- 5 号 p. 175-

- 4 号 p. 169-

- 3 号 p. 161-

- 2 号 p. 143-

- 1 号 p. 1-

- |<

- <

- 1

- >

- >|

-

孫 飛, 小川 登志男, 足立 吉隆, 佐藤 和久, 高木 空, 宮本 吾郎, 鈴木 飛鳥, 山中 晃徳, 中田 伸生, 石本 卓也, 中野 ...原稿種別: 論文

2025 年 89 巻 5 号 p. 175-181

発行日: 2025/05/01

公開日: 2025/04/25

[早期公開] 公開日: 2025/03/14ジャーナル フリー HTMLMetal additive manufacturing enables producing complex geometric structures with high accuracy and breaks the design constraints of traditional manufacturing methods. Laser powder bed fusion, a typical additive manufacturing process, presents a challenge in experimentally understanding the nano-scaled microstructure-process relationship regarding the wide range of process parameters. In this study, we aim to reveal the novel nanoscale structural features by advanced scanning transmission electron microscopy to clarify the formation mechanisms in 316L stainless steel by laser powder bed fusion. Here we show that the slender columnar grains were confined to the centreline of the melt pool along the build direction, and the columnar cell structure at the side branching of the melt pool grew along orthogonal directions to follow drastic changes in thermal gradient across adjacent melt pools. Novel nano-scaled modulated structures have been observed in the dislocation cells parallel to the laser scan direction, which were mainly caused by the elastic strain involving the thermal gradient inside the melt pool and across adjacent melt pools as well as the effective strain field in the dislocation cell interiors. An in-depth understanding of microstructure developments is worthy of fabricating high-performance materials by controlling the additive manufacturing process.

Mater. Trans. 64(2023)1143-1149に掲載.Fig.7のCaptionを修正.

