- Issue 16 Pages 2157-

- Issue 15 Pages 1805-

- Issue 14 Pages 1613-

- Issue 13 Pages S1141-

- Issue 12 Pages S1037-

- Issue 11 Pages 1443-

- Issue 10 Pages 1273-

- Issue 9 Pages 1077-

- Issue 8 Pages 917-

- Issue 7 Pages 751-

- Issue 6 Pages 585-

- Issue 5 Pages S389-

- Issue 4 Pages S1-

- Issue 3 Pages 403-

- Issue 2 Pages 233-

- Issue 1 Pages 19-

- Issue 16 Pages 2153-

- Issue 15 Pages 1977-

- Issue 14 Pages 1813-

- Issue 13 Pages S1285-

- Issue 12 Pages S1043-

- Issue 11 Pages 1667-

- Issue 10 Pages 1481-

- Issue 9 Pages 1231-

- Issue 8 Pages 891-

- Issue 7 Pages 711-

- Issue 6 Pages 538-

- Issue 5 Pages S407-

- Issue 4 Pages S1-

- Issue 3 Pages 347-

- Issue 2 Pages 173-

- Issue 1 Pages 14-

- Issue 16 Pages 1837-

- Issue 15 Pages 1711-

- Issue 14 Pages 1569-

- Issue 13 Pages S1205-

- Issue 12 Pages S1034-

- Issue 11 Pages 1423-

- Issue 10 Pages 1269-

- Issue 9 Pages 1059-

- Issue 8 Pages 925-

- Issue 7 Pages 775-

- Issue 6 Pages 627-

- Issue 5 Pages S287-

- Issue 4 Pages S1-

- Issue 3 Pages 301-

- Issue 2 Pages 147-

- Issue 1 Pages 12-

- Issue 16 Pages 2179-

- Issue 15 Pages 1795-

- Issue 14 Pages 1631-

- Issue 13 Pages S1053-

- Issue 12 Pages S1023-

- Issue 11 Pages 1501-

- Issue 10 Pages 1315-

- Issue 9 Pages 987-

- Issue 8 Pages 767-

- Issue 7 Pages 621-

- Issue 6 Pages 473-

- Issue 5 Pages S305-

- Issue 4 Pages S1-

- Issue 3 Pages 299-

- Issue 2 Pages 151-

- Issue 1 Pages 16-

- Issue 16 Pages 1945-

- Issue 15 Pages 1699-

- Issue 14 Pages 1531-

- Issue 13 Pages S1055-

- Issue 12 Pages S1013-

- Issue 11 Pages 1367-

- Issue 10 Pages 1215-

- Issue 9 Pages 1087-

- Issue 8 Pages 887-

- Issue 7 Pages 721-

- Issue 6 Pages 507-

- Issue 5 Pages S317-

- Issue 4 Pages S1-

- Issue 3 Pages 343-

- Issue 2 Pages 187-

- Issue 1 Pages 17-

- Issue 16 Pages 2405-

- Issue 15 Pages 2067-

- Issue 14 Pages 1865-

- Issue 13 Pages 1675-

- Issue 12 Pages S1055-

- Issue 11 Pages S1015-

- Issue 10 Pages 1479-

- Issue 9 Pages 1129-

- Issue 8 Pages 895-

- Issue 7 Pages 711-

- Issue 6 Pages 545-

- Issue 5 Pages S325-

- Issue 4 Pages S1-

- Issue 3 Pages 369-

- Issue 2 Pages 193-

- Issue 1 Pages 16-

- Issue 16 Pages 2573-

- Issue 15 Pages 2261-

- Issue 14 Pages 2073-

- Issue 13 Pages S1111-

- Issue 12 Pages S1001-

- Issue 11 Pages 1867-

- Issue 10 Pages 1657-

- Issue 9 Pages 1409-

- Issue 8 Pages 1043-

- Issue 7 Pages 841-

- Issue 6 Pages 649-

- Issue 5 Pages S415-

- Issue 4 Pages S1-

- Issue 3 Pages 431-

- Issue 2 Pages 225-

- Issue 1 Pages 3-

- |<

- <

- 1

- >

- >|

-

2020 Volume 106 Issue 9 Pages Cover-

Published: September 01, 2020

Released on J-STAGE: August 31, 2020

JOURNAL OPEN ACCESSDownload PDF (658K) -

2020 Volume 106 Issue 9 Pages Contents-

Published: September 01, 2020

Released on J-STAGE: August 31, 2020

JOURNAL OPEN ACCESSDownload PDF (2727K) -

2020 Volume 106 Issue 9 Pages Editorial-

Published: September 01, 2020

Released on J-STAGE: August 31, 2020

JOURNAL OPEN ACCESSDownload PDF (225K)

