- Issue 16 Pages 1251-

- Issue 15 Pages 1165-

- Issue 14 Pages 1033-

- Issue 13 Pages 989-

- Issue 12 Pages 899-

- Issue 11 Pages 795-

- Issue 10 Pages 721-

- Issue 9 Pages 653-

- Issue 8 Pages 569-

- Issue 7 Pages 513-

- Issue 6 Pages 427-

- Issue 5 Pages 395-

- Issue 4 Pages 343-

- Issue 3 Pages 89-

- Issue 2 Pages 35-

- Issue 1 Pages 1-

- Issue 16 Pages 2157-

- Issue 15 Pages 1805-

- Issue 14 Pages 1613-

- Issue 13 Pages S1141-

- Issue 12 Pages S1037-

- Issue 11 Pages 1443-

- Issue 10 Pages 1273-

- Issue 9 Pages 1077-

- Issue 8 Pages 917-

- Issue 7 Pages 751-

- Issue 6 Pages 585-

- Issue 5 Pages S389-

- Issue 4 Pages S1-

- Issue 3 Pages 403-

- Issue 2 Pages 233-

- Issue 1 Pages 19-

- Issue 16 Pages 2153-

- Issue 15 Pages 1977-

- Issue 14 Pages 1813-

- Issue 13 Pages S1285-

- Issue 12 Pages S1043-

- Issue 11 Pages 1667-

- Issue 10 Pages 1481-

- Issue 9 Pages 1231-

- Issue 8 Pages 891-

- Issue 7 Pages 711-

- Issue 6 Pages 538-

- Issue 5 Pages S407-

- Issue 4 Pages S1-

- Issue 3 Pages 347-

- Issue 2 Pages 173-

- Issue 1 Pages 14-

- Issue 16 Pages 1837-

- Issue 15 Pages 1711-

- Issue 14 Pages 1569-

- Issue 13 Pages S1205-

- Issue 12 Pages S1034-

- Issue 11 Pages 1423-

- Issue 10 Pages 1269-

- Issue 9 Pages 1059-

- Issue 8 Pages 925-

- Issue 7 Pages 775-

- Issue 6 Pages 627-

- Issue 5 Pages S287-

- Issue 4 Pages S1-

- Issue 3 Pages 301-

- Issue 2 Pages 147-

- Issue 1 Pages 12-

- Issue 16 Pages 2179-

- Issue 15 Pages 1795-

- Issue 14 Pages 1631-

- Issue 13 Pages S1053-

- Issue 12 Pages S1023-

- Issue 11 Pages 1501-

- Issue 10 Pages 1315-

- Issue 9 Pages 987-

- Issue 8 Pages 767-

- Issue 7 Pages 621-

- Issue 6 Pages 473-

- Issue 5 Pages S305-

- Issue 4 Pages S1-

- Issue 3 Pages 299-

- Issue 2 Pages 151-

- Issue 1 Pages 16-

- Issue 16 Pages 1945-

- Issue 15 Pages 1699-

- Issue 14 Pages 1531-

- Issue 13 Pages S1055-

- Issue 12 Pages S1013-

- Issue 11 Pages 1367-

- Issue 10 Pages 1215-

- Issue 9 Pages 1087-

- Issue 8 Pages 887-

- Issue 7 Pages 721-

- Issue 6 Pages 507-

- Issue 5 Pages S317-

- Issue 4 Pages S1-

- Issue 3 Pages 343-

- Issue 2 Pages 187-

- Issue 1 Pages 17-

- Issue 16 Pages 2405-

- Issue 15 Pages 2067-

- Issue 14 Pages 1865-

- Issue 13 Pages 1675-

- Issue 12 Pages S1055-

- Issue 11 Pages S1015-

- Issue 10 Pages 1479-

- Issue 9 Pages 1129-

- Issue 8 Pages 895-

- Issue 7 Pages 711-

- Issue 6 Pages 545-

- Issue 5 Pages S325-

- Issue 4 Pages S1-

- Issue 3 Pages 369-

- Issue 2 Pages 193-

- Issue 1 Pages 16-

- Issue 16 Pages 2573-

- Issue 15 Pages 2261-

- Issue 14 Pages 2073-

- Issue 13 Pages S1111-

- Issue 12 Pages S1001-

- Issue 11 Pages 1867-

- Issue 10 Pages 1657-

- Issue 9 Pages 1409-

- Issue 8 Pages 1043-

- Issue 7 Pages 841-

- Issue 6 Pages 649-

- Issue 5 Pages S415-

- Issue 4 Pages S1-

- Issue 3 Pages 431-

