- |<

- <

- 1

- >

- >|

-

Takeo Inomoto, Michitaka Matsuo, Masataka YanoArticle type: Regular Article

2016 Volume 56 Issue 8 Pages 1307-1314

Published: August 15, 2016

Released on J-STAGE: August 31, 2016

JOURNAL OPEN ACCESS FULL-TEXT HTMLA fundamental investigation of the carbon removal rate in the low-carbon-content region using a vacuum induction furnace (12 kg-scale, 600 kg-scale, and 7 t-scale) was carried out and the following results were obtained:

1) A 12 kg-scale experiment aimed at elucidating the adsorption element effect in the decarburization reaction was carried out. The kinetic analysis of the experimental results obtained by using high-chromium steel and a former experimental study of low alloy steel showed that the reaction rate can be estimated using an integrated reaction rate. Moreover, by using this estimation method, the reaction rate of different scale experimental results can also be well predicted.

2) Argon bubbling experimental results using a 7 t-scale vacuum induction furnace showed that the bubble burst under highly reduced pressure conditions can be considered to take place at the shallow depth of 40 mm. Furthermore, a major factor of reaction promotion in both 17 mass% Cr steel and low alloy steel can be estimated by the surface expansion and mass transfer promotion effect of bubble bursting.

View full abstractDownload PDF (834K) Full view HTML -

Zhe Wang, David Pinson, Sheng Chew, Harold Rogers, Brian Joseph Monagh ...Article type: Regular Article

2016 Volume 56 Issue 8 Pages 1315-1324

Published: August 15, 2016

Released on J-STAGE: August 31, 2016

Advance online publication: June 07, 2016JOURNAL OPEN ACCESS FULL-TEXT HTMLNew Zealand ironsand is mined for steel production. Its composition approximates that of titanomagnetite (Fe3−xTixO4) containing about 60 wt% iron and 8 wt% titania. The ironsand provides an alternative source of iron to conventional iron ores. Its addition into a sinter blend is an established method of utilisation in ironmaking. Knowledge of the interaction between ironsand and flux materials during sintering is helpful to understand the sintering mechanism of titanomagnetite. In this study, two-layer interaction couples between ironsand and flux materials (CaO, MgO and dolomite) were prepared and sintered in an atmosphere of pO2 = 0.5 kPa in the temperature range of 1200–1300°C for different times. When the ironsand was sintered with MgO, Mg2+ ions significantly diffused into the lattice of ironsand, which stabilised the system of FeOx–MgO and hindered the assimilation of ironsand particles. During the sintering of ironsand with CaO, a reaction zone consisting of perovskite and calcium ferrite formed between the two layers. In comparison, a reaction zone consisting of perovskite, MgO–FeO solid solution and calcium ferrite occurred during the sintering of ironsand with dolomite. Increasing sintering temperature significantly enhanced the penetration of calcium ferrite into the dolomite layer; whereas the perovskite phase and MgO–FeO solid solution remained at higher sintering temperatures due to their relatively high melting points.

View full abstractDownload PDF (2401K) Full view HTML -

Cao Son Nguyen, Ko-ichiro Ohno, Takayuki Maeda, Kazuya KunitomoArticle type: Regular Article

2016 Volume 56 Issue 8 Pages 1325-1332

Published: August 15, 2016

Released on J-STAGE: August 31, 2016

JOURNAL OPEN ACCESS FULL-TEXT HTMLWetting between liquid iron and coke influences liquid flow in the lower part of a blast furnace, which strongly affects the operation of the furnace. With increasing fluidity, the blast furnace performs more favourably and efficiently. To further improve blast furnace operation, the wetting behaviour of liquid iron on coke must be correctly understood. The effects of ash in the coke on reactive wetting in concave formations, such as holes formed at the contact area, must be considered. This study aims to elucidate the effects of the ash component in coke on the reactive wetting behaviour of carbon-unsaturated liquid iron on a simulant coke substrate and concave formations thereof. In this study, reactive wetting between the iron samples and the substrates was measured by a sessile drop method with a molten injection system at 1673 K. The results revealed that the apparent contact angle significantly decreased with time in the first 300 s after contact. After 300 s, the contact angle stabilized at a constant equilibrium value. The initial contact angles depended not only on the carbon concentration of the liquid iron, but also on the Al2O3 content in the substrates. Concave geometries formed when the carbon-unsaturated iron samples were wetted on substrates containing 0, 5, and 10 vol% Al2O3. The effect of Al2O3 on the carbon dissolution reaction was the main factor affecting the reactive wetting behaviour of substrates against liquid iron.

