- |<

- <

- 1

- >

- >|

-

伊藤 一真, 田中 悠太, 澤田 英明原稿種別: 論文

伊藤 一真, 田中 悠太, 澤田 英明原稿種別: 論文

2021 年 85 巻 12 号 p. 421-429

発行日: 2021/12/01

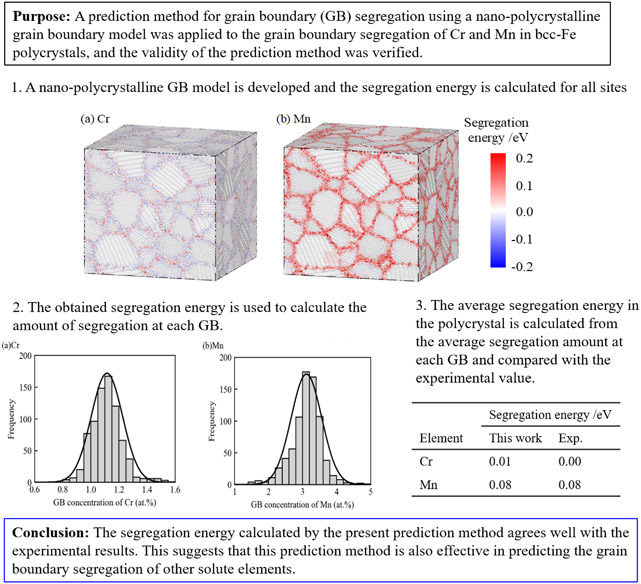

公開日: 2021/11/25

[早期公開] 公開日: 2021/10/15ジャーナル フリー HTMLA prediction method for grain boundary segregation using a nano-polycrystalline grain boundary model is applied to the grain boundary segregation of Cr and Mn in bcc-Fe polycrystals for which experimental results exist, and the validity of the prediction method is verified. In this prediction method, focusing on the fact that the atomic structure of grain boundaries is almost independent of grain size, grain boundaries of polycrystals with grain sizes of the order of micrometers are modeled as grain boundaries of nano-polycrystals, for which structural relaxation calculations by molecular dynamics calculations are possible. For this grain boundary model, the grain boundary segregation energy of each site is calculated exhaustively using the interatomic potential. In addition, the average amount of grain boundary segregation in the polycrystal is calculated from the obtained grain boundary segregation energy. With this prediction method, the average amounts of grain boundary segregation and segregation energies of Cr and Mn in bcc-Fe polycrystals can be calculated and compared with the experimental results. Calculated results for both elements reproduced the experimental results well, suggesting that this prediction method is also effective in predicting the grain boundary segregation of other solute elements.