抄録全体を表示PDF形式でダウンロード (38058K) HTML形式で全画面表示

抄録全体を表示PDF形式でダウンロード (38058K) HTML形式で全画面表示 -

木村 禎一, 末廣 智, 貞岡 和男, 奈須 義総, 魚江 康輔原稿種別: 論文

2025 年 89 巻 5 号 p. 182-187

発行日: 2025/05/01

公開日: 2025/04/25

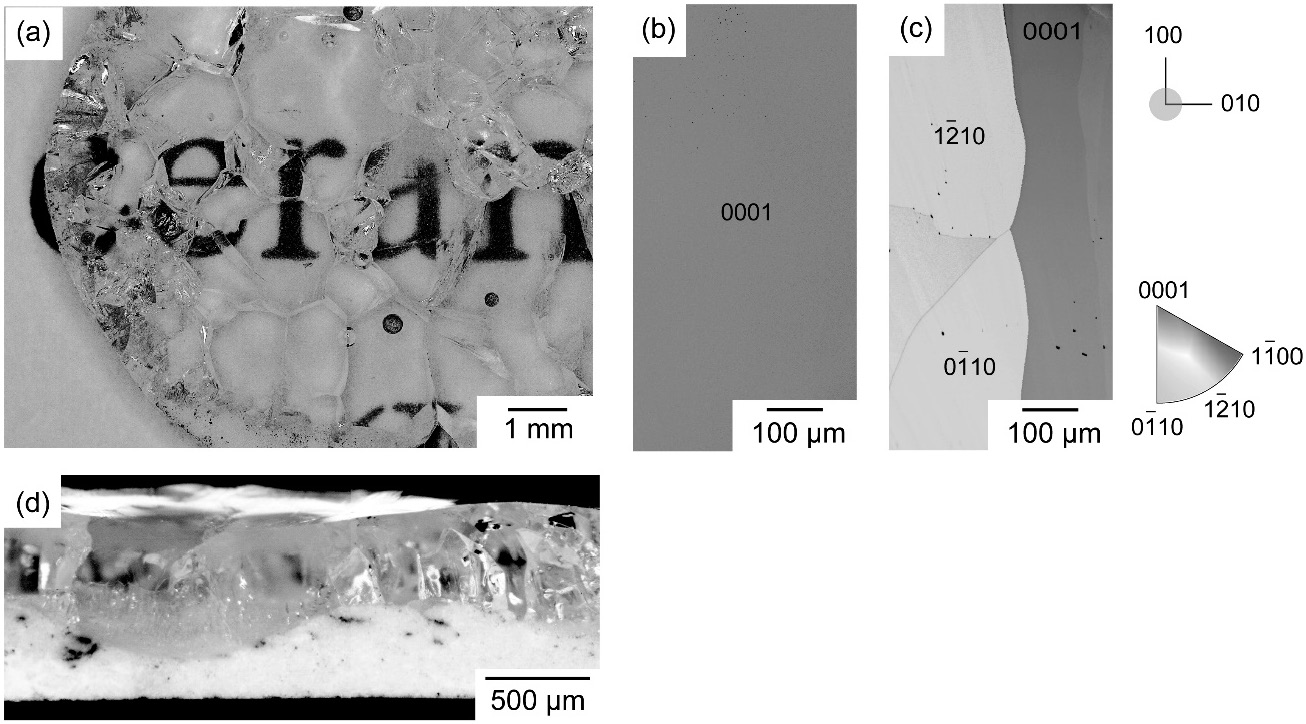

[早期公開] 公開日: 2025/03/14ジャーナル フリー HTMLPellets made of α-Alumina were sintered by fiber laser irradiation (1070 nm) for 1 min. The optical measurements showed that the laser selectively applied heat around the voids and gaps between grains in the green pellets. Even though the laser can penetrate deep inside the pellets, the heating efficiency is low because alumina poorly absorbs the laser energy. The graphite layer effectively improved the heating efficiency on the irradiated surface at the low-temperature region to “ignite” laser sintering. The microstructure of the sintered pellets was controlled by the microstructure of the green bodies. Porous pellets were obtained from coarse powders and transparent dense pellets from mixtures of coarse and fine powders. The porous pellets showed excellent bending strength owing to the joining of grains by the selective heating of gaps between them. The transparent pellets comprised large alumina single crystals anisotropically formed by spontaneous melt growth under laser irradiation.

Mater. Trans. 64(2023)1183-1187に掲載

抄録全体を表示PDF形式でダウンロード (1971K) HTML形式で全画面表示

抄録全体を表示PDF形式でダウンロード (1971K) HTML形式で全画面表示 -

高橋 諒, 佐藤 大樹, 村上 武, 鎌田 康寛, 清水 一行, 赤瀬 善太郎原稿種別: 論文

2025 年 89 巻 5 号 p. 188-194

発行日: 2025/05/01

公開日: 2025/04/25

[早期公開] 公開日: 2025/03/14ジャーナル フリー HTMLS50C steel and SCM440 steel were produced with systematically varied hardening depths, and their microstructure, hardness, and magnetic hysteresis properties were investigated. In S50C steel, a positive correlation was confirmed between the hardening depth and coercivity. To explore the mechanism behind this correlation, dynamic magnetic domain structure observations were conducted using Lorentz microscopy to investigate the behavior of domain wall movement within the hardened and base metal regions when a magnetic field was applied to the sample. In the ferrite-pearlite structure of the base metal, the domain size in the ferrite phase was large, facilitating domain wall movement. In contrast, in the martensite of the hardened region, the domain size was small, and numerous block and packet boundaries hindered the movement of domain walls. This was identified as the cause of the positive correlation. This study demonstrates the usefulness of magnetic non-destructive evaluation methods for assessing the hardening depth of surface-hardened materials.

抄録全体を表示PDF形式でダウンロード (17892K) HTML形式で全画面表示

抄録全体を表示PDF形式でダウンロード (17892K) HTML形式で全画面表示 -

山﨑 ゆきみ, 髙橋 和枝原稿種別: 論文

2025 年 89 巻 5 号 p. 195-204

発行日: 2025/05/01

公開日: 2025/04/25

ジャーナル フリー HTMLAntimony has been long used for battery and flame retardant, yet, not highlighted as a critical metal so far, because of its diffusion into common consumption resulting in feeling of ubiquitousness. Now, in transformation to sustainable energy, its value is increasing due to demand for new technologies such as solar power and recent Chinese export control. Antimony trioxide, the biggest demand of antimony, is mainly used as flame retardant assistant which is contained in automobiles and electric appliances. The newest law for recycling of such products, “act on promotion of recycling of small waste electrical and electronic equipment” (came into effect in 2013) mentions collection of end-of-life products and recycling of useful metals. According to this law, collection of used small electrical and electronic equipment (SEEE) and recycling of metals contained in SEEE are progressing, while recycling of antimony is still uncertain. In this study, we conducted a substance flow analysis (SFA) of antimony in Japan to analyze the present condition of recycling of antimony as flame retardant assistant. In addition, we evaluated obtainable amount and economical effect by antimony recycling focused on SEEE, as well as environmental effects including other metals contained in board of SEEE. The result of SFA showed that in 2020, antimony as flame retardant assistant, sharing more than 70% of whole amount of end-of-life antimony in Japan, were all discarded into landfill through incineration/smelting or directly, except export. Furthermore, we revealed that recycling of antimony in SEEE might have remarkable benefit economically and environmentally. Based on these results, it is suggested that domestically recycling of antimony from end-of-life product in Japan should be more promoted.

抄録全体を表示PDF形式でダウンロード (1676K) HTML形式で全画面表示

抄録全体を表示PDF形式でダウンロード (1676K) HTML形式で全画面表示

- |<

- <

- 1

- >

- >|