Relationship between Al2O3 amount in the substrate and dihedral contact angle. Fullsize ImageView full abstractDownload PDF (1176K) Full view HTML

Relationship between Al2O3 amount in the substrate and dihedral contact angle. Fullsize ImageView full abstractDownload PDF (1176K) Full view HTML -

Xuechao Luo, Wanlin Wang, Fanjun MaArticle type: Regular Article

2016 Volume 56 Issue 8 Pages 1333-1341

Published: August 15, 2016

Released on J-STAGE: August 31, 2016

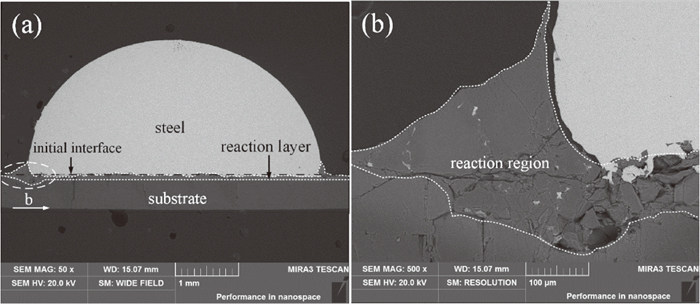

JOURNAL OPEN ACCESS FULL-TEXT HTMLThe wettability behavior and undercooling of molten steel on single crystal Al2O3 and MgO substrates in a reduced Ar–H2 atmosphere were investigated by using a sessile drop method. The results showed that there is no reaction layer formed at the steel/substrate interface when the oxygen partial pressure is at 10−25 atm, and the contact angle and undercooling degree show the maximal values. With the increase of oxygen partial pressure, the segregation of Si, Mn and the formation of a complex-oxide layer at the interface could be clearly observed; thus the wettability was great improved for both systems, also the contact angle and undercooling degree decreased. The thickness of the reaction layer was expanded with the increase of oxygen partial pressure, which increased from 0.8 µm to 31 µm for Al2O3 substrate, and from 62 µm to 280 µm for MgO substrate, suggesting that the interfacial reaction was getting intensive with the addition of oxygen partial pressure. The results also indicated that the MgO shows a better wettability with molten steel and is more effective for the induction of heterogeneous nucleation.

Cross-section view of the interface between droplet and MgO (100) substrate with oxygen partial pressure at 3.63×10−23 atm: (a) general view of the droplet, (b) details of the reaction region at the triple point of gas/steel/substrate. Fullsize ImageView full abstractDownload PDF (1833K) Full view HTML

Cross-section view of the interface between droplet and MgO (100) substrate with oxygen partial pressure at 3.63×10−23 atm: (a) general view of the droplet, (b) details of the reaction region at the triple point of gas/steel/substrate. Fullsize ImageView full abstractDownload PDF (1833K) Full view HTML -

Jue Tang, Mansheng Chu, Cong Feng, Feng Li, Yating Tang, Zhenggen LiuArticle type: Regular Article

2016 Volume 56 Issue 8 Pages 1342-1351

Published: August 15, 2016

Released on J-STAGE: August 31, 2016

JOURNAL OPEN ACCESS FULL-TEXT HTMLTiO2, V2O5, and Cr2O3 are the three characteristic and valuable components of high-chromium vanadium-bearing titanomagnetite. The coupled effect of the three components during oxidation roasting is investigated in the work. The ordinary iron ore together with analytically pure TiO2, V2O5, and Cr2O3 is used to prepare pellet samples and two typical on-site iron ores are used to verify the analyses. TiO2, V2O5, and Cr2O3 in one-component pellet form iron titanium solid solution, single V2O3, and iron chromium solid solution respectively to destroy the integrity of hematite recrystallization and restrain a wide range of connected crystal. TiO2 is conductive to form high melting point slag and increase the amount of liquid slag. As increased TiO2, V2O5, and Cr2O3, the compressive strength (CS) of pellet decreases. The reduction swelling index (RSI) of pellet is improved by TiO2 but worsened by V2O5 and Cr2O3. The decrease of CS is aggravated seriously by the coupled effect of TiO2&V2O5, and RSI of TiO2&V2O5 pellet is higher than TiO2 pellet but lower than V2O5 pellet. CS of TiO2&V2O5&Cr2O3 pellets is worse than one-component TiO2, V2O5, and Cr2O3 pellet but better than TiO2&V2O5 pellet, which is attributed to the new generated vanadium chromium solid solution cutting down the destroy of single V2O3 grains and remitting the decrease of CS more or less. The verified analyses of two typical on-site iron ores indicate that the obtained coupled effects of valuable components in high-chromium vanadium-bearing titanomagnetite during oxidation roasting are credible.