-

Yoshito Isei2020 Volume 106 Issue 9 Pages 591-601

Published: 2020

Released on J-STAGE: August 31, 2020

JOURNAL OPEN ACCESS FULL-TEXT HTMLThe instrumentation technology for process automation in the steel industry has been evolving with the demands of the times, adapting to its production process and its harsh environment as the latest measurement techniques applied by considering the physical measurement principles. Today, the instrumentation technology has become one of the essential technologies to maintain the competitiveness in the steel industry. In this review, the recent development trends and future prospects are described based on lectures and papers on process instrumentation technology published by the Iron and Steel Institute of Japan (ISIJ) in the last decade. The main challenges in recent steel processes were reducing greenhouse gas emissions, supplying high-quality products represented by high-strength steel sheets, and keeping stable operation without skilled workers. To meet these challenges, new measurement techniques that had been advanced in recent years, such as radio waves sensing, image processing, optical fiber sensors, and multivariate analysis, had been applied. The newly obtained process information contributes to further sophisticated processes automation, and is applied to Artificial Intelligence (AI) and Cyber-Physical Systems (CPS). In the next decade, it is hoped that the instrumentation technology will continue to make progress toward the establishment of a sustainable steel industry.

View full abstractDownload PDF (1864K) Full view HTML

View full abstractDownload PDF (1864K) Full view HTML

-

Seiji Nomura2020 Volume 106 Issue 9 Pages 602-610

Published: 2020

Released on J-STAGE: August 31, 2020

JOURNAL OPEN ACCESS FULL-TEXT HTMLBriquette blending carbonization process is one of the effective cokemaking technologies to increase the blending ratio of semi-soft coking coals. The effect of coal briquette size on coke quality and bulk density in coke oven was studied. It was revealed that coke strength DI15015 is dependent on the briquette size. DI15015 shows a maximum, a minimum or monotonic increase with increasing briquette size, which depends on the blend composition of the briquette and the powder coal. The mean size of coke decreases and coal charge bulk density increases with increasing the briquette size. Choice of suitable briquette size is important from the viewpoint of coke quality, productivity and coke oven operation.

