- Issue 16 Pages 2157-

- Issue 15 Pages 1805-

- Issue 14 Pages 1613-

- Issue 13 Pages S1141-

- Issue 12 Pages S1037-

- Issue 11 Pages 1443-

- Issue 10 Pages 1273-

- Issue 9 Pages 1077-

- Issue 8 Pages 917-

- Issue 7 Pages 751-

- Issue 6 Pages 585-

- Issue 5 Pages S389-

- Issue 4 Pages S1-

- Issue 3 Pages 403-

- Issue 2 Pages 233-

- Issue 1 Pages 19-

- Issue 16 Pages 2153-

- Issue 15 Pages 1977-

- Issue 14 Pages 1813-

- Issue 13 Pages S1285-

- Issue 12 Pages S1043-

- Issue 11 Pages 1667-

- Issue 10 Pages 1481-

- Issue 9 Pages 1231-

- Issue 8 Pages 891-

- Issue 7 Pages 711-

- Issue 6 Pages 538-

- Issue 5 Pages S407-

- Issue 4 Pages S1-

- Issue 3 Pages 347-

- Issue 2 Pages 173-

- Issue 1 Pages 14-

- Issue 16 Pages 1837-

- Issue 15 Pages 1711-

- Issue 14 Pages 1569-

- Issue 13 Pages S1205-

- Issue 12 Pages S1034-

- Issue 11 Pages 1423-

- Issue 10 Pages 1269-

- Issue 9 Pages 1059-

- Issue 8 Pages 925-

- Issue 7 Pages 775-

- Issue 6 Pages 627-

- Issue 5 Pages S287-

- Issue 4 Pages S1-

- Issue 3 Pages 301-

- Issue 2 Pages 147-

- Issue 1 Pages 12-

- Issue 16 Pages 2179-

- Issue 15 Pages 1795-

- Issue 14 Pages 1631-

- Issue 13 Pages S1053-

- Issue 12 Pages S1023-

- Issue 11 Pages 1501-

- Issue 10 Pages 1315-

- Issue 9 Pages 987-

- Issue 8 Pages 767-

- Issue 7 Pages 621-

- Issue 6 Pages 473-

- Issue 5 Pages S305-

- Issue 4 Pages S1-

- Issue 3 Pages 299-

- Issue 2 Pages 151-

- Issue 1 Pages 16-

- Issue 16 Pages 1945-

- Issue 15 Pages 1699-

- Issue 14 Pages 1531-

- Issue 13 Pages S1055-

- Issue 12 Pages S1013-

- Issue 11 Pages 1367-

- Issue 10 Pages 1215-

- Issue 9 Pages 1087-

- Issue 8 Pages 887-

- Issue 7 Pages 721-

- Issue 6 Pages 507-

- Issue 5 Pages S317-

- Issue 4 Pages S1-

- Issue 3 Pages 343-

- Issue 2 Pages 187-

- Issue 1 Pages 17-

- Issue 16 Pages 2405-

- Issue 15 Pages 2067-

- Issue 14 Pages 1865-

- Issue 13 Pages 1675-

- Issue 12 Pages S1055-

- Issue 11 Pages S1015-

- Issue 10 Pages 1479-

- Issue 9 Pages 1129-

- Issue 8 Pages 895-

- Issue 7 Pages 711-

- Issue 6 Pages 545-

- Issue 5 Pages S325-

- Issue 4 Pages S1-

- Issue 3 Pages 369-

- Issue 2 Pages 193-

- Issue 1 Pages 16-

- Issue 16 Pages 2573-

- Issue 15 Pages 2261-

- Issue 14 Pages 2073-

- Issue 13 Pages S1111-

- Issue 12 Pages S1001-

- Issue 11 Pages 1867-

- Issue 10 Pages 1657-

- Issue 9 Pages 1409-

- Issue 8 Pages 1043-

- Issue 7 Pages 841-

- Issue 6 Pages 649-

- Issue 5 Pages S415-

- Issue 4 Pages S1-

- Issue 3 Pages 431-

- Issue 2 Pages 225-

- Issue 1 Pages 3-

- |<

- <

- 1

- >

- >|

-

2024 Volume 110 Issue 2 Pages Contents-

Published: February 01, 2024

Released on J-STAGE: February 01, 2024

JOURNAL OPEN ACCESSDownload PDF (3121K) -

2024 Volume 110 Issue 2 Pages Editorial-

Published: February 01, 2024

Released on J-STAGE: February 01, 2024

JOURNAL OPEN ACCESSDownload PDF (200K)

-

Tetsuo Sakka, Yoshihiro DeguchiArticle type: Review

2024 Volume 110 Issue 2 Pages 35-40