View full abstractDownload PDF (3168K) Full view HTML -

Jintao Gao, Yiwei Zhong, Zhancheng GuoArticle type: Regular Article

2016 Volume 56 Issue 8 Pages 1352-1357

Published: August 15, 2016

Released on J-STAGE: August 31, 2016

Advance online publication: June 07, 2016JOURNAL OPEN ACCESS FULL-TEXT HTMLBased on the precipitation experiment results of titanium bearing molten slag during cooling liquation, perovskite (CaTiO3) was the first precipitated phase, and 1593–1563 K was the advantageous precipitation temperature of perovskite from the molten simulated slag with a basicity of 1.30. So if perovskite could be separated from the slag melt at this temperature range, at which perovskite becomes a solid state while other minerals form into the molten slag, it would be beneficial for the solid-liquid separation between them. Hence, selective separation experiments of perovskite from titanium bearing slag melt with a basicity of 1.30 at 1578 K by super gravity were carried out in this study, and the results confirmed that it was an effective method. In this process, the molten slag moved along the super gravity direction and went through the filter and then concentrated as the slag phase in the bottom crucible, in which it was practically impossible to find any perovskite grains. In contrast, all the perovskite grains were intercepted by the filter and concentrated as the perovskite phase on the filter, which appeared as the typical dendrite structure. Consequently, after super gravity separation with gravity coefficient of G = 660 to G = 840 at 1578 K for 10 minutes, the mass fraction of TiO2 in the perovskite phase was up to 46.36 wt%, whereas that of the slag phase was only 8.77 wt%. In this case, the recovery ratio of Ti in the perovskite phase was up to 78.17%.

View full abstractDownload PDF (985K) Full view HTML

-

Yoshiyuki UeshimaArticle type: Note

2016 Volume 56 Issue 8 Pages 1506-1508

Published: August 15, 2016

Released on J-STAGE: August 31, 2016

JOURNAL OPEN ACCESS FULL-TEXT HTMLDissolution experiments of solid alumina in four kinds of liquid slags corresponding to cover-slags, LF-slag and fluorspar were conducted at 1600°C under an atmosphere of dry air. The local dissolution rates of alumina and the flow velocities and wetting behaviors around the meniscus line were analyzed with the Marangoni number.

View full abstractDownload PDF (601K) Full view HTML

-

Wei Zhang, Juhua Zhang, Zhengliang Xue, Zongshu Zou, Yuanhong QiArticle type: Regular Article

2016 Volume 56 Issue 8 Pages 1358-1367

Published: August 15, 2016

Released on J-STAGE: August 31, 2016

Advance online publication: June 07, 2016JOURNAL OPEN ACCESS FULL-TEXT HTMLAn unsteady model of the top gas recycling oxygen blast furnace (TGR-OBF) process was established according to material and thermal balance principles. The restrictive kinetic step of the reaction in the bosh of oxygen blast furnace was considered, as well as the key nodes’ gas recycling processes and combustion equilibrium of the shaft injection gas. Typical unsteady analyses of the TGR-OBF processes are demonstrated by the unsteady model. It is concluded that the whole TGR-OBF processes could reach equilibrium in case of reasonable operation. Based on the default conditions in this paper, it takes about 6 times for the main gas elements travelling from tuyere zone to the furnace top, until the unsteady process turns to be a stable one. The fuel rate decreases from 496 kg/t to 426 kg/t and 403 kg/t when the blast oxygen content is increased from 21.5% to 50% and 98%, and instantaneously, the top gas volume drops from 1582 Nm3 to 1462 Nm3 and 1031 Nm3. Because most carbonaceous gases are deprived in the VPSA (Vacuum Pressure Swing Absorption) segment and also recycled inside of the blast furnace, the CO2 emissions in the TGR-OBF cases are 206.06 Nm3 and 99.56 Nm3/t compared to the CO2 emission of 664.58 Nm3/t in the conventional blast furnace.

View full abstractDownload PDF (1092K) Full view HTML

View full abstractDownload PDF (1092K) Full view HTML

-

Cheng-yi Zhu, Peng-ju Chen, Guang-qiang Li, Xiao-yan Luo, Wan ZhengArticle type: Regular Article

2016 Volume 56 Issue 8 Pages 1368-1377

Published: August 15, 2016

Released on J-STAGE: August 31, 2016

Advance online publication: June 16, 2016JOURNAL OPEN ACCESS FULL-TEXT HTMLA mathematical model about the variation of sulphur content in liquid steel during a 300 t RH refining process was established based on the consideration of thermodynamics, kinetics of desulphurization and conditions of practical production. The effect of initial sulphur content in the top slag on the ration of contribution of transitory desulphurization reaction in total desulphurization was included. The effects of initial sulphur content in the liquid steel, powder injection rate, particle size of powder, flow rate of RH driving gas and initial temperature of the bath on the temperature drop were taken into account. Sulphur content in the steel bath during desulphurization process and the final sulphur content in the liquid steel were analyzed. The lowest sulphur content can decrease to 10 ppm from 30 ppm by taking reasonable injection operating conditions to treat 10 min. The simulated results of sulfur removal rate and final sulphur content in liquid steel agree well with that of plant production under the same conditions, which indicates that the present model can be used to predict desulphurization process. The simulated results also show that powder injection desulphurization has better desulphurization efficiency compared with adding desulphurization agent simply onto the top of molten steel in the vacuum vessel in the practical production process.

