- Issue 16 Pages 2157-

- Issue 15 Pages 1805-

- Issue 14 Pages 1613-

- Issue 13 Pages S1141-

- Issue 12 Pages S1037-

- Issue 11 Pages 1443-

- Issue 10 Pages 1273-

- Issue 9 Pages 1077-

- Issue 8 Pages 917-

- Issue 7 Pages 751-

- Issue 6 Pages 585-

- Issue 5 Pages S389-

- Issue 4 Pages S1-

- Issue 3 Pages 403-

- Issue 2 Pages 233-

- Issue 1 Pages 19-

- Issue 16 Pages 2153-

- Issue 15 Pages 1977-

- Issue 14 Pages 1813-

- Issue 13 Pages S1285-

- Issue 12 Pages S1043-

- Issue 11 Pages 1667-

- Issue 10 Pages 1481-

- Issue 9 Pages 1231-

- Issue 8 Pages 891-

- Issue 7 Pages 711-

- Issue 6 Pages 538-

- Issue 5 Pages S407-

- Issue 4 Pages S1-

- Issue 3 Pages 347-

- Issue 2 Pages 173-

- Issue 1 Pages 14-

- Issue 16 Pages 1837-

- Issue 15 Pages 1711-

- Issue 14 Pages 1569-

- Issue 13 Pages S1205-

- Issue 12 Pages S1034-

- Issue 11 Pages 1423-

- Issue 10 Pages 1269-

- Issue 9 Pages 1059-

- Issue 8 Pages 925-

- Issue 7 Pages 775-

- Issue 6 Pages 627-

- Issue 5 Pages S287-

- Issue 4 Pages S1-

- Issue 3 Pages 301-

- Issue 2 Pages 147-

- Issue 1 Pages 12-

- Issue 16 Pages 2179-

- Issue 15 Pages 1795-

- Issue 14 Pages 1631-

- Issue 13 Pages S1053-

- Issue 12 Pages S1023-

- Issue 11 Pages 1501-

- Issue 10 Pages 1315-

- Issue 9 Pages 987-

- Issue 8 Pages 767-

- Issue 7 Pages 621-

- Issue 6 Pages 473-

- Issue 5 Pages S305-

- Issue 4 Pages S1-

- Issue 3 Pages 299-

- Issue 2 Pages 151-

- Issue 1 Pages 16-

- Issue 16 Pages 1945-

- Issue 15 Pages 1699-

- Issue 14 Pages 1531-

- Issue 13 Pages S1055-

- Issue 12 Pages S1013-

- Issue 11 Pages 1367-

- Issue 10 Pages 1215-

- Issue 9 Pages 1087-

- Issue 8 Pages 887-

- Issue 7 Pages 721-

- Issue 6 Pages 507-

- Issue 5 Pages S317-

- Issue 4 Pages S1-

- Issue 3 Pages 343-

- Issue 2 Pages 187-

- Issue 1 Pages 17-

- Issue 16 Pages 2405-

- Issue 15 Pages 2067-

- Issue 14 Pages 1865-

- Issue 13 Pages 1675-

- Issue 12 Pages S1055-

- Issue 11 Pages S1015-

- Issue 10 Pages 1479-

- Issue 9 Pages 1129-

- Issue 8 Pages 895-

- Issue 7 Pages 711-

- Issue 6 Pages 545-

- Issue 5 Pages S325-

- Issue 4 Pages S1-

- Issue 3 Pages 369-

- Issue 2 Pages 193-

- Issue 1 Pages 16-

- Issue 16 Pages 2573-

- Issue 15 Pages 2261-

- Issue 14 Pages 2073-

- Issue 13 Pages S1111-

- Issue 12 Pages S1001-

- Issue 11 Pages 1867-

- Issue 10 Pages 1657-

- Issue 9 Pages 1409-

- Issue 8 Pages 1043-

- Issue 7 Pages 841-

- Issue 6 Pages 649-

- Issue 5 Pages S415-

- Issue 4 Pages S1-

- Issue 3 Pages 431-

- Issue 2 Pages 225-

- Issue 1 Pages 3-

- |<

- <

- 1

- >

- >|

-

2024 Volume 110 Issue 5 Pages Contents-

Published: April 01, 2024

Released on J-STAGE: April 01, 2024

JOURNAL OPEN ACCESSDownload PDF (1237K) -

2024 Volume 110 Issue 5 Pages Editorial-

Published: April 01, 2024

Released on J-STAGE: April 01, 2024

JOURNAL OPEN ACCESSDownload PDF (203K)