Published: February 01, 2024

Released on J-STAGE: February 01, 2024

Advance online publication: November 28, 2023JOURNAL OPEN ACCESS FULL-TEXT HTMLAtomic spectral lines obtained by laser-induced breakdown spectroscopy (LIBS) often suffer from serious pulse-to-pulse fluctuation, which limits the accuracy of the quantitative analysis. Solving this problem is an important issue for improving the analytical performance of LIBS. In the present review the model to simulate the emission spectral intensity of LIBS measurements is introduced, and the method to evaluate the propagation of the pulse-to-pulse variation of plasma parameters to the variation of emission spectral intensity by the error propagation analysis is explained. The recent three studies found in the literature that investigated the pulse-to-pulse fluctuation of the spectral line intensities on the basis of error propagation analysis are reviewed.

View full abstractDownload PDF (1401K) Full view HTML

View full abstractDownload PDF (1401K) Full view HTML

-

Shinya Miura, Teppei Tamura, Ken-ichiro NaitoArticle type: Regular Article

2024 Volume 110 Issue 2 Pages 41-50

Published: February 01, 2024

Released on J-STAGE: February 01, 2024

Advance online publication: December 21, 2023JOURNAL OPEN ACCESS FULL-TEXT HTMLAs for steelmaking process such as basic oxygen furnace (BOF) and electric arc furnace (EAF), slag foaming consists of introducing gas bubbles into molten metal and slag by chemical reaction. In the case of the BOF process, excessive foaming is over the converter capacity, a phenomenon called “slopping”. Slopping reduces yield and equipment lifespan and increases production time. It is therefore important to control slag foaming properly. In previous studies by other investigators, the jet from top lance in BOF process effectively suppresses slag foaming. However, it is not obvious which mechanism of the jet from top lance is effective to suppress slag foaming, and its quantitative effect has not been reported. To clarify the relationship between slag foaming and the jet from top lance, the effects of the number of nozzle holes and lance height on the slag foaming were investigated by using a converter-shaped water-model device and test converter. The experimental results indicated that slag foaming height decreased as the number of nozzle holes increased. Also, slag foaming height changed instantly with the change in lance height, e.g., slag foaming height decreased as lance height increased, and vice versa. The foaming suppression mechanism of the jet from top lance is the entrainment of foaming slag into the jet. Consequently, slag foaming model that takes the effect of the jet from top lance into account is proposed. And it enables to predict the change in slag foaming height with time.

View full abstractDownload PDF (2406K) Full view HTML

View full abstractDownload PDF (2406K) Full view HTML

-

Takeru Hoshino, Yasutaka Ta, Hiromu Yano, Hiroyuki ToboArticle type: Regular Article