View full abstractDownload PDF (991K) Full view HTML

-

Yukinobu NatsumeArticle type: Regular Article

2016 Volume 56 Issue 8 Pages 1378-1385

Published: August 15, 2016

Released on J-STAGE: August 31, 2016

JOURNAL OPEN ACCESS FULL-TEXT HTMLA new cellular automaton (CA) model with a triple-layered multi-grid (TLMG) method for ternary alloys was developed, and prediction of microsegregation in Fe–C–Cr ternary alloys was performed by using the technique combining a two-dimensional CA model with the TLMG method and thermodynamic equilibrium (EQ) calculations. In this work, simulations of multi-dendritic growth were performed for twelve different Fe–C–Cr alloys by using the current CA model; then EQ calculations were conducted by utilizing the results of the previous CA simulations. The compositions of interdendritic liquids obtained by the CA simulations were used as initial input data for the EQ calculations. Microsegregation in the Fe–C–Cr alloys was evaluated using segregation indices corresponding to the ratios between the maximum and minimum concentrations in the calculation domains. The predicted values of a Cr segregation index increase with an increase in the carbon content in alloys; these values are in good agreement with the experimental data reported by Kishitake et al. [K. Kishitake, S. Matsuo and T. Okamoto Tetsu-to-Hagane, 63 (1977), p. 1108] The obtained results indicate that microsegregation in ternary alloys can be predicted quantitatively using the proposed method that includes CA simulations combined with EQ calculations.

View full abstractDownload PDF (1678K) Full view HTML -

Yanwu Dong, Zhouhua Jiang, Haibo Cao, Xiang Wang, Yulong Cao, Dong HouArticle type: Regular Article

2016 Volume 56 Issue 8 Pages 1386-1393

Published: August 15, 2016

Released on J-STAGE: August 31, 2016

Advance online publication: June 28, 2016JOURNAL OPEN ACCESS FULL-TEXT HTMLA novel single power two circuits electroslag remelting (ESR) with current carrying mould is presented in this paper. There are two processes with up power and down power for this technology. Numerical simulation of single power two circuits electroslag remelting process with current carrying mould (ESR-STCCM) as well as conventional ESR process for comparison is carried out in this paper. Results indicate that ESR-STCCM process changes the current circuit. Special current circuit results in different electromagnetic field, fluids flow and thermal field. Molten steel pool is shallower and mushy zone is narrower for ESR-STCCM than conventional ESR process. In addition, the temperature of slag-metal interface for ESR-STCCM with up power is higher than others ESR process investigated in this article that contributes to obtain smooth ingot surface quality. All in all, ESR-STCCM with up power is a promising process for improving the quality of material prone to segregation in comparison with other ESR process, based o the results obtained in this article.

View full abstractDownload PDF (1042K) Full view HTML -

Enif Gutiérrez, Saul Garcia-Hernandez, José de Jesús BarretoArticle type: Regular Article

2016 Volume 56 Issue 8 Pages 1394-1403

Published: August 15, 2016

Released on J-STAGE: August 31, 2016

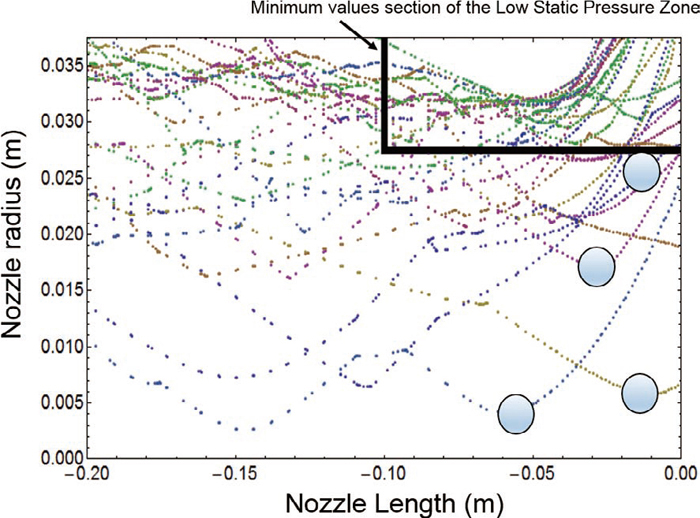

Advance online publication: July 07, 2016JOURNAL OPEN ACCESS FULL-TEXT HTMLNozzle clogging is still a standing problem in the continuous casting of steel since the deposition of alumina inclusions inside the Upper Tundish Nozzle (UTN) affects the productivity and the product quality. The present fundamental work studies the effects of inertial, gravitational, buoyant, pressure gradient, and Saffman forces on the deposited inclusion trajectories at the typical adhesion zone inside the UTN, using analytical and numerical techniques. For this, a mathematical model was developed considering the Navier-Stokes equations, the standard k-ε model, and the Lagrangian discrete phase model for a coupled system including the tundish, the UTN, the slide gate, the SEN, and the mould. The results show that the highest inclusion deposition rate is just below a low static pressure zone. At the low static pressure zone the pressure gradient force becomes important, attracting the inclusions to the nozzle wall, and once the inclusions leave this zone, this force does not promote a significant inclusion radial movement. In addition, at the highest deposition zone, the effects of the gravitational and buoyant forces do not promote a significant inclusion radial movement since these are aligned with the direction of the flow stream lines. In contrast, the Saffman force shows an important effect on the deposited inclusions, slowing down the inclusions in the vertical axis and increasing their radial movement.