抄録全体を表示Editor's pick

抄録全体を表示Editor's pick2022年新進論文賞

PDF形式でダウンロード (4673K) HTML形式で全画面表示 -

濱島 隼, 西本 明生原稿種別: 論文

2021 年 85 巻 12 号 p. 430-438

発行日: 2021/12/01

公開日: 2021/11/25

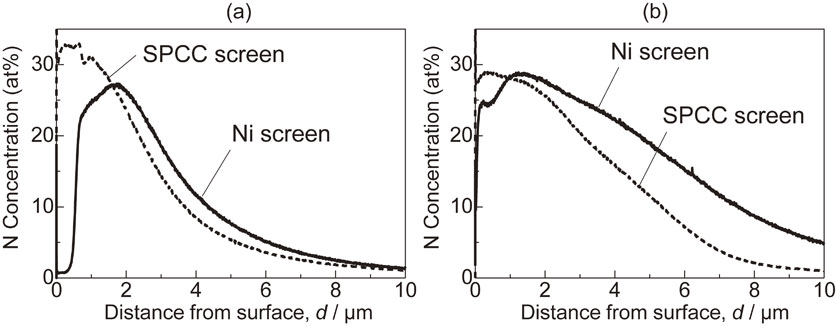

[早期公開] 公開日: 2021/11/08ジャーナル フリー HTMLActive screen plasma nitriding (ASPN) is a nitriding method that avoids the edge effects and arcing that occur during conventional direct current plasma nitriding (DCPN). Furthermore, applying voltage to a sample during ASPN allows the nitriding rate to be increased (S-DCPN). While steel is the predominant screen material, there are few reports of non-ferrous material screens. Therefore, in this study, we investigated the effect of a Ni screen on ASPN and S-DCPN. Low carbon steel S15C was treated by ASPN and S-DCPN using a Ni screen. A steel plate cold commercial (SPCC) screen was also prepared for comparison. Plasma nitriding was performed at 773 K for 240 min under an atmosphere of 75% N2 + 25% H2 at a gas pressure of 200 Pa. After the nitriding treatment, X-ray diffraction (XRD), glow discharge optical emission spectrometry (GD-OES), cross-sectional microstructure observation, surface microstructure observation, Vickers hardness test, and corrosion test were performed. As a result, when the Ni screen was used for S15C steel nitriding, more nitrogen atoms diffused into the sample than that when the SPCC screen was used; furthermore, nickel atoms diffused within the samples treated by both ASPN and S-DCPN using the Ni screen. ASPN-treated samples had less surface hardness and were higher corrosion resistance when prepared using the Ni screen than the SPCC screen. S-DCPN-treated samples had greater surface hardness and were less corrosion resistance when prepared using the Ni screen than the SPCC screen.

Fig. 7 GD-OES nitrogen profiles of S15C samples treated by (a) ASPN and (b) S-DCPN using Ni and SPCC screen. Fullsize Image抄録全体を表示PDF形式でダウンロード (4604K) HTML形式で全画面表示

Fig. 7 GD-OES nitrogen profiles of S15C samples treated by (a) ASPN and (b) S-DCPN using Ni and SPCC screen. Fullsize Image抄録全体を表示PDF形式でダウンロード (4604K) HTML形式で全画面表示 -

松井 大輝, 森田 孝治, 寺田 大将, 池田 賢一, 三浦 誠司原稿種別: 論文

2021 年 85 巻 12 号 p. 439-448

発行日: 2021/12/01

公開日: 2021/11/25

ジャーナル フリー HTMLKink formation and kink strengthening mechanisms were examined in the polycrystalline Ti3SiC2-MAX phase prepared by a spark-plasma-sintering technique. The creep behavior tested by compression at 1200℃ showed two deformation regions depending on the applied stresses; at lower stresses of <120 MPa, the stress exponent n exhibited ≈1.8, whereas at higher stresses, it exhibited n ≥ 6.0. The creep behavior can be ascribed to grain boundary sliding mechanism for the lower stresses with n ≈ 1.8 and dislocation-related creep mechanisms for the higher stresses with n ≥ 6.0. The kink bands were frequently observed to form in the grains deformed only at the higher stresses when its basal plane inclined by about 10-20° against the compressive axis. This suggests that the kink bands might be formed only when two factors of the large stresses acting on the basal plane and the resultant dislocation activities were satisfied. Nanoindentation tests conducted around the formed kink boundaries showed that the hardness increased linearly with decreasing in the distance from the kink boundaries and showed higher values around the kink boundaries. Since the kink boundaries blocked the slip line caused by the nanoindentation, those become a resistance against the dislocation motion caused by the indentation deformation. This suggests that the kink boundaries would be contributed to improve the mechanical properties of the Ti3SiC2-MAX phase.

(a) Low magnification SPM image of nanoindentations #0-#9 tested at the kink-formed grain; the arrows indicate kink boundaries of KB① and KB②. (b) Enlarged SPM image of the nanoindentations #2 and #4. (c) Nanohardness Hn plotted as a function of the distance L from the nearest kink boundary (KB) along the basal plane. Fullsize Image抄録全体を表示PDF形式でダウンロード (4595K) HTML形式で全画面表示

(a) Low magnification SPM image of nanoindentations #0-#9 tested at the kink-formed grain; the arrows indicate kink boundaries of KB① and KB②. (b) Enlarged SPM image of the nanoindentations #2 and #4. (c) Nanohardness Hn plotted as a function of the distance L from the nearest kink boundary (KB) along the basal plane. Fullsize Image抄録全体を表示PDF形式でダウンロード (4595K) HTML形式で全画面表示

- |<

- <

- 1

- >

- >|