View full abstractDownload PDF (1470K) Full view HTML

View full abstractDownload PDF (1470K) Full view HTML

-

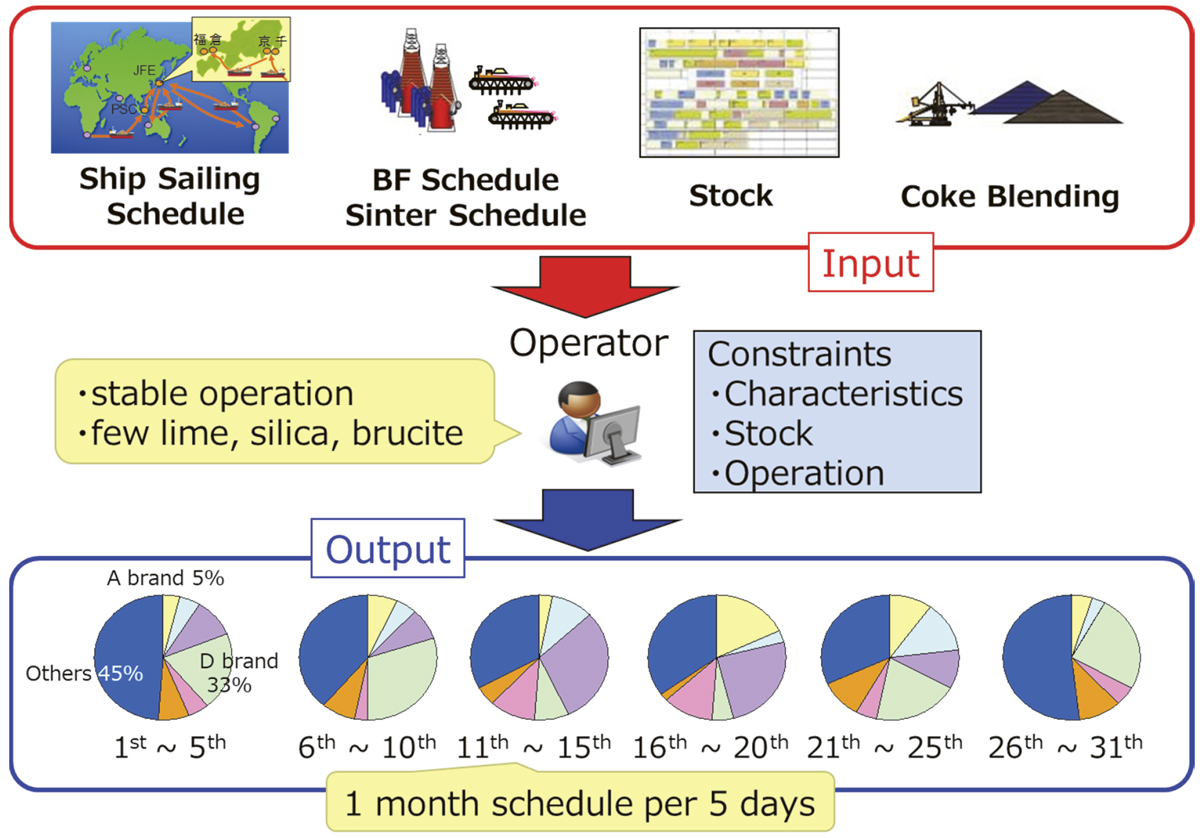

Akira Kumano, Yusuke Yoshinari, Osamu Yamaguchi, Toru Miyazawa2020 Volume 106 Issue 9 Pages 611-620

Published: 2020

Released on J-STAGE: August 31, 2020

JOURNAL OPEN ACCESS FULL-TEXT HTMLWe have developed an optimal scheduling method for raw material operations aiming the raw materials cost reduction. In this paper, we report optimization approaches to minimize the cost of ore blending in steel works.

The ore blending problem is to make schedules for the purpose of cost minimization under several constraints such as the stock in yards, ingredients in sintered ore. When formulating as a mathematical model, nonlinearity exists in this problem and make it complicated. However, this problem has characteristic that becomes a linear problem by fixing several key variables as constants. To overcome the nonlinearity, we developed our original Hybrid model that was a combination of Particle Swarm Optimization (PSO) and Linear Programming method (LP). We applied PSO to search the best way of fixing key variables, and obtained blending schedules by solving LPs. Our Hybrid model searched wide area effectively, and derived the solution within 2 minutes. Numerical experiments indicated a cost reduction of secondary materials by 1%.

View full abstractDownload PDF (5805K) Full view HTML

View full abstractDownload PDF (5805K) Full view HTML

-

Yutaka Tsuchida, Tetsushi Chida, Tomohiko Omura, Daisuke Hirakami2020 Volume 106 Issue 9 Pages 621-629

Published: 2020

Released on J-STAGE: August 31, 2020

JOURNAL OPEN ACCESS FULL-TEXT HTMLThermal Desorption Analysis (TDA) was conducted at multiple research institutions on common specimens, after hydrogen charging with various methods. The specimens were SCM435 steel with/without pre-straining and Vanadium alloyed steel (V steel). Hydrogen charging methods were cathodic charging, soaking in FIP solution and exposure to cyclic corrosion test.

All the TDA spectra (TDA curves) were separated systematically by Gaussian distribution function with unified parameters that are independent to method of hydrogen charging or research institute. They were basically composed of hydrogen trapped by cementite other than dislocation and grain boundary. The pre-strained SCM435 steel contains additional hydrogen trap sites of vacancy and vacancy cluster together with micro-void. The V steel contains further two types of trap sites, regarding two types of V carbide.