Sample of the deposited inclusions trajectories (30 μm). Fullsize ImageView full abstractDownload PDF (2245K) Full view HTML

Sample of the deposited inclusions trajectories (30 μm). Fullsize ImageView full abstractDownload PDF (2245K) Full view HTML -

Haitong Bai, Mikael Ersson, Pär Göran JönssonArticle type: Regular Article

2016 Volume 56 Issue 8 Pages 1404-1412

Published: August 15, 2016

Released on J-STAGE: August 31, 2016

JOURNAL OPEN ACCESS FULL-TEXT HTMLA swirling flow has been demonstrated to be beneficial for making the flow pattern even and to reduce turbulence during filling in ingot casting. A new swirling flow generation device, TurboSwirl, was applied to improve the flow pattern of the liquid steel as it flows into the mold so that a more stable flow could be obtained. A water model was built including the TurboSwirl with different flaring angles of the divergent nozzle, according to a former numerical study indicating that a much more beneficial flow pattern could be obtained by reducing the flaring angle. To validate the mathematical model, the air-core vortex formed in the water model experiment was used, and the length of the vortex was measured and compared to the numerical predictions. Different turbulence models including the standard k-ε, realizable k-ε and Reynolds stress model were tested. It was found that only the Reynolds stress model could most accurately simulate the high swirling flow including a vortex. In addition, the radial velocity of the water around the vortex was measured by an ultrasonic velocity profiler (UVP). The experimental results revealed a high turbulence of the swirling flow and strong fluctuations of the vortex. The radial velocity of the water around the upper part of the vortex could be predicted well compared to the experimental results by the UVP measurements.

View full abstractDownload PDF (895K) Full view HTML -

Eiichi Aritaka, Hisao Esaka, Kei ShinozukaArticle type: Regular Article

2016 Volume 56 Issue 8 Pages 1413-1419

Published: August 15, 2016

Released on J-STAGE: August 31, 2016

JOURNAL OPEN ACCESS FULL-TEXT HTMLThe feasibility of reducing macrosegregation via control of the solidified structure was investigated. Factors such as the size and complexity of equiaxed grains, which may influence this macrosegregation, were determined. In the first stage of the project, the influence of mechanical vibration on the complexity of the solidified structure was determined. Al-10 wt.%Cu alloys were used as model alloys. The size of the equiaxed grains varied with the amount of modifier. In addition, the complexity of the morphology of primary aluminum was characterized in terms of the fractal dimension, which was measured by using the box-counting method. The results revealed that the fractal dimension increased with increasing frequency of the vibration. Moreover, the diffusion layer in front of the growing interface may be washed away, owing to this vibration. The consequent decrease in thickness of this layer resulted in an increase in the degree of constitutional undercooling. Therefore, the break-down may occur, and hence complexity of the solid/liquid interface may increase. The results also revealed that the size and complexity of the equiaxed grains may be independently controlled to some extent.

View full abstractDownload PDF (902K) Full view HTML -

Hideo Mizukami, Mitsuhiro Numata, Akihiro YamanakaArticle type: Regular Article

2016 Volume 56 Issue 8 Pages 1420-1426

Published: August 15, 2016

Released on J-STAGE: August 31, 2016

JOURNAL OPEN ACCESS FULL-TEXT HTMLThe behavior for injection of magnesium vapor into molten steel and the potential of magnesium vapor for miniaturization of TiN size were evaluated by the experiment in tammann furnace and the experiment in vacuum furnace. From the results of these experiments, the partial pressure of magnesium reacting with molten steel could be increased, and the both high concentration in molten steel and high additive yield of magnesium into molten steel could be done together. It was confirmed that spinel MgO·Al2O3 was formed as a heterogeneous nucleus of TiN. The dissolved magnesium concentration governed the heterogeneous nucleus for TiN. The injection of magnesium vapor into molten steel could control the generation of heterogeneous nucleus during solidification.

View full abstractDownload PDF (798K) Full view HTML -

Tomohiro Takaki, Shinji Sakane, Munekazu Ohno, Yasushi Shibuta, Takash ...Article type: Regular Article