-

Daisuke Igawa, Yusuke Dohi, Takashi Matsui, Tetsuya Yamamoto, Kiyoshi ...Article type: Regular Article

2024 Volume 110 Issue 5 Pages 395-403

Published: April 01, 2024

Released on J-STAGE: April 01, 2024

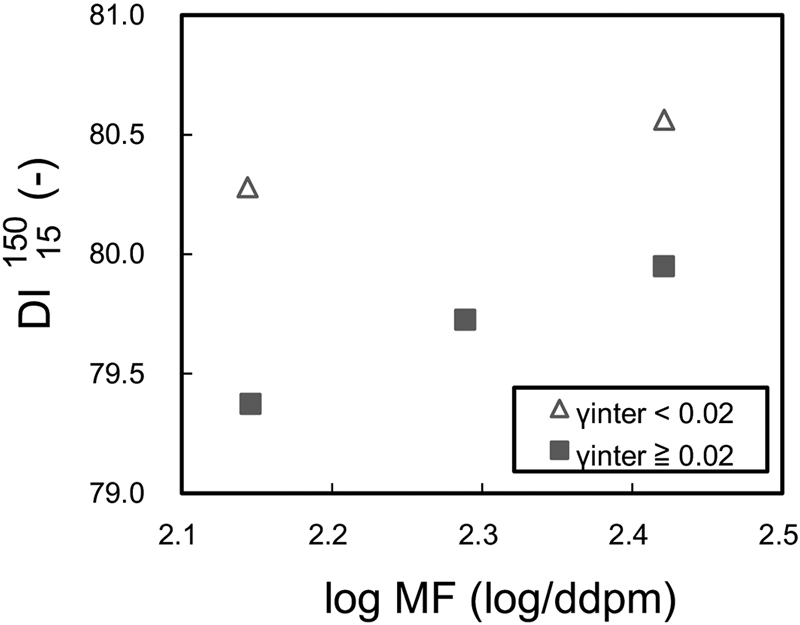

Advance online publication: January 23, 2024JOURNAL OPEN ACCESS FULL-TEXT HTMLIn our previous paper, a new measurement method for the coal adhesion property called “surface tension of semi-coke” was devised. The surface tension of a semi-coke sample obtained by heat treatment of a coal sample at 500°C was measured as a unique adhesion property. Conventionally, it has been thought that adhesion is dominant under a low MF (Gieseler maximum fluidity) condition. Moreover, it is important for effective coal utilization to develop a technique that enables production of high strength coke under low MF conditions, which has been thought to deteriorate coke strength. However, in the previous paper, the effect of surface tension on coke strength was investigated only under a single MF condition without changing the level of MF.

In this paper, the effects of surface tension on coke strength under adhesion dominant conditions (low MF and high TI (total inert content)) were investigated. As a result, it was found that the effect of surface tension on coke strength was significant when MF was low or TI was high. Therefore, it is considered that high strength coke can be produced even under low-grade conditions (low MF or high TI) by controlling surface tension. Finally, based on the results, the concept of the conventional MOF diagram was extended. This technique enables effective selection and utilization of coal resources.

View full abstractDownload PDF (2729K) Full view HTML

View full abstractDownload PDF (2729K) Full view HTML

-

Masaki Chiba, Kensuke Misawa, Hisanori Tanimoto, Masayoshi Kumagai, Sh ...Article type: Regular Article