The amount of trapped hydrogen was able to be analyzed quantitatively by Fermi-Dirac statistics considering entropy change as pre-exponential factor. It was shown to be controlled mostly by de-trapping process and should be changed according to the binding energy of trap site. This qualitative analysis was favorable for restoring the released hydrogen before TDA measurement.

View full abstractDownload PDF (1805K) Full view HTML

View full abstractDownload PDF (1805K) Full view HTML

-

Shunya Nomura, Toshihiko Kuwabara2020 Volume 106 Issue 9 Pages 630-639

Published: 2020

Released on J-STAGE: August 31, 2020

Advance online publication: April 28, 2020JOURNAL OPEN ACCESS FULL-TEXT HTMLThe elastic-plastic deformation behavior of a 440 MPa hot-rolled steel sheet subjected to many linear stress paths is precisely measured using biaxial tensile tests with cruciform specimens (ISO 16842: 2014) and multiaxial tube expansion tests (Kuwabara and Sugawara, 2013) to determine appropriate material models for finite element analysis (FEA). It was found that the Yld2000-2d yield function (Barlat et al., 2003) correctly reproduces the contours of plastic work (CPW) and the directions of the plastic strain rates (DPSR). Differential hardening (DH) models are determined by changing the values of exponent and material parameters of the Yld2000-2d yield function as functions of reference plastic strain. Moreover, FEA of the hole expansion forming of the test material is performed. The DH model correctly predicts the minimum thickness position that matches the fracture position of the specimen in experiment.

View full abstractDownload PDF (2959K) Full view HTML

View full abstractDownload PDF (2959K) Full view HTML

-

Atsushi Ueshita, Mikihito Hirohata, Taishi Nakayama2020 Volume 106 Issue 9 Pages 640-650

Published: 2020

Released on J-STAGE: August 31, 2020

JOURNAL OPEN ACCESS FULL-TEXT HTMLThe influence of surface treatment conditions on the welded joint characteristics of aged steel was investigated for verifying the applicability of weld repair to existing steel bridge members. Steel materials with deteriorated paint coatings extracted from an aged bridge that had been in service for a long term were prepared. The weld defects were not observed in the welded joints fabricated by these steels with different surface conditions. Although the tensile strength of welded joints was not affected by the surface treatment conditions, one specimen fractured at the middle in the thickness direction due to non-metallic inclusions. It could be confirmed that sound welded joints could be fabricated by the surface polishing with a disc grinder, which was possible on site, through the experiments by four different aged steels.