2016 Volume 56 Issue 8 Pages 1427-1435

Published: August 15, 2016

Released on J-STAGE: August 31, 2016

Advance online publication: June 23, 2016JOURNAL OPEN ACCESS FULL-TEXT HTMLLarge-scale phase-field studies of three-dimensional (3D) dendrite competitive growth at the converging grain boundary (GB) of a bicrystal binary alloy were carried out using the GPU-rich supercomputer TSUBAME 2.5 at Tokyo Institute of Technology. First, a series of thin-sample simulations were performed to investigate the effects of thin-sample thickness, unfavorably oriented (UO) grain inclination angle, and dendrite arrangement on an unusual overgrowth phenomenon whereby the favorably oriented (FO) grain is overgrown by the UO grain. It was concluded that the unusual overgrowth easily occurs as the thickness of the thin sample and the UO grain inclination angle decrease. It was also concluded that the interaction between FO and UO dendrites at the converging GB depends on the dendrite arrangement for relatively large dendrite spacing. Next, realistic large-scale simulations whereby multiple dendrites interact at the converging GB were performed. Unusual overgrowth was also observed in such large-scale simulations, and this phenomenon easily occurred at smaller UO dendrite inclination angles. Furthermore, it was also concluded that the FO and UO dendrites rearrange toward a space-to-face interaction. Because the interaction between FO and UO dendrites differs according to the location on the GB, a zigzag GB was formed, especially at small UO grain inclination angles.

Large-scale simulations with 768×1536×1536 lattice points and 7×106 steps were performed for multiple dendrites interaction at the converging grain boundary during directional solidification of a bicrystal binary alloy. Three simulations were performed for unfavorably oriented dendrite angles of 5°, 10°, and 15°. In each simulation, a 386 GPU of the GPU-rich supercomputer TSUBAME at Tokyo Institute of Technology was used, and the computational time was around 5.5 days. Fullsize ImageView full abstractDownload PDF (2239K) Full view HTML

Large-scale simulations with 768×1536×1536 lattice points and 7×106 steps were performed for multiple dendrites interaction at the converging grain boundary during directional solidification of a bicrystal binary alloy. Three simulations were performed for unfavorably oriented dendrite angles of 5°, 10°, and 15°. In each simulation, a 386 GPU of the GPU-rich supercomputer TSUBAME at Tokyo Institute of Technology was used, and the computational time was around 5.5 days. Fullsize ImageView full abstractDownload PDF (2239K) Full view HTML

-

Chuan-ming Du, Xu Gao, Sun-joong Kim, Shigeru Ueda, Shin-ya KitamuraArticle type: Regular Article

2016 Volume 56 Issue 8 Pages 1436-1444

Published: August 15, 2016

Released on J-STAGE: August 31, 2016

Advance online publication: June 23, 2016JOURNAL OPEN ACCESS FULL-TEXT HTMLSteelmaking slag with high P2O5 content is considered as an alternative resource of P. In such slag, P is mainly concentrated in 2CaO·SiO2-3CaO·P2O5 (C2S–C3P) solid solution, which has higher water solubility than other mineralogical phases, which indicates the possibility of selective leaching of P. In order to recover P from steelmaking slag, its dissolution ratio from C2S–C3P into aqueous solutions must be increased. In this study, the effects of acid as leaching agent, high temperature modification of C2S–C3P by Na2SiO3, and pH on the dissolution behavior of C2S–C3P in aqueous solutions have been investigated. The obtained results show that when oxalic acid (H2C2O4) or citric acid (H3C6H5O7) was used to leach P from C2S–C3P, dissolved Ca2+ ions were removed by CaC2O4 precipitation or by the formation of CaC6H5O7− complex, respectively. As a result, the precipitation of phosphates was suppressed, and P dissolution increased dramatically. On the other hand, the P-rich phase changed from the original C2S–C3P into 2CaO·SiO2-2CaO·Na2O·P2O5 with higher water solubility after Na2SiO3 addition, thus improving P dissolution in the H2C2O4 and H3C6H5O7 solution. At higher pH (pH ≥ 7), H2C2O4 was beneficial for P dissolution from the modified C2S–C3P. However, at lower pH (5 ≤ pH < 7), H3C6H5O7 was an optimal leaching agent for extracting soluble P. At pH 5, the dissolution ratio of P from the modified C2S–C3P in the H3C6H5O7 solution reached 85.7%.

View full abstractDownload PDF (1411K) Full view HTML -

Teija Sipola, Tuomas Alatarvas, Timo Fabritius, Paavo PerämäkiArticle type: Regular Article

2016 Volume 56 Issue 8 Pages 1445-1451

Published: August 15, 2016

Released on J-STAGE: August 31, 2016

JOURNAL OPEN ACCESS FULL-TEXT HTMLThe determination of alloying and impurity elements was performed from a stainless steel matrix and inclusions in process samples. An electrolytic extraction method was applied for the separation of inclusions using two different but commonly used electrolytes, 10% HCl and 10% acetylacetone in methanol. The elemental analyses were performed using atomic absorption spectrometry. The elements of interest were aluminum, arsenic, copper, vanadium, titanium and chromium. The aluminum containing inclusions were imaged using a field emission scanning electron microscope. The results for copper and chromium in both electrolytes, vanadium in 10% HCl electrolyte and arsenic in 10% acetylacetone electrolyte were in good agreement with industrial data. Titanium and aluminum were measured from the dissolved steel matrix but titanium was also detected in the inclusions. It was concluded that the analytical results for titanium and aluminum measured using an optical emission spectrometer is affected by the inclusions within the stainless steel.

