, respectively. Correspondingly, the sulfur content of 0.12% in initial slag increased to 0.125% and 0.15%. The coupled desulfurization kinetics model was established, the oxygen activity (aO) and sulfur distribution coefficient (Ls) are taken into consideration, and they change with the remelting time during the calculation. The results show that the calculated values are in good agreement with the experimental values. The desulfurization effect at the electrode tip is significantly better than the positions where the droplet passes through the slag layer and the slag pool/molten pool interface. The Ls and comprehensive mass transfer coefficient of sulfur (kS*) decrease with the remelting time, while the aO at each reaction position increases. Compared with the protective atmosphere, Ls and kS* have larger values during the air atmosphere ESR process, but the aO value is equal. Under the different atmospheres, the most types of inclusions in the steel are MnS, and the refining atmosphere has no significant effect on the types of inclusions.

View full abstract

-

Suresh Kodukula, Thomas Ohligschläger, David Porter

Article type: Regular Article

2021 Volume 61 Issue 1 Pages

380-386

Published: January 15, 2021

Released on J-STAGE: January 16, 2021

Advance online publication: September 11, 2020

JOURNAL

OPEN ACCESS

FULL-TEXT HTML

A new method to quantify the ridging phenomenon in ferritic stainless steels has been developed based on the evaluation of surface profiles after the tensile elongation of 100 mm wide sheet specimens. The ridging components of the surface profiles are extracted by a tailored spline filtering procedure. A ridging index is proposed to quantify the severity of the surface defect based on surface profile height and spacing parameters. The procedure is independent of the type of profilometer used as long as unfiltered raw profiles can be recorded. The reproducibility of the measurement method and its correlation with the visual assessment of strained specimens is discussed.

View full abstract

-

Huibin Liu, Yuantao Xu, Wei Li, Na Min, Xuejun Jin

Article type: Regular Article

2021 Volume 61 Issue 1 Pages

387-395

Published: January 15, 2021

Released on J-STAGE: January 16, 2021

JOURNAL

OPEN ACCESS

FULL-TEXT HTML

The effect of NiAl-type nanoparticles on the austenite stability was investigated during quenching-partitioning-tempering (QPT) processes in a cold rolled medium-manganese steel. A good combination of ductility (total elongation: 37.9%) and strength (yield strength: 995 MPa/ultimate tensile strength: 1260 MPa) is obtained after the first step of partitioning treatment at 630°C/1 h (P630) due to appropriate austenite stability and multiple strengthening mechanisms. Moreover, the yield strength and ductility increase further after the second step of tempering treatment at 500°C/2 h by about 113 MPa and 8.5% respectively. It was found that high density of intragranular NiAl-type nanoparticles precipitated during tempering improve the ductility from two aspects. NiAl-type nanoparticles could provide a harder and work-hardenable martensite matrix, which is beneficial for the stability and sustainability of the retained austenite during tensile deformations.

View full abstract

-

Yoshiyuki Furuya

Article type: Regular Article

2021 Volume 61 Issue 1 Pages

396-400

Published: January 15, 2021

Released on J-STAGE: January 16, 2021

JOURNAL

OPEN ACCESS

FULL-TEXT HTML

Fatigue tests were conducted up to 1011 cycles on high-strength steel to clarify a fatigue limit. The fatigue limit of the high-strength steel was not confirmed by gigacycle fatigue tests up to 1010 cycles, while our previous study suggested that the fatigue limit was probably confirmed by those up to 1011 cycles. However, the 1011 cycles fatigue testing was challenging since it took 2 months even by using ultrasonic fatigue testing at 20 kHz. In this study, 3 specimens were tested beyond 1010 cycles. Although a test on a specimen was terminated at around 5 × 1010 cycles, 2 specimens reached 1011 cycles without failure. In other word, no specimen failed above 1010 cycles. These results demonstrated the fatigue limit on high-strength steel in a gigacycle region. The fractured specimens below 1010 cycles revealed internal fractures originating from oxide-type inclusions. When the specimens failed in long-life regions, clear ODAs (Optically Dark Areas) were observed on the fracture surfaces at around the internal fracture origin, while the ODAs were obscure in case of failure in short-life regions. The runout specimens up to 1011 cycles were forcibly fatigue-fractured at higher stress amplitudes in the short-life regions. As the result, the ODA was observed on the forcibly fatigue-fractured surface. This meant that small internal cracks existed in the runout specimens since the ODA was a trace of small internal crack growth. Namely, non-propagating cracks were the mechanism of the appearance of the fatigue limit.

View full abstract

-

Suresh Kodukula, Timo Manninen, David Porter

Article type: Regular Article

2021 Volume 61 Issue 1 Pages

401-407

Published: January 15, 2021

Released on J-STAGE: January 16, 2021

Advance online publication: November 04, 2020

JOURNAL

OPEN ACCESS

FULL-TEXT HTML

A new method to calculate the plastic anisotropy r-values of austenitic and ferritic stainless steels has been developed. The mean orientation of individual grains is obtained from SEM-EBSD data and r-values for individual grains are calculated by weighting all slip systems according to their Schmid factors. Calculated and measured r-values are in good agreement for austenitic stainless steels. However, in ferritic stainless steels, which are highly anisotropic, good agreement requires the introduction of a Schmid factor threshold below which slip systems are inactive. The present method can be used to estimate local differences in r-values in ferritic stainless steels showing the local variations in texture responsible for ridging.

View full abstract

-

Shigeto Yamasaki, Masatoshi Mitsuhara, Hideharu Nakashima

Article type: Regular Article

2021 Volume 61 Issue 1 Pages

408-416

Published: January 15, 2021

Released on J-STAGE: January 16, 2021

Advance online publication: October 28, 2020

JOURNAL

OPEN ACCESS

FULL-TEXT HTML

In this study, the relationship between changes in the magnetic properties and creep strength with the addition of 3 or 6 mass% Co was investigated for ferritic steel containing 15 mass% Cr. Co addition up to 6 mass% hardly contributed to solid solution strengthening or precipitation strengthening at room temperature. However, in the range of 650 to 750°C, the steel with the larger amount of Co exhibited higher creep strength, which is explained by a reduction in the diffusion rate associated with a change in magnetic properties by Co addition. An increase of the volume magnetization of the steel with increasing Co content in the range from room temperature to about 800°C was confirmed. Comparing the difference in volume magnetization and the ratio of the creep strain rate for steels with different amounts of Co, a clear correlation was found. That is, at the temperature at which the difference in volume magnetization reached a maximum, the peak of the creep strain rate ratio was also observed. This result is explained as follows. In a low temperature region where the magnetization is large or in a high temperature region above the Curie point of both steels, the steels exhibit no significant difference in the creep strength. However, at a temperature where one steel loses its ferromagnetism but the other steel retains it, a significant difference in the creep strength is observed.

View full abstract