View full abstractDownload PDF (2727K) Full view HTML

View full abstractDownload PDF (2727K) Full view HTML

-

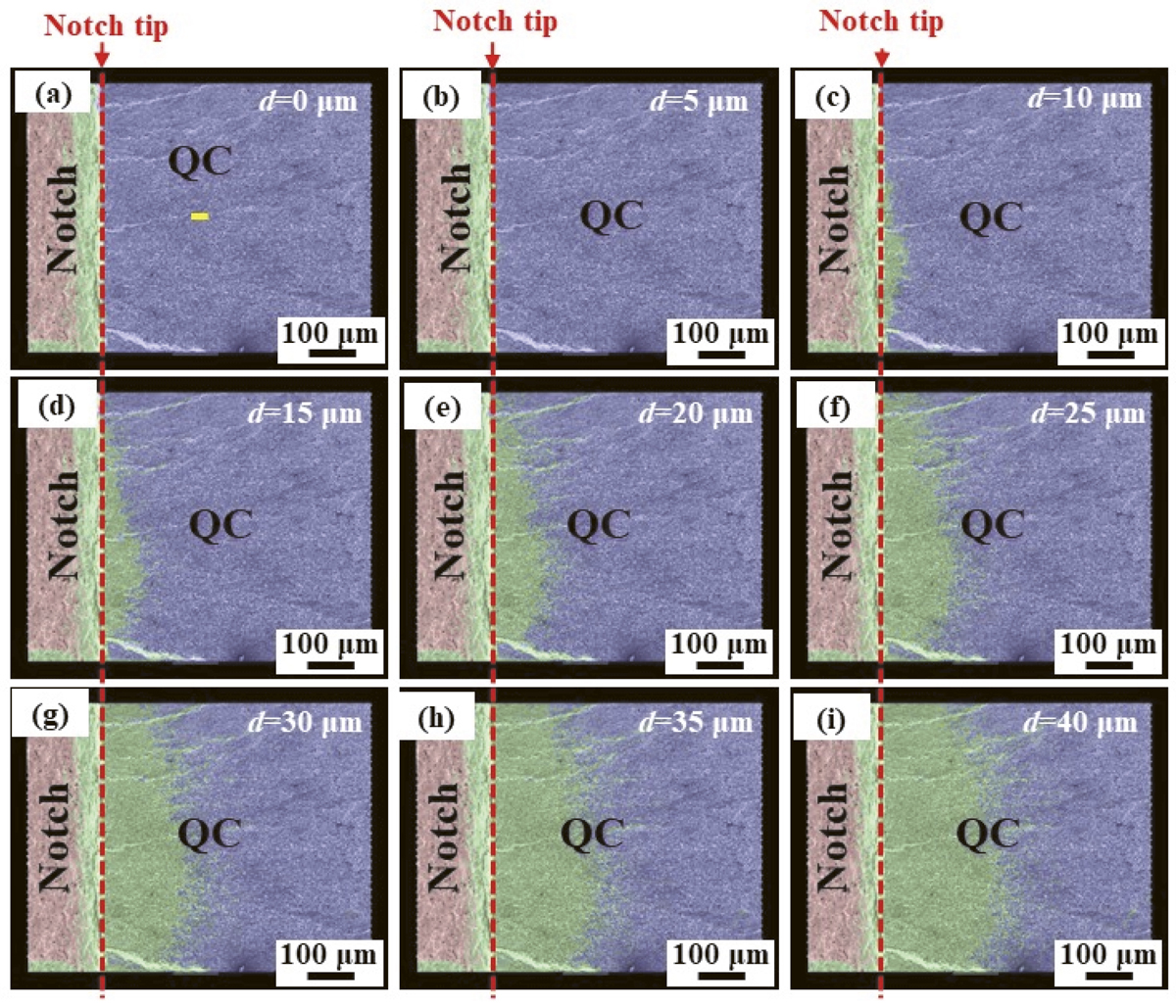

Tomoka Homma, Seiya Anata, Shoma Onuki, Kenichi Takai2020 Volume 106 Issue 9 Pages 651-661

Published: 2020

Released on J-STAGE: August 31, 2020

Advance online publication: April 28, 2020JOURNAL OPEN ACCESS FULL-TEXT HTMLThe processes leading to hydrogen-related fracture in X80 pipeline steel with stress concentration have been investigated comprehensively through observations of fracture surfaces and subsidiary cracks, a stress analysis, crack initiation and propagation analyses and a crystallographic analysis of fracture surfaces. Fracture morphology showed quasi-cleavage (QC) fracture under various amounts of hydrogen. It was found that QC cracks initiated in the area ranging from the notch tip to 100 µm inside based on interrupted tensile tests just before fracture strength with hydrogen charging. Moreover, fracture surface topography analysis (FRASTA) revealed that QC cracks initiated at the notch tip. A finite element analysis indicated that the equivalent plastic strain was maximum at the crack initiation site at the notch tip. In addition, a backscattered electron image showed that nanovoids of 50-250 µm in diameter were present near the initiation site. Regarding the crack propagation process, field emission scanning electron microscopy (FE-SEM), electron backscattered diffraction (EBSD) and FRASTA results indicated that some microcracks in ferrite grains coalesced stepwise and propagated. Trace analyses using EBSD revealed that the QC fracture surface consisted of {011} slip planes, {001} cleavage planes and non-specific index planes. These findings indicate that QC fracture initiates at the notch tip due to the interaction between dislocations and hydrogen associated with local plastic deformation, and propagates stepwise by coalescence through vacancies, nanovoids and microcracks on various planes associated with/without plastic deformation in ferrite grains.

