- |<

- <

- 1

- >

- >|

-

竹内 誠, 蓬田 貴裕, 菊池 伸明, 豊木 研太郎, 小林 慎太郎, 小谷 佳範, 中村 哲也, 日置 敬子, 岡本 聡原稿種別: 論文

竹内 誠, 蓬田 貴裕, 菊池 伸明, 豊木 研太郎, 小林 慎太郎, 小谷 佳範, 中村 哲也, 日置 敬子, 岡本 聡原稿種別: 論文

2022 年 86 巻 1 号 p. 1-7

発行日: 2022/01/01

公開日: 2021/12/25

[早期公開] 公開日: 2021/11/12ジャーナル フリー HTMLA large step on the initial magnetization curve has been widely observed in Nd-Fe-B hot-deformed magnets. This behavior has been considered as that the first- and latter-half parts of the initial magnetization curve correspond to the magnetization reversals of multi- and single-domain grains, respectively. In this study, the detailed magnetic domain structure of a Nd-Fe-B hot-deformed magnet has been studied for the initial magnetization and demagnetization processes by using a soft X-ray magnetic circular dichroism (XMCD) microscopy. The observed magnetization reversal behavior for the initial magnetization process is quite different from that previously considered. The multi-domain states move from grains to grains through the gradual displacement of domain wall passing through many grains, and then the massive domain wall displacement takes place. The latter part of domain wall displacement is similar with that found in the demagnetization process near the coercivity. Moreover, we found that there are several strong pinning sites which are identical for both the initial magnetization and the demagnetization processes.

Fig. 4 XMCD images of the Nd-Fe-B hot-deformed magnet for (a) thermally demagnetized state and after applying the magnetic field of (b) 0.45 T, (c) 1.2 T, and (d) 1.95 T, respectively. Black line shows the grain boundary traced from the SEM image shown in Fig. 2(c). Green line shows the grain of multi-domain state. Fullsize Image抄録全体を表示Editor's pick

Fig. 4 XMCD images of the Nd-Fe-B hot-deformed magnet for (a) thermally demagnetized state and after applying the magnetic field of (b) 0.45 T, (c) 1.2 T, and (d) 1.95 T, respectively. Black line shows the grain boundary traced from the SEM image shown in Fig. 2(c). Green line shows the grain of multi-domain state. Fullsize Image抄録全体を表示Editor's pick2023年新進論文賞

PDF形式でダウンロード (7916K) HTML形式で全画面表示 -

古川 翔, 岡 健太, 津志田 雅之, 北原 弘基, 安藤 新二原稿種別: 論文

2022 年 86 巻 1 号 p. 8-16

発行日: 2022/01/01

公開日: 2021/12/25

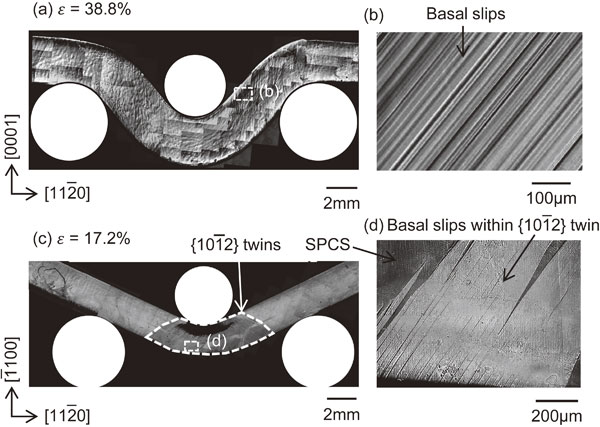

[早期公開] 公開日: 2021/11/19ジャーナル フリー HTMLThree-point bending tests were performed on pure zinc single crystals with different crystal orientations to investigate orientation dependence on bending deformation behavior. With basal planes parallel to the neutral planes, the specimens deformed due to basal slips and formed a gull-shape after deformation. On the other hand, the specimen whose neutral planes are perpendicular to basal planes and neutral axes are perpendicular to [0001] deformed due to second order pyramidal <c + a> slips, {1012} twinning and basal slips within {1012} twins, displaying a V-shape. Bending deformation behavior of pure zinc single crystals was found to show strong orientation dependence. Also, bending deformation behavior of pure zinc single crystals was found to differ from that of pure magnesium single crystals when the neutral plane and neutral axis are respectively perpendicular to basal planes and [0001].

Optical micrographs of (a) the specimen with basal planes parallel to the neutral planes and (c) the specimen whose neutral planes are perpendicular to basal planes and neutral axes are perpendicular to [0001] after bending tests; the enlargement of compression areas with basal slips surrounded by dashed white lines are shown in (b), and slip lines caused by SPCS around {10-12} twins and basal slips within {10-12} twins in the tension areas are shown in (d). Fullsize Image抄録全体を表示PDF形式でダウンロード (7286K) HTML形式で全画面表示

Optical micrographs of (a) the specimen with basal planes parallel to the neutral planes and (c) the specimen whose neutral planes are perpendicular to basal planes and neutral axes are perpendicular to [0001] after bending tests; the enlargement of compression areas with basal slips surrounded by dashed white lines are shown in (b), and slip lines caused by SPCS around {10-12} twins and basal slips within {10-12} twins in the tension areas are shown in (d). Fullsize Image抄録全体を表示PDF形式でダウンロード (7286K) HTML形式で全画面表示 -

藤岡 巧, 半谷 禎彦, 三ツ木 寛尚, 天谷 賢児原稿種別: 論文

2022 年 86 巻 1 号 p. 17-21

発行日: 2022/01/01

公開日: 2021/12/25

[早期公開] 公開日: 2021/12/10ジャーナル フリー HTMLPorous aluminum is lightweight and has good shock absorption properties. Therefore, by joining thermoplastic resin, which has been widely used in recent years, to porous aluminum, it is possible to achieve both strength and weight reduction while providing shock absorption properties. In this study, bonding of porous aluminum and a polycarbonate plate was performed. The polycarbonate plate was pressed against the heated porous aluminum to bond them. From the tensile test of the bonded specimen, it was found that bonded specimen, which was bonded at 400℃ can achieve higher strength than that at 300℃ owing to the anchor effect. The bonded specimen, which was bonded at 400℃, exhibited fracture at the porous aluminum part, while the bonded specimen, which was bonded at 300℃, exhibited fracture at the bonded surface.

Fig. 7 Appearance, X-ray CT images and fracture surfaces of bonded specimens. Arrows in X-ray CT images indicate areas where polycarbonate has penetrated into the pores of porous aluminum. Fullsize Image抄録全体を表示PDF形式でダウンロード (1826K) HTML形式で全画面表示

Fig. 7 Appearance, X-ray CT images and fracture surfaces of bonded specimens. Arrows in X-ray CT images indicate areas where polycarbonate has penetrated into the pores of porous aluminum. Fullsize Image抄録全体を表示PDF形式でダウンロード (1826K) HTML形式で全画面表示

- |<

- <

- 1

- >

- >|