- Issue 2 Pages 225-

- Issue 1 Pages 3-

- |<

- <

- 1

- >

- >|

-

2023 Volume 109 Issue 2 Pages Cover-

Published: February 01, 2023

Released on J-STAGE: January 31, 2023

JOURNAL OPEN ACCESSDownload PDF (663K) -

2023 Volume 109 Issue 2 Pages Contents-

Published: February 01, 2023

Released on J-STAGE: January 31, 2023

JOURNAL OPEN ACCESSDownload PDF (2238K) -

2023 Volume 109 Issue 2 Pages Editorial-

Published: February 01, 2023

Released on J-STAGE: January 31, 2023

JOURNAL OPEN ACCESSDownload PDF (580K)

-

Yasumitsu KondoArticle type: Review Article

2023 Volume 109 Issue 2 Pages 87-105

Published: 2023

Released on J-STAGE: January 31, 2023

JOURNAL OPEN ACCESS FULL-TEXT HTMLStudies on the oxide scale in hot-rolling process are reviewed. This paper outlines scale formation and the effects of alloying elements on scale formation, scale behaviour in hot-rolling processes such as rolling and descaling, blistering phenomenon, red scale, whisker generation, scale transformation, and Cu-induced hot shortness.

View full abstractDownload PDF (6009K) Full view HTML

View full abstractDownload PDF (6009K) Full view HTML

-

Yu-ki Taninouchi, Tsubasa Yamaguchi, Toru H. Okabe, Hiroaki NakanoArticle type: Regular Article

2023 Volume 109 Issue 2 Pages 106-115

Published: 2023

Released on J-STAGE: January 31, 2023

JOURNAL OPEN ACCESS FULL-TEXT HTMLSteel containers and equipment are used to handle Mg and Mg-alloy melts in industrial processes such as Mg casting and Ti smelting. In this study, the dissolution behavior of SUS430 ferritic stainless steel in liquid Mg was quantitatively evaluated in order to obtain fundamental information on the contamination of Mg with steel materials in these industrial processes. Pure Mg was sealed in a SUS430 crucible and melted at 1073−1273 K for 24−96 h. In addition to Fe and Cr, some minor elements in the SUS430 (Mn, Ni, and Cu) were evaluated as impurity elements dissolved in liquid Mg. The concentrations of Fe and Cr in liquid Mg reached a steady state within 24 h, and the empirical equations describing their temperature dependence were obtained. In contrast, the concentrations of Mn, Ni, and Cu in Mg increased with increase in melt holding time. With the dissolution of these elements, a region with Mn concentration lower than that of the original composition was formed on the inner wall of the SUS430 crucible. The validity of the experimental values of impurity concentration in Mg was discussed based on the thermodynamic data of Mg−i (i = Fe, Cr, Mn, Ni, and Cu) binary systems and SUS430. Furthermore, impurity uptake through liquid Mg during Ti production using the Kroll process was preliminary discussed. The findings of this study provide important and beneficial information for improving impurity control in the melting and casting of Mg and in Ti smelting using Mg as a reductant.