2024 Volume 110 Issue 2 Pages 51-60

Published: February 01, 2024

Released on J-STAGE: February 01, 2024

Advance online publication: December 15, 2023JOURNAL OPEN ACCESS FULL-TEXT HTMLFerrous Slag Hydrated Matrix has been developed by mixing steel slag as aggregate. The direct casting process from molten slag was investigated instead of the complicated and expensive Matrix manufacturing process. However, cracks during casting can reduce strength. To prevent crack formation, the mechanism of thermal stress crack initiation and the appropriate conditions for casting molten slag in rock form were investigated by casting experiments, sound measurements, and thermal stress analysis. Compared with the slag cooled in the mold, the slag under the optimum cooling condition suppressed the cracks and did not cause cracks inside the slag. The crack sound was measured by sound measurements. To suppress the cracks, it was suggested that the temperature in the slag should be uniform quickly within 10 min after the slag injection. The required solidification shell thickness could be estimated based on the tensile stress generated on the slag surface. Through casting experiments and thermal stress analysis, cooling conditions to suppress thermal stress cracks in slag casting were revealed. In other words, it was found that when the molten slag is poured into the mold and then is demolded at the stage where the solidification shell thickness sufficiently exceeds the strength of the slag surface against the tensile stress applied to the solidification shell. The solidified slag is thermally insulated, and the temperature inside the slag is uniform. It cools while remaining uniform.

View full abstractDownload PDF (4388K) Full view HTML

View full abstractDownload PDF (4388K) Full view HTML

-

Hirokazu Kobayashi, Yukio Takashima, Gentaro Takeda, Kenji Katoh, Tats ...Article type: Regular Article

2024 Volume 110 Issue 2 Pages 61-71

Published: February 01, 2024

Released on J-STAGE: February 01, 2024

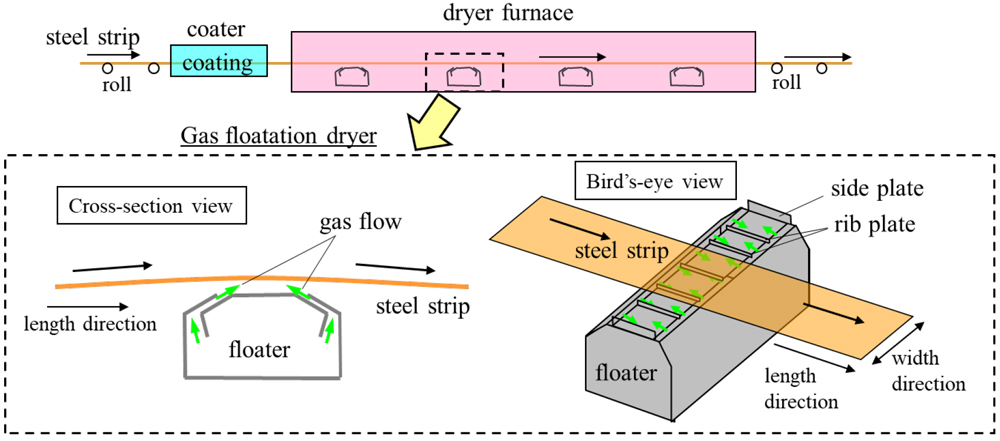

Advance online publication: November 28, 2023JOURNAL OPEN ACCESS FULL-TEXT HTMLFlotation dryer systems are widely used to dry liquid layers on substrates such as films, paper and steel strips, and many reports discussing design optimization for better heat transfer characteristics and strip stability are available.

As an advantage of this type of system, surface defects caused by contact between a support roll and the strip are prevented by floating the strip with a jet flow. However, since the friction force between the jet flow and the strip is smaller than that between a support roll and strip, flotation systems are prone to strip walking.

This tendency is noticeable in case of bad shape strip. Thus, it is important to improve the strip centering force. To our knowledge, no systematic in-depth study on prediction of the strip centering force with flotation dryers exists in the literature, and in particular, literature which compares experimental and analytical results is very rare.

In the present study, the centering force acting on a steel strip in a flotation dryer was investigated by experiments and simplified two-dimensional fluid analyses in order to evaluate the influence of the side plate geometry and the off-center value from the center of the floatation dryer on the centering force.

