- 5 号 p. 91-

- 4 号 p. 69-

- 3 号 p. 39-

- 2 号 p. 27-

- 1 号 p. 1-

- |<

- <

- 1

- >

- >|

-

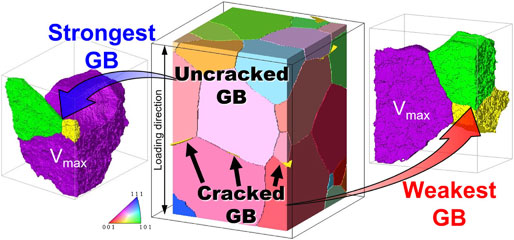

戸田 裕之, 平山 恭介, 山口 翔吾, 藤原 比呂, 比嘉 良太, 清水 一行, 竹内 晃久, 上椙 真之原稿種別: 論文

2024 年 88 巻 3 号 p. 39-47

発行日: 2024/03/01

公開日: 2024/02/25

ジャーナル フリー HTMLThe surrogate-based microstructural optimization was applied to describe the relationship between local crystallographic microstructure and intergranular hydrogen embrittlement in an Al-Zn-Mg alloy. The support vector machine with an infill sampling criterion was used to realise high-accuracy optimisation with a limited size of data set. The methodology integrates thoroughgoing microstructural quantification, a couple of coarsening processes and the surrogate modelling. An objective function was defined together with 66 design parameters, which quantitatively express the size, shape, orientation and damage during specimen machining for surface grain boundaries and grains. The number of design parameters was then reduced from 66 to 3 during the two-step coarsening process. It has been clarified that intergranular crack initiation is described using the simple size of grains and grain boundaries together with grain boundary orientation with respect to the loading direction. It can be inferred that those design parameters are of crucial importance for crack initiation through the elevation in stress normal to grain boundaries. Correlation between the selected design parameters and crack initiation was rather weak compared to the past application of a similar technique to particle damage. The reason for this was discussed. The present approach offers a cost-efficient solution for the prevention of hydrogen embrittlement through 3D design of crystallographic microstructure, which cannot be obtained with the conventional approaches for developing materials.

Mater. Trans. 64 (2023) 2729-2738に掲載

抄録全体を表示PDF形式でダウンロード (5456K) HTML形式で全画面表示

抄録全体を表示PDF形式でダウンロード (5456K) HTML形式で全画面表示 -

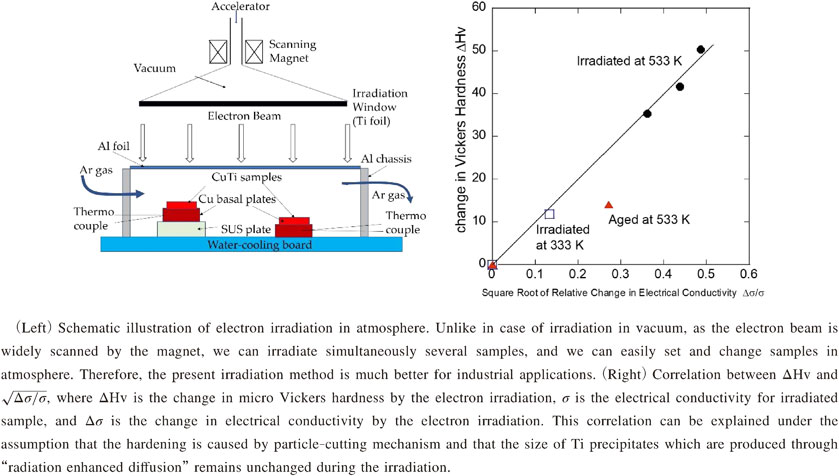

岩瀬 彰宏, 藤村 勇貴, 千星 聡, 斎藤 勇一, 堀 史説原稿種別: 論文

2024 年 88 巻 3 号 p. 48-52

発行日: 2024/03/01

公開日: 2024/02/25

ジャーナル フリー HTMLWe performed 1.5 MeV electron-irradiation at 333 K and 533 K for Cu-4.2 at% Ti alloy with a single phase of super-saturated solid solution, and investigated the irradiation-induced changes in Vickers hardness and electrical conductivity. With increasing the electron fluence, both of the hardness and the electrical conductivity increase. Such phenomena can be ascribed to the formation of Ti-rich precipitates that are caused by irradiation-enhanced diffusion of Ti atoms. The increase in electrical conductivity is caused by the reduction of Ti content in Cu matrix because of the formation of Ti-rich precipitates. The increase in hardness is also caused by Ti-rich precipitates that are effective obstacles against the motions of dislocations. We found a clear correlation between the irradiation-induced change in the hardness, ΔHv and change in electrical resistivity, Δρ, or that in electrical conductivity, Δσ, as ΔHv ∝ √-Δρ, or ΔHv ∝ √Δσ/σ, irrespective of irradiation temperatures. This correlation suggests that the precipitate-cutting mechanism governs the irradiation-induced increase in hardness; that is, 1.5 MeV electron-irradiation at relatively low temperatures of 333 K to 533 K should promote the nucleation of fine Ti-rich precipitates preferentially rather than the growth of them. The present result shows that energetic electron irradiation is a good tool to improve the mechanical and electrical properties of Cu-Ti alloys.