View full abstractDownload PDF (9126K) Full view HTML

View full abstractDownload PDF (9126K) Full view HTML -

Yuichi Shintaku, Katsuya Soejima, Seiichiro Tsutsumi, Kenjiro Terada2020 Volume 106 Issue 9 Pages 662-671

Published: 2020

Released on J-STAGE: August 31, 2020

JOURNAL OPEN ACCESS FULL-TEXT HTMLAn elastic-plastic constitutive law embedding cohesive cracks with plasticity-induced damage is proposed to realize degradation of strength and toughness under cyclic loading. A conventional elastic-plastic constitutive law with isotropic and kinematic hardening is combined with our cohesive-force embedding damage model to realize plastic deformation and fracture behavior under monotonic and cyclic loading by solving two kinds of conditional equations. One of them is local balance equation between cohesive traction and principal stress and the other is yield function with nonlinear isotropic and kinematic hardening law. The relationship between the cohesive traction and the crack opening displacement is determined by a cohesive zone model associated with energy release rate to represent process of stress release due to formation of crack surface. In addition, a new plasticity-induced damage is introduced into the cohesive zone model to realize the degradation of the tensile strength and the energy release rate caused by the accumulated plastic strain. On the other hand, the difference of the plastic deformation under various ranges of cyclic loading is represented by additional hardening law depending on a memory surface that is corresponding to plastic strain range. After the material parameters are identified from three experimental results under monotonic and cyclic loading, the capability of our proposed constitutive law is demonstrated by prediction of residual tensile strength and breaking strain of a metal after cyclic loading.

View full abstractDownload PDF (2496K) Full view HTML

View full abstractDownload PDF (2496K) Full view HTML

-

Masahiro Furuta, Rayko Simura, Toru Kawamata, Shigeru Suzuki2020 Volume 106 Issue 9 Pages 672-678

Published: 2020

Released on J-STAGE: August 31, 2020

JOURNAL OPEN ACCESS FULL-TEXT HTMLFeCo-2V (Permendur) is one of magnetostirictive alloys, and this alloy is a candidate material for application of vibration energy harvesting. Since their magnetic properties depends on their microstructure, the magnetic properties such as magnetization, magnetostiriction and inverse magnetostriction should be investigated in materials prepared by different processes. In this study, the magnetic properties of FeCo-2V alloy sheets with the different microstructure obtained from a bar were studied, in order to understand influences of the microstructure on the magnetic properties. The results showed that crystalline grains in alloy sheets cut from the bar grow with increasing temperature, while grains in hot-rolled alloy sheets do not grow so much by annealing. It was also shown that inverse magnetostriction in well-annealed alloys reveal good vibration power generation property, and the texture in hot-rolled alloy sheets seems to be unfavorable to the vibration power generation property.

View full abstractDownload PDF (4134K) Full view HTML

View full abstractDownload PDF (4134K) Full view HTML

-

Setsuo Takaki, Takuro Masumura, Toshihiro Tsuchiyama2020 Volume 106 Issue 9 Pages 679-682

Published: 2020

Released on J-STAGE: August 31, 2020

JOURNAL OPEN ACCESS FULL-TEXT HTMLElastic stiffness c11, c12 and c44 are key parameters in the analysis of elastic deformation behaviors. In order to determine the values of these parameters, Young’s modulus of single crystal; E100, E110 and E111 are needed as well as Young’ modulus Ep and Poisson’s ratio ν in poly-crystal. In this paper, the values of Young’s modulus in single crystalline iron are summarized and then elastic stiffness was estimated for pure iron under the conditions; Ep=208.2 GPa and ν=0.291 that are reliable values for isotropic poly-crystalline iron. As a result, it is found that Young’s modulus of single crystalline iron should be as follows: E100=127.8 GPa, E110=214.3 GPa, E111=276.6 GPa. From these values, elastic stiffness of iron is calculated at c11=228.1 GPa, c12=135.0 GPa, c44=113.2 GPa. Diffraction Young’s modulus of iron can be estimated on the basis of Kröner model by applying the values of elastic stiffness. It is also confirmed that the average value of diffraction Young’s modulus agrees with the value of Young’s modulus Ep (208.2 GPa) of ideal poly-crystalline iron.

View full abstractDownload PDF (439K) Full view HTML

View full abstractDownload PDF (439K) Full view HTML

- |<

- <

- 1

- >

- >|