View full abstractDownload PDF (6050K) Full view HTML

View full abstractDownload PDF (6050K) Full view HTML

-

Daiki Terazawa, Yusuke Shimada, Kyohei Ishikawa, Tetsuya Namegawa, Mas ...Article type: Regular Article

2023 Volume 109 Issue 2 Pages 116-128

Published: 2023

Released on J-STAGE: January 31, 2023

JOURNAL OPEN ACCESS FULL-TEXT HTMLThe effect of prior austenite (γ) recrystallization and BN precipitation on B segregation behavior at prior austenite grain boundaries (PAGBs) was investigated by electron backscatter diffraction (EBSD) and time of flight secondary ion mass spectroscopy (TOF-SIMS). We measured changes in the BO2− signal intensity (SI) at PAGBs of 0.09C steel during isothermal holding after deforming at 850°C. The γ recrystallization started within 10 seconds of isothermal holding, and SI at recrystallized PAGBs 10 seconds after deforming was almost the same as prior to the deformation, whereas SI at non-recrystallized PAGBs showed lower values. When subjected to isothermal holding for more than 10 seconds, BN precipitation increased and SI at PAGBs decreased. This decrease in SI was attributable to the decrease in the amount of soluble B caused by BN precipitation. We also confirmed that SI at PAGBs of 70% Ni steel decreased immediately after deforming at 700°C, to levels lower than prior to the deformation. These findings indicate that the amount of segregated B at PAGBs decreases with deformation and the subsequent recovery behavior of SI depends on the recrystallization state. In addition, we measured the change in Vickers hardness (ΔHv) of 0.09C steel associated with B addition to investigate the effect of the amount of segregated B at PAGBs on the hardenability. ΔHv expressed in a linear function and increased as SI at PAGBs increased. These results suggest that the hardenability of B added steel is strongly related to segregated B at PAGBs.

View full abstractDownload PDF (8538K) Full view HTML

View full abstractDownload PDF (8538K) Full view HTML

-

Shohtaroh Hashimoto, Hidenori Takebe, Kenichi Mori, Mitsuo MiyaharaArticle type: Regular Article

2023 Volume 109 Issue 2 Pages 129-143

Published: 2023

Released on J-STAGE: January 31, 2023

Advance online publication: October 13, 2022JOURNAL OPEN ACCESS FULL-TEXT HTMLThe cyclic fatigue, dwell fatigue and room temperature creep properties were evaluated in three types of Ti-6Al-4V forged bar samples having different micro-texture-regions (MTR) and tensile properties in the loading direction. In the S-N curve where the stress(σnor) was normalized by 0.2%-proof-stress, the fatigue lives of all samples were almost the same, whereas the dwell fatigue lives were not the same. So the ratio of the cyclic fatigue life to dwell fatigue life (dwell debit) changed to 2–60. In cyclic fatigue the initiation site was a facet of 1–2 α grains, and the fracture surface was typical. In dwell fatigue and creep, on the other hand, facet and dimple regions were confirmed. In addition, the facet region consisted of initiation facets of 1–2 α grains and the propagation facets which were the majority of the facet region. Initiation facets in dwell fatigue occurred earlier than 25% of the life ratio, and the angle between the c-axis of the α grains with the initiation facets and loading direction was 15–55°. The propagation facets were the MTR in which the angle between the c-axis of the α grains and loading direction was 30° or less. The lengths of the facet regions were proportional to the MTR size. In dwell fatigue, the larger the σnor or MTR size, the larger was the dwell debit. Therefore, the MTR size was considered the dominant factor determining the dwell fatigue life.