Mater. Trans. 64 (2023) 2232-2236に掲載

抄録全体を表示PDF形式でダウンロード (1511K) HTML形式で全画面表示

抄録全体を表示PDF形式でダウンロード (1511K) HTML形式で全画面表示 -

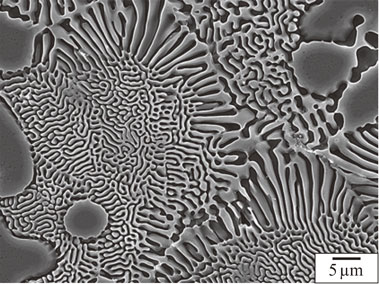

岡田 雄司, 池野 浩平, 寺田 芳弘原稿種別: 論文

2024 年 88 巻 3 号 p. 53-57

発行日: 2024/03/01

公開日: 2024/02/25

[早期公開] 公開日: 2023/12/08ジャーナル フリー HTMLThe binary Mg-14Ca (mass%) hypoeutectic alloy exhibits a fine lamellar structure of α-Mg and C14 (Mg2Ca) phases with the lamellar spacing of 0.9 µm, together with a small amount of the primary α-Mg phase. Tensile creep tests were conducted for the alloy at temperatures between 473-523 K and stresses between 30-50 MPa. The overall creep rate vs. time in a log-log diagram for the alloy shows a downward curvature from stress application until creep rupture. A well-defined steady-state is barely evident. The decrease in the creep rate during the transient stage is emphasized at lower temperatures and lower stresses. The coarse lamellar structure with the lamellar spacing between 1.5-2.5 µm is evident at colony boundaries during the accelerating creep stage. It is found that the stress exponent of the minimum creep rate, n, is 7, and the activation energy for creep, Qc, is 146 kJ/mol. The value of Qc is close to that for the lattice self-diffusion of magnesium (136 kJ/mol). It is deduced that the creep for the alloy is controlled by dislocation climb.

Fig. 5 FE-SEM image of the Mg-14Ca alloy creep-ruptured at 498 K under a stress of 40 MPa. The rupture life is 180 h (6.5 × 105 s). Fullsize Image抄録全体を表示PDF形式でダウンロード (3587K) HTML形式で全画面表示

Fig. 5 FE-SEM image of the Mg-14Ca alloy creep-ruptured at 498 K under a stress of 40 MPa. The rupture life is 180 h (6.5 × 105 s). Fullsize Image抄録全体を表示PDF形式でダウンロード (3587K) HTML形式で全画面表示 -

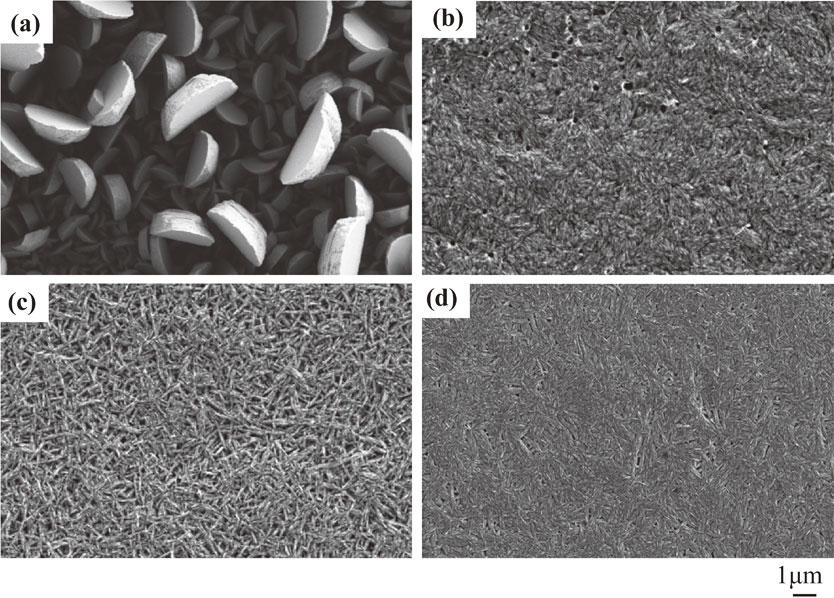

今谷 智貴, 大上 悟, 谷ノ内 勇樹, 青木 泰紀, 中野 博昭原稿種別: 論文

2024 年 88 巻 3 号 p. 58-67

発行日: 2024/03/01

公開日: 2024/02/25

[早期公開] 公開日: 2023/12/08ジャーナル フリー HTMLThe effect of structure of organic additives on the electrodeposition behavior of Zn from alkaline zincate solution and its crystal morphology was investigated. Zn was electrodeposited on an Fe electrode at 20-1000 A·m−2, 2.4 × 104 C·m−2, 300 K from unagitated zincate solutions containing the various organic additives as a leveling agent. The suppression effect of additives on the charge transfer and diffusion of ZnO22− ions in Zn electrodeposition corresponded to the number of adsorption site per a straight chain molecule of polymer. The effect of polymer alone on the decrease in size of Zn platelets crystals was small, but the crystal size significantly decreased with coexistence of low molecular additive. The crystal size of deposited Zn decreased in spite of small suppression effect on Zn deposition, showing that the crystal size of deposited Zn doesn’t depend on the overpotential for deposition. With coexistence of low molecular additive with polymer, the crystal of deposited Zn was fine regardless of kind of polymer even though Zn deposited at the diffusion control of ZnO22− ions.

Fig. 11 SEM images of Zn films deposited at 200 A·m−2 from the zincate solutions containing both additives of polymer and low molecular compound. [(a) Q, (b) PB+Q, (c) PM+Q, (d) PB・PM+Q] Fullsize Image抄録全体を表示PDF形式でダウンロード (6122K) HTML形式で全画面表示

Fig. 11 SEM images of Zn films deposited at 200 A·m−2 from the zincate solutions containing both additives of polymer and low molecular compound. [(a) Q, (b) PB+Q, (c) PM+Q, (d) PB・PM+Q] Fullsize Image抄録全体を表示PDF形式でダウンロード (6122K) HTML形式で全画面表示

- |<

- <

- 1

- >

- >|