The centering force in the experiment and analysis showed a good correlation. Therefore, it is thought that the centering performance of actual floatation dryers can be estimated by simplified experiments and analyses.

View full abstractDownload PDF (6915K) Full view HTML

View full abstractDownload PDF (6915K) Full view HTML

-

Daichi Izumi, Nobuyuki Ishikawa, Pello Uranga, Nerea Isasti, Jose Mari ...Article type: Regular Article

2024 Volume 110 Issue 2 Pages 72-82

Published: February 01, 2024

Released on J-STAGE: February 01, 2024

Advance online publication: November 28, 2023JOURNAL OPEN ACCESS FULL-TEXT HTMLRecrystallization and grain growth during plate rolling are prevented by Nb addition both with the solute drag and the Nb carbide precipitation. Although a fine microstructure is achieved in the base material, welding heat completely changes the microstructure in the heat affected zone (HAZ). In this study, laboratory simulation of the coarse grain HAZ (CGHAZ) thermal cycle of double submerged arc welded linepipe was carried out using low carbon steels containing different Nb contents. Extraction residue analysis of the simulated CGHAZ samples revealed that almost all the Nb remained in solid solution. To clarify the interaction of Nb carbide dissolution and grain growth on overall simulated HAZ microstructure evolution, additional weld HAZ thermal simulations were performed. It was found that Nb carbides remain undissolved at HAZ peak temperatures up to 1200°C and showed significant pinning effect to prevent austenite grain growth. Significant grain growth was seen after continuous fast heating to 1350°C peak temperature, while the higher Nb added steel showed a slower overall austenite grain growth rate, suggesting that grain growth in the HAZ at higher temperature was suppressed by the combined effects of slower coarse Nb carbide dissolution providing some pinning, and the solute drag effect of higher amounts of Nb in solid solution. A pronounced retardation of longer-term isothermal grain growth was identified at 1350°C at higher levels of solute Nb, confirming the influence of Nb solute drag on high temperature resistance to austenite grain coarsening.

View full abstractDownload PDF (7217K) Full view HTML

View full abstractDownload PDF (7217K) Full view HTML

-

Kyosuke Matsuda, Takuro Masumura, Toshihiro Tsuchiyama, Yusuke Onuki, ...Article type: Short Article

2024 Volume 110 Issue 2 Pages 83-88

Published: February 01, 2024

Released on J-STAGE: February 01, 2024

Advance online publication: October 12, 2023JOURNAL OPEN ACCESS FULL-TEXT HTMLThe reverse transformation behavior during heating in Fe-10%Mn-0.1%C (mass%) martensitic alloy consisting of α’-martensite, ε-martensite and retained austenite was investigated using the in-situ neutron diffraction. When the temperature was elevated with a heating rate of 10 K/s, the ε→γ reverse transformation occurred first at the temperature range of 535–712 K, where Fe and Mn hardly diffused. In the temperature range where the ε→γ reverse transformation occurred, the full width at half maximum of the 200γ peak increased, indicating that the austenite reversed from ε-martensite contains high-density dislocations. In addition, the transformation temperature hardly depends on the heating rate and the crystal orientation of the reversed austenite was identical to that of the prior austenite (austenite memory), which suggests that the ε→γ reverse transformation would proceed through the displacive mechanism. After completion of the ε→γ transformation, the α’→γ reverse transformation occurred at the temperature range of 842–950 K. When the heating rate is low (<10 K/s), the reverse transformation start temperature significantly depends on the heating rate. It could be because the diffusional reverse transformation accompanying the repartitioning of Mn occurs. On the other hand, a higher heating rate (≥10 K/s) resulted in the disappearance of the heating rate dependence. This was probably due to the change in the transformation mechanism to the massive-type transformation, which is diffusional transformation without repartitioning of Mn.

View full abstractDownload PDF (3477K) Full view HTML

View full abstractDownload PDF (3477K) Full view HTML

- |<

- <

- 1

- >

- >|