2024 Volume 110 Issue 5 Pages 404-413

Published: April 01, 2024

Released on J-STAGE: April 01, 2024

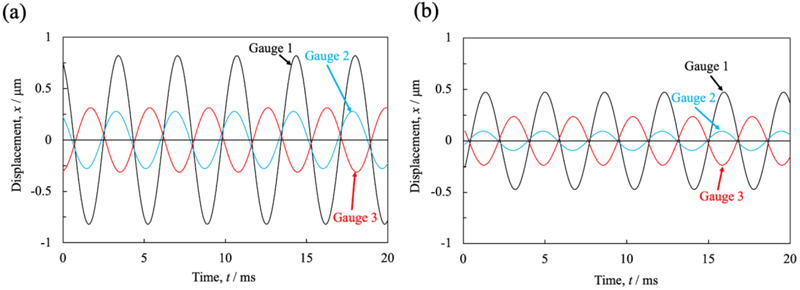

Advance online publication: February 09, 2024JOURNAL OPEN ACCESS FULL-TEXT HTMLTo understand the mechanism of vibration energy harvesting using magnetostrictive Fe-Ga alloys, the dynamic strains at different locations of a U-shaped device during vibration were simulated. In the simulations, the previous results for location-dependent strain in the vibration experiments were fitted with trigonometric functions. The results show that the amplitude and phase of the strain vary with location, and that the electromagnetic force is generated at different locations. Since magnetic induction is thought to occur due to an external magnetic field, the magnetic domain structure near the cube orientation of Fe-Ga alloy single crystals was observed using a Kerr effect microscope. As a result, Bloch magnetic domain structures with different contrasts of brightness and darkness were observed depending on the applied magnetic field. It was shown that striped magnetic domains were dominant when the applied magnetic field was small, while lancet magnetic domains oriented to the magnetic field appeared with transverse straight supplementary domains as a magnetic domain under a saturated magnetic field. The domain patterns in one direction magnetic fields were not necessarily the same as those observed in the opposite direction. This indicates that Fe-Ga alloy single crystals are used as a core for vibrational energy harvesting. Also, the motion of magnetic walls is thought to play an important role in the vibrational properties of the material, and inhomogeneous elastic strain associated with magnetic domains evolves microscopically in single crystals.

View full abstractDownload PDF (3177K) Full view HTML

View full abstractDownload PDF (3177K) Full view HTML

-

Takumi Aibara, Yoshiaki Morisada, Kohsaku Ushioda, Masayoshi Kamai, Ta ...Article type: Regular Article

2024 Volume 110 Issue 5 Pages 414-425

Published: April 01, 2024

Released on J-STAGE: April 01, 2024

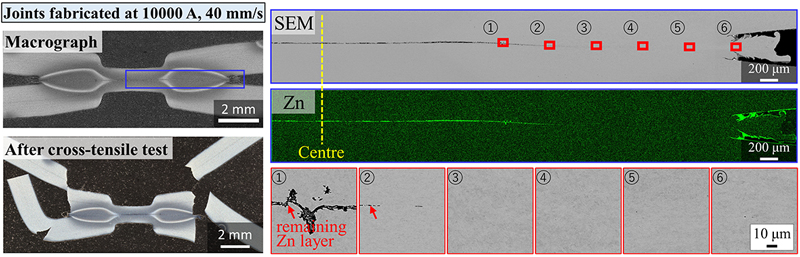

Advance online publication: February 22, 2024JOURNAL OPEN ACCESS FULL-TEXT HTMLThe microstructural evolution and tensile properties of joints fabricated by the newly developed cold spot joining (CSJ) method were investigated using galvannealed DP 780 MPa steel sheet. The novel solid-state joining method called CSJ is proved to make the joining interface plastically deformed under high pressure and appropriate current by expelling Zn-Fe coated layer, resulting in the sound joints with strong interface. Joints exploiting CSJ method were made focusing on the effects of the pressing speed and current level. Microstructural observations of the joints revealed that the lower pressing speed increases the interface temperature. In addition, the increase in the current also increases the interface temperature. The increase in the interface temperature has a positive effect in terms of expelling Zn-Fe coated layer. The positive effect of increasing current is more significant than that of decreasing the pressing speed. The increase in temperature near the interface by increasing current promotes the removal of the Zn-Fe coating layer, resulting in plastic deformation near the joining interface. Appropriate pressure and current settings can facilitate the sound spot joints with enough tensile strength. Both tensile-shear and cross-tension tests have confirmed a plug failure in the base material region.

View full abstractDownload PDF (12903K) Full view HTML

View full abstractDownload PDF (12903K) Full view HTML

- |<

- <

- 1

- >

- >|