View full abstractDownload PDF (773K) Full view HTML

-

Anil Kumar Parida, Shatrughan Soren, Raghu Nandan Jha, Nelepu Krishnam ...Article type: Regular Article

2016 Volume 56 Issue 8 Pages 1452-1461

Published: August 15, 2016

Released on J-STAGE: August 31, 2016

JOURNAL OPEN ACCESS FULL-TEXT HTMLIn this paper processing effects were studied while 12 mm thick circular blanks of hardened-tempered AISI 1040 graded medium carbon steel, applied in cylindrical cup manufacturing by a new modified processing route as an innovative approach. The processing route mainly consisted of pre-forming of flat blanks to a little draw in shape, followed by multistage drawing without blank-holder. The wall ironing was purposefully accompanied with deep drawing by ensuring suitable die-punch design to reduce wall thickness as well as earing tendency on cup edges. Thus, evolution of cup dimensions and quality, wall thickness distribution profiles, drawability and ironability parameters, punch force history, hardness distribution profiles, strain distribution profiles, spring back tendency by Demeri split ring test, and microstructures of cup wall zones were discussed.

With appropriate heat treatment cycle, the steel showed a good combination of strength-ductility-formability and thus indicated its moderate drawability with high strength applications, i.e. up to ~634 MPa. The multistage cup drawing process feasibility was confirmed by manufacturing of >50 mm long cylindrical cups with uniform wall thickness and without any common forming defect. The microstructure study of cup walls also further substantiated the process feasibility. Moreover, the data pertaining to strain distribution profiles and spring back tendency of cups were shown for the process engineers to optimise the process and draw tool design, as a future scope of work.

View full abstractDownload PDF (1601K) Full view HTML -

Ning Zhang, Ping Yang, Chengxu He, Weimin MaoArticle type: Regular Article

2016 Volume 56 Issue 8 Pages 1462-1469

Published: August 15, 2016

Released on J-STAGE: August 31, 2016

Advance online publication: June 23, 2016JOURNAL OPEN ACCESS FULL-TEXT HTMLIn this study, the electrical steel samples containing different-sized {110}<229> and {110}<112> oriented grains are cold rolled and annealed to investigate the effect of these grains on deformation and recrystallization texture evolution, and the origins and evolution of {110}<229> and {110}<112> grains in recrystallized samples are paid special attention. After rolling, initial {110}<229> and {110}<112> grains lead to γ-fiber deformation texture and γ-fiber as well as {112}<110> deformation textures respectively, and the crystal rotations show combined effects of initial orientation, surface shear and surrounding matrix. After annealing, in the case of large initial grains, preferred {hk0}<001> nucleation occurs in initial {110}<229> grains and lead to {hk0}<001> recrystallization texture accordingly. Compared to initial {110}<001> grains, the lower intensity of {hk0}<001> texture, spreading to cube component, is attributed to the deviation of deformed orientation from {111}<112>. In contrast, coarse recrystallized microstructure and weak recrystallization texture are obtained in initial {110}<112> grains. Similarly, small {110}<229>-<112> grains in annealed hot bands also contribute to {hk0}<001> recrystallization texture, meanwhile {112}<110> deformed matrix induced by initial {110}<112> grains affect texture and microstructure evolution. With respect to {110}<229> and {110}<112> grains in recrystallized samples, the majority of them nucleate in α-fiber deformed matrix, and larger size than {110}<001> recrystallized grains is illustrated.

View full abstractDownload PDF (1981K) Full view HTML

-

Arun Kumar Singh, Nitu Rani, Saurabh KunduArticle type: Regular Article

2016 Volume 56 Issue 8 Pages 1470-1479

Published: August 15, 2016

Released on J-STAGE: August 31, 2016

JOURNAL OPEN ACCESS FULL-TEXT HTMLNine samples of low-carbon steel were prepared by varying composition of Cr and Mn. The weight% of Cr and Mn in samples are 0.2Cr, 0.5Cr and 5Cr, and 0.5Mn, 1.0Mn and 1.5Mn respectively.

The electrochemical tests such as corrosion potential, EIS, Linear polarization and Cyclic polarization were conducted on samples in simulated pore solution with and without the presence of 3.5% NaCl. Separately, samples were exposed to wet-dry corrosion test and their corrosion products were examined by XRD and FTIR. Further, oxidised surface was studied by SEM/EDS.

The samples show passive behaviour in chloride free pore solution but passivity breaks after chloride addition. Even, 5Cr containing steels could not hold passive characteristic in chloride medium. In wet-dry corrosion test, 5Cr containing steels develop loose and voluminous corrosion products which is highly detrimental for rebar application.

On the contrary, the lower Cr containing steels, 0.2Cr and 0.5Cr, produce thin and adherent rust in wet-dry corrosion test. In electrochemical test, these steel samples too transfer from passive to active state after chloride ion addition in pore solution but their behaviour is superior. More particularly, two steel chemistry 0.2Cr, 0.5Mn and 0.5Cr, 1.5Mn show a sign of repassivation and pitting resistance respectively.