View full abstractDownload PDF (11810K) Full view HTML

View full abstractDownload PDF (11810K) Full view HTML

-

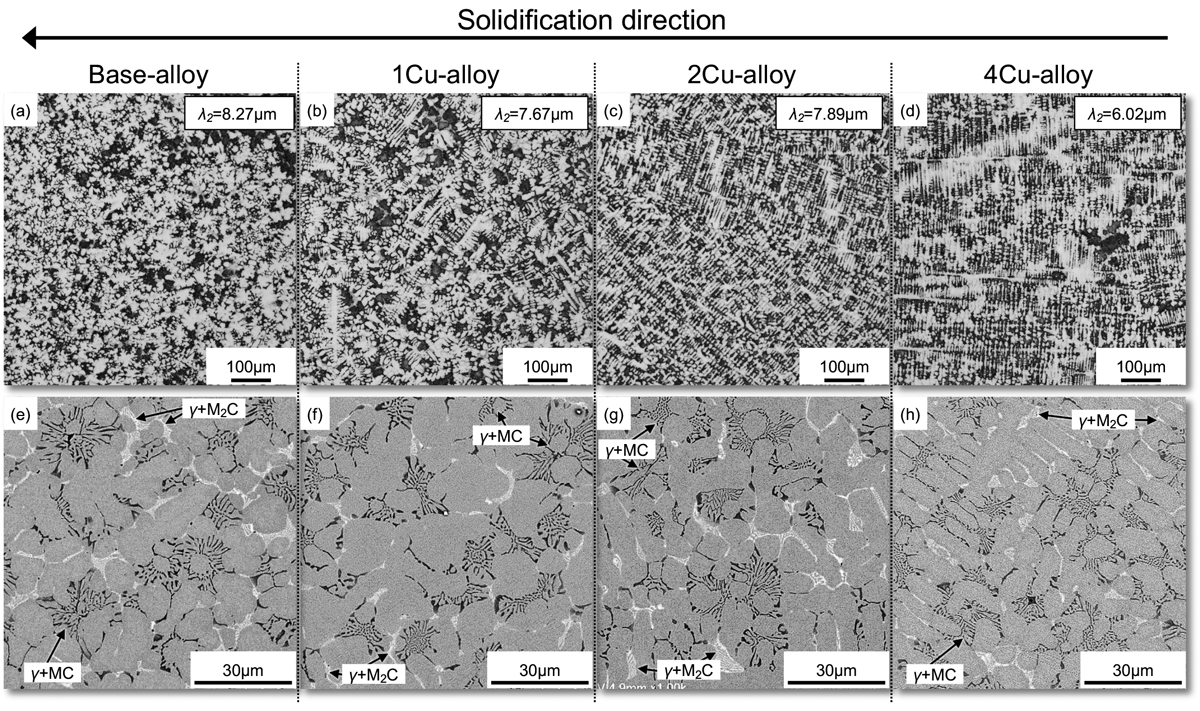

Yuki Tanaka, Kazunori Kamimiyada, Kohei Morishita, Hirofumi MiyaharaArticle type: Note

2023 Volume 109 Issue 2 Pages 144-148

Published: 2023

Released on J-STAGE: January 31, 2023

JOURNAL OPEN ACCESS FULL-TEXT HTMLEffect of copper addition on solidification microstructure was investigated for high carbon high speed steel type alloys (Fe-2.0%C-5%Cr-5%Mo-5%V-0~4%Cu). The microstructure of all as-cast specimens with different copper content was composed of dendrite of primary γ, MC-γ eutectic and M2C-γ eutectic but it was found X-ray diffraction peaks of α phase by X-ray diffractometry. The volume fraction of each phase in solidification microstructure was approximately constant regardless of copper content. The shapes of dendrite of primary γ changed significantly in response to amount of copper addition: that of specimen with no copper was equiaxed while that of specimen containing copper was columnar which tends to be marked with increasing amount of copper addition. Furthermore, the secondary dendrite arm spacing λ2 decreased with increasing amount of copper addition. As a result, it concluded that the effect of copper addition on solidification microstructure is columnar crystallization and decreasing λ2 of the dendrite with primary γ.

View full abstractDownload PDF (2272K) Full view HTML

View full abstractDownload PDF (2272K) Full view HTML

- |<

- <

- 1

- >

- >|