View full abstractDownload PDF (1728K) Full view HTML

-

Yasuaki Hamano, Motomichi Koyama, Shigeru Hamada, Hiroshi NoguchiArticle type: Regular Article

2016 Volume 56 Issue 8 Pages 1480-1486

Published: August 15, 2016

Released on J-STAGE: August 31, 2016

JOURNAL OPEN ACCESS FULL-TEXT HTMLThe fatigue limit of a tempered martensitic steel was evaluated in specimens with stress concentration sources, which were introduced with a small drill and focused ion beam (FIB). In a previous study using ferrite-pearlite steel, the fatigue limit of a specimen with a FIB notch was almost the same as the fatigue limit of a specimen with a drill hole, and the non-propagating cracks were found around both shapes of stress concentration sources. However, the fatigue limit of the specimen with a FIB notch was about 100 MPa lower than the fatigue limit of the specimen with a drill hole in tempered martensitic steel. Additionally, the non-propagating crack was observed only in the specimen with a FIB notch. The stress concentration source shapes in both materials are the same, then the difference in fatigue limit stems from the material property. This indicates that there is applicable range where stress concentration source is regarded as a pre-crack, and the range depends on material. At first, the reason for the difference in fatigue limit was discussed in terms of the non-propagating crack. In this part, we discussed non-propagating crack phenomenon around drill hole. Secondly, the effect of hardness which caused the difference in fatigue limit was discussed by using an analytical result of Dugdale model. Finally, we inferred the notch sensitivity from the propagation by deformation at crack tip. After that, we concluded that the propagation by fracture at crack tip is also important factor in analyzing notch sensitivity.

View full abstractDownload PDF (936K) Full view HTML

-

Eiji Yamasue, Kazuyo Matsubae, Kenichi Nakajima, Ichiro Daigo, Keiichi ...Article type: Regular Article

2016 Volume 56 Issue 8 Pages 1487-1496

Published: August 15, 2016

Released on J-STAGE: August 31, 2016

Advance online publication: June 23, 2016JOURNAL OPEN ACCESS FULL-TEXT HTMLThe concept of total material requirement (TMR) is introduced in this study in order to quantify the recyclability of scrap steel from an end-of-life (EoL) vehicle. The specific TMRs for the recycling of scrap steels (urban ore TMR, UO-TMR) from the EoL vehicle are estimated for four cases: conventional press-method, shredder and separation method, additional recycling of scrap steel from automobile shredder residue (ASR) and all-recycling using the press method. The trade-off between the increase in functionality of recycled steel (i.e., decrease in influence of copper as a contaminant) and the additional inputs, such as pig iron or nickel required for the functional improvement, were also evaluated. The estimated UO-TMR ranged between 3.7 and 4.0 kg/kg, and the factors of “material itself” and “melting” were dominant. The effect of ASR input into an electric arc furnace, as part of an all-recycling scenario, was outweighed by additional lime input and the energy needed to heat glass materials. Considering dilution by cold pig iron, the shredder and separation method appears to be the most effective, in terms of TMR. Furthermore, the effectiveness is discussed, of both the dilution by pig iron and the addition of nickel for suppressing surface hot-shortness.

View full abstractDownload PDF (1176K) Full view HTML -

Toshiyuki Takahashi, Seiji YokoyamaArticle type: Regular Article

2016 Volume 56 Issue 8 Pages 1497-1505

Published: August 15, 2016

Released on J-STAGE: August 31, 2016

JOURNAL OPEN ACCESS FULL-TEXT HTMLSeveral amounts of electric arc furnace (EAF) steel slag ultimately end up in final landfill sites. After developing a method to estimate the impacts of eluate from slag, particularly on phytoplankton, this study assessed novel slag applications to aquatic environments. First, metal components were eluted from EAF slags of common steel or stainless steel with a leaching condition based on JIS K 0058-1. The metal components in slag were analyzed using emission spectrochemical analyses. After incubation of green algae Chlorella as phytoplankton with culture media containing eluates from the respective slags, the effects of the respective eluates on algae were investigated using microscopy and flow cytometry. Results demonstrated that concentrations of metal effluents from slags, even for EAF steel slag, which included more hazardous materials than common slag, were almost all lower than environmental quality standards for effluent and drinking water. Analyses of algal cells treated with each eluate revealed that eluate induced neither lethality nor growth inhibition. Instead of cytotoxicity, the addition of each eluate enhanced algal growth. Infrared spectroscopy and potentiometry using a diaphragm-type electrode to measure aquatic CO2 revealed that metal components from both slags in media produced greater amounts of aquatic CO2 available for photosynthesis, thereby enhancing algal proliferation. Taken together, results show that using EAF slag in aquatic environments might be beneficial, not toxic, for photosynthetic organisms. Furthermore, bioassay using flow cytometry can estimate vigorous and aberrant algal growth simultaneously.

View full abstractDownload PDF (517K) Full view HTML

- |<

- <

- 1

- >

- >|